Why Heavy-Duty Marine Diesel Maintenance is Critical for Your Vessel

Heavy-duty diesel maintenance is the systematic care of marine diesel engines to ensure reliable operation, prevent costly breakdowns, and maximize engine lifespan. For vessel owners, this maintenance is critical. Miles from shore, engine failure is not just an inconvenience—it’s a serious danger.

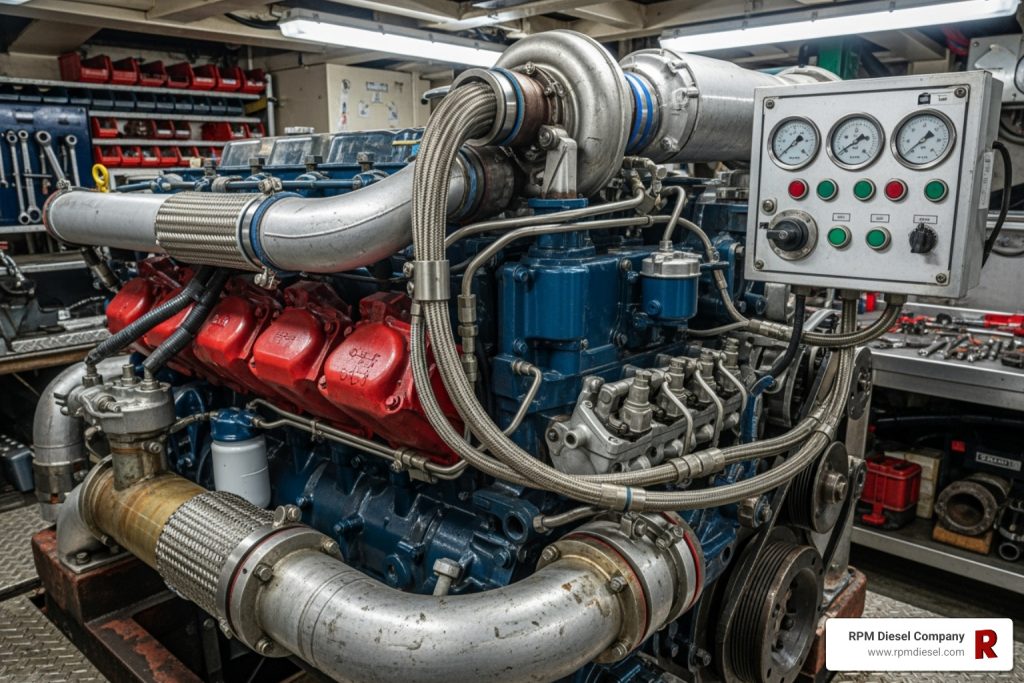

