Why Your Marine Diesel’s Fuel System Deserves Expert Attention

Diesel Fuel Injection Service is the professional maintenance, testing, repair, and calibration of the fuel delivery system in marine diesel engines. This critical service directly impacts your vessel’s reliability, fuel efficiency, and power output at sea.

Here’s what you need to know:

- What it includes: Injector testing and cleaning, high-pressure pump calibration, diagnostic scanning, and component rebuilding or replacement.

- When you need it: Typically every 1,000-1,500 operating hours, or when experiencing hard starts, excessive smoke, power loss, or increased fuel consumption.

- Why it matters: The fuel injection system is vital for engine health. Poor atomization or timing can lead to engine damage, reduced efficiency, or catastrophic failure at sea.

- Who should do it: Only licensed facilities with factory-trained technicians and specialized marine diesel equipment. This is not a job for a general automotive mechanic or a DIY project.

Unlike automotive diesels measured in miles, your marine engine’s health depends on operating hours and faces unique challenges like saltwater corrosion and continuous load demands. As one industry expert notes, “These types of repairs require extensive knowledge and experience and should only be attempted at licensed and authorized facilities.”

This guide will walk you through everything you need to know about marine diesel fuel injection service—from recognizing warning signs to understanding why choosing a marine diesel specialist is essential for your vessel’s safety and performance.

Diesel Fuel Injection Service basics:

