Why Marine Diesel Engine Troubleshooting Matters for Your Boat

Marine diesel engine troubleshooting is essential if you want to keep your boat running smoothly and safely. Diesel engines are reliable, but when they do stop, it’s almost always due to simple, fixable issues you can quickly diagnose:

- Fuel problems (especially clogged filters)

- Cooling system issues (like overheating or impeller failure)

- Electrical faults (battery or alternator issues)

- Lubrication problems (low oil or leaks)

- Air intake blockage or exhaust issues

The keywords are routine checks and preventive maintenance. Most marine diesel engine problems result from minor issues that quietly build up over time—often preventable through regular attention and care.

In this short guide, you’ll learn exactly how to spot these common problems early, so you can spend less time dockside waiting for repairs, and more time out at sea.

Essential marine diesel engine troubleshooting terms:

– MTU marine engine parts

– cummins marine engines for sale

– diesel parts and service

Understanding Common Marine Diesel Engine Problems

Marine diesel engines have a reputation for reliability and efficiency. But even the best engines occasionally run into trouble. The good news is, most marine diesel issues are straightforward and fixable—if you know what to look for.

Regular marine diesel engine troubleshooting is crucial. The better you understand these common problems, the quicker you’ll spot trouble and get back out on the water.

Let’s take a closer look at some of the most frequent issues you might encounter with your marine diesel engine.

Fuel System Problems

Believe it or not, fuel issues account for nearly all marine diesel engine failures. At the top of the list is the clogged fuel filter. Filters trap dirt and contaminants, but over time they can get blocked, reducing fuel flow and causing engines to lose power or even stop altogether.

Another common fuel-related challenge is air in the fuel lines. If air bubbles enter your fuel system, combustion becomes irregular, causing your engine to sputter, stall, or struggle to start smoothly.

And let’s not forget contaminated fuel. Water, dirt, and microbial “diesel bug” growth in your fuel tank can seriously damage injectors and fuel pumps.

As experienced boaters often say:

“Don’t fill your tank with dirt! Be especially careful if filling from cans and get yourself a fuel filter funnel.”

If you notice your engine running rough, losing power gradually, or failing to start altogether, check your fuel system first. And if you’re sailing a yacht with shallow fuel tanks, keep them at least one-third filled. This prevents sediment from stirring up and clogging your filters when your boat heels under sail.

Cooling System Issues

Marine diesel engines rely heavily on an efficient cooling system. Unlike cars, marine diesels typically use a closed-loop freshwater/antifreeze mix that’s cooled by raw water via a heat exchanger.

One of the first signs of cooling trouble is overheating. This issue often points to restricted raw water flow or a failing impeller. Saltwater engines especially face scaling buildup inside the heat exchanger, reducing cooling effectiveness.

Another common cooling problem is impeller failure. The rubber blades inside your water pump can deteriorate or break off, cutting off water flow to your engine. Lastly, blocked water inlets (from debris, marine growth, or barnacles) can quickly restrict cooling water flow.

At RPM Diesel Company, we’ve seen engines develop significant salt buildup after just 600 hours of use. Proper cooling system maintenance helps avoid costly repairs down the line—so keep an eye on water flow and temperatures regularly.

Electrical System Failures

Today’s marine diesel engines depend on electrical power for starting, monitoring, and running smoothly. Just one bad connection can sideline your entire engine.

One common electrical issue is battery problems. Corroded terminals, weak batteries (below 12.6 volts), or cells unable to hold a charge all spell trouble. If battery voltage drops significantly when cranking (below 9-10 volts), it’s time for a replacement.

Faulty wiring is another frequent nuisance. Corrosion, loose connections, and damaged insulation can cause intermittent issues or even prevent your engine from starting at all. Lastly, alternator problems can leave your batteries inadequately charged, creating ongoing starting headaches.

Regularly checking your batteries, wiring, and alternator is a crucial part of effective marine diesel engine troubleshooting.

Lubrication System Problems

Think of oil as your engine’s lifeblood—reducing friction, keeping things cool, and protecting metal parts from corrosion. Lubrication system issues must never be ignored, as serious engine damage can happen quickly without proper oil pressure.

