Why Your Marine Diesel’s Performance Depends on the Common Rail Pump

Common rail pump repair is one of the most critical maintenance tasks for modern marine diesel engines. Whether your yacht is showing signs of hard starting, loss of power under load, or excessive smoke, the high-pressure fuel pump at the heart of your common rail system may be the culprit.

Quick Answer: Common Rail Pump Repair Overview

- Symptoms: Hard starting, rough idling, power loss, black smoke, high fuel consumption

- Main Components: Plungers, seals, gaskets, Suction Control Valve (SCV), drive shaft

- Essential Tools: Torque wrench, fuel line disconnect tools, specialized test bench

- Critical Steps: Clean disassembly, component inspection, precise reassembly, pressure testing

- DIY Risk Level: High – requires clean-room conditions and specialized equipment

- Professional Testing: Bosch EPS 815 or equivalent test stand mandatory

- Repair vs. Replace: Depends on extent of internal damage and pump age

According to industry research, the global common rail diesel injection system market was valued at USD 15.5 billion in 2022 and continues to grow. These systems operate at extreme pressures – often exceeding 30,000 PSI – making them both incredibly efficient and exceptionally sensitive to contamination and wear.

For marine vessel owners, a failing common rail pump doesn’t just mean inconvenience. It means being stranded offshore, costly emergency repairs, and potentially catastrophic engine damage. The complexity of these systems, with their precise tolerances and electronic controls, means that repairs require specialized knowledge far beyond traditional mechanical fuel injection pumps.

The good news? Understanding the repair process, knowing when to tackle it yourself versus calling in experts, and maintaining proper fuel quality can extend your pump’s lifespan significantly. Some marine diesel engines see their common rail pumps last 5,000 hours or more with proper care, while neglected systems can fail in under 2,000 hours.

Is Your Marine Common Rail Pump Failing? Diagnosis and Key Components

When your marine diesel starts acting up on the water, that sinking feeling in your gut is all too familiar. Is this a simple fix, or are you looking at days in the shop and thousands in repairs? The good news is that common rail pump failures rarely happen without warning. Your engine will tell you something’s wrong—you just need to know what to listen for.

Understanding the symptoms and knowing what’s happening inside that high-pressure pump can mean the difference between a quick diagnosis and weeks of troubleshooting. Let’s break down what you need to watch for and what makes these pumps tick.

Common Failure Symptoms in Marine Diesels

Your engine is constantly communicating with you. When the common rail pump starts to fail, you’ll notice changes in how your vessel performs—sometimes subtle at first, then impossible to ignore.

Hard starting is often the first red flag. You turn the key, the engine cranks and cranks, but it just won’t fire up. This is especially common on cold mornings when the pump needs to generate full pressure quickly. A no-start condition takes this a step further—the engine simply refuses to start at all because fuel pressure has dropped below the minimum threshold needed for combustion.

Once you do get running, rough idling becomes apparent. The engine sounds uneven, almost like it’s missing on a cylinder or two. It might shake more than usual or produce that distinctive “lumpy” sound that tells you something’s not right with fuel delivery.

Out on the water, loss of power under load is where things get really concerning. You push the throttle forward, but your boat doesn’t respond the way it should. Maybe you can’t reach your normal cruising speed, or the engine bogs down when you try to accelerate. This happens because the pump can’t maintain the extreme pressures—often exceeding 30,000 PSI—needed for optimal performance.

Keep an eye on your fuel consumption too. If you’re suddenly burning through diesel faster than normal for the same trips, your pump might be working inefficiently. The system compensates for low pressure by injecting more fuel, which means increased fuel consumption and money wasted.

Excessive black smoke billowing from your exhaust is hard to miss. While a puff of black smoke during hard acceleration is normal, persistent clouds of soot indicate incomplete combustion. When fuel pressure is off, the injectors can’t atomize the diesel properly, leading to that telltale smoke.

Modern marine diesels have another way of warning you: engine alarms. The ECU constantly monitors fuel rail pressure, and when it drops below safe operating levels, it’ll trigger an alarm at your helm. Never ignore these warnings—they’re your early alert system.

These symptoms don’t always point exclusively to the pump. They can overlap with problems in your Diesel Injector Repairs, which is why professional diagnostics with proper fuel pressure testing equipment is so important. A failing pump can stress the injectors, and bad injectors can make a marginal pump fail completely.