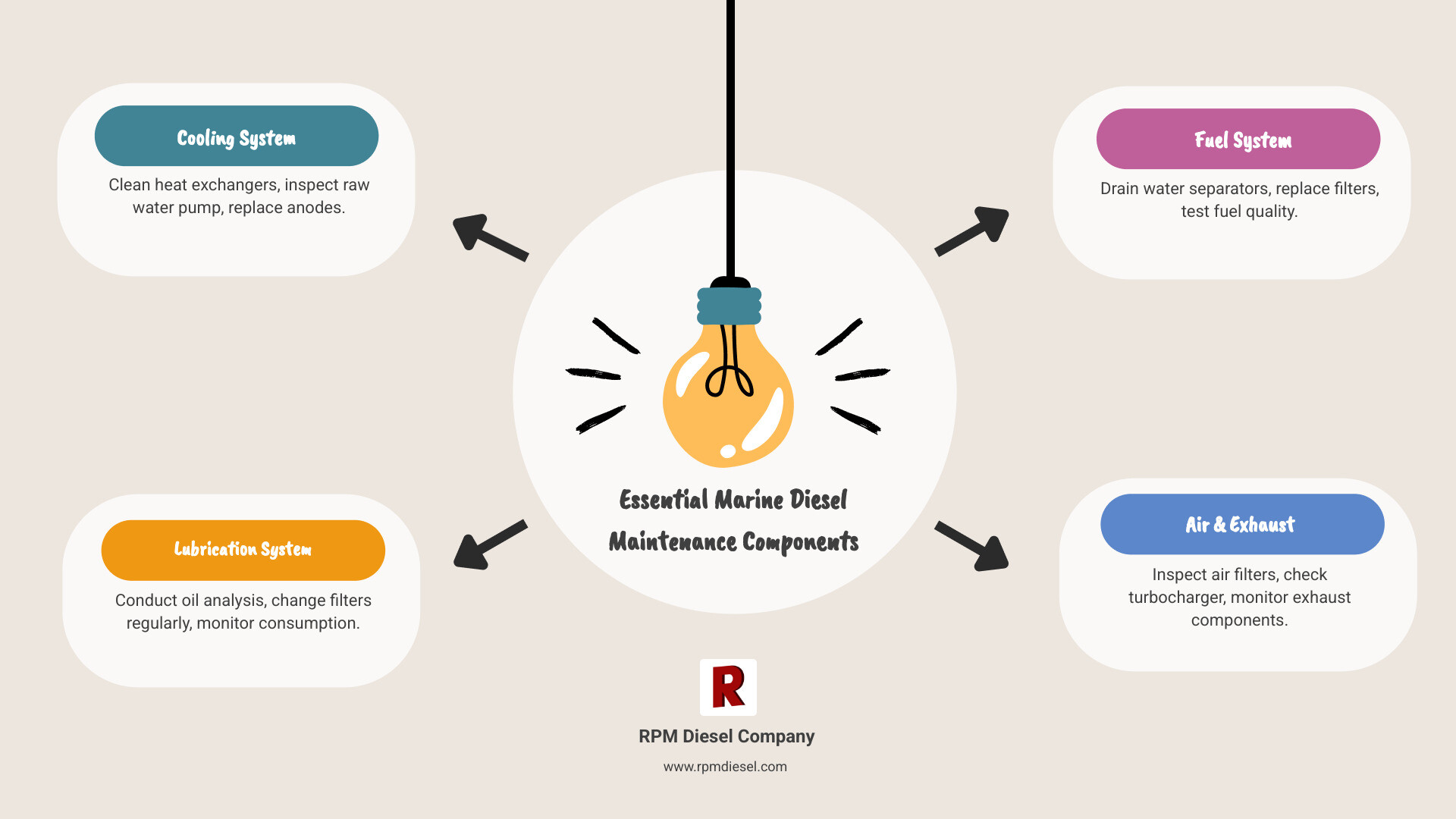

Essential Marine Diesel Maintenance Components:

- Cooling System: Heat exchanger cleaning, raw water pump inspection, anode replacement

- Lubrication System: Regular oil analysis, filter changes, monitoring consumption rates

- Fuel System: Water separator draining, filter replacement, fuel quality testing

- Air & Exhaust: Filter inspection, turbocharger checks, exhaust component monitoring