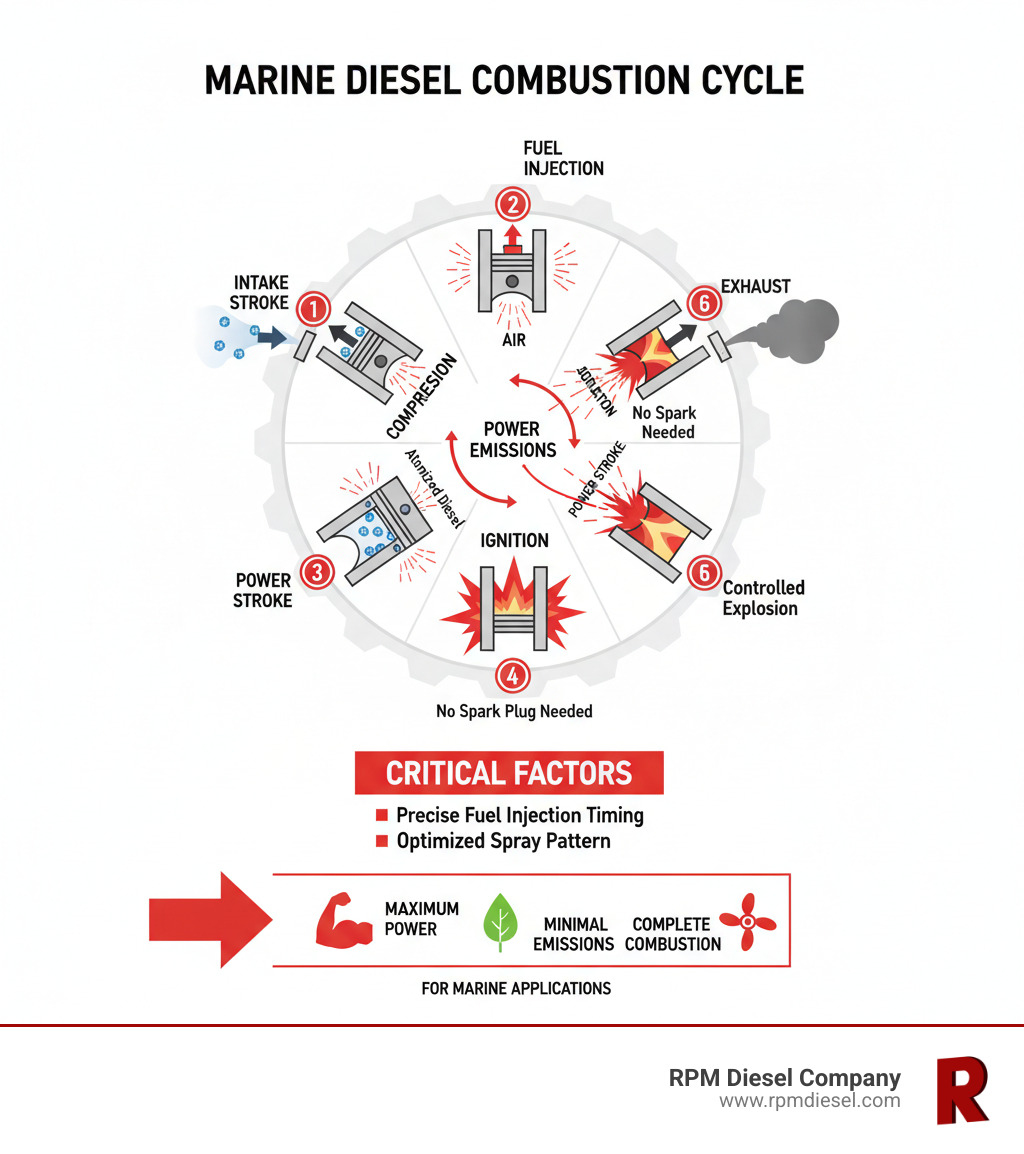

The Critical Role of Fuel Injection in Marine Diesel Performance

Your marine diesel’s fuel injection system is where precise engineering meets raw power. It delivers fuel at the right moment, in the right amount, and atomized into a fine mist for efficient combustion. When it works correctly, your engine is reliable and strong. When it fails, you’re reminded just how critical this system is.

A properly functioning fuel system is essential for:

- Engine Longevity: Clean, complete combustion prevents carbon deposits that accelerate wear on cylinder walls, piston rings, and valves. Regular Diesel Fuel Injection Service protects your investment by keeping your engine running within optimal parameters.

- Fuel Efficiency: At sea, every drop of fuel counts. A properly atomized fuel spray ensures maximum energy extraction from your diesel. A poor spray pattern means you’re wasting money by sending unburned fuel out the exhaust.

- Consistent Power Output: Reliable thrust is a matter of safety, whether you’re navigating tight quarters or pushing through rough seas. A failing fuel system can cause power lags just when you need full throttle the most.

- Reduced Emissions: Efficient fuel injection is your first line of defense against excessive exhaust. Complete combustion minimizes unburned hydrocarbons and particulate matter, helping you stay compliant with increasingly strict marine regulations.

Most importantly, proactive maintenance helps prevent catastrophic failure at sea. A failing fuel injection system can lead to a complete engine shutdown, leaving you without propulsion when you’re miles from shore. In rough conditions, this isn’t just an inconvenience—it’s a serious danger.

The system’s precision is remarkable. Injectors create a fine mist through tiny, precisely machined holes. Over time, these holes can clog or wear out, degrading the spray pattern from a mist to a stream of irregular droplets. This leads to poor combustion, reduced power, and increased fuel use. In severe cases, a single bad injector can damage an entire cylinder—a repair far more costly than the preventative service.

This delicate balance is why expert Diesel Fuel Injection Service isn’t something to put off. Your marine diesel deserves specialists who understand these systems inside and out.

Warning Signs: When Your Marine Diesel Needs Attention

Your marine diesel will often signal problems before they become emergencies. Recognizing these warning signs is key to avoiding a costly breakdown at sea. If you notice any of the following symptoms, it’s time to schedule a professional inspection.

-

Excessive Smoke: Thick black smoke usually indicates too much fuel is being injected or it’s not burning completely, often due to dirty or worn injectors. White smoke suggests unburnt fuel is passing through the engine, which can be caused by poor atomization or incorrect injection timing.

-

Rough Idling or Stalling: An engine that idles unevenly, shakes, or stalls points to inconsistent fuel delivery. This could be a sticking injector or a fuel pump struggling to maintain pressure.

-

Difficulty Starting: If your engine cranks excessively before firing up, especially when cold, it may be a sign of low fuel pressure or injectors that aren’t spraying properly.

-

Loss of Power: A sluggish throttle response or an inability to reach cruising speed often means the engine isn’t getting enough fuel, or the fuel isn’t being delivered efficiently. Clogged injectors or a weak fuel pump are common culprits.

-

Increased Fuel Consumption: If you’re burning through diesel faster than usual, your fuel system is likely delivering too much fuel or burning it inefficiently. This is money wasted and a clear sign that service is needed.

-

Engine Knocking: Sharp, metallic sounds from the engine should never be ignored. This often indicates that fuel is being injected at the wrong time, creating excessive cylinder pressure that can cause serious internal damage.

Ignoring these signs is a gamble. What starts as a minor issue can quickly escalate into a major failure. If you’re experiencing any of these symptoms, a professional Diesel Fuel Injection Service is the next step to diagnose the problem before it leaves you stranded.

A Comprehensive Guide to Marine Diesel Fuel Injection Service

A comprehensive Diesel Fuel Injection Service is essential for both proactive maintenance and addressing performance issues. The approach varies depending on your engine’s specific fuel system, as each type requires different tools and expertise.

