Why Northern Lights Lugger Generator Parts Are Essential for Marine Reliability

Northern lights lugger generator parts are the backbone of dependable marine power systems. When a generator fails miles from shore, having the right parts and knowing where to source them is critical for safety and peace of mind.

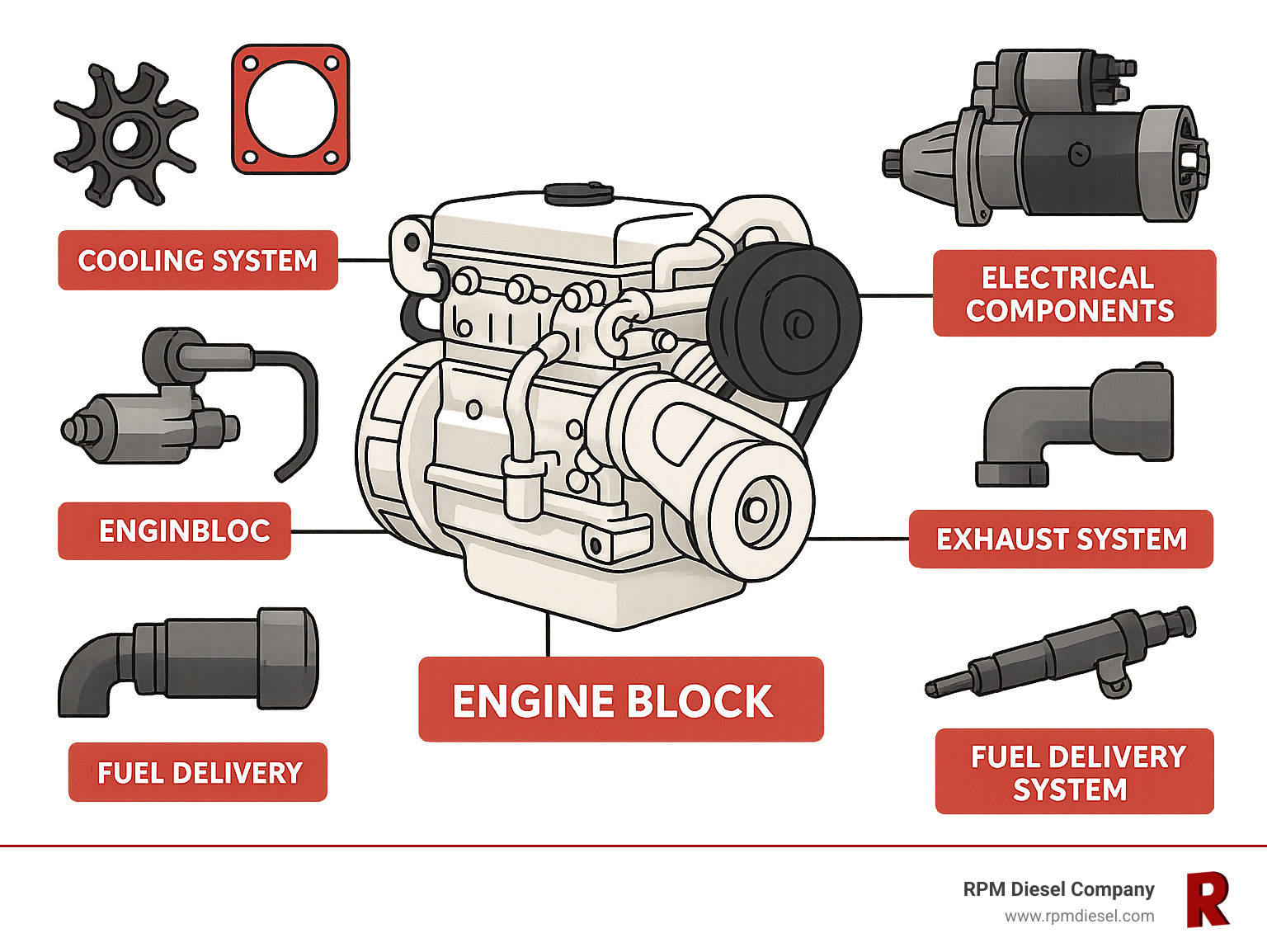

Most Common Northern Lights Lugger Generator Parts:

