Why Your Marine Generator’s Cooling System Is Critical for Reliable Power at Sea

A diesel generator cooling system is essential for keeping your marine engine running reliably. Without it, your generator would quickly overheat, leaving you without power far from shore. Engine failure at sea is not just an inconvenience; it can be dangerous.

Key facts about diesel generator cooling systems:

- Primary function: Absorbs 25-30% of the heat from fuel combustion.

- Two main types: Open-loop (raw water) and closed-loop (jacket water).

- Key components: Heat exchanger, water pumps, thermostat, coolant, and hoses.

- Optimal temperature: Around 180°F for jacket water discharge.

- Critical maintenance: Regular coolant checks, system flushing, and component inspection.

Your diesel engine creates immense heat as a byproduct of generating power. The cooling system’s job is to manage this thermal load, transferring waste heat away from critical components to prevent them from warping or seizing. Understanding how your cooling system works is crucial for ensuring reliable power on any vessel, from luxury yachts to commercial ships.

Anatomy of a Marine Generator Cooling System

Your marine diesel generator cooling system manages the enormous heat produced when converting fuel into power, handling roughly 25-30% of the fuel’s total heat energy. Without this system, the engine would be destroyed in minutes.

Let’s review the key components:

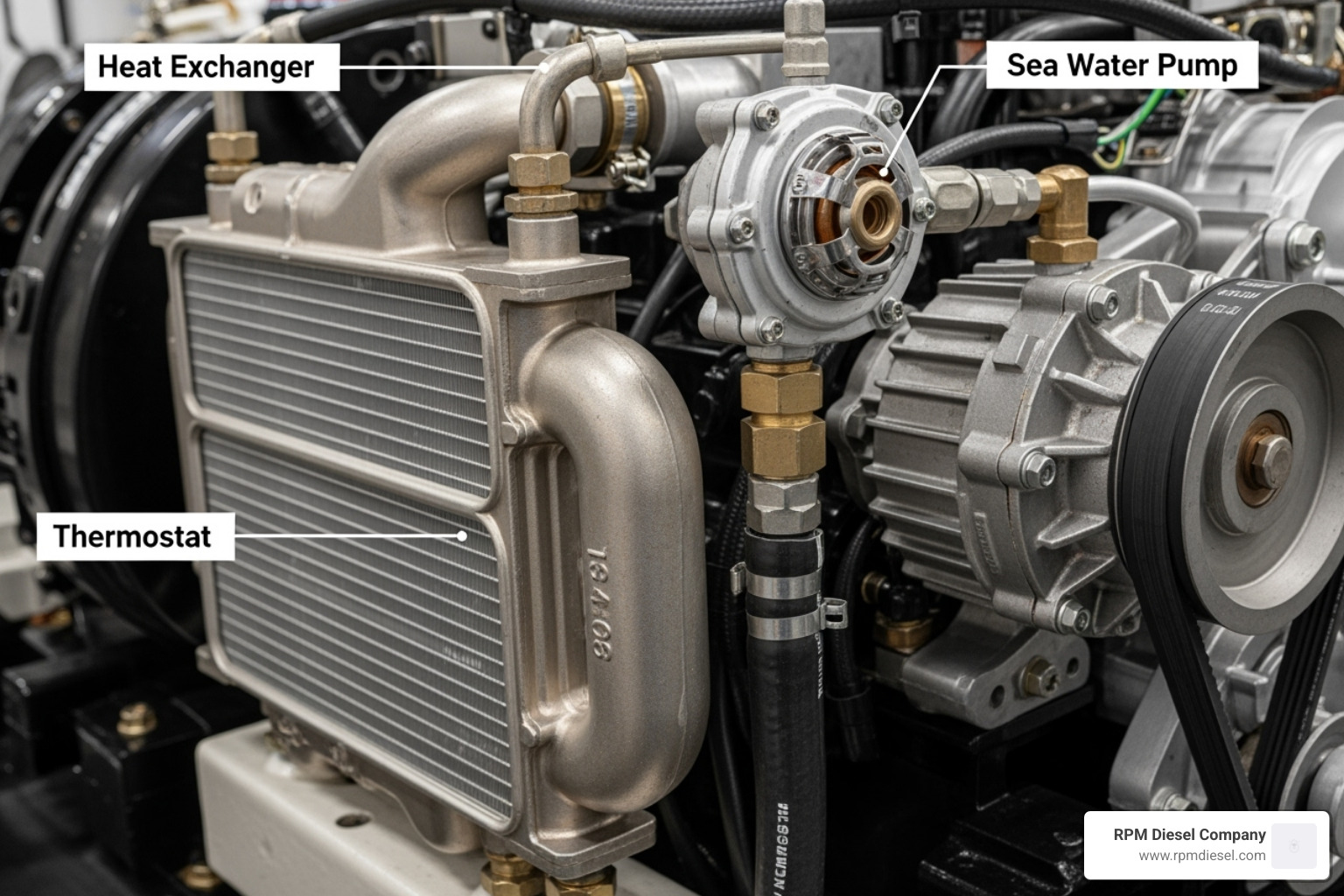

The heat exchanger is the system’s core. Unlike a truck’s radiator, this compact unit allows hot engine coolant and cold seawater to transfer heat without mixing, protecting the engine’s internal parts from corrosive saltwater.

Your sea water pump pulls raw seawater from outside the vessel and pushes it through the heat exchanger. These pumps are built with durable, flexible impellers that can handle sand, small debris, and corrosive saltwater.

The jacket water pump circulates the internal coolant mixture through the engine block and cylinder heads, ensuring all hot metal parts are evenly cooled to prevent warping or cracking.

The thermostat acts as the system’s brain. It remains closed when the engine is cold to allow a quick warm-up. Once the engine reaches its optimal temperature (around 180°F), it opens to allow coolant to flow to the heat exchanger for cooling.

Your coolant and antifreeze is a specialized blend of demineralized water and glycol that prevents freezing, raises the boiling point, and contains inhibitors to protect against internal corrosion. Quality coolant is essential for preventing expensive repairs.

The hoses and pipes form the network that carries coolant and seawater between components, withstanding heat, pressure, and corrosion.

Your expansion tank provides space for the coolant to expand as it heats up, preventing pressure buildup that could damage seals or hoses. It also helps keep the system free of air.

Sacrificial anodes are small metal components, usually made of zinc, that protect the heat exchanger and other components from galvanic corrosion by corroding first.

For a deeper technical dive into these components, you can learn more about the components of a diesel generator cooling system.

