Why Your Marine Diesel Engine Deserves Better Care

A marine diesel engine tune up is fundamentally different from an automotive one. Unlike gasoline engines with spark plugs, your marine diesel uses compression ignition—a robust design that can last over 1,000,000 miles with proper care.

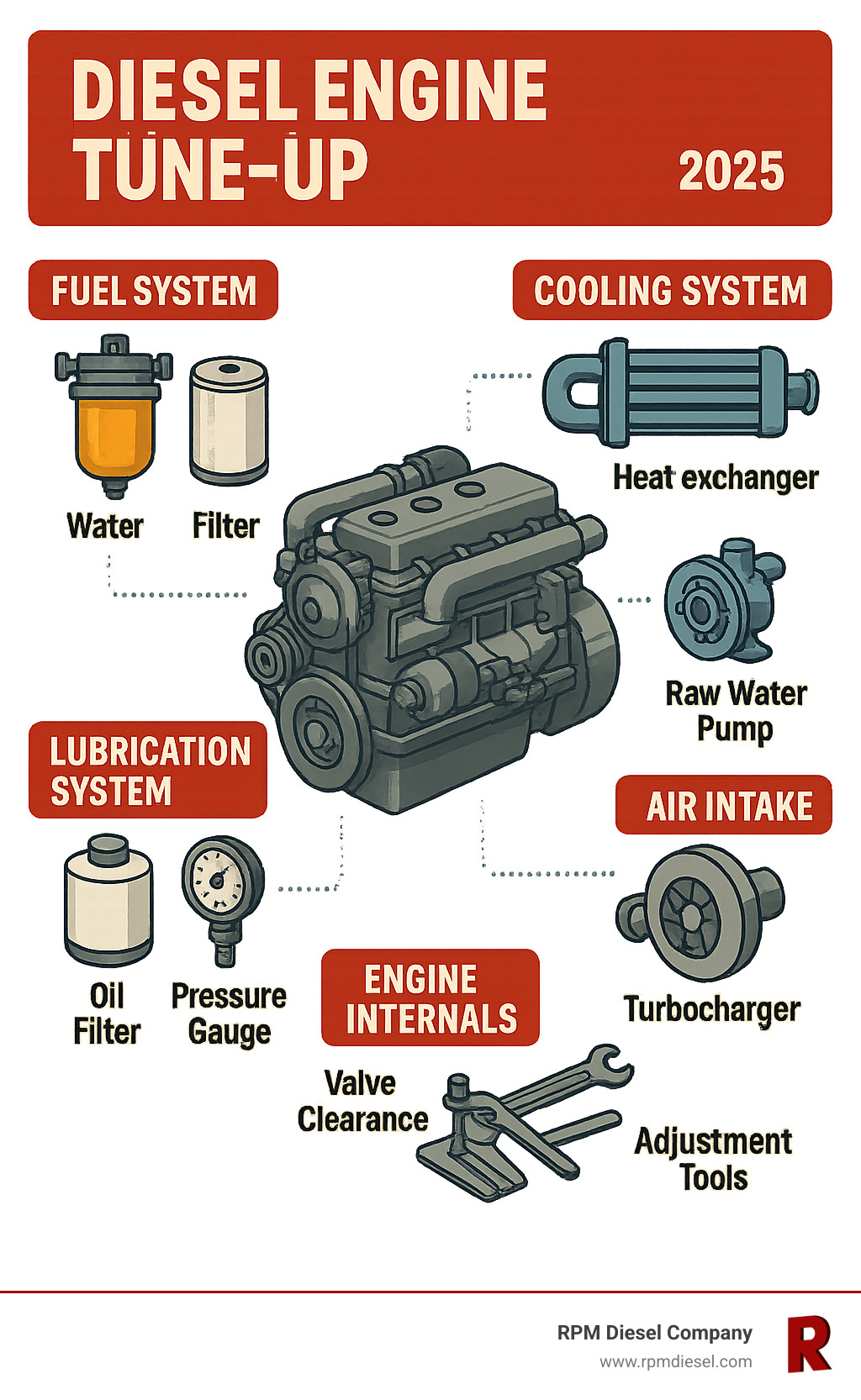

What’s included in a marine diesel tune-up:

