Why Marine Diesel Engine Overhauls Matter for Vessel Reliability

A diesel engine overhauling procedure restores your marine engine to factory specifications by disassembling, inspecting, cleaning, repairing, and reassembling all major components. Its the most reliable way to stop wear from becoming failure, regain lost power and efficiency, and extend engine life at a fraction of replacement cost.

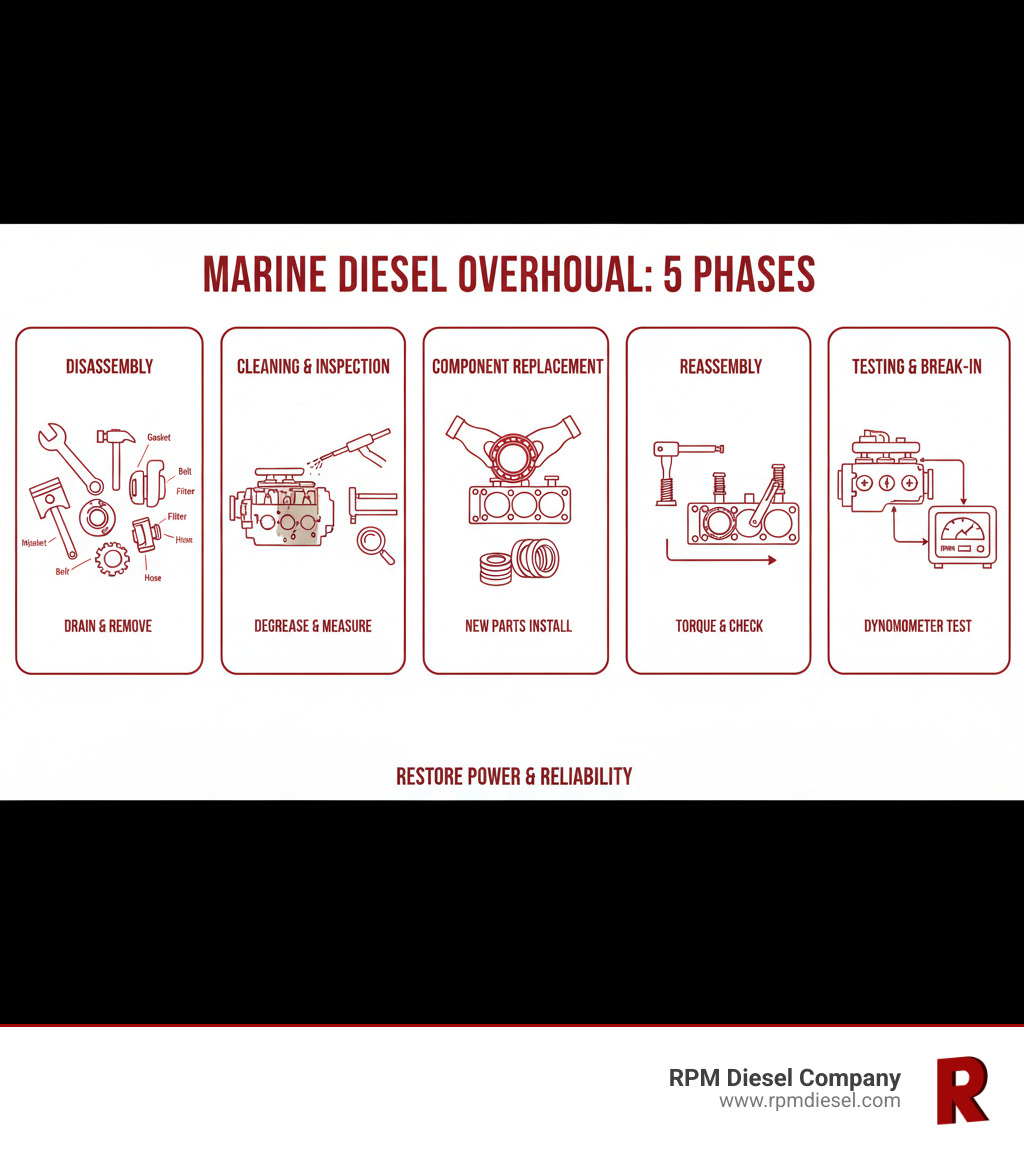

The 5 Essential Phases of a Marine Diesel Overhaul:

