Why a Diesel Engine Maintenance Checklist is Your Best Defense Against Breakdown at Sea

A diesel engine maintenance checklist is essential for preventing unexpected failures and ensuring your vessel’s reliability. Here’s what every marine diesel owner needs to know:

Essential Maintenance Tasks by Frequency:

- Daily (Pre-Departure): Check coolant level, oil level and color, belt tension, battery connections, fuel leaks, exhaust water flow, and listen for unusual sounds

- Monthly/100 Hours: Change engine oil and filter, inspect fuel filters, drain water separator, check zinc anodes, clean sea strainer

- Annual/1000 Hours: Replace raw water pump impeller, replace all fuel filters, service cooling system, flush heat exchanger, check valve clearance, inspect turbocharger

Critical Components Requiring Regular Attention:

- Fuel system (filters and water separators)

- Lubrication system (oil and filters)

- Cooling system (both raw water and freshwater circuits)

- Air intake and exhaust systems

- Electrical system and battery

- Zinc anodes for corrosion protection

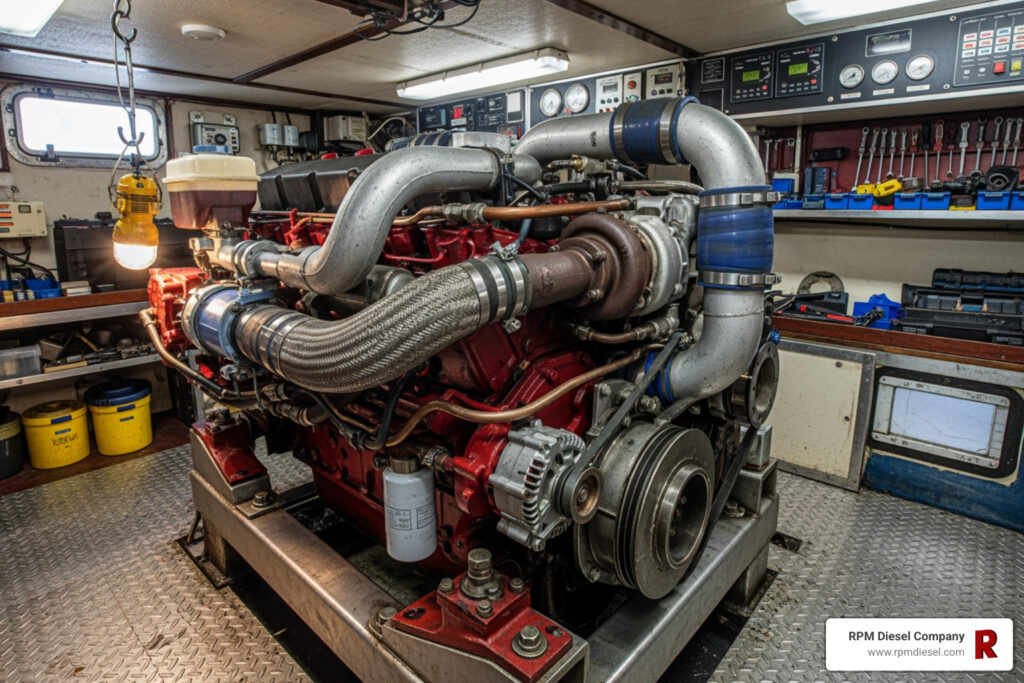

Your marine diesel engine is the heart of your vessel. When it fails miles from shore, you’re not just inconvenienced—you’re potentially in danger.

According to industry research, 9 out of 10 diesel engine problems result from contaminated fuel. The marine environment makes this even worse, with saltwater corrosion, constant humidity, and relentless vibration working together to accelerate wear on every component.

The good news? A well-maintained diesel engine can last between 1,000,000 and 1,500,000 miles—up to 30 years of reliable service. That’s seven times longer than a typical gasoline engine.

But here’s the reality: marine diesels face challenges that land-based engines never see. Salt air corrodes electrical connections. Moisture breeds algae in fuel tanks. A failed impeller can destroy an engine in minutes. These aren’t hypothetical problems—they happen to unprepared boat owners every season.

