Why Your Marine Generator’s Fuel Lines Are Critical to Reliable Power

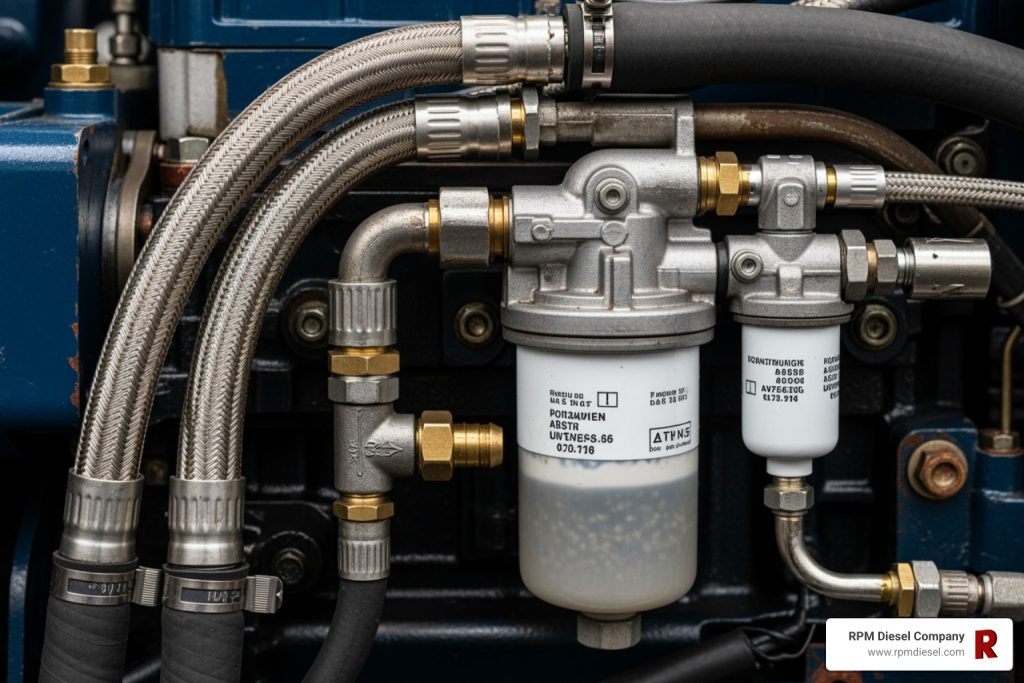

Diesel generator fuel lines are the lifelines delivering fuel from your tank to your engine. When they fail, your power stops. These components must handle pressurized fuel, resist harsh marine environments, and maintain perfect seals to keep your generator running when you need it most.

Key facts about diesel generator fuel lines:

- Primary function: Transport fuel from tank to engine while preventing air intrusion

- Common materials: Stainless steel (fireproof), USCG-rated rubber hose (A1-15), and approved nylon tubing

- Typical lifespan: 10+ years for quality lines, but inspection needed annually

- Failure symptoms: Hard starting, engine stalling, visible leaks, or fuel smell

- Critical requirement: Must be marine-rated and fire-resistant for safety

Ignoring fuel line health can lead to costly repairs and leave you stranded without power. Your marine diesel generator’s fuel system operates under constant vibration, temperature changes, and salt air exposure. The lines must handle supply pressure and heated return fuel that can exceed 150°F. A single crack or loose fitting can introduce air into the system, causing your generator to lose prime and fail to start.

This guide will walk you through identifying problems, choosing the right materials, and maintaining your fuel lines for reliable operation on any marine generator brand.