- Fuel system service – Filter changes, water separator draining, injector cleaning

- Cooling system maintenance – Heat exchanger inspection, impeller replacement, coolant flush

- Lubrication checks – Oil and filter changes, pressure testing

- Air intake cleaning – Filter replacement, turbocharger inspection

- Engine vitals – Valve adjustments, compression testing, timing verification

The marine environment is brutal. Salt air, humidity, vibration, and water contamination create unique challenges. Your diesel needs specialized care from technicians who understand these demands.

Regular tune-ups don’t just prevent breakdowns; they restore your engine’s original power and efficiency, releasing what one expert calls “a stable of unused horses.” A well-maintained diesel means confident cruising, while a neglected one risks being stranded at sea.

What is a Marine Diesel Tune-Up and Why is it Critical?

Imagine being miles offshore when your engine sputters. A proper diesel engine tune up is designed to prevent that sinking feeling.

Your marine diesel is different from a car’s gasoline engine. It has no spark plugs, distributors, or ignition wires. It uses compression ignition: air is compressed until it’s hot enough to ignite injected fuel. This simple design is incredibly robust when maintained (see the Marine diesel engine entry for an in-depth technical overview).

A well-maintained marine diesel can run for over 1,000,000 hours before major repairs, far surpassing typical gasoline engines. This is why commercial vessels and serious boaters swear by diesel power.

This legendary longevity requires consistent, proper maintenance. A diesel engine tune up is about reliability when your life depends on it. At sea, there’s no roadside assistance. An engine failure can be dangerous.

A comprehensive tune-up restores fuel efficiency, brings back smooth power, and extends its already impressive lifespan. It’s a preventative physical exam for your engine.

For professional service you can trust, our team provides expert Diesel Engine Maintenance Fort Lauderdale with the specialized knowledge your marine diesel deserves.

The Unique Demands of the Marine Environment

The ocean is harsh. Salt air creeps into every crevice, causing corrosion. High humidity creates condensation that can contaminate your fuel and oil systems.

Constant vibration from waves loosens connections and wears components. The cooling system also faces unique challenges, using raw seawater that can cause marine growth and salt buildup, requiring specialized heat exchangers.

Fuel quality issues are magnified at sea. Water contamination is almost inevitable, as diesel fuel absorbs moisture from the air. This water can breed microbes (“diesel bug”) that clog your fuel system.

The water contamination risk extends beyond fuel to oil, air intake, and electrical systems. Every component must be more robust and corrosion-resistant than its land-based counterpart.

Key Differences from Automotive Tune-Ups

Marine diesels follow different rules than cars. Service intervals are measured in operating hours, not miles.

Marine-specific cooling systems are entirely different, using heat exchangers, raw water pumps, and crucial zinc anodes that sacrifice themselves to prevent engine corrosion.

Water separators are not optional; they are critical for combating the constant threat of water in the fuel on a boat.

Unlike many modern automotive diesels, marine engines prioritize reliability and power over complex emissions equipment. The emphasis on corrosion prevention is paramount—every bolt, gasket, and seal must withstand the destructive marine environment.

Your marine diesel engine tune up addresses these unique challenges with specialized procedures, marine-grade parts, and expert knowledge of what the ocean demands.

The Comprehensive Marine Diesel Engine Tune Up Checklist

A proper marine diesel engine tune up is a preventative measure to keep you from being stranded. It’s a thorough exam where we check every system, following manufacturer specifications with specialized marine tools.

When you need parts or repairs beyond routine maintenance, we’re your trusted partner for Diesel Engine Parts and Repair Service.

Fuel System Integrity and Service

Your fuel system is critical. Dirty or contaminated fuel can shut down your engine, which is why this service is a priority.

- Changing fuel filters: We replace both primary and secondary filters. Diesel injection systems are incredibly sensitive to dirt.