Understanding Different Marine Fuel Injection Systems

Marine diesels use several types of fuel injection technology, from robust mechanical systems to highly sophisticated electronic ones. Knowing which type your vessel has helps you understand its service needs.

| System Type | Key Characteristics | Pressure Range | Control Method | Service Complexity |

|---|---|---|---|---|

| Mechanical Injectors | Simplest design; relies on pressure from pump to open injector; no electronic control. | Lower (up to ~3,000 psi) | Mechanical linkages, cam-driven pump | Moderate; rebuildable, requires calibration |

| HEUI (Hydraulic Electronic Unit Injectors) | Uses engine oil pressure, amplified by a plunger, to generate high fuel injection pressure; electronically controlled. | Medium-High (up to ~21,000 psi) | Electronic (ECM) | High; requires specialized tools for oil/fuel systems |

| Common Rail Diesel Injection (CRDI) | Fuel stored at very high pressure in a common rail; electronically controlled injectors open and close rapidly. | Very High (up to ~35,000+ psi) | Electronic (ECM) | Very High; extremely precise, sensitive to contamination |

Mechanical injectors are the workhorses found in many older marine diesels. They are robust and often cost-effective to service, as they can be disassembled, cleaned, and rebuilt with new wear parts before being calibrated on a test bench.

HEUI systems use high-pressure engine oil to actuate the fuel injection process, allowing for more precise electronic control than mechanical systems. Servicing them is more complex, as issues can stem from either the oil or fuel side, requiring specialized diagnostic equipment.

Common Rail (CRDI) is the most advanced system in modern marine diesels, offering superior efficiency and lower emissions. Fuel is held at extreme pressure in a shared “rail,” and injectors are controlled electronically with incredible precision. These systems are highly sensitive to contamination, and service demands specialized tools and clean-room conditions.

The Scope of a Professional Diesel Fuel Injection Service

A professional service is a methodical process that goes far beyond a simple inspection.

- Advanced Diagnostics: We start by using state-of-the-art scanning tools to communicate with your engine’s Electronic Control Module (ECM). This allows us to read fault codes and analyze live data to pinpoint issues without guesswork.

- Injector and Pump Service: Each injector is removed and evaluated on a specialized test bench for spray pattern, pressure, and fuel volume. High-pressure pumps are also tested for consistent pressure delivery. Based on the results, components may undergo ultrasonic cleaning, rebuilding with new internal parts, or replacement.

- Calibration and Testing: After service, every component is calibrated to precise manufacturer specifications on our test benches. This simulates real-world operating conditions and ensures balanced, reliable performance once reinstalled.

We maintain relationships with top suppliers to ensure access to high-quality parts. For those interested, Bosch provides authoritative information on diesel parts used across the industry.