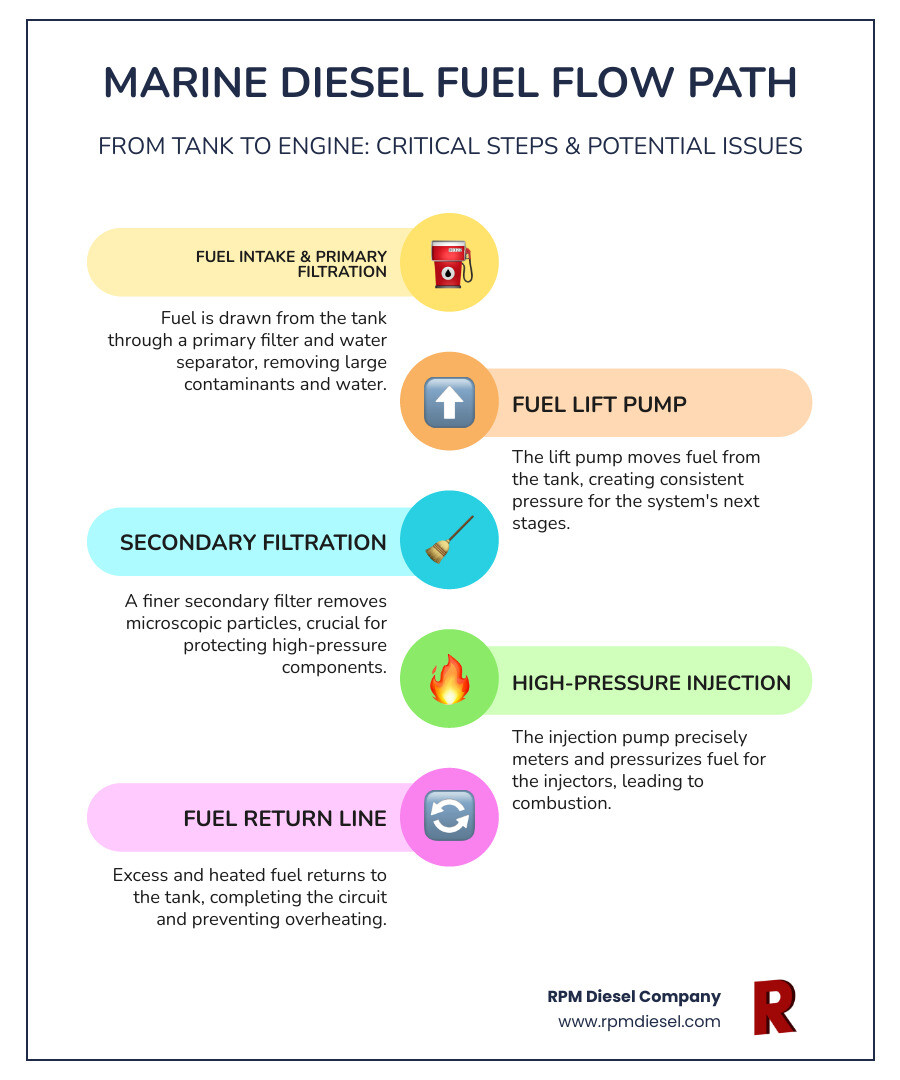

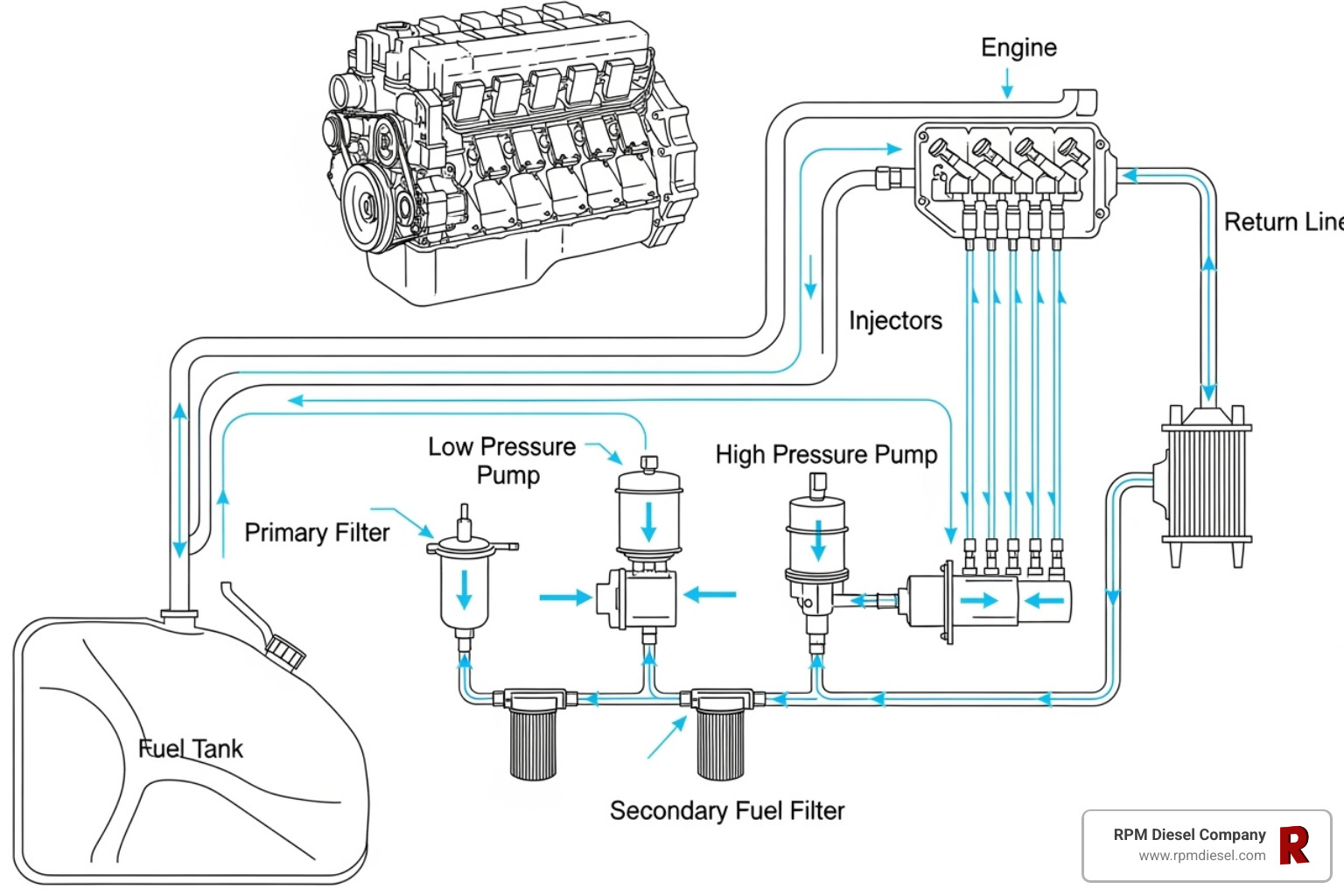

Understanding Your Marine Generator’s Fuel System

Understanding how fuel flows from your tank to the engine helps you spot problems before they leave you without power. The fuel’s journey involves two main circuits: a low-pressure circuit to move fuel from the tank to the engine, and a high-pressure circuit to precisely inject it.

Both circuits depend on properly functioning diesel generator fuel lines to maintain seals and prevent air intrusion. Understanding these systems is key to effective Marine Diesel Engine Repair.

The Core Components and Their Roles

- Fuel Tank: Where fuel is stored and where problems like water intrusion and biological growth often begin.

- Primary Fuel Filter/Water Separator: The first line of defense, catching larger debris (10-30 microns) and separating water from the fuel. The clear bowl is an early warning system for contamination.

- Fuel Lift Pump: Draws fuel through the primary filter and pushes it toward the engine at low pressure.

- Secondary Fuel Filter: Provides finer filtration (2.5-5 microns) to protect sensitive injection components from microscopic particles.

- High-Pressure Injection Pump: Transforms the low-pressure fuel flow into precisely timed, high-pressure pulses for the injectors.

- Fuel Injectors: Atomize the high-pressure fuel into a fine mist for efficient combustion. Worn injectors can cause rough running and smoke. Regular Diesel Fuel Injection Service is crucial.

- Return Line: Carries excess, often heated, fuel back to the tank.

Fuel Injection Systems: From Mechanical to Common Rail

Diesel injection technology has evolved, and your system type affects maintenance.

- Mechanical Injection: Robust and reliable, these systems are simpler to service but less precise.

- Electronically Controlled Systems: Combine mechanical components with an ECU for better fuel economy and performance.

- Common Rail Fuel Injection Systems: The most advanced type, using a high-pressure rail to supply all injectors. These systems are highly efficient and clean-burning but are extremely sensitive to fuel contamination. Learn more in our guide on the Common Rail Fuel Injection System.

The more advanced your injection system, the more critical your diesel generator fuel lines and filtration become. A tiny particle that a mechanical system might tolerate can shut down a common rail engine.

Identifying Common Fuel Line Failures

Your diesel generator fuel lines face a constant battle against heat, vibration, and salt air. Fortunately, your generator will usually provide warning signs before a complete failure.