Anatomy of a Marine Common Rail Pump

Here’s where things get technical, but stay with me—understanding what’s inside your common rail pump helps you grasp why common rail pump repair requires such precision and specialized knowledge.

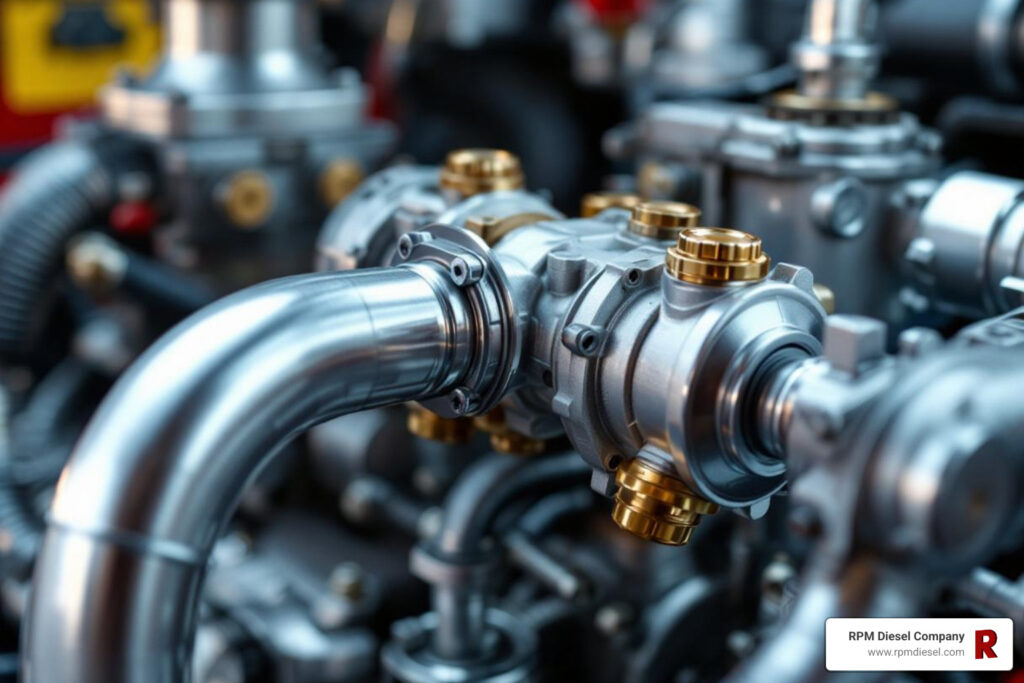

Think of your common rail pump as a highly sophisticated fuel compressor. It takes low-pressure diesel from your fuel tank and transforms it into an ultra-high-pressure supply that feeds the injectors. This isn’t your grandfather’s mechanical injection pump—this is precision engineering operating at pressures that would make a pressure washer look gentle.

The heart of the pump consists of plungers (also called pumping elements). These reciprocating components compress the fuel with incredible force. Even microscopic wear on these plungers can cause a significant pressure drop. When we open up a failing pump, scoring or pitting on these plungers is often the first thing we find.

The Suction Control Valve (SCV) or Inlet Metering Valve (IMV) is the brain’s connection to the brawn. This electronically controlled valve regulates exactly how much fuel enters the pumping chamber. The ECU constantly adjusts this valve based on engine load, speed, and temperature. When the SCV fails—and it’s a common failure point—you get erratic fuel pressure that causes most of the symptoms we discussed earlier.

The drive shaft connects everything to your engine’s timing gears. It spins constantly, transferring rotational energy to drive those plungers thousands of times per minute. While the shaft itself rarely fails, the bearings that support it can wear, leading to noise and eventually catastrophic failure if ignored.

Now here’s what typically causes the actual failures: seals and gaskets. These are the unsung heroes that contain all that high-pressure fuel. They’re made from specialized materials that can withstand extreme pressures and constant exposure to diesel fuel, but they don’t last forever. A leaking seal might seem minor, but it can allow fuel to bypass the pumping elements, dropping rail pressure significantly.

The pump housing itself is a precision-machined component, typically made from high-grade aluminum or steel. While it’s designed to last the life of the engine, extreme stress or contaminated fuel can cause internal wear or even cracking.