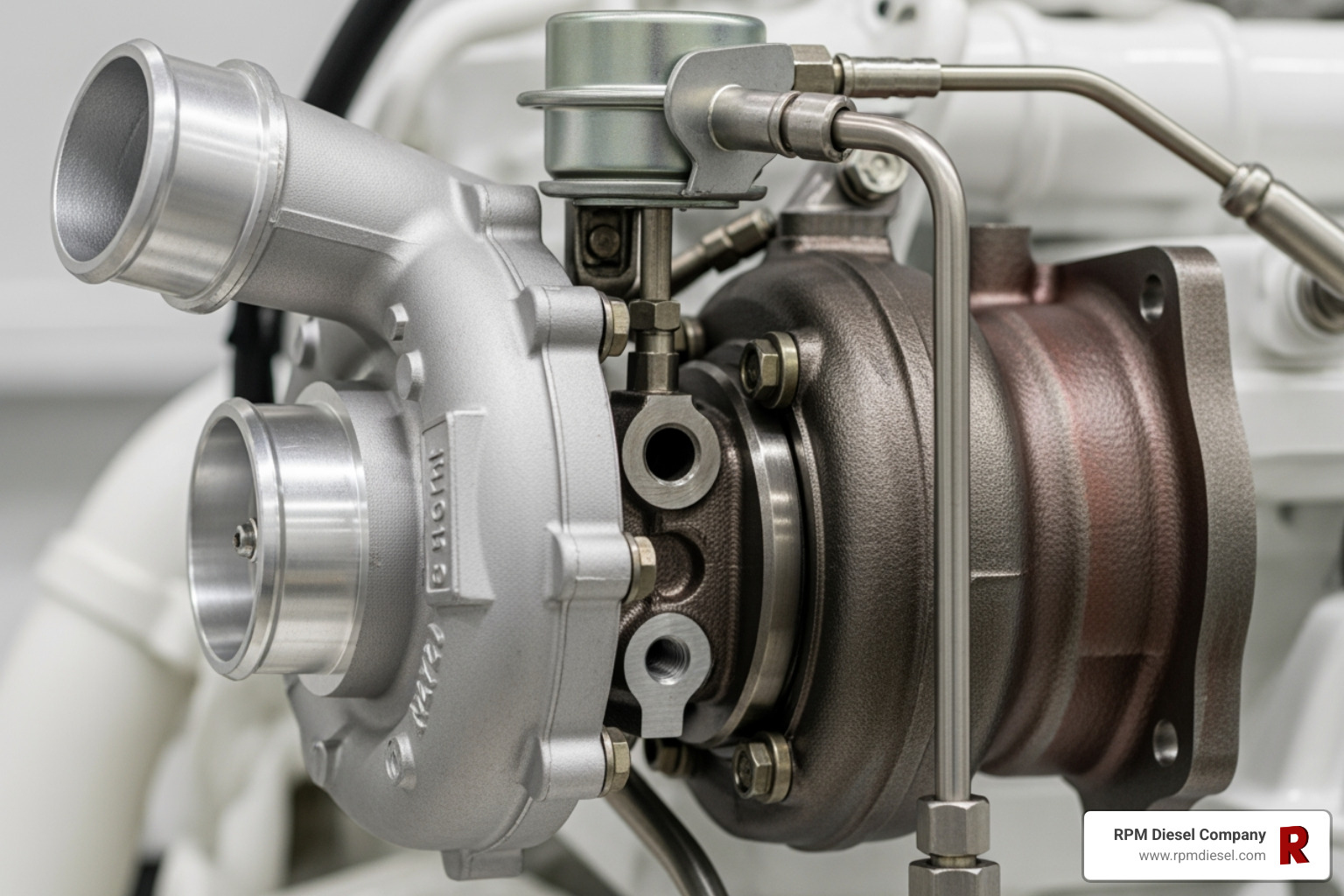

The Integral Role of Turbochargers

Your turbocharger and fuel injection system work as a team. A failure in one can easily be mistaken for a problem with the other.

Turbochargers force more air into the cylinders, allowing the engine to burn more fuel and produce more power. The fuel injection system is programmed to deliver fuel based on the expected amount of air from the turbo. If the turbo isn’t delivering enough air due to a leak or wear, the engine receives too much fuel. This results in black smoke, power loss, and poor fuel economy—symptoms that perfectly mimic a fuel system problem.

Because of this, a comprehensive Diesel Fuel Injection Service should always include a turbocharger inspection. This integrated approach ensures we identify the true source of any performance issue, preventing unnecessary repairs and guaranteeing your engine achieves the correct air-fuel ratio for optimal combustion, efficiency, and longevity. You can learn more about complete marine diesel systems through resources like Cummins Engines.

Why a Specialist is Non-Negotiable for Marine Diesels

Choosing between a general mechanic and a marine diesel specialist can be the difference between a lasting repair and a recurring nightmare. For your vessel’s complex fuel injection system, specialized expertise isn’t a luxury—it’s a necessity.

General Mechanic vs. Marine Diesel Expert

An automotive mechanic and a marine diesel expert work in two different worlds. A marine specialist understands the unique challenges your engine faces:

- Harsh Environment: Marine engines are under constant assault from saltwater corrosion, which attacks electrical connections, fuel lines, and metal components. A specialist knows where to look for damage and uses marine-grade parts and protective coatings for repairs.

- Sustained Loads: Unlike a car, a marine diesel runs at high RPMs under heavy load for hours. This creates different wear patterns and service requirements than stop-and-go driving. Service intervals are based on operating hours, not mileage—a critical distinction.

- Specialized Equipment: Modern marine fuel systems, especially common rail, operate at extreme pressures and require diagnostic tools, test benches, and calibration equipment found only in dedicated marine service facilities.

Attempting to service a marine diesel without this specific knowledge and equipment is a recipe for failure, often leading to more expensive problems down the line.

Benefits of a Professional Diesel Fuel Injection Service

Choosing a specialist like RPM Diesel provides peace of mind and tangible benefits:

- Factory-Trained Expertise: Our technicians receive ongoing training directly from manufacturers like Detroit Diesel and MTU. They are experts in the latest fuel injection technologies and repair procedures.