- Oil, fuel, and air filters – Replace every 250-500 hours

- Impeller kits with gaskets – Critical for cooling system function

- Water pumps and exhaust elbows – High-wear items in marine environments

- Starters, alternators, and voltage regulators – Essential electrical components

- Fuel injectors and spare parts kits – For optimal engine performance

Since 1963, Northern Lights has built a reputation for anvil-tough reliability in commercial fishing boats, luxury yachts, and passenger vessels. Their generators are powered by rugged Lugger diesel engines, designed for Alaska’s demanding conditions where failure isn’t an option.

Maintaining this reliability means using genuine parts and following maintenance schedules. A core philosophy of reducing components leads to more reliable, easier-to-maintain units, making Northern Lights generators simpler to service than many competitors.

RPM Diesel Company, a factory-authorized dealer since 1956, specializes in sourcing marine generator parts. Whether for routine maintenance or emergency repairs, genuine OEM parts can prevent a minor issue from becoming a costly breakdown.

Why Choosing Genuine Parts Matters for Your Marine Generator

On the water, your Northern Lights generator is a lifeline. A common mistake is using aftermarket parts over genuine northern lights lugger generator parts to save a few dollars. Northern Lights generators are engineered for durability in harsh marine environments, a standard proven since 1963 in Alaska’s demanding conditions.

Every genuine part, from fuel filters to impellers and O-rings, is manufactured to precise specifications for your model, ensuring perfect function in a salty, vibrating environment. Choosing genuine OEM parts also protects your investment and the manufacturer’s warranty, which often requires their use.

The Risks of Using Non-Genuine Components

Using aftermarket parts can lead to significant problems:

- Engine failure: Cheaper parts like fuel filters might not seal properly, leading to expensive internal engine damage.

- Reduced performance: Non-genuine voltage regulators can deliver unstable power, harming electronics and increasing fuel consumption.

- Costly repairs: An aftermarket water pump might fail and cause engine overheating, leading to repair bills that dwarf the initial savings.

- Safety hazards: Substandard fuel lines can leak, and inferior electrical components can cause fires. In the marine world, safety standards like those from the American Boat and Yacht Council (ABYC) are critical, and non-genuine parts may not meet them.

- Voided warranty: Using non-genuine parts typically voids your warranty, leaving you responsible for all repair costs.

Benefits of Sticking with OEM Northern Lights Parts

Sticking with genuine northern lights lugger generator parts provides several key advantages:

- Perfect Fit and Compatibility: Genuine parts are guaranteed to fit and integrate seamlessly with your specific model.

- High-Quality Materials: OEM parts use corrosion-resistant alloys and marine-grade components tested for salt air, vibration, and temperature extremes.

- Peace of Mind: Knowing every component meets Northern Lights’ exacting standards provides confidence when you’re far from shore.

- Maintained Resale Value: A generator with a documented history of genuine parts is more attractive to prospective buyers.

As a factory-authorized dealer since 1956, we’ve seen the long-term results of both choices. Proper maintenance with genuine components leads to decades of reliable power.