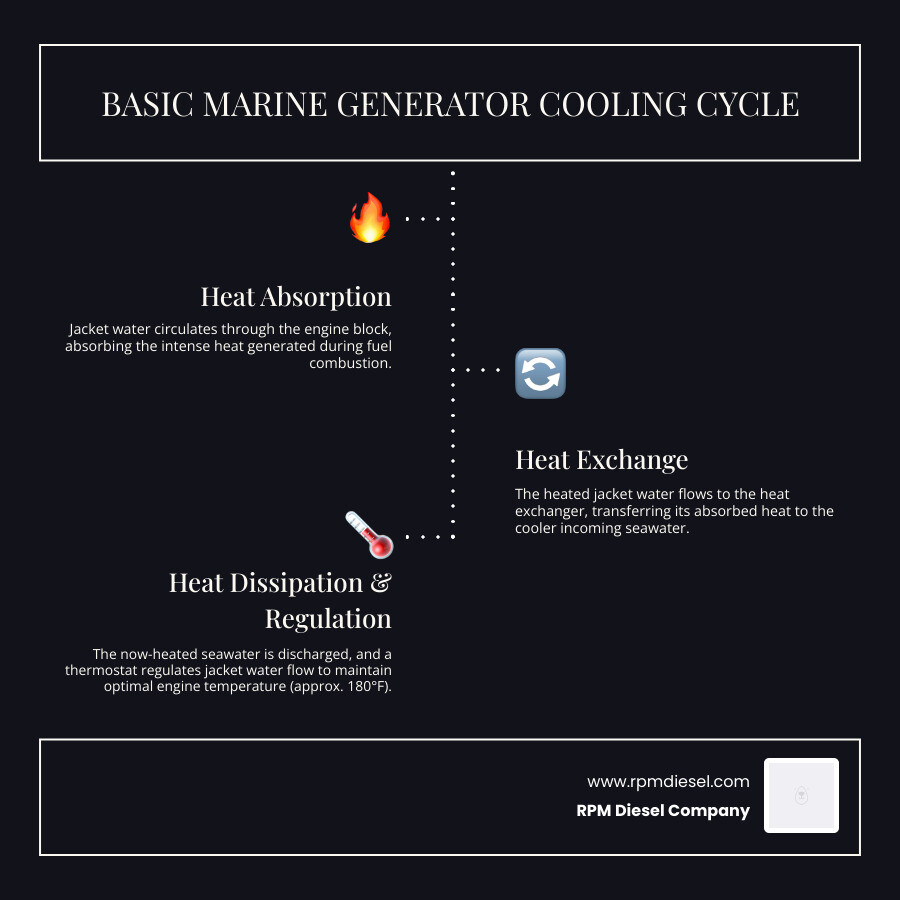

How a Liquid-Cooled Diesel Generator Cooling System Works

Let’s follow the coolant’s journey. The cycle begins with jacket water circulation, as the pump sends coolant through passages in the engine block and cylinder heads. During heat absorption from the engine block, the coolant picks up thermal energy from hot components like cylinder liners, pistons, and often the lube oil cooler and turbocharger.

The heated coolant then flows to the heat exchanger. Simultaneously, the sea water pump draws in cool seawater and pushes it through separate passages within the heat exchanger. Heat transfers from the hot jacket water to the cooler seawater without the fluids mixing. The cooled jacket water returns to the engine, and the warmed seawater is discharged overboard.

Thermostatic regulation maintains the optimal operating temperature of around 180°F. The thermostat adjusts coolant flow to the heat exchanger, ensuring the engine warms up quickly and stays at a consistent temperature for efficient combustion, proper oil viscosity, and minimal thermal stress.

Key Cooling System Configurations for Marine Use

When selecting a diesel generator cooling system, you’ll find two primary designs. Understanding the difference is key to protecting your investment and ensuring reliability.

| Feature | Open-Loop (Raw Water) System | Closed-Loop (Freshwater/Jacket Water) System |

|---|---|---|

| Complexity | Simpler, fewer components | More complex, additional components (heat exchanger, second pump) |

| Corrosion Risk | High, direct exposure of engine components to corrosive seawater | Low, engine components are protected by internal freshwater/coolant |

| Maintenance | Requires frequent flushing of raw water passages, anode replacement | Requires coolant quality checks, heat exchanger cleaning, anode replacement |

| Temperature Stability | Less stable, influenced by seawater temperature | More stable, better temperature control for optimal engine operation |

| Typical Applications | Smaller, older, or less frequently used generators; auxiliary systems | Most modern marine generators, primary power generators, continuous operation |

| Coolant Type | No internal coolant (seawater is the coolant) | Freshwater + Antifreeze/Corrosion Inhibitor mixture |

Open-Loop (Raw Water) Cooling

An open-loop system involves direct seawater circulation through the engine’s internal passages. Its main advantage is simplicity, with fewer components like a heat exchanger or internal coolant circuit to maintain.

However, this design carries a high risk of corrosion because saltwater flows directly through the engine. It is also highly vulnerable to blockages from marine life and debris, such as barnacles, sand, or algae, which can clog cooling passages and cause overheating. While initial costs may be lower, the long-term risks associated with the corrosive marine environment often outweigh the benefits of simplicity.