- Preparation & Disassembly – Safely drain fluids, remove external components, and systematically disassemble the engine while labeling all parts

- Cleaning & Inspection – Thoroughly clean components and measure critical tolerances using precision tools like micrometers and bore gauges

- Component Replacement – Replace worn parts including gaskets, seals, piston rings, and bearings with marine-grade components

- Reassembly – Rebuild the engine following exact torque specifications and checking all clearances

- Testing & Break-in – Verify performance through dynamometer testing and proper break-in procedures

Marine diesels can exceed 1,500,000 miles (vs. ~200,000 for gasoline) with proper care, but saltwater accelerates corrosion, scaling, and moisture-related fuel issues. A professional overhaul addresses these marine-specific stressors so your engine runs like new for years to come.

Recognizing the Need: When to Overhaul Your Marine Diesel Engine

Your marine diesel will warn you before major trouble. Addressing symptoms early prevents costly failures and keeps you safe offshore. Key indicators that its time for a diesel engine overhauling procedure include:

- Increased Oil Consumption: Often from worn rings, valve guides, or seals.

- Excessive Exhaust Smoke: Blue = oil burn; black = incomplete combustion (injectors/air); persistent white = coolant/water intrusion.

- Loss of Power: Sluggish RPMs and poor acceleration point to compression or fuel delivery issues.

- Unusual Engine Noises: Knocking or rattling can indicate bearing or valvetrain wear.

- High Operating Hours: Follow OEM hour-based overhaul intervals to avoid unexpected failures.

- Decreased Fuel Efficiency: Rising fuel use signals internal wear or injector problems.

- Fuel/Water Contamination: Modern injectors are microns-precise; see research on fuel contamination. Diesel smell in oil or milky oil are red flags.

Acting on these signs is a smart investment in reliability and longevity. For more, see Reasons to Consider Diesel Engine Overhaul Fort Lauderdale.

The Comprehensive Marine Diesel Engine Overhauling Procedure

When major service is due, a full overhaul returns your engine to OEM specs and dependable operation. At RPM Diesel, our proven diesel engine overhauling procedure is precise, marine-focused, and documented end-to-end.

Phase 1: Preparation and Disassembly

We secure power, implement safety protocols, and carefully drain oil/coolant/fuel for inspection and proper disposal. External systems are removed and labeled, then the engine is lifted to our clean, climate-controlled shop for 360-degree access. Meticulous disassembly preserves orientation and wear patterns to ensure flawless reassembly.