A visual inspection combined with understanding performance symptoms will help you catch problems early.

Signs of Trouble: Symptoms of Failing Fuel Lines

- Hard starting or stalling: Often the first sign of air intrusion from a crack or loose fitting on the suction side.

- Loss of power: Indicates fuel starvation from a partially blocked or collapsing line.

- Visible fuel leaks: A serious fire hazard that demands immediate attention.

- Smell of diesel fuel: Can indicate a small, weeping leak that isn’t yet visible.

- Air bubbles in fuel: If you have a clear filter bowl, bubbles are definitive proof of an air leak. As many boaters find, having Generator fuel lines replaced due to deterioration can solve multiple mysterious issues.

Common Culprits: What Causes Fuel Line Problems?

- Deterioration and aging: Rubber and plastic lines break down over time from exposure to fuel, heat, and UV light. Lines over ten years old are suspect.

- Cracks and leaks: Caused by vibration, age, and improper routing. Internal cracks can let air in without a visible fuel leak.

- Internal collapse: The hose looks fine externally, but the inner wall collapses, restricting fuel flow.

- Clogs and blockages: Dirt, rust, and biological growth from the fuel tank can block lines.

- Vibration and abrasion: Unsecured lines can rub against other components and wear through.

- Improper installation: Sharp bends, kinks, or loose fittings create stress points that will eventually fail.

When these issues require specialized expertise, our Diesel Generator Repair Services can diagnose and fix fuel line problems before they leave you without power.

A Guide to Marine Diesel Generator Fuel Lines Materials and Installation

Choosing the right materials and following proper installation practices for your diesel generator fuel lines is critical for safety and reliability, regardless of the generator brand, like Westerbeke Marine Generators.

Choosing the Right Material for Your Diesel Generator Fuel Lines

Fuel lines must resist pressurized fuel, heat, vibration, and salt air. The right choice is essential.

- Stainless Steel: The gold standard for durability and fire safety, often used for hard lines in the engine compartment. It’s more expensive and less flexible but offers maximum protection.

- USCG-rated Rubber Hose (A1-15): The workhorse for flexible lines. The A1-15 rating means it can withstand 2.5 minutes of direct fire exposure, providing critical time in an emergency. Replace these hoses if they are over ten years old.

- Approved Plastic/Nylon Tubing: Lighter and more flexible, these materials must be specifically rated for marine fuel use to be safe and effective.

| Material | Durability | Cost | Flexibility | Regulations (Marine) |

|---|---|---|---|---|

| Stainless Steel | High | High | Low | Often mandated/preferred for hard lines, fire resistance |

| USCG A1-15 Rubber | Medium | Medium | High | Required for flexible fuel lines |

| Approved Plastic/Nylon Tubing | Medium | Low-Medium | High | Must be specifically fuel-rated and compatible with fuel type |

The Dangers of Improper Materials

Using the wrong materials is a recipe for disaster. Never use galvanized piping, as diesel fuel dissolves the zinc coating, contaminating your fuel and destroying expensive injection pumps and injectors. This is a critical point emphasized by industry experts: Never Use Galvanized Piping on Your Fuel Supply Line!. Similarly, non-marine rated hoses lack the required fire resistance and can become a fuel source in a fire.

Best Practices for Fuel Line Installation and Routing

Proper installation prevents premature failure. Follow these key principles:

- Heat Management: Keep lines away from hot exhaust components. Hot fuel reduces generator output and can cause shutdowns.

- Vibration Control: Secure all lines with rubber-lined clamps to absorb vibration and prevent chafing.

- Flexible Connections: Always use flexible hose sections to connect the engine to any rigid piping to accommodate engine movement.

- Proper Bend Radius: Avoid sharp bends or kinks, which restrict flow and create stress points.

- Correct Sizing: Use the manufacturer-specified diameter (e.g., 3/8″ supply, 1/4″ return) to ensure adequate fuel flow.

- Return Line Routing: The return line must discharge below the minimum fuel level in the tank and never connect to the suction line.

Adhering to these practices as part of your Diesel Engine Maintenance program ensures a safe and reliable fuel system.

Proactive Maintenance for a Reliable Fuel System

Consistent attention to your diesel generator fuel lines and supporting components is the key to preventing unexpected failures. A few minutes of proactive maintenance can save hours of troubleshooting later.