A common warning sign of lubrication trouble is low oil pressure, often caused by leaks, worn bearings, or a failing oil pump. Contaminated oil—from water or fuel getting in—also seriously reduces its protective qualities. And don’t overlook oil leaks from failing gaskets or loose fittings, which can quickly drop your oil level below safe limits.

Always remember this wise advice from seasoned mariners:

“Check the oil level with the dipstick on each day that you use the engine.”

Healthy diesel engines typically run 45-65 psi of oil pressure at cruising speeds, dipping to around 30 psi at idle. If you’re seeing pressures below 20 psi at idle, it’s time to have your engine thoroughly checked.

Air Intake and Exhaust Issues

Your engine needs plenty of air—about one cubic meter per minute for every 20 horsepower at cruising speeds. Even a small blockage can choke your engine’s power and efficiency.

A clogged or dirty air filter is a common culprit. Regularly inspect, clean, or replace these filters to keep air flowing smoothly.

Also, pay close attention to your exhaust smoke color. Different smoke types indicate specific issues:

- White smoke usually means water is entering combustion chambers or unburned fuel is escaping.

- Black smoke indicates incomplete combustion, often from overloaded engines, dirty injectors, or restricted air flow.

- Blue smoke points to oil burning, typically from worn piston rings or valve seals.

Marine mechanic Meredith Anderson sums it up perfectly: “Smoke from an engine tells quite a story, providing huge diagnostic clues as we try to figure out what is going on.”

When you see unusual exhaust smoke, it’s often your engine giving you an early warning—one you should definitely heed.

Understanding these common marine diesel engine issues helps you catch potential problems early and save big headaches down the road. If you’re ever unsure or facing persistent issues, contacting expert technicians like our team at RPM Diesel Company is your best bet. We provide comprehensive marine diesel engine troubleshooting, servicing, and support—so you can enjoy more time at sea and less time dockside.

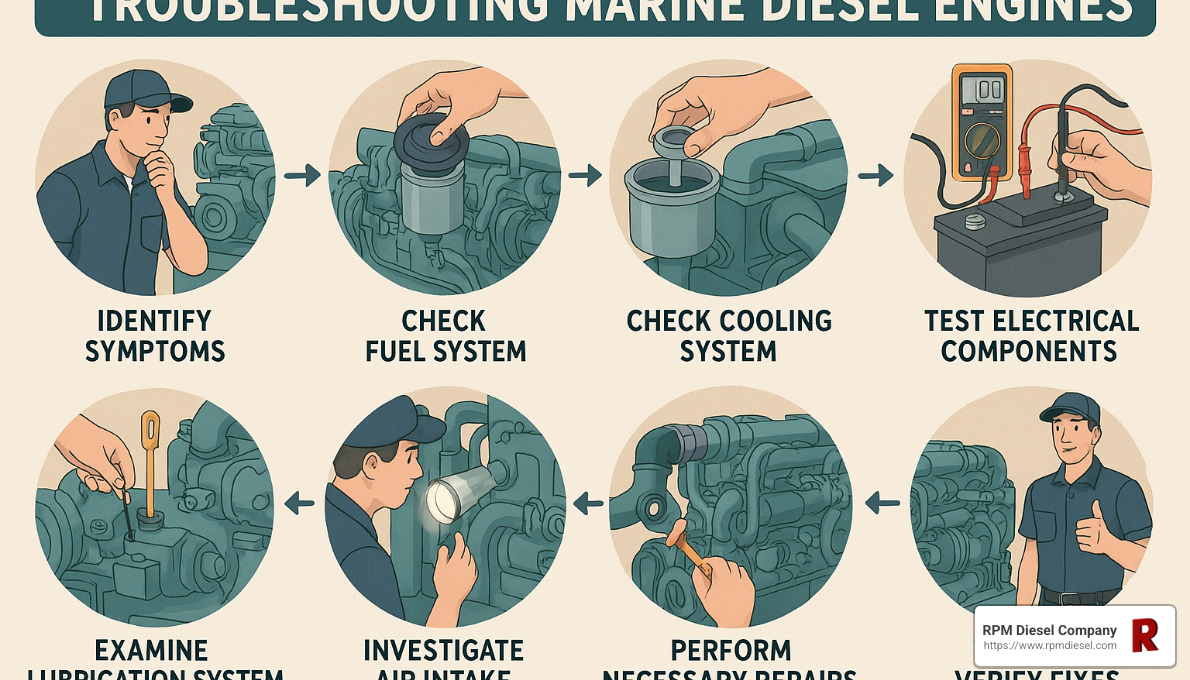

Marine Diesel Engine Troubleshooting Guide

When your boat’s diesel engine starts acting up, it can be tempting to panic—but don’t worry. With a calm, systematic approach to marine diesel engine troubleshooting, you can quickly zero in on the problem and get back out on the water.