The solution is simple: proactive maintenance. Regular checks catch small issues before they become expensive emergencies. They improve fuel efficiency, maintain your vessel’s resale value, and most importantly, keep you safe on the water.

This guide gives you a comprehensive maintenance checklist specifically designed for marine diesel engines, from daily pre-departure checks to annual service intervals.

Diesel engine maintenance checklist terms explained:

Why Your Marine Diesel Needs a Different Kind of Care

Your marine diesel engine isn’t just working hard—it’s working in one of the harshest environments imaginable. While a truck diesel might deal with dust and temperature swings, your boat’s engine faces something far more relentless: saltwater, constant humidity, and non-stop vibration every time you’re underway.

This is why you can’t just follow a generic diesel engine maintenance checklist. Marine diesels need specialized care that accounts for the unique challenges of life at sea.

The saltwater environment is particularly brutal. Salt air doesn’t just corrode what you can see—it attacks electrical connections, accelerates rust, and creates havoc throughout your engine systems. The constant moisture breeds algae in fuel tanks and promotes condensation in places you’d never expect. And that persistent vibration? It loosens connections, creates stress fractures, and tests every bolt and fitting hour after hour.

One of the biggest differences between marine and land-based diesels is the cooling system. Your engine uses a dual cooling system: a freshwater circuit that actually cools the engine block, and a raw water circuit that pulls water directly from the ocean to cool that freshwater through a heat exchanger. It’s an neat solution, but that raw seawater brings its own problems.

This is where sacrificial zinc anodes become your engine’s best friend. These humble chunks of metal protect your expensive engine components from galvanic corrosion—an electrochemical process that happens when different metals sit in saltwater together. The zinc corrodes instead of your engine parts. It’s a beautiful trade-off, but only if you regularly inspect and replace those anodes before they’re completely eaten away.

Clean fuel is absolutely critical for marine diesels. Modern fuel injectors operate with tolerances measured in microns—we’re talking about gaps smaller than 1/25,000th of an inch. Even microscopic contaminants or water droplets can cause catastrophic damage to these precision components. The devastating effects of dirty fuel are well-documented, and they’re even worse in the marine environment where condensation and water intrusion are constant threats.

That’s why fuel-water separators are essential equipment on any boat. These filters do exactly what their name suggests—they separate water and sediment from your fuel before it reaches the engine. Regular draining of these separators and timely fuel filter replacements aren’t optional tasks; they’re insurance against expensive repairs.

Marine diesels also typically run at lower RPMs for extended periods compared to automotive engines. This continuous operation at steady speeds requires higher quality, marine-grade oils specifically formulated to handle the unique stresses of marine service, including higher carbon buildup and the demanding conditions of saltwater operation.

The Heart of the System: Key Components to Watch

Understanding your engine’s core systems makes maintenance less mysterious and more manageable. Each system depends on the others, and a problem in one area often triggers issues elsewhere.