Phase 2: Cleaning and Detailed Component Inspection

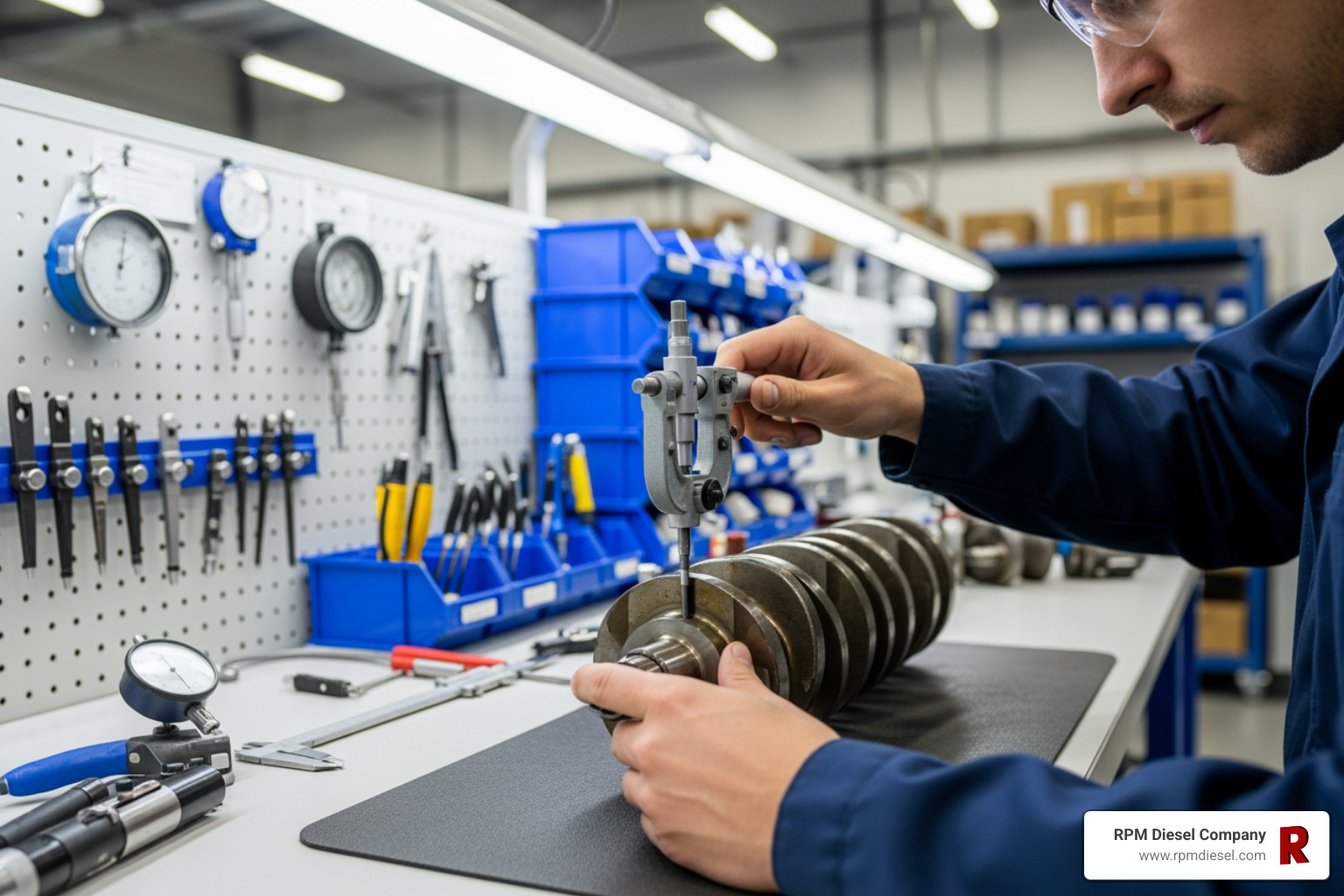

Components are cleaned using methods appropriate to their materials (hot alkaline tanks for cast iron, gentler solutions for aluminum, ultrasonic for intricate parts). We measure critical dimensions with micrometers, bore gauges, and dial indicators, checking blocks/liners/pistons, crankshaft/bearings, and cylinder heads/valvetrains against OEM tolerances. Non-destructive testing (Magnetic Particle and Dye Penetrant Inspection) and pressure testing expose invisible cracks and leaks. Any part out of spec is machined or replacedno compromises.

Phase 3: The Rebuild – The Reassembly Diesel Engine Overhauling Procedure

We replace all wear items with marine-grade components, often using comprehensive Diesel Engine Overhaul Kits. Bearings, pistons, and rings are installed with assembly lube; clearances (including ring gaps and bearing oil film) are verified; and head gaskets are sealed using OEM torque and angle sequences. Every specification and tightening sequence is followed precisely to restore like-new performance and longevity.

Specialized Techniques and Marine-Specific Considerations

Your engine operates in salt, moisture, and constant motionconditions that demand marine-specific expertise. Our diesel engine overhauling procedure includes targeted services that harden your engine against the sea.

