Why Professional Testing Keeps Your Marine Engine Running

Bosch injector testing is the key to keeping your marine diesel engine reliable when you’re miles from shore. When you’re out on the water, engine failure isn’t just inconvenient – it can be dangerous.

Quick Answer for Bosch Injector Testing:

- Professional equipment required: Bosch EPS 205 or EPS 708 test benches

- Key tests performed: Spray pattern, flow rate, leak testing, electrical resistance

- Testing pressure: Up to 2,200 bar for common rail injectors

- Results format: Pass/fail diagnosis with detailed PDF report

- Typical turnaround: 24-48 hours at authorized service centers

- Cost: $50-65 per injector depending on type and location

Your Bosch injectors are precision instruments that deliver fuel at incredibly high pressures – sometimes over 2,000 bar. Even tiny problems can cause big issues. Poor fuel atomization leads to black smoke, power loss, and accelerated engine wear. In extreme cases, faulty injectors can melt pistons or damage cylinders.

The marine environment makes proper injector function even more critical. Salt air, moisture, and fuel quality variations all stress these components. Regular testing helps catch problems before they leave you stranded.

Modern Common Rail injectors are more sophisticated than older mechanical systems. They need specialized Bosch test equipment to properly evaluate their electronic controls and spray patterns. Only authorized service centers have access to the calibrated test benches and genuine Bosch specifications needed for accurate diagnosis.

This guide will walk you through the professional testing process, help you understand test results, and show you how proper maintenance protects your investment.

Why Bosch Injector Testing is Critical for Your Marine Diesel Engine

Your Bosch injectors are the heart of your marine diesel’s fuel delivery system, atomizing fuel with incredible accuracy to keep your engine running smoothly. Think of Bosch injector testing as a health checkup for your engine. Proper injector performance ensures better fuel efficiency, smoother operation, and the reliability you need miles from shore.

Modern marine engines, especially those with Common Rail injection systems, are highly sophisticated. Unlike older mechanical injectors, Common Rail systems use a shared fuel rail and precise electronic controls for better performance and economy, but they demand higher maintenance standards.

The harsh marine environment, with its salt air, temperature fluctuations, and varying fuel quality, puts extra stress on these components, making regular testing critical.

Recognizing the Symptoms of a Failing Injector

Your marine diesel engine will warn you when injectors are failing. Recognizing these signs early can save you from expensive repairs and dangerous situations at sea.

Excessive black smoke is a key sign. A dark trail behind your vessel indicates poor fuel atomization and incomplete combustion, which wastes fuel.

Power loss and increased fuel consumption are also common. If your engine feels sluggish or struggles to reach normal speeds, injectors may not be delivering enough fuel.

Engine misfires and irregular rhythm, or a rough, stuttering idle, suggest one or more injectors are firing incorrectly, which can be caused by failing electrical circuits.

Listen for unusual engine noise or “diesel knock.” This sharp sound suggests fuel is igniting at the wrong time, often due to poor atomization or incorrect injection timing.

In severe cases, you might find fuel contaminating your engine oil. This can occur if internal injector seals fail, allowing fuel to leak into the crankcase and dilute the oil.

The High Stakes of Neglect: Potential Engine Damage

Ignoring injector problems leads to bigger, more expensive issues. For marine diesels, the consequences of neglect can be catastrophic.

Cylinder wear accelerates when a poor spray pattern washes lubricating oil from cylinder walls, causing metal-to-metal contact and damage.

Melted pistons are a severe consequence. Fuel spraying directly onto a piston creates hot spots that can lead to complete piston failure.

Exhaust system damage occurs when unburned fuel enters the exhaust, destroying expensive components like catalytic converters or particulate filters.

Costly downtime means your boat is at the dock instead of on the water, resulting in lost revenue for commercial operators and frustration for recreational boaters.

Complete engine failure is the ultimate risk. A single failed injector can lead to a total breakdown, leaving you stranded and putting your vessel and safety at risk.

Fortunately, professional Bosch injector testing can identify these problems before they become disasters, protecting your investment and your peace of mind.

The Professional Bosch Injector Testing Process Explained

At RPM Diesel Company, your injectors undergo a thorough diagnostic process. Bosch injector testing requires specialized equipment and factory training, not basic shop tools. This precision, high-tech approach calibrates every test to OEM standards, providing accurate results you can trust for repair decisions.