- Electrical System: Battery maintenance, alternator inspection, wiring checks

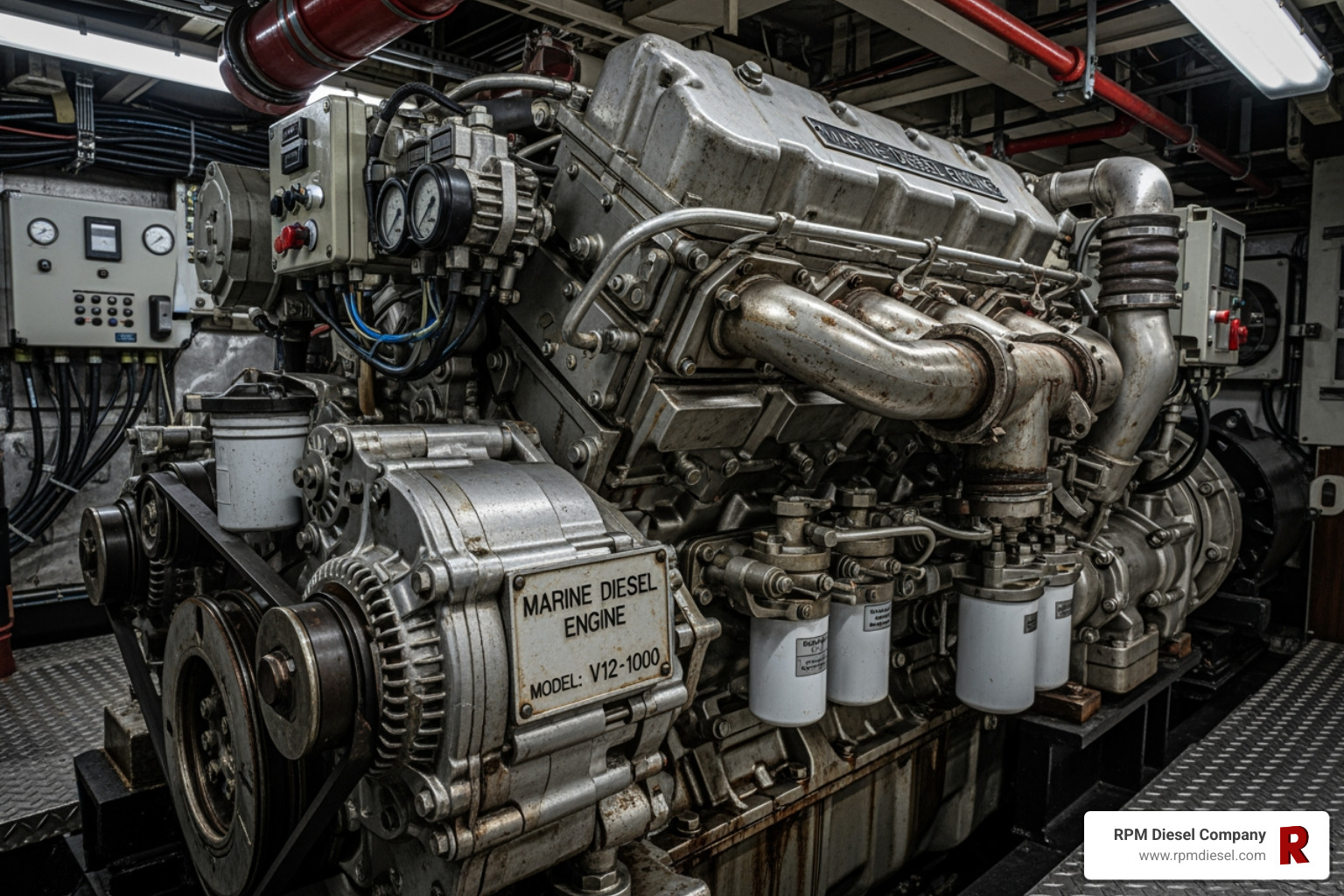

Marine diesel engines face unique challenges. Constant saltwater exposure creates severe corrosion risks, while high humidity accelerates wear on electrical systems. Unlike land-based engines, marine diesels often run under constant, heavy loads for hours or even days without shutdown.

A well-maintained marine diesel can run for thousands of hours between major services. Neglecting basic maintenance, however, risks catastrophic failure when you need your engine most. Your engine’s reliability depends on consistent, thorough maintenance, from checking oil levels to systematic attention to cooling systems, fuel quality, and all interconnected components.

Must-know Heavy-duty diesel maintenance terms:

Understanding the Unique Demands on Marine Diesel Engines

Life at sea is tough on engines. Unlike a vehicle that can pull over, a marine diesel must keep running, no matter the conditions. The marine environment creates challenges that land-based engines never face.