Key Component Servicing

Our Engine Performance Services by RPM Diesel cover:

- Fuel Injectors & Governors: Test and calibrate for precise fueling and stable RPM control.

- Turbochargers: Inspect balance and clearances to restore boost and efficiency.

- Heat Exchangers: Clean and pressure-test; replace compromised tubes and seals to prevent overheating.

- Water Pumps: Rebuild/replace raw and freshwater pumps, focusing on impellers, bearings, and seals.

The Marine Diesel Engine Overhauling Procedure: Unique Challenges

- Galvanic Corrosion: Inspect and replace sacrificial zinc anodes to protect high-value components; see Galvanic Corrosion.

- Raw Water System Integrity: Clean and verify strainers, hoses, and passages to avoid overheating from blockages or growth.

- Specialized Repairs: Apply metal stitching on repairable castings and precision grind crankshafts when economically and technically appropriate.

From marine-grade fasteners to corrosion-resistant coatings, every choice is made for the saltwater environment.

Overhaul vs. Replacement: Making the Right Choice for Your Vessel

When serious wear appears, youre choosing between a professional overhaul or a full repower. For many vessels in Fort Lauderdale, Miami, and across Florida, a high-quality diesel engine overhauling procedure delivers the best value: lower cost, faster turnaround, and documented, like-new performance.

Why owners choose overhaul:

- Typically 40-60% less than replacement

- Weeks of downtime versus months

- OEM-spec clearances and updated components

- Environmental benefits from reusing major castings

| Consideration | Engine Overhaul | Engine Replacement |

|---|---|---|

| Cost | Typically 40-60% of replacement cost | $15,000 – $50,000+ plus installation & modification costs |

| Downtime | Generally 2-6 weeks | Can take 2-6 months or more |

| Longevity | Restores engine to OEM specs for thousands of hours | New engine life expectancy |

| Environmental Impact | Lower; reuses major components | Higher; requires new manufacturing and disposal of old engine |

When emissions goals or unrepairable block damage demand it, replacement is the answer. Otherwise, choosing to rebuild your engine with RPM Diesel offers proven reliability and strong resale value.

Why Marine Diesel Engine Overhauls Matter for Vessel Reliability

A diesel engine overhauling procedure restores performance and reliability by returning your marine engine to factory specifications through systematic teardown, inspection, precise machining, and reassembly. Addressing corrosion, salt buildup, and fuel moisture unique to marine use extends service life and keeps operating costs downoften at a fraction of replacement. For many yacht and workboat owners, its the smartest long-term investment.

Recognizing the Need: When to Overhaul Your Marine Diesel Engine

Catching issues early prevents failures offshore. Consider an overhaul if you notice:

- Rising oil consumption (worn rings/guides/seals)

- Blue/black/white smoke trends that persist

- Loss of power or inability to reach cruising RPM

- New knocks or rattles under load

- High hours beyond OEM intervals

- Increasing fuel burn on familiar routes

- Fuel/water contamination risks; see research on fuel contamination

A timely overhaul restores efficiency and reliability for cruising South Floridas waters. Learn more: Reasons to Consider Diesel Engine Overhaul Fort Lauderdale.

The Comprehensive Marine Diesel Engine Overhauling Procedure

A full overhaul is a planned restorationnot a quick fix. Our multi-phase diesel engine overhauling procedure delivers reliable, like-new performance for vessels across Fort Lauderdale, Miami, and the Florida coast.

Phase 1: Preparation and Disassembly

Secure power, drain and assess fluids, label every connection, and remove the engine to our controlled shop for a meticulous teardown that protects orientation and wear patterns.

Phase 2: Cleaning and Inspection

Use appropriate cleaning (alkaline, non-caustic, ultrasonic) for material types; measure every critical dimension (block/liners/pistons, crank/bearings, head/valvetrain) with precision tools; employ NDT (Magnetic Particle, Dye Penetrant) and pressure testing to uncover hidden defects. Out-of-spec parts are machined or replaced.