Closed-Loop (Jacket Water) Cooling

This is the standard for modern marine generators. A closed-loop system uses an internal freshwater/coolant circuit that is completely sealed off from the outside environment. The heat exchanger function is to transfer heat from this internal coolant to raw seawater without the two fluids ever mixing.

This design offers superior corrosion protection, as the engine’s internal components are only exposed to clean, treated coolant. It also provides stable engine temperatures, maintaining the optimal 180°F regardless of the surrounding seawater temperature. This consistency improves fuel efficiency and extends engine life.

While there is increased complexity and more maintenance points (e.g., two pumps, a heat exchanger), the improved reliability and longevity make the closed-loop diesel generator cooling system the preferred choice for most marine applications.

Essential Maintenance for Your Marine Diesel Generator Cooling System

Your diesel generator cooling system works tirelessly to prevent catastrophic overheating. Proper maintenance is not just about following a schedule; it’s about protecting your investment and ensuring you have power when it matters most.

A well-maintained system leads to improved efficiency, extended engine life, and the prevention of breakdowns at sea. Most generator failures can be traced back to cooling system issues. The long-term cost savings are substantial, as routine care is far less expensive than a major engine rebuild.

The Importance of Coolant Quality and Maintenance

Your coolant is a complex chemical mixture designed to protect your engine. Always use demineralized water as the base, as tap water contains minerals that cause scale. A shocking fact: just 1/16 inch of scale buildup insulates like an extra inch of steel, severely hindering heat transfer.

Antifreeze properties from ethylene or propylene glycol not only prevent freezing but also raise the boiling point to around 265°F under pressure. Proper pH levels (8-9.5) prevent acidic conditions that corrode metal. Corrosion inhibitors are additives that protect metal surfaces, but they deplete over time, making regular coolant changes essential. The dangers of scale buildup include hot spots that can crack cylinder heads and warp engine blocks.

Routine Maintenance Checklist

- Inspect coolant levels and quality: When the engine is cool, check the level in the expansion tank. Coolant should be clear and brightly colored; if it’s murky or rusty, it needs attention. Use test strips to check additive levels.

- Check hoses for cracks and leaks: Look for cracking, soft spots, or bulging, especially around clamps and connections where vibration causes stress.

- Clean sea strainers regularly: Check strainers after every few hours of operation, especially in waters with seaweed or debris, to prevent blockages.

- Inspect and replace sacrificial anodes: These zinc anodes protect your heat exchanger from corrosion. Replace them when they are about 50% consumed.

- Check water pump impellers for wear: Periodically inspect the rubber impeller for cracks, missing blades, or hardness. A failed impeller will stop water flow and cause rapid overheating.

- Test thermostat operation: A stuck thermostat can cause the engine to run too cool (stuck open) or overheat (stuck closed), reducing efficiency and increasing wear.

- Perform periodic system flushing: Flush the system every two years or 500 hours, as recommended by most manufacturers. Always use distilled water for flushing and refilling.

Troubleshooting Common Cooling System Failures

Your diesel generator cooling system often provides warning signs before a major failure. Recognizing these symptoms can prevent you from being stranded without power and facing a costly repair.

Common warning signs include:

- Overheating alarms: A temperature gauge in the red zone indicates the engine is struggling to shed heat. Shut down the engine immediately to prevent permanent damage.

- Visible coolant leaks: Puddles of green, orange, or red fluid indicate a leak in the closed-loop system. Check hoses, connections, and the heat exchanger.

- White smoke from exhaust: This often means coolant is leaking into the combustion chambers, usually due to a failed head gasket.

- Milky engine oil: Coolant mixing with lubricating oil gives it a milky appearance. This is a serious issue, often linked to a failed head gasket, that compromises lubrication.

- Low coolant flow or reduced performance: Weak discharge from the raw water outlet or a sluggish generator can indicate a cooling problem.

Resolving Common Problems in a Diesel Generator Cooling System

When problems arise, work systematically through the most likely causes.