Saltwater corrosion is a primary enemy, attacking every metal surface from heat exchangers to exhaust components. Constant humidity causes condensation, leading to rust and electrical issues. Furthermore, marine engines often operate under constant load operation for extended periods, leading to significant wear.

Your engine’s cooling system works overtime, relying on a seawater circuit and a freshwater circuit. Heat exchangers transfer heat from the engine’s coolant to raw seawater, while sacrificial anodes protect metal parts from galvanic corrosion.

For more detailed guidance on keeping your marine diesel running smoothly, check out our comprehensive marine diesel maintenance resources.

Key Differences from Land-Based Engines

Marine diesels face unique stresses that make heavy-duty diesel maintenance even more critical. Constant vibration from waves can loosen bolts and clamps. Ventilation challenges in confined engine rooms can lead to overheating. Fuel quality concerns are magnified, as water contamination risk is always present, requiring robust, multi-stage filtration.

The criticality of on-board repairs cannot be overstated. When a problem occurs miles offshore, inaccessibility at sea means you can’t call a tow truck. You must be prepared.

The Importance of Proactive Maintenance at Sea

Reactive maintenance at sea is dangerous and expensive. Proactive maintenance is essential for safe boating.

- Ensuring Crew Safety: A reliable engine is your lifeline back to port, especially in rough weather or busy shipping lanes.

- Protecting Your Investment: A well-maintained engine can run for thousands of hours, delaying costly repairs or replacement.

- Maximizing Fuel Efficiency: Clean filters and a properly tuned engine save money on every trip.

- Avoiding Costly Emergency Repairs: Scheduled maintenance is far cheaper than emergency repairs in remote locations. As we always say, “Preventative work will save a headache and large repair bill!”

A proactive approach to heavy-duty diesel maintenance turns your engine into a reliable partner for all your maritime voyages.

For practical tips on keeping your marine diesel in top condition, visit our diesel engine maintenance tips page.

The Core of Heavy-Duty Diesel Maintenance

Successful heavy-duty diesel maintenance for marine engines means understanding that all systems work together. The foundation of reliability rests on essential systems checks, thorough component inspection, and adhering to regular servicing schedules.

Your marine engine must be ready at a moment’s notice. The key to avoiding engine failure is following manufacturer specifications. These guidelines are your roadmap to reliable operation.

Lubrication System: The Lifeblood of Your Engine

The lubrication system is your engine’s circulatory system. Oil lubricates moving parts, removes heat, and traps contaminants. Service intervals are measured in operating hours, not miles, with most marine diesels requiring oil changes every 250 hours or annually.

- Engine Oil Analysis: A “blood test” for your engine, revealing internal wear or leaks before they become catastrophic.

- Correct Oil Grade: Use the manufacturer-specified grade, like CJ-4 for modern engines, to prevent harmful deposits.

- Filter Replacement & Consumption: Always replace the oil filter with each oil change and monitor oil consumption, as a sudden increase indicates a problem.

Cooling System: Preventing Catastrophic Overheating

Overheating can destroy a marine diesel. The cooling system is critical in the harsh saltwater environment.

Marine engines use a two-circuit system: a closed freshwater circuit cools the engine, while a raw water circuit uses seawater to cool the freshwater. This protects the engine from direct saltwater exposure.

- Heat Exchanger Cleaning: Seawater deposits microbes and debris that clog heat exchangers. We use ultrasonic cleaning to restore efficiency.

- Raw Water Pump Impeller: This rubber workhorse pushes seawater through the system. We inspect it regularly and replace it every 250-500 hours to prevent failure.

- Anode Replacement: Sacrificial zinc anodes corrode to protect expensive engine components from galvanic corrosion. They require regular replacement.

- Coolant Quality & Hoses: We test coolant for acidity and freeze protection, replacing it every 2-5 years. We also inspect all hoses and clamps for cracks or leaks.