In the marine world, you’ll most commonly encounter pumps from two major manufacturers. Bosch CP1, CP3, and CP4 series pumps are workhorses in the industry. The CP3, in particular, has earned a reputation for reliability when properly maintained. Bosch also manufactures the Bosch Diesel Injectors that pair with these pumps, creating an integrated high-pressure fuel system.

Denso HP series pumps are the other major player in marine applications. They operate on similar principles but with their own design characteristics and specific repair requirements.

Each pump model has its quirks and specific repair considerations. The CP4, for instance, is known for being more sensitive to fuel quality than its predecessors. This is why at Bosch Common Rail Rebuilders facilities, technicians need model-specific knowledge and repair kits—there’s no one-size-fits-all approach to common rail pump repair.

Understanding these components helps you appreciate why this isn’t a backyard repair job. We’re talking about tolerances measured in microns, pressures that can pierce skin, and electronic controls that require specialized diagnostic equipment. When something goes wrong inside that pump, precision repair or replacement is the only path forward.

The Complete Guide to Marine Common Rail Pump Repair

Tackling a common rail pump repair on your marine diesel engine is a serious undertaking. It’s not like fixing a leaky faucet! These sophisticated systems demand extreme precision, immaculate cleanliness, and a deep understanding that goes far beyond what most DIY mechanics usually encounter. Here at RPM Diesel, we know the unique challenges of keeping marine engines running perfectly in Florida’s demanding environment, and we understand why getting these repairs right the first time is so crucial for your vessel’s reliability.

Essential Tools and Preparation

Before you even think about touching your common rail pump, the first step is preparing your workspace and gathering the right gear. Think of it like a surgeon preparing for an operation – cleanliness and the right tools are non-negotiable!

First and foremost, you need a spotless workspace. We truly can’t stress this enough. Common rail systems are incredibly sensitive to even the smallest speck of dirt or dust. A tiny particle, invisible to the naked eye, can cause major damage inside these high-pressure components. So, make sure your repair area is carefully clean, ideally a dust-free zone.

Next, let’s talk about tools. Beyond your everyday wrenches and screwdrivers, you’ll need some specialized items:

- A torque wrench is an absolute must-have. Fasteners on common rail pumps have very specific tightening values. Over-tightening can strip threads or warp components, while under-tightening can lead to dangerous leaks. Precision here is key!

- Fuel line disconnect tools help you safely and cleanly remove those high-pressure fuel lines without causing damage.

- Precision measuring tools like calipers or micrometers might be needed if you’re checking clearances or wear on internal parts.

Safety is also paramount. Diesel fuel is flammable, and working with it requires care. Always wear eye protection to guard against splashes and chemical-resistant gloves to protect your skin. Make sure you’re in a well-ventilated area when dealing with fuel and cleaning solvents.

Finally, you’ll need lint-free cloths for cleaning and drying parts, along with approved common rail cleaning solvents. When it comes to replacement parts, always opt for high-quality repair kits and genuine components. Generic parts often don’t meet the tight tolerances needed for common rail systems. Using genuine parts means they’re designed to exact manufacturer specifications, offering guaranteed fit, durability, and often a warranty for peace of mind. If you’re working on a Bosch pump, connecting with experienced Bosch Common Rail Rebuilders ensures you get the best quality parts and expertise.

Step-by-Step Disassembly and Cleaning for common rail pump repair

This is where the real work begins, and it’s a process that demands patience and extreme attention to detail. Precision and cleanliness will be your best friends.

Start with safety first: Always disconnect the vessel’s battery to prevent any accidental engine cranking or electrical mishaps. Work in a well-ventilated area, especially when draining fuel or using solvents. Make sure the engine is completely cool before you even think about touching the fuel system. And have appropriate containers ready to catch any draining fuel – diesel is flammable, so keep open flames or sparks far away.

When it’s time for removing the pump, be gentle. Carefully disconnect all fuel lines, electrical connectors, and mounting bolts. Here’s a crucial tip: mark the orientation of components and their exact positions. Take lots of photos from different angles! This will be invaluable when you’re putting everything back together.

Now for the meticulous disassembly. You’ll need to follow the specific instructions in your pump’s service manual. Each pump model, whether it’s a Bosch CP1, CP3, CP4, or a Denso HP series, will have its own unique steps. Work systematically, keeping all fasteners and small parts organized. We often use magnetic trays or labeled containers to keep everything in its place. As you take things apart, practice extreme contamination avoidance. Keep all internal components covered or, better yet, submerged in clean diesel fuel to protect them from dust and moisture.