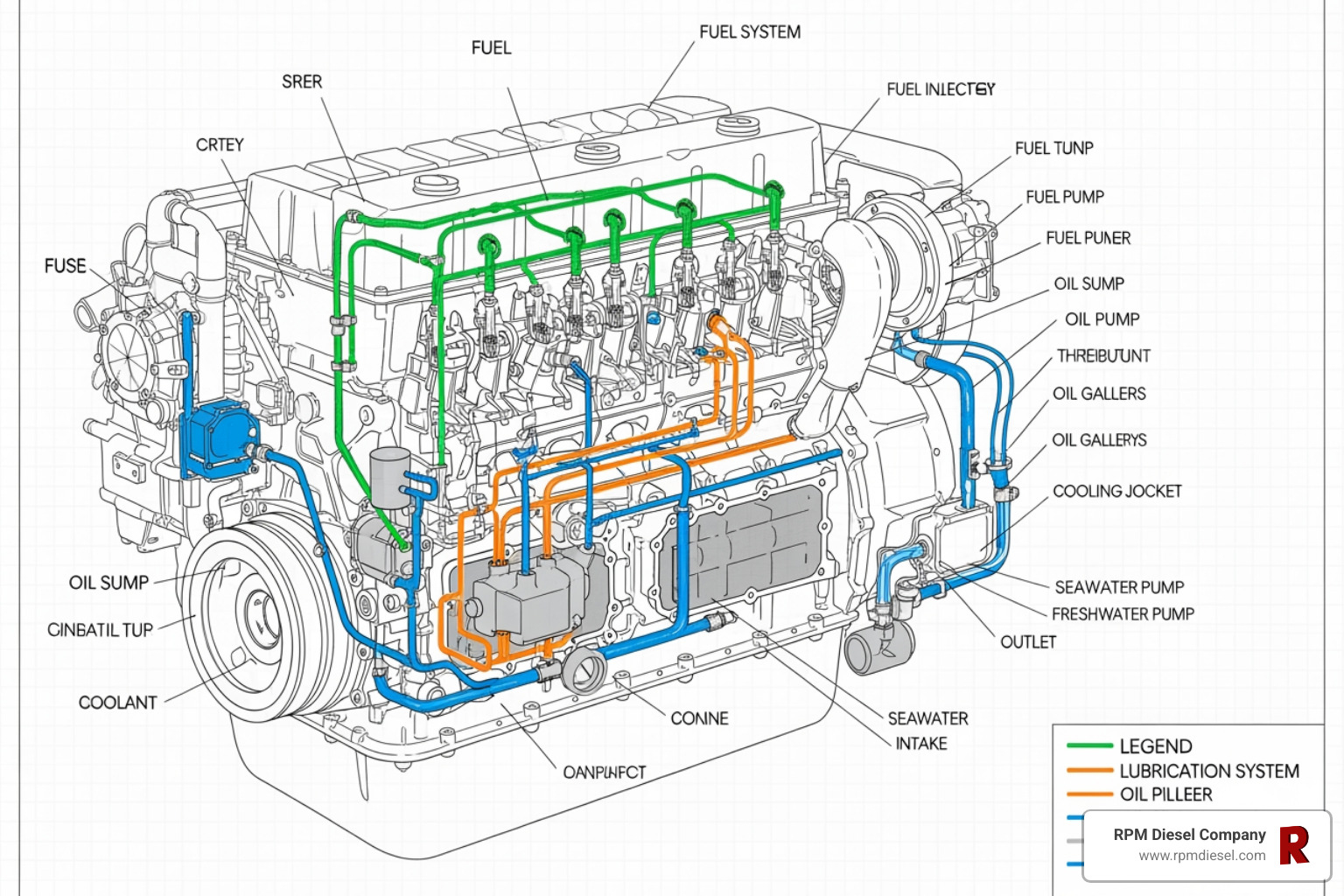

The Fuel System is where most problems start. It includes everything from your fuel tank through the fuel lines, lift pump, primary and secondary filters, the crucial fuel-water separator, and finally those precision injectors. Since contaminated fuel causes the majority of marine diesel failures, keeping this system clean is your top priority. For specialized service needs, professional marine diesel fuel injector service ensures these precision components perform flawlessly.

The Lubrication System is your engine’s lifeblood. The oil sump, oil pump, oil cooler, and oil filter work together to keep metal parts from grinding against each other, dissipate heat, and carry away contaminants. Without proper lubrication, your engine would seize in minutes.

The Cooling System is that dual-circuit setup we discussed earlier. It includes the raw water pump, sea strainer, heat exchanger, freshwater pump, coolant, hoses, and zinc anodes. Overheating is one of the fastest ways to destroy a marine diesel, so this system demands regular attention.

The Air Intake & Exhaust System lets your engine breathe. Your diesel needs clean air flowing through the air filter and intake manifold, often boosted by a turbocharger, then exhausting through the manifold, exhaust elbow, muffler, and exhaust hose. Restrictions in either direction spell trouble.