Marine Diesel Performance Boost

Fuel System: Ensuring Clean and Efficient Combustion

Modern high-pressure fuel systems demand exceptionally clean fuel. Even microscopic contaminants can cause expensive damage.

- Draining Water Separators: This should be a daily habit. Water in fuel can quickly destroy injectors and pumps.

- Fuel Filter Replacement: Filters protect the injection system. They should be changed on schedule, or more frequently if fuel quality is questionable.

- Fuel Quality & Algae: Purchase fuel from reputable sources. In warm climates, use additives to prevent algae growth that can clog the entire system.

Common Rail Injector Cleaning Service

Air Intake & Exhaust Systems

An engine needs to breathe. Clean air intake and efficient exhaust are vital for power and efficiency.

- Air Filter Inspection: Salt spray and airborne particles can clog filters quickly, reducing power and increasing fuel consumption.

- Turbocharger & Intercooler Checks: We inspect turbochargers for leaks or unusual noises. The intercooler, which cools compressed air from the turbo, also needs regular servicing (typically every 1,000 hours) to remove salt and vapor buildup that reduces engine power.

- Exhaust Elbow and Riser Inspection: These components mix hot exhaust with corrosive seawater and must be inspected regularly for rust and carbon buildup.

Regular inspection and timely replacement prevent the kind of damage that can leave you stranded.

How a Diesel Engine Turbocharger Works

Establishing a Proactive Maintenance Schedule

A solid maintenance plan combines operating hours with time-based intervals. Your engine cares about how long it’s been running, but some components degrade over time even when idle. A high-use vessel might hit hour-based intervals first, while a weekend cruiser may reach calendar-based ones. Both are important.

Ship Engine Maintenance Plans at RPM Diesel

Routine Checks (Daily and Weekly)

Daily and weekly checks are your early warning system, catching small issues before they become major problems.

- Daily (Before Starting): Check engine oil and coolant levels. Perform a visual inspection for oil, fuel, or coolant leaks in the engine bay and bilge. Check belt tension. Crucially, drain your fuel/water separator.

- Weekly: Clean the seawater strainer to ensure proper cooling water flow. Check battery terminals for corrosion, which is accelerated by salt air. A clean engine room makes spotting problems easier.

Periodic & Seasonal Heavy-Duty Diesel Maintenance

Deeper service addresses wear and tear on components over longer intervals.

- Oil and Filter Changes: Typically every 250 hours or annually. Clean oil is critical for engine longevity.

- Fuel Filter Changes: Follow a similar schedule to oil changes, but be prepared to change them sooner if you encounter poor quality fuel.

- Impeller Replacement: We recommend replacing the raw water pump impeller annually or every 250-500 hours. A failed impeller means immediate overheating.

- Belts and Hoses: Proactively replace these every few years, based on manufacturer guidelines, to prevent unexpected failures.

- Coolant Changes: Every two to five years, depending on the coolant type. Old coolant becomes corrosive and can damage the system from the inside.

- Seasonal Service: For vessels in colder climates, winterization (flushing with antifreeze, stabilizing fuel) is crucial to prevent freeze damage. Summer recommissioning ensures the vessel is ready for the new season.

The key to successful heavy-duty diesel maintenance is consistency. Skipping services might seem to save money short-term but almost always costs more in the long run.

RPM’s Top Marine Diesel Maintenance Tips

Diagnosing & Preventing Common Marine Diesel Failures

Even with meticulous heavy-duty diesel maintenance, problems can arise. Learning to recognize early warning signs—unusual noises, performance loss, or changes in exhaust smoke—is key to preventing emergencies at sea.

Common Issues and Their Prevention

- Overheating: The most dangerous issue. Often caused by a clogged seawater intake, failed raw water pump impeller, or fouled heat exchanger. Prevention involves regular inspection of all cooling system components.

- Hard Starting: Frequently caused by contaminated fuel, air in the fuel lines, or worn glow plugs. Daily draining of the water separator is a key preventive measure.