For cleaning standards, only use approved solvents specifically designed for fuel system components. Harsh chemicals can easily damage delicate surfaces or seals. Clean each component thoroughly, removing any carbon buildup, varnish, or tiny metal particles. Once clean, dry the parts with filtered, compressed air. Never use shop rags that can leave lint behind – remember, lint is a contaminant! If you’re working on a Bosch pump, resources like A detailed guide on Bosch pump repair can be incredibly helpful, just remember to apply it to your specific marine context.

Inspection and Critical Reassembly Steps

With everything sparkling clean, it’s time for a thorough inspection. This stage is where you truly determine the success of your common rail pump repair.

Your first priority is identifying worn or damaged seals and gaskets. These are primary wear items. Look for any signs of hardening, cracking, flattening, or leakage on all O-rings, seals, and gaskets. Always replace these components with new ones from a high-quality repair kit. It’s a small investment that makes a huge difference.

Next, carefully check for scored plungers. Examine the surfaces of the plungers and their bores for any scoring, pitting, or excessive wear. Even minor imperfections here can lead to a significant drop in fuel pressure. Also, inspect the pump housing for cracks, especially in high-stress areas.

When it comes to reassembly, replacing all gaskets and worn parts is non-negotiable. In professional rebuilds, all normal wearing parts are replaced or re-manufactured every single time. If any hard parts show significant wear or damage, they simply must be replaced.

Before putting things back together, ensure proper lubrication. Lubricate all internal moving parts and new seals with clean diesel fuel. This helps with assembly and provides initial protection.

Finally, following torque sequences is critical. Reassembly requires strict adherence to the manufacturer’s torque specifications and sequences. This ensures an even clamping force, preventing distortion and premature failure. Grab your calibrated torque wrench and follow those numbers! And throughout this entire reassembly process, continue to maintain a spotless environment. Any contamination introduced now could lead to immediate failure of your newly repaired pump. For deeper insights into the intricacies of Bosch systems, exploring resources like Bosch Common Rail Repair can provide valuable context for the meticulous work required.

Post-Repair: Testing, Prevention, and Key Considerations

You’ve put in the hard work, carefully disassembled, cleaned, and reassembled your common rail pump. That’s a huge step! But the journey isn’t quite over. The real proof of a successful common rail pump repair comes from thorough testing. For marine engines operating off the sunny coast of Florida, reliability isn’t just a luxury; it’s absolutely everything.

Best Practices for Testing a Repaired Pump

This is truly where a professional common rail pump repair shines compared to a DIY attempt. Proper testing requires specialized equipment that most boat owners simply don’t have access to. It’s about ensuring your pump will perform flawlessly when you’re miles offshore.

At RPM Diesel, we rely on advanced, specialized test stands. Machines like the Bosch EPS 815, along with Hartridge AVMPC-2, Hartridge HA400, Hartridge HA123, and Bacharach Specialist stands, are vital for our work. These aren’t just fancy gadgets; they’re essential for bringing your pump back to life with precision. They allow us to simulate real-world engine conditions right here in our shop.

With these specialized tools, we can verify pressure and flow, making sure your pump delivers fuel exactly as it should. We also test solenoid function for components like the SCV or IMV, confirming they respond accurately. Plus, we carefully check for leaks to prevent any fuel loss or safety hazards. Most importantly, these stands enable us to calibrate your pump, bringing it back to the original factory specifications. This precision guarantees your engine’s best performance, efficient fuel use, and a long, healthy life.

Once the pump is given a clean bill of health on the test bench, the work isn’t quite done. Back on your vessel, it’s crucial to properly prime the fuel system before starting the engine. This removes any air that might have entered during installation. Then, we carefully bleed air from lines to ensure a smooth, air-free fuel delivery.

A professional Fuel Injection Service always includes this comprehensive testing and careful reinstallation. It’s how we guarantee your pump’s performance and your peace of mind on the water.

Preventing Future Failures: The Role of Fuel Quality and Maintenance

Even the most expertly performed common rail pump repair won’t last if we don’t address the root causes of failure. For marine common rail systems, contamination and poor maintenance are the biggest culprits. Think of it like this: a healthy pump needs clean, healthy fuel!