Marine diesel engines aren’t mysterious. They simply follow set mechanical processes. When something interrupts these processes—like fuel contamination, overheating, or electrical issues—the engine stops or runs poorly.

To help you pinpoint common problems quickly, follow this clear, easy-to-use troubleshooting guide:

Diagnosing Fuel System Problems in Marine Diesel Engines

Since most marine diesel engine issues begin with the fuel system, start your troubleshooting here.

First, verify your actual fuel level. Don’t trust gauges alone—use a dipstick to confirm how much fuel is in the tank. Next, inspect your fuel for any contamination. Look carefully for water, debris, or diesel bug (bacteria). Drain the pre-filter using its drain screw if contamination is suspected.

If the fuel looks questionable, replace your fuel filters immediately. Even if they seem clean, changing filters often resolves issues fast. After replacing filters or whenever you suspect air has entered the fuel lines, you’ll also need to bleed air from the fuel system to ensure smooth running.

To properly bleed the system, first make sure the tank has plenty of fuel. Open and release bleed screws from the lowest to highest points until clear diesel flows without bubbles. Then tighten each screw securely. If needed, loosen injector unions slightly until clean fuel emerges. Click here for detailed steps to bleed the fuel system.

Troubleshooting Cooling System Issues in Marine Diesel Engines

Cooling system problems, especially overheating, can quickly lead to serious engine damage. If your engine runs hot, tackle the cooling system next.

Begin by checking your raw water intake and strainer—ensure the seacock is open, and remove any debris or marine growth from the strainer basket. Next, carefully inspect the impeller. Remove the pump cover plate and look for missing or damaged blades. If blades are broken, be sure to locate and clear any debris that might block the cooling passages.

Also, check your drive belt tension—about half-inch (1cm) play is ideal, with no more than a 45-degree twist. Finally, confirm coolant levels. Only open the coolant cap when the engine is cold, and top up with the correct antifreeze mixture if levels are low. Temporarily removing the thermostat can help you diagnose if it’s causing overheating.

Identifying Electrical System Failures

Electrical issues in marine diesel engines can seem tricky, but with patience and a simple multimeter, they become much easier.

Start by testing your battery voltage. A fully charged battery should read around 12.6 volts. At around 12.2 volts, it’s about half discharged. If your battery voltage drops below 9 volts during engine cranking, it’s likely time for replacement. Next, check all battery connections—cleaning any corrosion with fine emery paper—and ensure terminals are tight.

Carefully inspect wiring and fuses for damage, loose connections, or corrosion. Also, test your alternator if your battery isn’t holding a charge well. Check the alternator’s drive belt tension and consider having it professionally tested if unsure.

Additionally, examine your glow plugs in colder weather by briefly touching the terminals with a damp cloth while wearing gloves—they should heat noticeably.

Recognizing Lubrication System Problems

Oil-related issues can lead to costly engine damage if ignored. Always make lubrication checks part of your daily routine.

First, check oil levels regularly with the dipstick—ideally every time before running the engine. Look at oil color and consistency too. Healthy oil should be clear and smooth, not milky (which indicates water contamination) or excessively dark.

If the engine’s oil warning alarm activates or the gauge shows low oil pressure, immediately stop the engine and investigate. Also, check closely around gaskets, fittings, and filters for signs of oil leaks.

Changing your oil filter every season is a smart habit. If issues arise, don’t wait—replace the filter immediately and inspect the oil quality closely. At RPM Diesel Company, we’ve fixed many engines where costly repairs could have been easily avoided with simple oil checks and regular filter replacements. For more detailed guidance, visit our page on Marine Diesel Engine Repairs.