- Excessive Smoke: Black smoke indicates incomplete combustion (overload, bad injectors). White smoke can be steam (coolant leak) or unburnt fuel. Blue smoke means the engine is burning oil (worn rings or seals).

- Loss of Power: Often traces back to clogged fuel or air filters. Salt buildup on the intercooler is a common marine-specific cause.

- Fuel Contamination: Water, algae, and debris can destroy modern fuel systems. Prevention includes buying quality fuel and diligent filter maintenance.

The Role of Technology and Professional Diagnostics

Modern marine diesels are complex machines with electronic control units (ECUs) that monitor hundreds of parameters. This requires advanced diagnostic capabilities.

Telematics and remote monitoring can provide real-time data on engine performance, alerting you to potential issues before they escalate. The engine control unit (ECU) stores fault codes and operational data, but interpreting this requires professional-grade diagnostic tools.

Professional diagnostic equipment goes beyond basic code readers to provide comprehensive system analysis. This is crucial for troubleshooting and for maintaining compliance with modern environmental regulations, such as those from the EPA for compliance with emission standards. Systems like Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) require precise, data-guided maintenance.

Professional diagnostics aren’t just for fixing problems—they’re about preventing them. Our certified technicians use advanced tools to spot trends and potential issues, saving you money and ensuring your engine runs at peak efficiency.

Frequently Asked Questions about Marine Diesel Maintenance

Here are concise answers to the most common questions we receive about heavy-duty diesel maintenance for marine engines.

Why is my marine diesel engine overheating?

Overheating is a serious and common issue. The most frequent causes are:

- A clogged seawater intake (from seaweed, plastic, or marine growth).

- A failed raw water pump impeller.

- A fouled or clogged heat exchanger.

- Low coolant levels, often indicating a leak.

- A collapsed hose restricting coolant flow.

Regular inspection of the entire cooling system is the best prevention.

How often should I service my marine diesel engine?

Service intervals depend on manufacturer recommendations and are based on operating hours. A typical schedule includes:

- Daily Checks: Fluid levels, visual leak inspection, draining the fuel/water separator.

- Minor Service (every 100-250 hours): Oil and filter changes, plus basic inspections.

- Major Annual Service: A thorough inspection of all systems, including cooling, fuel, belts, and hoses.

Always consult your owner’s manual for specific intervals. Consistency is key.

What does different colored exhaust smoke indicate?

Exhaust smoke is a key diagnostic indicator:

- Black Smoke: Too much fuel or not enough air (incomplete combustion). Often caused by an overloaded engine, dirty air filter, or faulty injectors.

- White Smoke: If it disappears quickly, it’s likely harmless steam. If it persists, it could be unburnt fuel (misfire) or a coolant leak into the combustion chamber (a serious issue).

- Blue Smoke: The engine is burning oil. This is typically due to worn piston rings, valve seals, or turbocharger seal problems.

Any unusual smoke requires prompt investigation to prevent a minor issue from becoming a major failure.

Your Partner for Reliable Marine Performance

On the water, your engine is your lifeline. That’s why heavy-duty diesel maintenance is a job for experts. At RPM Diesel Company, we understand that your marine diesel deserves professional care to perform at its peak.

Our certified technicians are authorized by major manufacturers like Detroit Diesel and MTU, so they know these engines inside and out. We focus on proactive maintenance to ensure engine longevity and, most importantly, your safety at sea. We’ve seen how skipping routine service can lead to dangerous situations, and our goal is to prevent that.

We help your engine achieve peak performance through attention to detail, from testing coolant chemistry to replacing an impeller before it fails. We also specialize in sourcing genuine Diesel Engine Maintenance Parts, ensuring every component works as the engineers intended.

When you partner with RPM Diesel Company, you get decades of marine diesel expertise and a commitment to reliability and peace of mind.

For comprehensive service that keeps your marine diesel running smoothly for thousands of hours, explore our professional engine diesel maintenance solutions. Because when it comes to marine engines, experience and reliability are everything.