The Electrical System powers everything from starting to monitoring. The battery, starter, alternator, wiring, glow plugs, and various sensors all need to work reliably. Salt corrosion loves electrical connections, making regular inspection essential.

The Turbocharger on many modern marine diesels uses exhaust gases to force more air into the engine, dramatically increasing power and efficiency. These precision components demand clean oil and proper cool-down procedures after hard running. Neglect them, and you’re looking at a very expensive replacement.

The Ultimate Marine Diesel Engine Maintenance Checklist

Alright, fellow mariners! Now that we’ve chatted about the unique challenges our marine diesels face and the vital systems keeping them purring, it’s time for the nitty-gritty. This comprehensive diesel engine maintenance checklist isn’t just a list of chores; it’s your personal roadmap to peak performance and unwavering reliability. It’s how we ensure your vessel is always ready for the beautiful waters of Florida, from the busy canals of Fort Lauderdale to the vibrant shores of Miami.

Your Daily Pre-Departure Marine Diesel Engine Maintenance Checklist (The “WOBBLES” Check)

Before you even think about casting off those lines, we always recommend performing our quick and easy “WOBBLES” check. This simple routine, taking just a few minutes, is your very best defense against any unwelcome surprises out on the water. Think of it as giving your engine its morning coffee – a quick wake-up call to make sure everything’s perfectly in order.

First up is W – Water Check. You’ll want to take a peek at the coolant level in your freshwater expansion tank, making sure it’s snugly between the “min” and “max” marks. Don’t forget to inspect your raw water strainer – we want it sparkling clean and free of any unwanted guests. And here’s a little secret from us to you: always ensure all seacocks for the engine’s raw water intake are wide open! (We’ve all heard those unfortunate tales of melted impellers from a forgotten closed seacock!)

Next, we move to O – Oil Check. Grab that dipstick and check the engine oil level. It should be right within that sweet spot of the operating range. While you’re there, take a good look at the oil’s color and consistency. A little dark is normal for a diesel, but if it looks milky (hello, water contamination!) or feels gritty, that’s a definite red flag. A burnt smell? Also a sign to investigate.

Then it’s time for B – Belts Check. Give all your drive belts – like those for the alternator and raw water pump – a thorough inspection. Look for any tell-tale cracks, fraying, or glazing. You also want to check their tension; a properly tightened belt should only give about half an inch when you press it firmly.

Another important “B” is for Battery & Bilge Check. Quickly check your battery terminals for any corrosion and make sure all connections are nice and tight. Then, cast your eyes over the bilge for any unusual fluid. A tiny bit of water might be normal, but any fuel, oil, or coolant hanging out in the bilge needs your immediate attention.

Now, let’s talk L – Leaks Check. Give your entire engine a good visual scan for any tell-tale drips or puddles of fuel, oil, or coolant. Pay extra close attention to hose connections, around the oil pan, and along those fuel lines. Trust us, a small leak never gets smaller on its own!

Moving on to E – Exhaust Check. After you start your engine, make sure you see a steady, healthy stream of cooling water exiting with the exhaust. No water, or just a trickle, means you’ve got a problem with your raw water system. Also, take a moment to inspect the exhaust hose itself for any signs of it getting too soft or too hard, which can point to trouble inside.

Finally, the S – Sound Check. This one’s all about listening. As your engine idles, really tune in. Are there any new or unusual noises? A knock, a squeal, a grind, or a rattle can all be early whispers of a bigger issue. Your engine really does communicate through sound, and learning its language can save you a lot of headaches down the line.