How to Find and Source Northern Lights Lugger Generator Parts

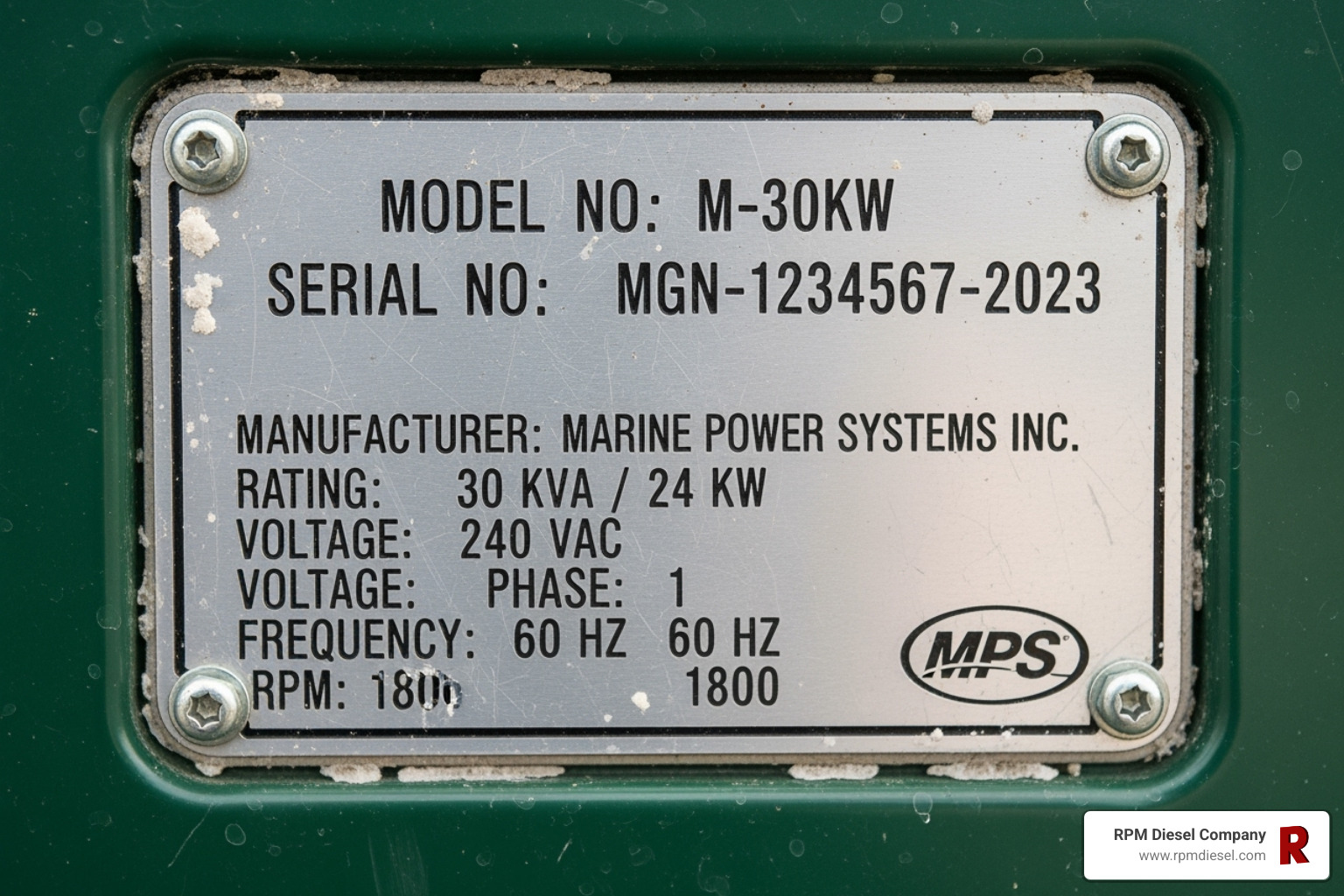

Finding the right northern lights lugger generator parts is straightforward with the right information and resources. Your generator’s model number and serial number are the most important pieces of information, acting as a unique identifier for sourcing correct parts.

Northern Lights heavily marinizes base engines from manufacturers like John Deere or Toyota, adding specialized cooling systems, electrical components, and corrosion-resistant materials. This is why genuine northern lights lugger generator parts are essential, as generic equivalents are not designed for the unique stresses of marine life.

Identifying the Correct Part Number

Your generator itself holds the clues to identifying the correct part.

- Start with the data plate: It’s usually on the generator housing or engine block. This plate shows your exact model (e.g., M673LD3G) and unique serial number. Take a clear photo of it.

- Consult your owner’s manual: It has exploded diagrams with part numbers and often includes recommended spare parts lists.

