Why Understanding How Your Marine Diesel Engine Works Matters

Understanding how marine diesel engines work is fundamental for any vessel owner who values reliability. A marine diesel operates on compression ignition: air is drawn into a cylinder and compressed to extremely high temperatures (around 600°C). Diesel fuel is then injected, and the intense heat causes it to ignite spontaneously, driving a piston that turns the crankshaft and powers your propeller.

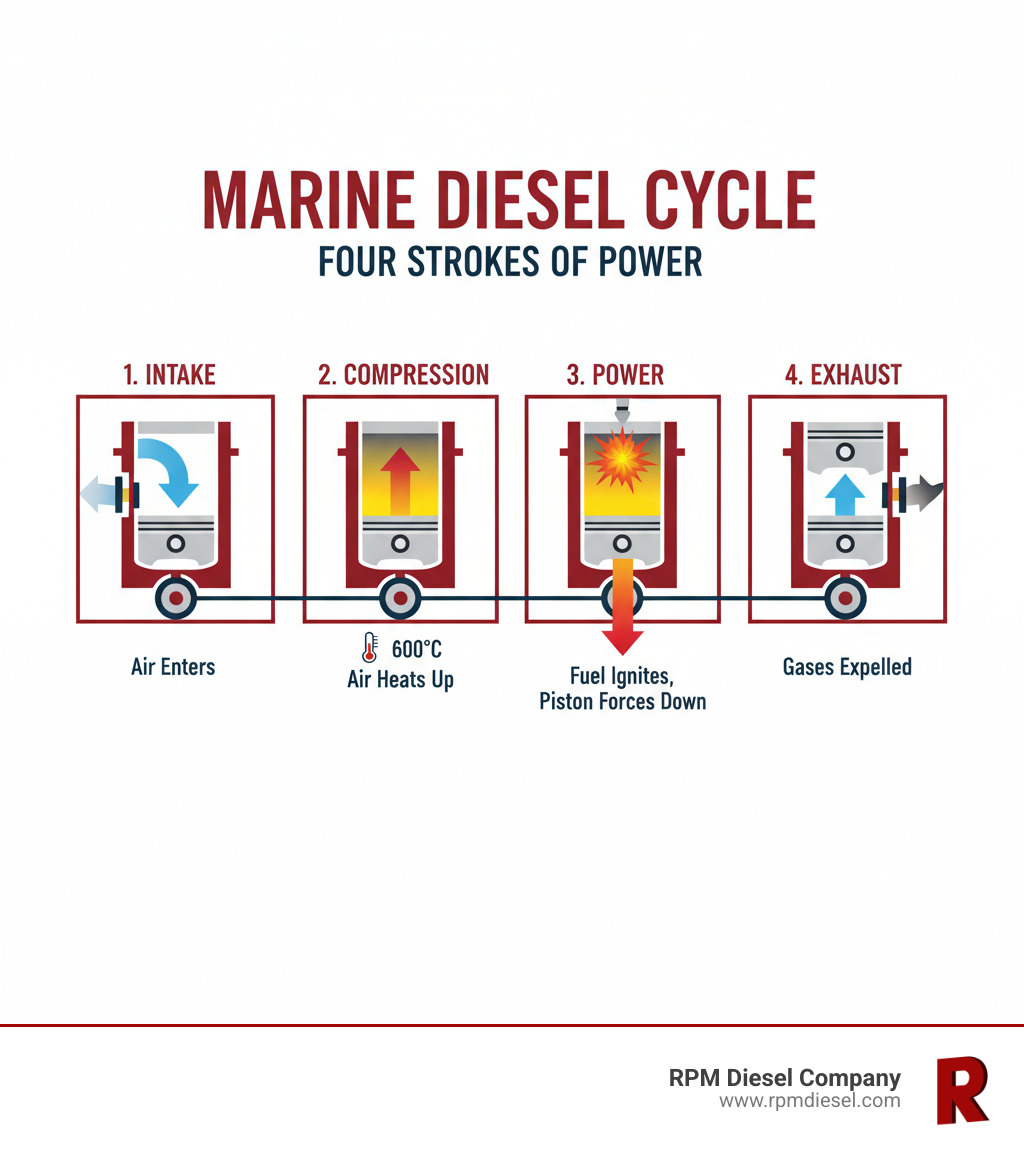

Here’s the basic four-stroke cycle:

- Intake – Fresh air enters the cylinder.