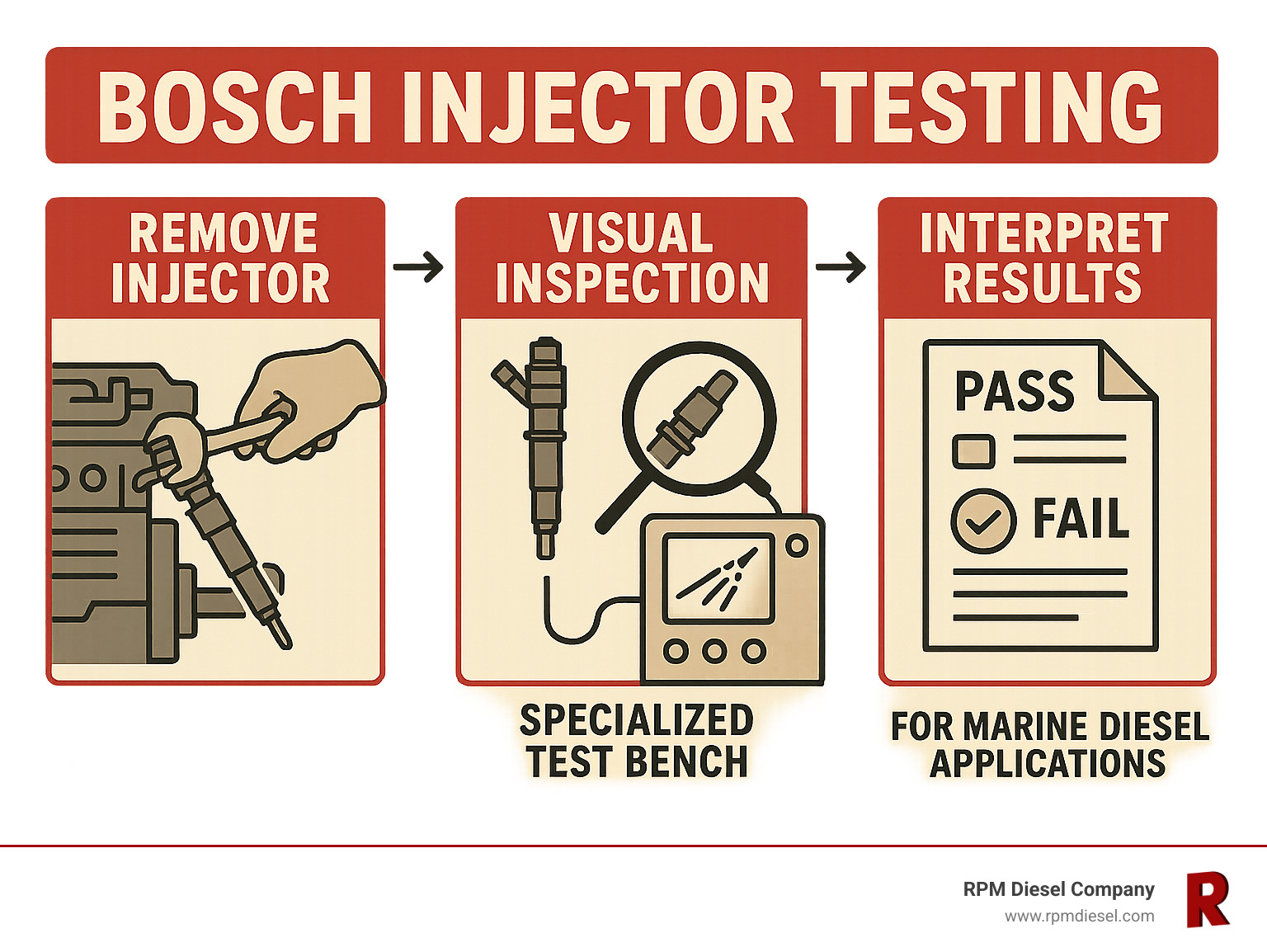

Step 1: Careful Removal and Visual Inspection

Safe injector removal is the critical first step to prevent fuel system contamination or damage. Our technicians thoroughly clean the area around each injector before removal.

We carefully label every fuel line and connection to ensure correct reassembly. Once removed, each injector gets a thorough visual inspection for external damage, corrosion, leaks, or unusual wear patterns that can indicate underlying issues.

Step 2: The Core of the Test: Specialized Bosch Equipment

Our Bosch injector testing capabilities center around state-of-the-art test benches like the Bosch EPS 205 test stand and Bosch EPS 708 test bench. These machines are designed to meet Bosch’s exact testing requirements.

The EPS 205 is a warranty-approved, precise machine for testing various common rail injectors. For the most demanding jobs, our EPS 708 generates up to 2,200 bar (over 31,000 PSI), essential for modern high-pressure systems.