- Clogged sea strainer or heat exchanger: This is a top cause of overheating. Start by cleaning the sea strainer. If flow is still poor, the heat exchanger may be clogged with marine growth or scale and require professional cleaning. While servicing, check and replace sacrificial anodes if they are more than half consumed.

- Failed water pump impellers: These flexible rubber parts wear out. A damaged impeller with missing blades or cracks will reduce water flow and cause overheating. Keep a spare on board.

- Stuck thermostat: If stuck open, the engine will run too cool. If stuck closed, it will overheat quickly. Replacement is often the safest solution.

- Air locks in the system: Air pockets, especially after maintenance, can stop coolant circulation. The system must be properly bled to remove all trapped air.

- Leaking head gasket: Symptoms like white smoke, milky oil, and coolant loss without external leaks often point to a failed head gasket, which requires professional repair.

- Saltwater corrosion damage: Salt is a relentless enemy. Regular freshwater flushing and timely anode replacement help, but severe corrosion may require component replacement.

Always let the engine cool completely before working on the cooling system to avoid burns from hot, pressurized coolant.

Frequently Asked Questions about Marine Generator Cooling

Here are answers to common questions we receive about diesel generator cooling systems.

Why is my generator overheating even with low hours?

Low engine hours don’t prevent cooling system issues in a marine environment. The most common causes are:

- Internal deposit buildup: Even with light use, mineral deposits and degraded coolant can form insulating scale inside cooling passages.

- Hidden marine growth: Barnacles and algae can grow in raw water intakes and heat exchanger tubes while the generator is idle, restricting water flow.

- Antifreeze degradation: Coolant additives that prevent corrosion break down over time, not just with use. After a couple of years, the coolant may lose its protective qualities.

- Corrosion from sitting idle: If coolant protection is weak, moisture and salt air can cause internal corrosion, leading to blockages or leaks.

How often should I flush the cooling system?

Always start with your manufacturer’s recommendations. As a general guideline for marine environments, we recommend flushing the diesel generator cooling system every two years or 500 hours, whichever comes first.

If you use Extended Life Coolant (ELC), the interval may be longer, but you must still test the coolant regularly to ensure it remains effective. For standard coolants, more frequent checks of supplemental coolant additives (SCAs) are necessary. Regular flushing is critical in marine settings to remove salt, scale, and other contaminants.

Can I use automotive coolant in my marine generator?

This is not recommended. Marine diesel engines have different requirements than automotive gasoline engines.

- Different additive packages: Automotive coolants often contain silicates, which can form abrasive gels that damage water pump seals in heavy-duty diesel engines.

- Silicate-free coolants needed: Marine diesels, especially those with wet sleeve cylinder liners, require silicate-free coolants to prevent premature wear.

- Component protection: Marine-grade coolants use specific inhibitors (like nitrites or organic acids) formulated to protect the specialized materials and components in your generator.

Using the wrong coolant can lead to expensive repairs. Always use a coolant specifically recommended for heavy-duty diesel engines.

Conclusion

Your diesel generator cooling system is a critical component that quietly manages the immense heat your engine produces. It is the key to the reliable power you depend on at sea.

We’ve covered the essential components, from the heat exchanger to the thermostat, all working to maintain the optimal 180°F operating temperature. We’ve also seen why a closed-loop system offers superior protection against corrosion compared to an open-loop design in harsh marine environments.

Proactive maintenance is your best insurance policy. Regular coolant checks, system flushing every two years or 500 hours, and replacing sacrificial anodes are not just suggestions—they are essential practices to prevent catastrophic failure.

Your cooling system handles 25-30% of your fuel’s heat energy. Respecting that workload through proper care ensures your generator will be ready when you need it.

At RPM Diesel Company, our worldwide service experience has taught us that the best repair is the one you prevent. Your diesel generator cooling system deserves diligent attention to ensure safety and reliability on the water.

Find the essential Northern Lights generator parts to maintain your cooling system and keep your marine generator running at peak performance.