- Compression – The piston compresses the air, heating it to about 600°C.

- Power – Fuel is injected, ignites, and forces the piston down.

- Exhaust – Burnt gases exit through the exhaust valve.

This process repeats thousands of times per minute, converting fuel into thrust. Knowing how it works helps you spot warning signs, communicate with mechanics, and make informed maintenance decisions. Knowing what’s happening inside your engine puts you in control.

Marine diesel engines differ from automotive versions. They are built heavier for the marine environment, use specialized seawater cooling systems, and operate at lower RPMs for sustained power. Designed for durability and fuel efficiency, they are the standard for commercial shipping and popular in recreational vessels.

How marine diesel engines work terms to know:

The Core Principle: How Marine Diesel Engines Work Through Compression Ignition

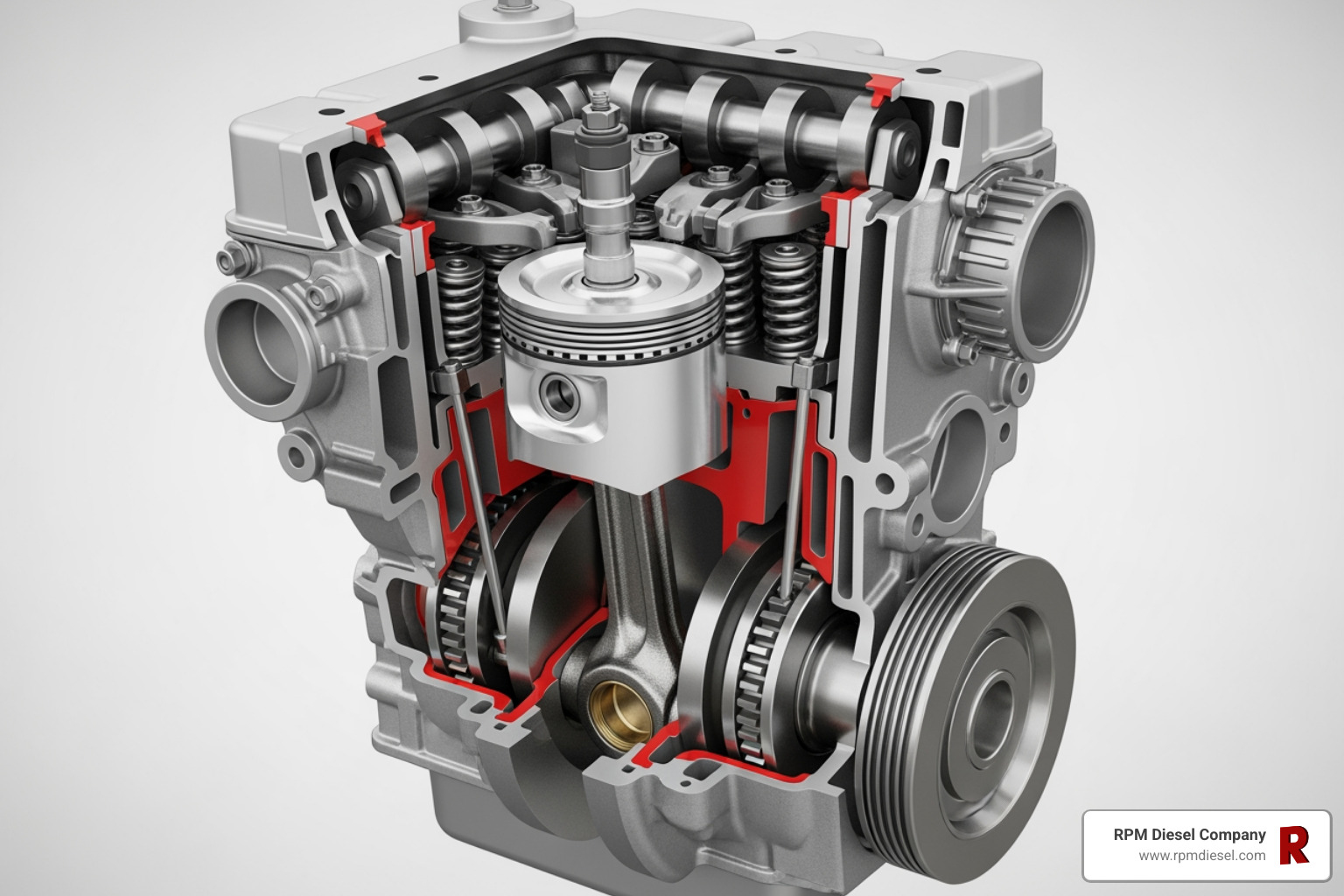

The core principle of every marine diesel engine is compression ignition. Instead of spark plugs, these engines use a simple, robust principle to ignite fuel.

Here’s how marine diesel engines work: A piston traps and compresses air in a cylinder, heating it to scorching temperatures around 600°C (1100°F). A precise burst of high-pressure diesel fuel is then injected into the hot air, causing spontaneous ignition. The resulting combustion forces the piston down, and this linear motion is converted to the rotational motion of the propeller by the connecting rod and crankshaft. The high pressures involved (180-195 bar) necessitate the renowned durability and reliability of diesel engines, which also contributes to their excellent fuel efficiency.

The Four-Stroke Cycle Explained

This process typically occurs in a four-stroke cycle, common in recreational and commercial vessels in Florida. It involves four piston movements to create power every two crankshaft rotations.

- Intake Stroke: The piston moves down, and the inlet valve opens, allowing fresh air to enter the cylinder. A turbocharger, if present, forces more air in.

- Compression Stroke: The inlet valve closes, and the piston moves up, compressing the air. This raises its pressure to over 100 bar and its temperature past 500°C, preparing it for combustion.

- Power Stroke: A fine spray of diesel fuel is injected into the superheated air, causing instant ignition. The expanding gases force the piston down, delivering power that turns the crankshaft.