These machines allow us to properly test Common Rail injectors, Piezo injectors, Solenoid injectors, and older mechanical injectors. The key difference is calibration and capability; these benches simulate exact engine conditions for accurate, actionable data.

Step 3: Key Parameters Measured During Bosch Injector Testing

On the test bench, each injector undergoes a detailed analysis of its performance, far beyond a simple pass/fail check.

Spray pattern analysis is a telling test. A healthy injector produces a finely atomized, symmetrical cone of fuel. A distorted pattern or a stream instead of a mist indicates a problem that can lead to engine damage.

Fuel flow rate testing measures how much fuel is delivered under different conditions, including full-load quantity, idle speed quantity, and crucial pilot injection quantity for common rail systems.

Leak testing checks for nozzle seat leakage at the tip and control valve leakage back to the tank. Excessive leakage can cause low rail pressure and hard starting.

For electronic injectors, we perform electrical resistance and “buzz” tests to verify the solenoid or piezo actuator. This requires specialized equipment due to the high voltages (50-90V) in Common Rail systems.

Additional tests include injector start behavior, back pressure testing for piezo injectors, and ISA detection for select Bosch piezo injectors. Each test provides crucial data for recommending the most cost-effective repair.

Decoding the Test Results: Repair, Rebuild, or Replace?

After testing, the most important phase is understanding the results. Our marine diesel experience allows us to translate technical data into clear, actionable recommendations that protect your engine and wallet.

Our philosophy at RPM Diesel Company is simple: “Replace only what’s needed = Saving Money.” We help you avoid replacing entire sets of injectors when only one or two need attention.

Understanding Your Injector Test Report

After Bosch injector testing, you receive a detailed PDF report from our Bosch test equipment, not just a simple pass/fail call.

Your report includes precise measurements for spray pattern quality, fuel flow rates, leak test results, and electrical resistance readings, all compared against Bosch’s factory specifications.

This technical data can be overwhelming, so we explain what each number means for your engine. For example, a low flow rate translates to reduced power, while excessive leak-back affects starting. This data-driven approach removes guesswork from your decision, providing precise measurements of how each injector performs compared to a new one.

Making an Informed Decision for Your Vessel

With detailed test results, we help you determine the best path forward. Injector service decisions are custom to your specific situation.

Targeted repairs may be sufficient for minor issues, such as a specific electrical fault on an otherwise healthy injector.

Nozzle replacement is often a cost-effective solution for older mechanical injectors, restoring like-new performance by replacing just the worn tip.

Complete rebuilding is an option when multiple internal parts show wear but the main housing is salvageable. This involves full disassembly, cleaning, replacement of seals and springs, and retesting to meet Bosch specifications.

New injector replacement is recommended for severe internal damage or when rebuilding costs are too high. We use only genuine Bosch components.

Testing the complete set of injectors, even if only one seems to be failing, saves money long-term. We often find multiple declining injectors. Testing the full set ensures balanced performance and prevents future failures, as one new injector won’t compensate for several underperforming ones. This approach prevents the frustration of another failure just a few months later.

The Importance of Authorized Service and Preventative Maintenance

Your marine engine’s fuel system is your lifeline at sea, making quality and reliability critical. At RPM Diesel Company, we focus on proactive, preventative steps to protect your investment, not just fixing problems as they arise. For a deeper technical dive, an excellent technical guide on injector actuation shows the complexity of these systems.

Why Choose an Authorized Bosch Diesel Service Center for Bosch Injector Testing?

The difference between authorized and unauthorized service is having the right tools, training, and parts to do the job correctly the first time.

OEM-approved equipment like our Bosch EPS 205 and EPS 708 test benches is essential. These machines are calibrated to Bosch’s exact specifications, ensuring your Bosch injector testing results are accurate.

Our factory-trained technicians receive rigorous, hands-on training from Bosch. Their expertise on all injector types, from common rail to mechanical, means they can spot problems others might miss.

We use only genuine Bosch parts to ensure proper “Fit, Form & Function.” Cheap, non-OEM injectors often fail basic tests. Counterfeit injectors are even worse, causing severe engine damage.

Warranty protection on our authorized repairs covers both parts and labor, giving you peace of mind for extended trips.

We have access to the latest test data and repair methods from Bosch, information unavailable to unauthorized shops.

You can verify our repair quality through the Bosch QualityScan portal, checking the authenticity and repair information of your components online.

Proactive Maintenance Tips for Injector Longevity

While professional Bosch injector testing is crucial, smart maintenance can prevent most issues.

High-quality marine diesel fuel is critical. Contamination and moisture are the leading causes of injector failure, with particles as small as 10 microns causing damage. Always use reputable suppliers and consider extra filtration.