Interpreting Warning Lights and Alarms

Modern marine diesel engines often have helpful warning lights and alarms designed to catch problems early before they cause serious damage. Pay attention—these signals are your friends!

Oil pressure and temperature alarms indicate serious, immediate issues—stop the engine, investigate carefully, and don’t restart until the problem is resolved. Charging system warnings typically signal alternator or battery issues, so check your electrical system carefully. Some newer engines even display specific fault codes that help pinpoint the exact problem.

Don’t shrug off these warnings—they exist to protect your engine and your wallet. As one wise mechanic said:

“This simple, hands-on guide to practical diesel engine care makes repair and maintenance more user-friendly than ever before.”

At RPM Diesel Company, our experienced technicians can help you interpret warning lights or codes and get you back out on the water quickly and safely. After all, a little care and prompt action can make all the difference in keeping your boat running smoothly season after season.

Essential Maintenance Tips to Prevent Engine Troubles

When it comes to marine diesel engines, an ounce of prevention truly is worth a pound of cure. Regular maintenance and simple routine checks are your best friends in the fight against unexpected breakdowns. Not only will proactive care extend the life of your engine, but it’ll also save you from headaches—and potentially costly repairs—down the line.

Here’s how you can effectively practice marine diesel engine troubleshooting by preventing issues before they even start.

Routine Maintenance Practices

Keeping your marine diesel engine in great shape doesn’t need to be complicated. Establishing a clear maintenance schedule and sticking to it is key. Here are a few guidelines to help you keep things ship-shape:

Before you cast off, always perform quick daily checks. Make sure you inspect the oil level and condition, coolant levels, and belt tension. Take a glance for leaks around hoses, fittings, and filters. Don’t forget to check your raw water strainer—keeping it clean can prevent cooling system issues down the road.

In addition to daily checks, follow regular service intervals based on engine hours or at least once per year. Change your oil and filters, replace fuel filters, and inspect your impeller for wear. It’s also wise to check valve clearances and conduct a compression test if you notice any performance issues.

Seasonal maintenance involves diving deeper into your engine’s health. Flush your cooling system, clean your fuel system, and inspect and replace sacrificial zincs as needed. It’s also a great opportunity to check hoses, clamps, and wiring that might be wearing out.

One of the most overlooked yet valuable practices is to keep detailed maintenance records. Note down dates, engine hours, services performed, and any parts you’ve replaced. Accurate records help catch emerging problems early and make future troubleshooting efforts much easier. At RPM Diesel Company, our Marine Diesel Engine Maintenance services follow manufacturer-recommended schedules to ensure your engine stays reliable and efficient.

A quick tip from seasoned mariners: Run your marine diesel engine regularly, even during downtime, to keep components lubricated and prevent corrosion. Also, always warm up the engine gradually before putting it under load, and let it cool down briefly after use. These small habits significantly extend your engine’s lifespan and overall reliability.

Tools and Spare Parts to Keep on Board

Having the right tools and spare parts aboard your boat can make all the difference when trouble strikes far from port. After all, even the best-maintained engine might surprise you occasionally.

A basic toolkit for marine diesel engine troubleshooting includes essentials like wrenches, screwdrivers, oil and fuel filter wrenches, pliers, and wire cutters. A good-quality multimeter is invaluable to quickly diagnose electrical issues. An impeller puller and strap wrench are also handy items. Don’t forget basics like spare fuses and a reliable flashlight.

In addition to tools, carrying a sensible inventory of spare parts is crucial. Always have spare fuel filters (both primary and secondary), oil filters, a fresh impeller kit, and drive belts aboard. Extra fluids such as coolant and engine oil of the correct grade are must-haves. You might also consider keeping fuel additives, spare gaskets, hose clamps, and extra fuses handy.

At RPM Diesel Company, we’ve learned through experience that a simple replacement like a fresh fuel filter or a spare impeller often makes the difference between quickly fixing an issue on the water or calling for a tow. Being well-prepared with these essentials provides peace of mind and keeps your boating trips enjoyable—not frustrating.

When to DIY Repairs vs. Calling a Professional

Knowing when to tackle repairs yourself and when to call in the experts is an essential skill every boat owner should master.