- Exhaust Stroke: The piston moves up again, the exhaust valve opens, and the burnt gases are pushed out. The valve then closes, and the cycle repeats.

The precise opening and closing of the inlet valve and exhaust valve is controlled by the camshaft and valve timing, ensuring the engine runs efficiently.

Two-Stroke vs. Four-Stroke: What’s the Difference?

While four-stroke engines are common, large ships often use two-stroke marine diesel engines. The main difference is the number of piston movements per power cycle.

A four-stroke engine completes a power stroke every two crankshaft rotations (four piston movements). A two-stroke engine delivers a power stroke with every single crankshaft rotation (two piston movements).

This means two-stroke engines offer greater power density for their size, making them ideal for massive commercial vessels. They use a scavenging process where fresh air pushes out exhaust gases simultaneously, eliminating separate intake and exhaust strokes. Four-stroke engines, however, generally provide better fuel economy at variable speeds and are preferred for their smoother operation in smaller applications.

Here’s a quick comparison:

| Feature | Four-Stroke Marine Diesel Engine | Two-Stroke Marine Diesel Engine |

|---|---|---|

| Power Cycle | 4-strokes, 2 crankshaft rotations | 2-strokes, 1 crankshaft rotation |

| Common Applications | Recreational boats, smaller commercial vessels, auxiliary power (generators) on larger ships | Main propulsion for large commercial vessels (tankers, container ships) |

| Power Density | Good, but generally less power-to-weight ratio than comparable 2-stroke designs | Excellent power-to-weight ratio for large applications (approx. 1.8x more powerful for similar weight in large plants) |

| Complexity | More valves (inlet and exhaust), camshaft runs at half crankshaft speed | Fewer valves (often only exhaust valves), simpler mechanical design, camshaft runs at same crankshaft speed |

| Fuel Efficiency | Very good, especially at variable speeds | Highly efficient, particularly at constant, low RPMs using heavy fuel oil |

| Size/Footprint | Generally more compact, allowing for flexible engine room layouts | Very large and tall, optimized for long stroke and direct propeller drive |

| Propeller Drive | Often requires reduction gearbox to match engine RPM to propeller speed | Can directly drive propeller shaft due to very low operating RPMs (e.g., 80-120 rpm) |