Regular fuel filter changes are your first line of defense. Stretching intervals is false economy, as a clogged filter can starve injectors or allow harmful particles to pass, leading to expensive problems.

Water contamination is a diesel engine’s nightmare, causing internal corrosion. Ensure your tank is sealed, drain water separators regularly, and consider using fuel additives.

Fuel additives for marine use can extend injector life. Lubricity improvers are vital for modern low-sulfur diesel. Cleaning agents prevent “tip coking” (carbon buildup), and fuel stabilizers are crucial for boats not used year-round.

These simple steps make a huge difference in reliability, keeping you on the water and out of the repair dock.

Frequently Asked Questions about Marine Bosch Injector Testing

We’ve had countless conversations with boat owners from Fort Lauderdale to Miami about Bosch injector testing. Here are the most common questions and our honest answers to help you make smart decisions for your marine diesel engine.

How often should I have my marine diesel injectors tested?

The recommended testing frequency depends on your injector type and engine usage.

For older vessels with mechanical injectors, we recommend testing every 1,000 hours or two years. These systems are prone to tip wear, which causes poor fuel atomization, black smoke, and cylinder wear.

For newer marine engines with Common Rail injectors, routine service intervals are less common as they are built to last. Instead, we recommend condition-based testing. Test your injectors if you notice symptoms like black smoke, power loss, increased fuel use, or rough running.

For commercial vessels or boats with high operational hours, including Bosch injector testing in your annual maintenance schedule is smart preventative care. Always start with the manufacturer’s recommendations in your service manual.

What is the difference between testing a mechanical injector and a common rail injector?

The difference in complexity is like comparing a hammer to a Swiss watch.

Mechanical injectors are simpler, operating on hydraulic pressure. Testing involves a “pop test” to check opening pressure and a visual inspection of the spray pattern. It’s straightforward but provides limited data.

Common Rail injectors are far more complex, operating at pressures over 2,200 bar and firing multiple times per combustion cycle. They are controlled electronically with millisecond precision.

Testing Common Rail injectors requires computerized test benches like the Bosch EPS 205 or EPS 708. These machines measure dozens of parameters, including precise flow rates, electrical resistance, back pressure, and various leak types. We evaluate not just mechanical function but also the injector’s ability to respond to computer commands with perfect accuracy.

Can I test Bosch injectors myself?

While the DIY impulse is understandable, injector testing is a job that requires professional expertise and equipment.

Bosch injector testing involves extremely high pressures (over 29,000 PSI) that are incredibly dangerous and can cause severe injury. Our test benches have safety enclosures for this reason. High switching voltages (50-90V) in Common Rail injectors also pose a shock hazard.

Professional testing requires specialized, calibrated equipment costing tens of thousands of dollars, like our Bosch EPS test benches. Uncalibrated setups yield unreliable results, leading to incorrect repairs.

There’s also a high risk of damaging these precision components. An improper test can turn a repairable injector into an expensive replacement.

For your safety and your engine’s health, trust professionals with the right equipment and training to perform Bosch injector testing safely and accurately.

Conclusion

When you’re miles from shore, your marine diesel engine’s reliability isn’t just about performance – it’s about getting home safely. Bosch injector testing is your insurance policy against the unexpected, giving you the confidence to explore those beautiful waters from Miami to West Palm Beach without worry.

The results speak for themselves. Professional testing delivers improved engine performance that you can feel, optimized fuel economy that saves you money at every fill-up, and most importantly, the kind of reliability that lets you sleep soundly during overnight anchorages. These precision components work incredibly hard under extreme conditions, and they deserve the same level of professional care you’d give any critical system on your vessel.

At RPM Diesel Company, we’ve built our reputation on understanding that your engine is more than just machinery – it’s your ticket to freedom on the water. Our state-of-the-art Bosch-approved equipment and factory-trained technicians don’t just diagnose problems; we prevent them. Whether you’re dealing with a stubborn performance issue or planning proactive maintenance, our comprehensive approach ensures you get accurate answers and effective solutions.

Don’t let a small injector problem turn into a major emergency when you’re enjoying a sunset cruise off Delray Beach. The investment in professional diagnostics pays for itself many times over by protecting your engine, your wallet, and most importantly, your safety.

The peace of mind that comes from knowing your Bosch injectors are performing to specification is priceless. When you choose professional testing, you’re choosing reliability, efficiency, and the confidence to explore wherever the tide takes you.

Ready to give your marine diesel the professional care it deserves? Learn more about our comprehensive Bosch Diesel Services and find why boat owners throughout South Florida trust RPM Diesel Company to keep their engines running flawlessly, season after season.