Routine Inspection and Maintenance Checklist

- Before every trip: Visually scan fuel lines for cracks, chafing, or dampness around fittings. Check that clamps are tight.

- Weekly: Drain the water separator bowl on your primary fuel filter. Consistent water or debris indicates a larger fuel quality issue.

- Monthly: Inspect the entire engine compartment for any lines rubbing against bulkheads or other components. Clean pump strainers.

- Annually: Conduct a comprehensive inspection of the entire piping system and consider professional fuel testing.

The Critical Role of Fuel Quality and Storage

Perfect diesel generator fuel lines cannot overcome bad fuel. Diesel degrades over time, and marine environments accelerate this process.

- Water Contamination: Water is the biggest enemy, promoting biological growth (algae, bacteria) that clogs filters and corrodes components.

- Temperature Effects: Fuel temperatures above 100°F reduce generator output. At 150°-160°F, many generators will shut down.

- Fuel Treatment: Use quality fuel stabilizers and biocides to extend fuel life and prevent biological growth. Fuel polishing systems are also beneficial for long-term storage.

Fuel Filter Service: Your First Line of Defense

Your fuel filters protect sensitive injection components. Change primary and secondary filters every 200-300 running hours or annually, whichever comes first. Always use the manufacturer-recommended micron rating for your filters (e.g., 10-30 microns for primary, 2.5-5 for secondary). Sticking to service intervals is one of the best investments in your generator’s longevity. For more guidance, explore our resources on Diesel Generator Maintenance.

Frequently Asked Questions about Marine Diesel Generator Fuel Lines

Here are answers to the most common questions we receive about generator fuel systems.

How often should I replace my marine generator’s fuel lines?

There’s no single answer, but follow these guidelines:

- Inspect regularly: Before each trip, check for cracking, hardening, swelling, or chafing. If you see any of these signs, replace the line immediately, regardless of age.

- Consider age: If your flexible diesel generator fuel lines are over 10 years old, they are on borrowed time, even if they look fine externally. Internal deterioration is common.

- Use proper materials: For the longest service life, always use USCG-rated materials like A1-15 fire-resistant hose for flexible lines and stainless steel for hard lines.

Can I use non-marine fuel lines on my marine diesel generator?

Absolutely not. This is a critical safety issue. Non-marine hoses lack the required fire resistance and are not designed for the marine environment. Using them creates a serious fire hazard and can void your insurance coverage. Always use lines that meet USCG A1-15 standards, which are designed to withstand 2.5 minutes of fire exposure without leaking.

What’s the most common cause of a generator failing to start due to a fuel issue?

In our experience, air intrusion into the fuel system is the culprit in about 80% of fuel-related starting failures. Diesel engines are extremely sensitive to air. The most common source is an invisible leak on the suction side of the system—a tiny crack in a hose or a loose fitting. When the lift pump tries to draw fuel, it sucks in air instead, causing the engine to lose prime. If your generator cranks but won’t start, or starts and then dies, an air leak is the most likely cause.

Conclusion: Ensuring Uninterrupted Power on the Water

Your marine diesel generator is your lifeline to comfort and safety on the water. Its reliability hinges on the health of its fuel system, where the diesel generator fuel lines play a critical role. As we’ve covered, ensuring dependable power comes down to three fundamental principles:

- Use Correct Materials: Always use marine-grade, USCG-approved fuel lines like A1-15 rated hose. Never use automotive hoses or galvanized piping, which can lead to catastrophic failure and create serious safety hazards.

- Ensure Proper Installation: Secure lines to prevent vibration damage, route them away from heat sources, and use flexible connections at the engine. Proper installation is key to a long service life.

- Perform Regular Maintenance: A simple routine of inspecting lines, checking fittings, and changing filters can prevent the vast majority of fuel-related generator problems, especially air intrusion, which is the most common cause of starting failures.

By following these principles, you can prevent most fuel system issues and enjoy uninterrupted power on your vessel. When you need expert service or high-quality parts for your Northern Lights Generators or other marine diesel systems, the specialists at RPM Diesel have the factory-trained expertise and extensive inventory to keep you running.

For comprehensive parts and service support, visit https://rpmdiesel.com/northern-lights-generator-parts/northern-lights-generator-parts/ and ensure your power systems are ready for your next voyage.