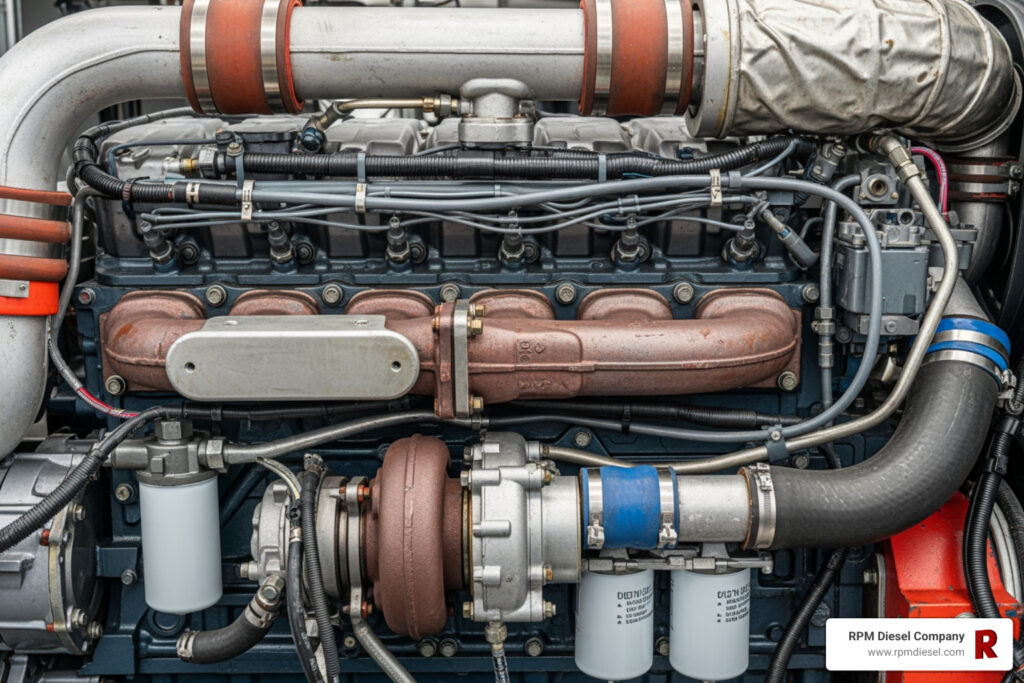

Anatomy of a Marine Diesel: Key Components and Systems

Understanding how marine diesel engines work reveals a system of precision components working in harmony. The core parts—engine block, cylinder head, pistons, connecting rods, and crankshaft—convert fuel into rotational power. Marine engines are built tougher than land-based versions. For example, they use a heavier flywheel to smooth out power pulses from combustion, ensuring steady power to the propeller.

Beyond these core components, several critical support systems are essential for reliability in the demanding Florida marine environment.