- Cross-reference engine information: Northern Lights assigns its own part numbers to all components, even on base engines from other manufacturers like Shibaura, because they are upgraded for marine duty.

- If you’re lost, send us what you have—a photo, description, or even a sketch. We’ve been tracking down parts since 1956 and can identify what you need.

Where to Buy Genuine Northern Lights Lugger Generator Parts

Once you have the part number, you need a reliable supplier.

- RPM Diesel Company has been a factory-authorized Northern Lights dealer since 1956. We are marine diesel specialists, not just parts suppliers. Our warehouse stocks thousands of genuine northern lights lugger generator parts, from oil filters and fuel filters to impeller kits.

- Working with authorized dealers like us ensures you get genuine parts backed by the manufacturer’s warranty and proven performance.

- Our online parts request system makes ordering easy. We specialize in tracking down both common and hard-to-find components.

- As a full-service marine diesel company, we understand how parts work in the real world. Our technicians provide on-site service throughout South Florida and work with vessels worldwide.

When you need northern lights lugger generator parts, you want an experienced partner. Contact us, and let’s get your generator running reliably. Reliability is what Northern Lights is all about, and it’s what we’ve delivered since day one.

Common Replacement Parts and Proactive Maintenance

Even robust Northern Lights generators require routine maintenance. Their simple design makes this manageable, preventing small issues from becoming major problems. With proper care, many Northern Lights units run well past 10,000 hours. The secret is proactive maintenance, which saves money and prevents unexpected failures.

At RPM Diesel Company, we know that proactive maintenance will save you money and the stress of an unscheduled breakdown.

Top 5 Most Common Replacement Parts

After decades of working with northern lights lugger generator parts, we know which components need the most attention.

- Filters (Oil, Fuel, Air): These protect your engine from contaminants. Replace oil filters, fuel filters, and air filters every 250-500 hours or annually. Northern Lights offers specific filters like the 24-01201 oil filter and 24-51201 fuel filter for certain models.

- Impellers and Water Pumps: The rubber impeller (e.g., kit 25-11002) is vital for the cooling system. A failed impeller can cause the engine to overheat quickly.

- Belts and Hoses: These drive components like the alternator and raw water pump and carry essential fluids. They degrade over time in the harsh marine environment.

- Zinc Anodes: These sacrificial anodes protect expensive engine parts from corrosion. Check them every six months.

- Starters and Alternators: The starter gets the engine running, and the alternator charges the batteries. Failure of either component will leave you without power.

Maintenance Tips to Extend Part Life

The best maintenance tip is to pay attention to your generator.

- Regular Inspections: Before starting the generator, look for leaks or frayed belts, and listen for unusual noises.

- Following Service Intervals: Adhere to the maintenance schedule in your owner’s manual to keep the system running smoothly and preserve your warranty.

- Running Under Proper Load: Operating your generator at 50-80% capacity prevents “wet stacking” (carbon buildup in the exhaust) and is better for the engine.

- Keeping Things Clean: A clean engine runs cooler and makes it easier to spot leaks or other issues early.

- Checking for Leaks: Address any oil, fuel, or coolant leak immediately to prevent it from becoming a larger problem.

We’re here to help with both routine maintenance and unexpected challenges. Our team provides comprehensive onsite services and carries an extensive inventory of genuine northern lights lugger generator parts to keep your power system reliable.

Understanding Your Northern Lights Lugger Generator Model

Northern Lights was born in the late 1950s in Cooper Landing, Alaska, from a need for power systems that could withstand the harsh environment. The founding principle was simple: fewer parts mean fewer things to break. This focus on simplicity, durability, and reliability is why the generators are known as “anvil-tough.”

The company’s Lugger diesel engines are at the heart of this reliability. They are heavily marinized from premium John Deere or Toyota base blocks, rebuilt for marine duty. Newer series like the L4105 and L6105 feature individual cylinder heads, forged crankshafts, and replaceable wet liners for easier service and greater strength.