Phase 3: The Rebuild – The Reassembly Diesel Engine Overhauling Procedure

Replace all wear items with marine-grade components, often via Diesel Engine Overhaul Kits. Verify clearances and end play, use assembly lube, and follow OEM torque and angle sequences throughout. The result: OEM-spec compression, oil pressure, and durability.

Specialized Techniques and Marine-Specific Considerations

Marine engines face salt, humidity, vibration, and growth that land engines dont. Our diesel engine overhauling procedure includes services that directly target these realities in South Florida waters.

Key Component Servicing

- Fuel injectors calibrated to microns-level precision to curb smoke and fuel waste

- Turbocharger balance/clearance checks to restore boost and efficiency

- Heat exchanger cleaning and pressure testing, with zinc replacement

- Raw/freshwater pump rebuilds (impellers, bearings, seals)

- Mechanical governor overhaul where fitted

Our Engine Performance Services by RPM Diesel ensure your supporting systems match the quality of your rebuilt powerhead.

The Marine Diesel Engine Overhauling Procedure: Unique Challenges

- Guard against galvanic corrosion by inspecting/replacing sacrificial anodes throughout the vessel and cooling system

- Verify raw water intake/hoses/strainers for debris and marine growth

- Use metal stitching on repairable castings and precision crankshaft grinding when appropriate

We select corrosion-resistant fasteners, seals, and coatings so your overhauled engine thrives in saltwater.

Overhaul vs. Replacement: Making the Right Choice for Your Vessel

An expertly executed diesel engine overhauling procedure is often the best value: lower cost, faster turnaround, and documented like-new performance. Replacement is reserved for unrepairable blocks, parts obsolescence, or emissions goals.

For an additional technical reference, see this PDF: https://climber.uml.edu.ni/default.aspx/fulldisplay/4050199/DieselEngineOverhaul.pdf

Recognizing the Need: When to Overhaul Your Marine Diesel Engine

Our vessels run best when we act early. Consider a professional diesel engine overhauling procedure if youre seeing:

- Rising oil use or milky oil

- Persistent blue/black/white smoke

- Noticeable power loss or poor RPM under load

- New internal noises

- Hours beyond OEM overhaul guidance

- Fuel economy decline

- Signs of contamination (see research on fuel contamination)

A scheduled overhaul restores performance, efficiency, and peace of mind for Florida cruising. More insights: Reasons to Consider Diesel Engine Overhaul Fort Lauderdale.

The Comprehensive Marine Diesel Engine Overhauling Procedure

A true overhaul is a clean-room approach to restoring OEM performance, not just swapping parts. Our multi-phase diesel engine overhauling procedure is built for marine duty in Fort Lauderdale, Miami, and beyond.

Phase 1: Preparation and Disassembly

Disconnect power, drain and assess fluids, label every hose/lead, and remove the engine to our controlled facility for detailed teardown.

Phase 2: Cleaning and Detailed Component Inspection

Clean using methods matched to each material; measure with precision tools against OEM specs; apply NDT and pressure testing to catch hidden defects. Any part outside tolerance is machined or replaced.

Phase 3: The Rebuild – The Reassembly Diesel Engine Overhauling Procedure

Replace all gaskets, seals, rings, and bearings (often via marine Diesel Engine Overhaul Kits). Install rotating/reciprocating assemblies with assembly lube, verify every clearance, and follow torque/angle sequences precisely. Result: like-new reliability, compression, and oil control.

Specialized Techniques and Marine-Specific Considerations

Marine conditions demand marine solutions. Our overhaul approach hardens your engine against saltwaters unique challenges.

Key Component Servicing

- Injector testing/calibration for crisp combustion and low smoke

- Turbocharger checks for balance/play to restore response and economy

- Heat exchanger cleaning/pressure testing with zinc service

- Raw/freshwater pump rebuilds to prevent overheating

- Governor overhaul for smooth RPM control

Explore our marine-focused Engine Performance Services by RPM Diesel.