Water contamination is truly disastrous for common rail components. It can cause corrosive damage, reduce the vital lubrication fuel provides, and even lead to cavitation damage at the extreme pressures these systems operate under. The marine environment brings unique challenges like constant moisture, which is a critical factor for your fuel system. Even tiny bits of debris in fuel are a major threat. These microscopic particles can score plungers, clog delicate valves, and quickly wear down all the precision parts inside your pump. This is why repair manuals rightfully stress the absolute importance of using clean fuel.

This is why the importance of water separators cannot be overstated. Make sure your vessel has top-notch fuel-water separators, and check them often. They are your vital first line of defense against water making its way into your sensitive common rail system. Just as critical are regular fuel filter changes. We recommend changing your fuel filters religiously, often even more frequently than the manufacturer’s suggested schedule for marine use. Clogged filters force your pump to work harder, restricting fuel flow and potentially leading to costly damage. Finally, always commit to using high-quality marine diesel from reputable suppliers. Cheaper fuel can contain more contaminants or lack the proper lubricating properties, both of which are detrimental to your pump’s health.

Research on preventative replacement shows that proactive maintenance prevents catastrophic failures, a truth that applies directly to the longevity of your fuel pump. Being proactive with your fuel quality and maintenance is always far less costly and stressful than dealing with unexpected repairs.

Repair vs. Replace: Making the Cost-Effective Choice

The big question for many marine vessel owners is whether to repair a failing common rail pump or replace it entirely. It’s a decision that weighs heavily on budget, desired reliability, and the actual extent of the damage.

Let’s look at the costs. A common rail pump repair often involves replacing specific worn parts like plungers, seals, gaskets, or control valves. This can typically cost anywhere from $1,000 to $2,000, including both parts and the specialized labor. The goal is to restore the pump’s function, and if done correctly by a certified specialist, its performance can be very close to new. On the other hand, purchasing a new common rail pump can range from $2,000 to $4,000 or more, depending on the model, plus additional labor for installation. A new pump offers guaranteed optimal function right out of the box, backed by a manufacturer’s warranty.

When considering long-term reliability, a new pump generally provides the longest expected lifespan, offering years of dependable operation if properly maintained. A professionally repaired pump, using high-quality parts and expert techniques, can also deliver excellent longevity, often several years. However, its overall lifespan might not always match that of a brand-new unit, as some original components remain.

The deciding factor often comes down to the extent of internal damage. If the pump housing itself is cracked, or if critical components are severely scored beyond repair, then replacement becomes the necessary choice. This is also true if the cost of repair starts to creep too close to the price of a brand-new pump. In such cases, investing in a new unit usually provides the best long-term value and peace of mind, ensuring your vessel’s utmost reliability when you’re out on the water.

Conclusion: Ensuring Your Vessel’s Reliability

As we’ve journeyed through the intricate world of marine common rail fuel systems, it’s clear that the common rail pump is truly the heart of your diesel engine. Keeping it in prime condition isn’t just about good maintenance; it’s about safeguarding your adventures on the water. A successful common rail pump repair demands an incredible eye for detail, an immaculate workspace, the right specialized tools, and most importantly, rigorous testing. When you’re dealing with immense pressures and microscopic tolerances, even the smallest mistake can lead to big problems, potentially leaving you adrift or facing hefty repair bills.

For our valued boat owners throughout Fort Lauderdale, Miami, West Palm Beach, Boca Raton, and Delray Beach, your engine’s reliability is paramount. That’s why entrusting these complex repairs to seasoned professionals is always the smartest course. At RPM Diesel, we stand firm in our commitment to using only genuine parts, strictly adhering to manufacturer specifications, and performing comprehensive test bench validation. This meticulous approach ensures your repaired pump delivers the powerful performance and lasting reliability you depend on, mile after mile.

We take immense pride in our role as a Bosch Diesel Specialist: Expert 2025 Quality – RPM Diesel. Our team boasts factory authorizations, state-of-the-art diagnostic and repair equipment, and a crew of experienced, certified technicians ready to tackle even the most challenging common rail fuel system issues. When you need expert diagnostics and professional repair that truly guarantees performance and peace of mind on the water, trust the specialists. We invite you to explore our comprehensive Common Rail Injector Service today and experience the RPM Diesel difference.