- Genuine OEM Parts: We use genuine OEM or authorized high-quality aftermarket parts that are designed to withstand the marine environment. This ensures proper fit, performance, and longevity. For more on quality components, resources like Bosch Auto Parts’ diesel section are informative.

- Accurate Diagnostics: Our advanced equipment allows us to pinpoint the exact cause of a problem, saving you money on unnecessary parts and labor. We fix the root issue, not just the symptoms.

- Emissions Compliance: A properly calibrated fuel system ensures your engine operates within environmental guidelines, helping you avoid potential fines. For more on modern standards, see resources from manufacturers like Cummins Engines.

- Warranty and Confidence: We stand behind our work with a comprehensive warranty on both parts and labor. This is our commitment to quality and your assurance of a reliable repair.

In areas like Fort Lauderdale, Miami, and West Palm Beach, choosing a marine diesel specialist is the only way to protect your investment and ensure safe operation on the water.

Frequently Asked Questions about Marine Fuel Injection

We hear many of the same questions from vessel owners in our shop and on service calls across South Florida. Here are answers to some of the most common concerns about marine diesel fuel injection systems.

How often do marine diesel injectors require service?

Unlike cars, marine engine maintenance is based on operating hours, not miles. As a general guideline, mechanical fuel injection systems should be serviced every 1,000 to 1,500 operating hours. However, this can vary.

Always prioritize your manufacturer’s recommendations as the most accurate guide. Other factors that influence service frequency include:

- Fuel Quality: Poor quality or contaminated fuel can clog injectors much faster.

- Engine Load: Engines that run consistently under heavy loads may require more frequent service than those used for light cruising.

- Operating Environment: High humidity can lead to water condensation in fuel tanks, affecting system health.

Sticking to a proper service schedule is a direct investment in your engine’s longevity and fuel efficiency, preventing costly wear and maximizing performance.

Can fuel additives replace professional injector service?

Think of fuel additives as vitamins: they are great for maintenance but can’t cure a serious problem. Quality additives can help keep a healthy system clean and provide necessary lubricity for modern low-sulfur diesel. They are a useful part of a preventative maintenance strategy.

However, additives cannot fix mechanical problems. They will not repair a worn spring, a cracked nozzle tip, or an internally worn fuel pump. If you are experiencing symptoms like excessive smoke, power loss, or hard starting, you are likely past the point where an additive can help. These signs indicate a need for professional diagnosis and repair through a comprehensive Diesel Fuel Injection Service.

Use additives to supplement professional service, not replace it. When your engine shows clear signs of trouble, it’s time to call an expert.

Is it better to repair or replace a faulty marine fuel injector?

The best choice depends on the injector type, the nature of the failure, and a cost-benefit analysis. Our goal is to provide the most reliable and economical solution for your vessel.

-

Rebuilding: For many older mechanical injectors and pumps, rebuilding is an excellent, cost-effective option. These components were designed to be serviced. Our technicians can restore them to OEM specifications with new wear parts, often saving you 40-60% compared to the cost of a new unit, with a comparable warranty.

-

Replacement: For modern electronic injectors, especially in common rail systems, replacement is usually the only reliable path. These are built to microscopic tolerances and contain non-serviceable electronic components. Attempting a rebuild is risky and unlikely to provide the long-term reliability required for marine use. In these cases, a new or factory-remanufactured unit is the best investment.

A professional assessment is crucial. We use specialized equipment to accurately diagnose the injector’s condition and will provide you with clear options so you can make an informed decision.

Conclusion: Ensure Your Vessel’s Reliability and Performance

Your marine diesel’s fuel injection system is the heart of its performance and reliability. Proper maintenance is not just about efficiency—it’s about safety and peace of mind on the water. As we’ve covered, recognizing warning signs early and entrusting your engine to a specialist are the keys to preventing catastrophic failure.

Proactive Diesel Fuel Injection Service rewards you with better fuel economy, consistent power, and a longer-lasting engine. It’s always cheaper and safer than dealing with a breakdown miles from shore. A general mechanic lacks the specific knowledge of the marine environment and the specialized tools required for the job. A marine diesel specialist is a necessity.

At RPM Diesel, we live and breathe marine engines. Serving the communities of Fort Lauderdale, Miami, West Palm Beach, and beyond, we are the authorized experts for major brands like Detroit Diesel and MTU. We combine factory training with an extensive parts inventory to get the job done right and get you back on the water faster. Protecting your investment through expert service is what we do best.

Don’t wait for a small issue to become a major problem. Let our team ensure your vessel is reliable, efficient, and ready for your next adventure.

Contact us for professional Marine Diesel Fuel Injection Service