For routine tasks like changing oil and filters, bleeding air from fuel systems, or replacing belts and impellers, DIY repairs are usually manageable. Basic electrical troubleshooting and simple adjustments typically don’t require professional assistance either, especially if you’re comfortable around engines.

However, some tasks genuinely require the specialized expertise of marine diesel professionals. If you’re facing internal engine issues such as compression problems, major oil leaks, or complex fuel injection system repairs, it’s time to seek professional help. Similarly, extensive cooling system overhauls or major electrical system failures generally need professional tools and experience to address safely and effectively.

Another good rule of thumb: If you’re unsure about the cause of an issue or nervous about performing a repair yourself, trust your gut and call in the pros. At RPM Diesel Company, our seasoned technicians can quickly diagnose and address challenging issues. Our extensive inventory of hard-to-find parts and years of marine diesel expertise means your engine is always in safe hands.

As world-famous cruising sailors Lin and Larry Pardey said:

“If you can’t repair it, maybe it shouldn’t be on board.”

This advice emphasizes the importance of self-sufficiency and the value in knowing your engine inside and out. But it also stresses the wisdom of recognizing your limits—knowing when to call in the cavalry is part of being a responsible boat owner.

At RPM Diesel Company, we’re always ready to step in whenever your marine diesel engine maintenance or troubleshooting tasks exceed your comfort level. With our help, you’ll have more time on the water enjoying your boat and less time stuck dockside worrying about engine troubles.

Frequently Asked Questions About Marine Diesel Engines

What Do Different Types of Exhaust Smoke Indicate?

The color of your exhaust smoke is like your engine trying to talk to you. When you’re marine diesel engine troubleshooting, paying attention to these smoke signals can save you hours of guesswork.

White smoke is actually quite normal when you first start a cold engine—just a brief puff that quickly disappears. But if that white cloud sticks around, your engine is telling you something’s wrong. It could be water sneaking into places it shouldn’t be (like a failed head gasket or cracked cylinder head), fuel not burning properly due to compression issues, or simply that your engine is running too cold.

Black smoke is your engine’s way of saying “I can’t breathe properly!” This happens when fuel isn’t burning completely. Think of it like trying to run with a stuffy nose—not efficient at all. The most common culprits? You might be overloading your engine, pushing it beyond its comfort zone. Or perhaps your air filter is clogged, your injectors need cleaning, or your injection timing is off. Sometimes it’s as simple as a fouled propeller or dirty hull creating too much drag.

When you see blue smoke billowing out, your engine is burning oil. This typically means wear and tear has created pathways where oil can sneak into the combustion chamber—worn valve stem seals, tired piston rings, or oil leaking into the air intake system are the usual suspects.

As one of our veteran mechanics at RPM Diesel likes to say, “Smoke from an engine tells quite a story—it’s like the engine’s way of sending up a flare about what’s happening inside.” We always use smoke diagnosis as our first clue when tackling engine problems.

How Can I Test Compression in My Marine Diesel Engine?

Compression testing is particularly valuable for older engines or when you suspect internal issues might be brewing. Good compression is the heartbeat of your diesel engine—without it, you’re going nowhere fast.

For a professional compression test, you’ll need specialized equipment. The process involves removing all injectors or glow plugs, installing a compression gauge in one cylinder, disabling the fuel system, and cranking the engine several times. You’ll record the pressure reading for each cylinder and compare them—they should all be within 10-15% of each other. Healthy diesel engines typically show compression readings between 200 and 500 psi.

But what if you’re out on the water without professional tools? You can perform a simple substitute test. Remove the valve cover and use the proper tool (socket and tommy bar) to manually rotate the engine. Pay attention to how much resistance you feel as each cylinder reaches compression—they should all feel roughly the same. If one cylinder feels weaker, try adding a small amount of oil and testing again. If compression improves with oil, your piston rings are likely worn; if not, you might have valve issues.

Significant variations between cylinders usually mean it’s time to give us a call at RPM Diesel Company. Some internal problems require professional attention and specialized equipment to resolve properly.

What Are the Steps for Bleeding Air from a Diesel Fuel System?

Air in the fuel system is like a hiccup in your engine’s diet—annoying and disruptive. It’s one of the most common issues we encounter during marine diesel engine troubleshooting, especially after fuel filter changes or running your tank too low.