- Draining water separators: This is vital in the humid marine environment where diesel fuel absorbs water. We recommend checking the separator weekly.

- Inspecting fuel lines: We look for the smallest leaks, cracks, or kinks that could starve the engine or introduce air into the system.

- Cleaning fuel injectors: This is a job for professionals. Carbon deposits can ruin the spray pattern of these precision components. We advise against DIY injector work.

- Testing injection pump timing: This ensures fuel arrives at the exact right moment for optimal combustion, power, and efficiency.

We also stress using quality fuel and additives. For more details, see our guides on Engine Additives RPM Diesel and Understanding the Common Rail Injection System in Diesel Engines.

Cooling and Lubrication System Maintenance

These systems are your engine’s life support, preventing overheating and internal friction.

- Inspecting heat exchangers: We check for clogs, corrosion, and leaks that compromise heat transfer from engine coolant to raw seawater.

- Servicing raw water pumps: We check for leaks and wear on the pump that circulates seawater through the heat exchanger.

- Replacing impellers: This small rubber part inside the raw water pump degrades over time. A failed impeller means no cooling.

- Flushing coolant: Old coolant becomes acidic and loses its anti-corrosive properties. We flush and replace it to prevent internal corrosion.

- Testing the thermostat: We ensure the thermostat opens and closes correctly to maintain proper engine temperature.

- Checking hoses and clamps: We inspect every hose for cracks or bulges and ensure all clamps are tight.

- Changing engine oil: This is the most important low-cost maintenance. We change oil and filters every 250 hours or annually.

- Checking oil pressure: Abnormal pressure is an early warning sign of internal engine problems.

Our guide to The Basics of Marine Diesel Engine Maintenance covers more essentials.

Air Intake, Exhaust, and Engine Vitals

These systems ensure efficient combustion and provide a window into your engine’s internal health.

- Inspecting air filters: A clean, high-quality air filter is critical, as diesels are less tolerant of dirt than gasoline engines.

- Cleaning the air intake system: We remove carbon and oil deposits from the intake manifold that restrict airflow and reduce efficiency.

- Checking turbocharger performance: We inspect for shaft play, oil leaks, and carbon buildup. Our Diesel Turbocharger Services at RPM specialists handle these complex components.

- Inspecting the exhaust manifold and riser: We look for leaks, cracks, and corrosion, especially in water-jacketed sections.

- Adjusting valve clearance: This precision work ensures optimal engine breathing and combustion and requires professional expertise.

- Performing a compression test: This is a key diagnostic tool that measures how well combustion chambers are sealed, indicating the health of rings, valves, or gaskets.

- Checking engine mounts: Worn mounts cause excessive vibration and misalignment, which can damage drivetrain components.

Benefits, Frequency, and Warning Signs

A proactive approach to your marine diesel engine tune up provides peace of mind and delivers benefits that go far beyond simply avoiding breakdowns. If you’re unsure if your vessel needs attention, our guide on How to Determine if You Need a Marine Diesel Engine Repair Service can help.

Benefits of a Regular Marine Diesel Tune-Up

Investing in regular diesel engine tune up services protects your investment and ensures worry-free hours on the water.

- Improved reliability: This is the top benefit. A well-maintained diesel is your most dependable crew member, ensuring you get home safely.

- Improved fuel economy: A tuned engine with clean injectors and proper timing uses fuel more efficiently, saving you money.

- Restored engine performance: A tune-up brings back the power you may have gradually lost. Learn more about a Diesel Engine Performance Boost.

- Extended engine lifespan: Regular tune-ups catch small problems before they become expensive catastrophes, helping your engine achieve its legendary longevity.

- Quieter operation and reduced emissions: A healthy engine runs smoother and cleaner, helping you comply with regulations like the EPA’s standards for marine engines.

- Preventing catastrophic failure: You avoid the kind of failure that can ruin your trip and endanger your passengers.