The Marine Diesel Engine Overhauling Procedure: Unique Challenges

- Control galvanic corrosion by inspecting/replacing anodes in the cooling system and across the vessel

- Ensure raw water system integrity (intakes, strainers, hoses) to avoid sudden overheat events

- Employ metal stitching on salvageable castings and precision crankshaft grinding where warranted

Every fastener, seal, and coating is chosen with saltwater in mind, so your engine stays reliable after the rebuild.

Overhaul vs. Replacement: Making the Right Choice for Your Vessel

Deciding whether to overhaul your marine diesel engine or replace it entirely is a significant decision for any vessel owner. It boils down to a careful balance of cost, downtime, and long-term value. While a new engine might seem appealing, an expertly performed diesel engine overhauling procedure often presents a more practical and economical solution.

Let’s weigh the options:

| Feature | Engine Overhaul ](https://climber.uml.edu.ni/default.aspx/fulldisplay/4050199/DieselEngineOverhaul.pdf)

Frequently Asked Questions about Marine Diesel Overhauls

We know a diesel engine overhauling procedure is a major decision. Here are quick answers to common questions from South Florida vessel owners.

What is the difference between an engine overhaul and a rebuild?

In marine service, these terms are typically used interchangeably: a complete teardown, cleaning, inspection to OEM specs, replacement of wear items (rings, bearings, seals, gaskets, etc.), and precise reassembly to restore like-new performance.

How long does a marine diesel overhaul take?

It depends on engine size/complexity, findings during inspection, and parts availability. With our deep inventory (Detroit Diesel, MTU, and more), many jobs complete in weeks; complex or rare engines can take longer. We provide a clear timeline after initial inspection.

Can I perform a diesel engine overhaul myself?

Its not a DIY job. Youll need specialized tools, OEM procedures, precision measurements in thousandths of an inch, and calibrated torque/angle equipment. A factory-authorized overhaul from RPM Diesel includes proper testing and warranty coverageess risk, better results.

Restore Your Engine’s Power and Reliability

When your marine diesel engine completes a comprehensive diesel engine overhauling procedure with RPM Diesel, something remarkable happens. It’s not just repaired—it’s truly reborn.

You’ll immediately notice the restored performance. That sluggish acceleration? Gone. Your vessel will surge forward with the same authority it had when new, reaching its designed top speed effortlessly. The power is back, and so is the confidence that comes with it.

More importantly, you gain improved reliability. Every worn bearing has been replaced. Every critical tolerance has been verified. Every system has been carefully inspected and rebuilt to factory specifications. This means your engine starts reliably every time, runs smoothly under load, and dramatically reduces your risk of unexpected breakdowns when you’re miles from shore. There’s real peace of mind in knowing your engine won’t leave you stranded.

Your fuel bills will thank you, too. A properly overhauled engine operates at peak efficiency, burning fuel cleanly and completely. Many owners report noticeable improvements in fuel economy, which translates to real savings over the years of cruising ahead.

Perhaps most significant is that an overhaul gives your engine a genuine new lease on life. We’re talking about extending your engine’s operational lifespan by decades at a fraction of the cost of replacement. For owners of classic vessels or those with specific engine models where finding a replacement would be difficult or prohibitively expensive, this is invaluable. Your engine can deliver another generation of reliable service.

At RPM Diesel, we bring decades of expertise to every overhaul. As factory-authorized technicians for major manufacturers like Detroit Diesel and MTU, we don’t just meet specifications—we exceed them. Our comprehensive service capabilities, combined with our extensive parts inventory and skilled technicians serving Fort Lauderdale, Miami, and the entire Florida coast, mean your engine receives the highest level of care available.

We understand that your marine diesel engine represents a significant investment and is essential to your vessel’s operation. That’s why we treat every overhaul with the meticulous attention it deserves, ensuring that when your engine leaves our workshop, it’s ready for thousands more hours of dependable service on the water.

Don’t let a tired engine keep you from enjoying Florida’s incredible waterways. Experience the RPM Diesel difference, where precision meets passion, and your engine is restored to its full glory.