Before you start the bleeding process, make sure you have enough fuel in your tank—seems obvious, but we’ve seen many “fuel system problems” that were simply empty tanks! Next, locate all the bleed screws in your system. They’re typically found on the fuel filter housing, lift pump, and injection pump.

Since this process can get messy, place some absorbent rags or a container under the bleed points to catch any spilled fuel. Then open the first bleed screw (usually at the fuel filter or lift pump) and operate the manual lift pump until you see fuel flowing without any bubbles. Once you have bubble-free fuel, tighten that bleed screw and move to the next point.

The key is to work systematically through your fuel system, from low-pressure to high-pressure points. If your engine still won’t start after bleeding the main points, you might need to bleed at the injectors themselves. This involves slightly loosening the injector unions and cranking until fuel appears, then retightening them.

When you first start the engine after bleeding, don’t be alarmed if it runs roughly for a few moments—this is normal as any remaining air works its way out of the system.

For more detailed guidance specific to your engine model, check out our Diesel Engine Troubleshooting Guide.

Here’s a tip from our technicians: When you’re comfortably docked in harbor, take some time to locate and mark all the bleed screws on your engine. Make a simple diagram if needed. This small bit of preparation can save you significant time and frustration if you need to bleed the system during less ideal circumstances.

Conclusion

Mastering the basics of marine diesel engine troubleshooting doesn’t have to be intimidating. With a bit of knowledge, preparation, and regular attention, you can keep your engine running smoothly and your boat safely afloat.

One of the most important things you’ll learn when troubleshooting marine diesel engines is that most issues come down to simple, fixable problems. Fuel filters, air in the fuel system, basic electrical faults, or cooling system hiccups are often the culprits behind engine trouble. Knowing what signs to look out for and which steps to take can dramatically cut down on downtime—and stress!

Of course, the heart of any reliable marine diesel engine is a thoughtful routine maintenance plan. Consistent, preventive care will greatly reduce the chances of surprise breakdowns. Regularly checking oil and coolant levels, inspecting impellers, and keeping an eye on your batteries and wiring can mean the difference between a relaxing weekend at sea and an unexpected stay in the marina.

When issues do arise, a systematic, step-by-step approach is your best friend. Resist the urge to panic or randomly swap out parts. Instead, calmly work through fuel, cooling, electrical, lubrication, and air intake/exhaust systems in order. This methodical approach isn’t just good practice—it’s how professional marine diesel mechanics tackle engine troubles every day.

Knowing when to handle repairs yourself and when to call in reinforcements is equally important. Simple tasks like replacing filters, bleeding air from the fuel system, or checking belts and hoses are completely manageable for most boat owners. But if you encounter more complex issues like internal engine trouble, cooling system overhauls, fuel injector problems, or major electrical faults, don’t hesitate to reach out to experienced marine diesel experts like RPM Diesel Company.

Another key tip is to always carry a selection of essential spare parts on board. Items like spare filters, extra drive belts, impellers, coolant, engine oil, and basic tools can often be the difference between a quick fix and a ruined day on the water.

Above all, keeping your marine diesel engine healthy doesn’t have to be complicated or stressful. At RPM Diesel Company, we’re passionate about helping boat owners like you feel confident and prepared. Our team has deep expertise in marine diesel engine sales, service, and maintenance, backed by an extensive inventory of parts from leading manufacturers.

Serving boaters across Fort Lauderdale, Broward County, Dade County, Miami, West Palm Beach, Boca Raton, Delray Beach, and worldwide, RPM Diesel Company is your trusted partner for comprehensive marine diesel engine support. Whether you’re dealing with routine maintenance or unexpected issues, our factory-trained technicians can quickly diagnose the problem and get you back on the water.

For additional resources, tips, and expert advice, check out our detailed Marine Diesel Engine Maintenance resource center. You’ll find plenty of helpful guides to keep your boat performing at its best.

Your marine diesel engine is an incredible piece of machinery, carrying on the legacy of Rudolf Diesel’s brilliant invention. With proper care and smart troubleshooting practices, your engine will keep humming happily for years to come—so you can spend less time troubleshooting and more time enjoying the open sea.

![]()