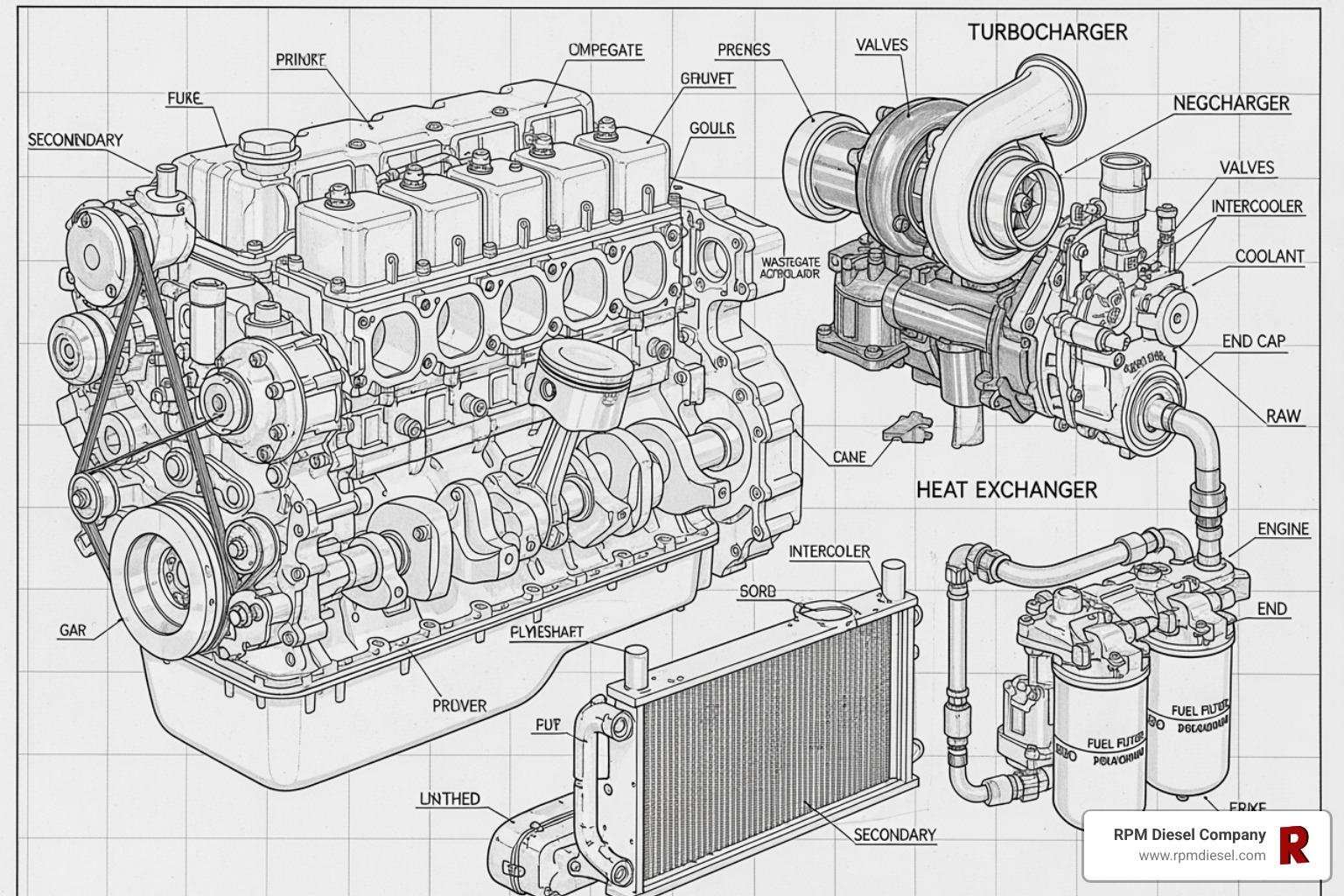

The Fuel System: The Engine’s Lifeline

Up to 90% of diesel engine problems trace back to contaminated fuel. In Florida’s humid climate, keeping fuel clean is a constant battle. Modern diesel injectors have tolerances measured in microns (1/25,000th of an inch), and even microscopic dirt or water particles can cause catastrophic damage.

The fuel’s journey begins in the fuel tanks, where keeping them full helps prevent condensation and microbial growth. Fuel passes through a primary fuel filter and water separator, the first line of defense. A lift pump then draws fuel to a secondary fuel filter for finer filtration. This protects the high-pressure injection pump, which pressurizes fuel up to 380 bar or more. Finally, fuel injectors atomize the fuel into a fine mist for combustion.

The effects of diesel fuel contamination can be devastating. Regular replacement of both primary and secondary fuel filters is essential insurance against failure.

The Cooling System: Beating the Heat

Marine diesels use a dual cooling system to manage heat. The raw water system draws seawater through a strainer and a seawater pump with a rubber impeller. This water circulates through a heat exchanger to cool the engine’s internal coolant and is then discharged overboard, often with the exhaust. The impeller is a wear item that needs regular inspection.

The freshwater system is a closed loop circulating an antifreeze/water mixture through the engine block and cylinder head. This hot coolant transfers its heat to the raw water in the heat exchanger without mixing. A thermostat regulates the engine’s temperature, typically between 70-85°C (160-185°F), for optimal efficiency.

For saltwater boaters, sacrificial anodes (zinc or aluminum) are critical. Placed in the raw water passages, they corrode instead of expensive engine parts, preventing galvanic corrosion. Regular inspection and replacement are non-negotiable. Also, ensure you have a proper seacock on any through-hull fitting below the waterline for safety.

The Lubrication and Air/Exhaust Systems

Your lubrication system is vital. An oil pump pushes oil from the oil sump through an oil filter to all moving parts. Engine oil reduces friction, cools components, cleans away contaminants, and helps seal pistons. Regular oil and filter changes are fundamental to engine longevity.