Your Scheduled Marine Diesel Engine Maintenance Checklist: Monthly to Annually

Beyond those crucial daily WOBBLES, a more structured schedule for deeper maintenance is absolutely vital. We’ve combined the common intervals suggested by manufacturers with our own extensive experience to bring you a truly comprehensive plan. These are general guidelines. You should always, always consult your specific engine’s owner’s manual for its unique recommendations. And if your vessel is operating in really tough conditions or sees a lot of use, we often suggest shortening these intervals.

| Task Category | Monthly/100-Hour Tasks |

|---|---|

| Monthly/100-Hour Tasks | – Change engine oil & filter (every 100-200 hours or annually). – Inspect primary fuel filter for contamination and replace if needed. – Drain water from the fuel-water separator regularly (daily for some, or as needed). – Inspect and replace zinc anodes if they are 50% deteriorated (check every 2 weeks initially, then monthly). – Clean raw water sea strainer. – Test battery under load. |

| Annual/1000-Hour Tasks | – Replace raw water pump impeller (annually or every 250 hours, depending on manufacturer). – Replace all fuel filters (primary and secondary). – Thoroughly service the cooling system: flush heat exchanger, clean seawater passages with descaling solution (every 750-800 hours or couple of years), change coolant and check valve clearance (every 500 hours or 2 years). – Inspect turbocharger for unusual noises, oil leaks, and free movement of the wheel. – Inspect and service fuel injectors (around the 1,000-hour or 4-5 year mark). More info about marine diesel fuel injector service. – Inspect engine mounts for cracks or misalignment. – Check and adjust valve clearances as per manufacturer’s specifications. – Inspect exhaust elbow for rust, scaling, or blockage. – Inspect all hoses for bulges, softness, wear, or cracks. – Check all electrical connections for corrosion and tightness. |

Reading the Signs: Troubleshooting Common Marine Diesel Issues

Even if you follow your diesel engine maintenance checklist to the letter, sometimes things still go a little wonky. It’s just part of life on the water! But here’s the good news: your marine diesel engine is always trying to tell you something. It “talks” through sights, sounds, and even smells. Learning to understand these little messages is your secret weapon. It helps you catch small problems before they turn into big, scary ones, keeping you safe and far from a breakdown miles offshore. We often joke that “your nose knows best” when it comes to engine smells, and trust us, your ears are just as important!

Decoding Your Engine’s Exhaust Smoke

Think of your engine’s exhaust as a secret code. The color of the smoke it puts out can tell you a lot about what’s happening inside. Paying attention to these visual clues is super important, as ignoring them can lead to much bigger headaches down the road.

Let’s break down what each color might mean:

-

Black Smoke: If you see black smoke, it usually means your engine isn’t burning all its fuel properly. It’s getting too much fuel for the amount of air it has. This can happen if the engine is overloading (working too hard), if your air filter is clogged and choking the engine, if your fuel injectors are faulty and spraying fuel unevenly, or if there are turbocharger issues preventing enough air boost.

-

Blue Smoke: Ah, blue smoke! This is a classic sign that your engine is burning oil. It means oil is somehow getting into the combustion chamber – the spot where fuel and air mix and ignite – which definitely shouldn’t be happening. Most often, this points to worn piston rings or worn valve seals or valve guides, allowing oil to sneak past.

-

White Smoke: A little bit of white vapor when you first start up on a chilly morning is totally normal. But if that white smoke sticks around, or it’s heavy, that’s a serious warning sign. It could mean you have water in your fuel (a common issue from condensation in the tank), a coolant leak (perhaps a cracked head or a blown head gasket letting coolant into the engine), or even unburnt fuel due to injector timing problems, low compression, or a glow plug that’s not doing its job.

What Do These Sounds and Symptoms Mean?

It’s not just what you see; what you hear (and feel!) from your engine is just as important. Your marine diesel has a whole symphony of normal sounds. When something changes, it’s usually trying to tell you something important.

-

Engine Won’t Start or Won’t Even Crank: This is a classic frustration! Often, it’s an electrical issue, like a dead battery, corroded terminals, or a faulty starter. If the engine does crank but still won’t fire up, then we usually suspect a fuel system problem. This could be clogged filters, air in the fuel lines, contaminated fuel, or problems with the glow plugs, especially on those cooler Florida winter mornings.

-

Overheating: If that temperature gauge starts climbing, it’s an immediate emergency! An overheating engine can suffer severe damage very quickly. The usual suspects for this are a failed raw water pump impeller, a clogged sea strainer (blocking the raw water intake), low coolant levels, a blocked heat exchanger, or restricted seawater passages.