When to Schedule Your Next Diesel Engine Tune Up

Unlike cars, marine diesels track maintenance by operating hours. Always consult your owner’s manual first, as manufacturer service intervals are the roadmap to engine longevity.

Most diesels need service every 250 to 500 operating hours, with more comprehensive tune-ups at key milestones like 1000 hours. Annual service is crucial even for low-hour boats, as time and the marine environment cause wear even when the engine is idle.

Logbook tracking is invaluable for staying on top of maintenance. Also, schedule service after long periods of storage before starting the new season.

Here’s a quick reference, though your manual always takes precedence:

| Task | Interval |

|---|---|

| Oil Change | Every 250 hours or annually |

| Fuel Filter | Every 500-1000 hours or annually |

| Impeller | Annually or every 250-500 hours |

| Valve Adjustment | Every 1500 hours or as specified |

| Coolant Flush | Every 2-3 years |

Telltale Signs Your Engine Needs Attention

Your diesel communicates warning signs. Addressing them early prevents major problems.

- Excessive smoke: Black smoke often means too much fuel or not enough air. White smoke can indicate unburned fuel or a coolant leak.

- Difficulty starting: This often points to fuel delivery or compression problems.

- Unusual noises or vibrations: New knocking, rattling, or excessive shaking needs immediate attention.

- Loss of power or RPMs: If your engine struggles to reach its usual performance, it’s time for a check-up.

- Increased fuel consumption: This indicates the engine is working harder than it should.

- Overheating: Never ignore high temperatures. This can destroy an engine quickly.

- Sheen on the water: Any fuel or oil leak needs to be addressed immediately.

Frequently Asked Questions about Marine Diesel Tune-Ups

Here are answers to the most common questions we get about marine diesel engines and their maintenance.

How often should my marine diesel engine be tuned up?

Unlike cars, a diesel engine tune up schedule is based on operating hours and manufacturer recommendations, not mileage. The duration of operation is what matters.

The general rule is a basic service at least annually or every 250 operating hours, whichever comes first. This is your engine’s lifeline. More comprehensive tune-ups, including valve adjustments and injector servicing, occur at major milestones like 1000 hours. Skipping these intervals risks expensive damage.

Can I perform a diesel tune-up myself?

While owners can perform basic maintenance like checking fluids, belts, and changing primary fuel filters, a full tune-up is more complex. A complete diesel engine tune up requires specialized tools and experience for tasks like valve adjustments, injector testing, compression testing, and injection pump timing.

Incorrect adjustments can lead to thousands in repairs. The smartest DIY move is often knowing when to call a professional.

What is the most common problem a tune-up prevents?

The two biggest problems a tune-up prevents are fuel system contamination and cooling system failure.

In humid marine environments, water contaminates fuel, leading to microbial growth (“diesel bug”) that clogs fuel systems and destroys expensive injection components. Regular service keeps the fuel system clean.

Cooling system failure is also common. Saltwater corrosion damages components like heat exchangers and impellers. An overheated engine can suffer catastrophic damage, like a cracked block, often from a simple failed impeller that wasn’t replaced in time. A tune-up addresses these wear items before they fail.

Conclusion: Protect Your Investment with Professional Service

Your marine diesel is a significant investment and the mechanical heart of your vessel. Don’t gamble on its maintenance with a “hope for the best” approach.

A comprehensive diesel engine tune up is your insurance policy against being stranded. Skipping scheduled service can turn a perfect trip into an expensive rescue.

Professional service provides genuine peace of mind. You can cruise with confidence, knowing your engine’s fuel, cooling, and other critical systems have been professionally inspected and optimized. Our technicians understand the unique challenges of the marine environment, from salt air to water contamination.

As an authorized dealer for major manufacturers like Detroit Diesel and MTU, we have the genuine parts and technical knowledge to keep your engine at peak performance. The value is simple: invest a little now to prevent costly repairs later. Regular tune-ups extend engine life, improve fuel efficiency, and ensure reliability when you need it most.

Let our expertise ensure your engine delivers reliable service for years to come. Find out how Regular Maintenance with RPM can protect your investment, season after season.