The air intake system feeds the engine clean air via an air filter. A 40-hp diesel can consume over 5,000 cubic feet of air per hour. Many marine diesels use a turbocharger, which uses exhaust gas to spin a turbine that compresses more air into the cylinders, boosting power. After a hard run, let a turbocharged engine idle for 5-15 minutes to cool down, preventing bearing damage.

Finally, the exhaust system removes burnt gases. They flow from the exhaust manifold into a wet exhaust, where raw cooling water is mixed in to reduce temperature and noise. The mixture passes through an exhaust riser or exhaust elbow (a common corrosion point needing replacement every 3-5 years) and often a water-lift muffler before exiting the vessel.

Why Diesel? Advantages and Modern Evolution

Marine diesel engines are popular on Florida’s coasts for good reason. They are tough, efficient, and reliable. Understanding how marine diesel engines work and why they are favored helps you appreciate your vessel’s power source.

The Diesel Advantage Over Other Engine Types

When compared to gasoline or electric options, marine diesels offer several key benefits for confidence and efficiency on the water.

- Superior fuel efficiency: Diesel engines provide a longer range per tank, ideal for long cruises. Diesel fuel also has a higher energy density than gasoline, delivering more power per gallon.

- Durability and longevity: Built with heavy-duty components to handle high pressures, diesel engines have a significantly longer lifespan than gasoline counterparts, often lasting for thousands of hours with proper maintenance.

- Best reliability: With no spark plugs or complex electrical ignition systems sensitive to moisture, diesel engines are inherently more dependable in a marine environment.

- Improved fuel safety: Diesel fuel is less volatile and has a higher flash point than gasoline, reducing the risk of fire onboard.

- High torque output: Diesels produce tremendous pulling power at low RPMs, which is excellent for maneuvering heavy vessels and pushing through rough seas.

The Evolution and Future of Marine Diesel

How marine diesel engines work has evolved significantly. Early diesels were simple and mechanical, but modern engines use sophisticated electronic engine management systems. These digital controls precisely manage fuel injection and timing, leading to better performance, improved fuel efficiency, and cleaner emissions. Common rail fuel injection systems, for example, use extremely high pressure to optimize combustion. These advanced systems require specialized diagnostic tools and expert service.

Stricter emissions regulations, such as the international IMO Tier standards and rules from the USA: Marine Diesel Engines – Emission Standards, have driven innovation. Technologies like exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) are now used to reduce pollutants.

Despite emerging technologies, diesel engines remain vital. They are the backbone of hybrid propulsion systems, acting as generators to charge batteries or directly drive motors. For applications requiring long range and continuous power, like commercial vessels and large yachts, diesel is still the most practical choice. They also serve as reliable onboard generators (auxiliary engines), powering all the systems on your vessel.

Keeping Your Engine Reliable: Maintenance and Troubleshooting

A marine diesel’s longevity depends on diligent maintenance. At RPM Diesel Company, we know preventative maintenance is less expensive and stressful than emergency repairs miles from shore. It’s an investment in peace of mind, ensuring your vessel is always ready for its next adventure in Fort Lauderdale, Miami, or beyond.

Essential Maintenance for Longevity

Regular checks are your best defense against breakdowns. A quick pre-departure inspection can save you major headaches.

- Daily Checks (The WOBBLES Checklist):

- Water: Check for raw water flow from the exhaust and any leaks.

- Oil: Check the engine oil level and condition.

- Belts: Inspect for wear and proper tension (½-inch deflection). Black dust indicates slippage.

- Battery: Verify clean, tight connections.

- Leaks: Scan for any fluid leaks (oil, fuel, coolant).

- Exhaust: Observe smoke color and listen for unusual sounds.

- Sound/Smell/Spares: Note strange noises or odors and confirm spares are onboard.

Beyond daily checks, perform regular service. Oil and filter changes are needed every 100-200 hours or annually. Replace fuel filters every 200-300 hours to protect against contamination. Inspect the seawater pump impeller annually or every 250 hours, replacing it if damaged. Check sacrificial anodes regularly and replace them at 50% consumption to prevent galvanic corrosion. A cooling system flush is recommended every 2-3 years. For long-term storage, proper winterization or preparation for inactivity is key, including stabilizing fuel and changing oil.