Northern Lights engineers group service points on one side for easy access in cramped engine rooms. Today, the company offers marine generator sets from 4.5 to 400 kW for a wide range of vessels.

Key Features of Popular Generator Models

The Gem Series represents Northern Lights’ commitment to compact power and reliable performance, making them perfect for vessels where space is at a premium.

| Model | kW Output (60 Hz) | RPM | Cylinders | Length (in.) | Width (in.) | Height (in.) | Dry Weight (lbs.) |

|---|---|---|---|---|---|---|---|

| M673LD3G | 5 | 1800 | 3 | 27.5 | 16.7 | 20.5 | 371 |

| M673L3G | 6 | 1800 | 3 | 27.5 | 16.7 | 20.5 | 371 |

| M773LW3G | 9 | 1800 | 3 | 32.7 | 17.4 | 23.7 | 537 |

| M773LW3G | 12 | 1800 | 3 | 38.5 | 19.0 | 25.3 | 743 |

| M844DW3G | 16 | 1800 | 4 | 45.9 | 19.5 | 27.5 | 948 |

| M844LW3G | 20 | 1800 | 4 | 45.9 | 19.5 | 27.5 | 948 |

| M864W3G | 25 | 1800 | 4 | 45.9 | 19.5 | 27.5 | 948 |

| M944W3FG | 30 | 1800 | 4 | 58.6 | 26.5 | 30.9 | 1,329 |

A key feature is the 1800 RPM operating speed (for 60 Hz), which ensures quieter operation, less wear, and longer engine life. The design emphasizes component reduction for reliability. Optional sound enclosures significantly reduce noise, and single-side service access is standard. On units 12kW and larger, front power take-offs are available to run shipboard hydraulics.

Common Issues and Failure Points

Even the most reliable generators have common wear points. Knowing them helps you stay ahead of problems.

- Exhaust Elbow Corrosion: This part lives in a harsh environment of hot exhaust and cooling seawater. Soot and corrosion can cause blockages. Regular inspection is key.

- Water Pump Failure: If the raw water pump or impeller fails, the engine will overheat. Watch for rising temperatures or reduced water flow from the exhaust.

- Voltage Regulator Problems: Unstable voltage can damage sensitive electronics. Look for flickering lights or erratic power.

- Fuel System Blockages: Rough running or shutdown is often caused by contaminated fuel or clogged filters.

- Oily Exhaust Discharge: An oily film in the exhaust on a generator with reasonable hours often points to exhaust elbow issues or carbon buildup, not major engine wear. Running the generator under a proper load helps prevent this.

Understanding your model and its common issues helps maintain its reliability. When you need northern lights lugger generator parts or expert service, we’re here to help.

Conclusion

When you’re miles from shore, the quality of your generator parts is paramount. Genuine northern lights lugger generator parts are an insurance policy against the challenges of marine life.

Choosing genuine OEM parts over aftermarket alternatives prevents frustrating and dangerous failures at sea. It provides the peace of mind that your power system is reliable when you need it most.

This guide has shown how to identify the correct parts and which components, like filters and impellers, require regular replacement. These parts are designed to protect more expensive systems within your engine. Simple habits like running your generator under proper load, changing filters on schedule, and addressing leaks promptly can add thousands of hours to its operational life.

Knowing your specific Northern Lights model, from a compact M673LD3G to a robust M944W3FG, makes you a more informed owner when ordering parts or requesting service.

Since 1956, RPM Diesel Company has been the go-to source for northern lights lugger generator parts. Our institutional knowledge comes from generations of marine diesel experts who have seen how genuine parts contribute to longevity, with some generators running strong past 15,000 hours.

Our commitment extends beyond sales. We understand the unique demands of marine power systems and stock the specialized parts required. From routine items to hard-to-find components for older models, we are here to keep your generator running like new.

Don’t wait for a breakdown to be reminded of why quality matters. For northern lights lugger generator parts and expert service, contact us. Let our expertise work for you, so you can focus on enjoying your time on the water with the confidence that comes from reliable power.