How marine diesel engines work with transmission systems

Your engine’s power reaches the propeller through a transmission system. Common marine applications include:

- Conventional propeller shaft: The engine connects to a long shaft that passes through a watertight seal (a stuffing box or dripless shaft seal) to the propeller. A gearbox reduces engine RPM to an efficient propeller speed.

- Saildrive: Common on sailboats, this system integrates the engine and gearbox into a single unit mounted through the hull, with the propeller directly beneath. It offers efficient thrust and minimal drag.

- Sterndrive (Inboard/Outboard): The engine is mounted inside the hull, but the drive unit passes through the transom. This provides outboard-like maneuverability and the ability to trim the drive.

Common Problems and What They Mean

Understanding common issues allows for quicker diagnosis and better communication with service professionals like us at RPM Diesel Company.

- Difficulty starting: Often caused by low battery charge, poor connections, clogged fuel filters, or air in the fuel lines.

- Overheating: Usually a cooling system problem, such as a clogged raw water strainer, failed impeller, or blocked heat exchanger.

- Loss of power: Frequently caused by clogged fuel filters, faulty injectors, a restricted air intake, or a fouled propeller.

- Excessive smoke: The color indicates the problem:

- Black Smoke: Incomplete combustion, often from an overloaded engine or clogged air intake.

- Blue Smoke: Burning oil, suggesting worn piston rings or valve guides.

- White Smoke: Water/coolant in the combustion chamber (e.g., blown head gasket) or late fuel injection timing. (Some white vapor is normal on a cold start).

- Unusual noises: Knocks, whines, or rattles require immediate investigation as they can signal serious internal wear.

- Clogged filters and a fouled propeller are often overlooked but severely impact performance. Regular checks are crucial.

Frequently Asked Questions about How Marine Diesel Engines Work

Here are answers to common questions about marine diesel engines, helping you understand and maintain the heart of your vessel.

Why don’t diesel engines have spark plugs?

Diesel engines use compression ignition, not spark plugs. The piston compresses air in the cylinder, heating it to over 320°C (600°F). When fuel is injected into this superheated air, it ignites spontaneously. This process is more reliable in a marine environment because it requires fewer electrical components.

What is the most important maintenance task for a marine diesel?

While all maintenance is important, the single most critical task is ensuring a clean fuel supply. In Florida’s humid climate, fuel contamination is the primary enemy of a marine diesel. Modern injection systems have extremely fine tolerances, and even microscopic debris or water can cause catastrophic damage to the high-pressure pump and injectors. Regularly changing your primary and secondary fuel filters and using a quality water separator are paramount for engine reliability and longevity.

What is the main difference between a 2-stroke and 4-stroke marine diesel?

The main difference is how many piston strokes it takes to complete one power cycle.

-

A 4-stroke engine completes a power cycle in four piston strokes (two crankshaft rotations). Common in recreational boats and as auxiliary generators, they are known for fuel efficiency across various speeds and lower emissions.

-

A 2-stroke engine completes a power cycle in just two piston strokes (one crankshaft rotation). It uses a “scavenging” process to clear exhaust and intake air simultaneously. This design offers a higher power-to-weight ratio, making it the standard for main propulsion on massive commercial vessels like container ships and tankers.

Conclusion: Your Partner in Marine Diesel Power

You now have a better understanding of how marine diesel engines work. These robust power plants are the heart of many vessels due to their reliability, durability, and fuel efficiency. From the four-stroke cycle to the fuel and cooling systems, each part provides dependable power for exploring Florida’s waters and beyond.

At RPM Diesel Company, we believe an informed boat owner is a safer one. This knowledge, combined with a commitment to preventative maintenance, is the best way to extend your engine’s life and enjoy peace of mind on every trip.

For those times when you need expert eyes for complex diagnostics, specialized repairs, or reliable routine service, our team is ready. Our factory-trained technicians proudly serve Fort Lauderdale, Miami, and the entire South Florida region. We’re dedicated to keeping your marine diesel running smoothly.

Let RPM Diesel Company be your trusted partner in marine diesel power. We’re here to ensure your vessel’s heart continues to beat strong, reliably pushing you toward your next adventure. Explore our marine diesel services today.