-

Sudden Loss of Power or Sluggish Performance: Does your engine feel like it’s lost its pep? If it’s suddenly feeling weak or sluggish, it might be a clogged fuel filter that’s starving the engine of fuel. Other culprits could be a turbocharger failure, an air intake restriction, or even dirty fuel injectors that aren’t delivering fuel efficiently.

-

Unusual Noises: Every engine has its own unique hum. When you hear something new or out of place, pay attention!

- A knocking sound can sometimes point to fuel system issues, like bad injectors, or it could be a warning sign of more serious internal problems such as worn bearings.

- A squealing noise is often the sound of loose or worn belts that need attention.

- A grinding sound might suggest issues with the starter, the water pump, or other rotating components that are struggling.

- And if you hear a rattling, it could be anything from loose components needing tightening to a sign of internal engine wear that requires expert eyes.

Frequently Asked Questions about Marine Diesel Maintenance

After years of working with boat owners throughout Florida—from Fort Lauderdale to Miami and beyond—we’ve heard just about every question imaginable about marine diesel maintenance. Here are the ones that come up most often, along with the honest answers we give our customers.

How often should I service my marine diesel engine?

The short answer? It depends on two things: what your manufacturer recommends and how hard you work your engine.

Your owner’s manual is the bible here. Manufacturers set service intervals based on extensive testing, and these guidelines are typically measured in operating hours or calendar time—whichever comes first. This matters because an engine sitting idle in the Florida heat can actually develop problems just as readily as one that’s running hard every weekend.

From our experience, a solid diesel engine maintenance checklist follows this rhythm: daily checks using our WOBBLES routine before every departure, monthly or 100-200 hour services covering oil changes and basic inspections, and annual or 500-1000 hour comprehensive services that dig deeper into your engine’s health.

But here’s the thing—Florida’s marine environment doesn’t play by average rules. If you’re running your boat hard, spending long hours at sea, or even leaving it sitting unused for months at a time, you’ll want to shorten those intervals. Harsh conditions demand more frequent attention. We’ve seen too many engines suffer because owners stuck rigidly to “normal” schedules when their conditions were anything but normal.

What are the most critical spare parts to have on board?

Nothing ruins a perfect day on the water faster than a breakdown that could’ve been fixed with a $20 part you don’t have. We always tell customers: the right spare parts aren’t an expense—they’re insurance.

The essentials you should keep aboard include primary and secondary fuel filters (because clean fuel is everything), a raw water pump impeller (these fail without warning), engine belts for both your alternator and raw water pump, at least one gallon of the correct marine-grade engine oil, spare zinc anodes (especially critical in saltwater), and an assortment of hose clamps in various sizes.

Beyond these basics, we recommend self-fusing silicone tape for emergency hose repairs—it’s saved more than a few trips—and a basic tool kit with wrenches, screwdrivers, pliers, and a filter wrench. Having these items means the difference between fixing a problem yourself in fifteen minutes or calling for a tow.

Can I perform all this maintenance myself?

This is probably the question we get asked most, and we appreciate that boat owners want to be self-sufficient. The honest answer is that some maintenance is absolutely DIY-friendly, while other tasks genuinely require professional expertise.

The daily and monthly checks we’ve covered—your WOBBLES routine, checking fluid levels, visual inspections, and even changing filters—these are tasks most boat owners can and should learn to handle themselves. They’re fundamental to understanding your engine’s personality and catching problems early. Plus, there’s real satisfaction in knowing your engine inside and out.

But when we get into annual service tasks like valve adjustments, compression testing, turbocharger inspections, and especially fuel injector servicing, you’re entering territory that requires specialized tools, diagnostic equipment, and years of experience. We’ve seen well-intentioned DIY attempts turn a simple adjustment into an expensive repair. Marine diesel fuel injector service, for instance, demands precision that’s measured in microns—there’s just no room for error.

That’s where our certified technicians at RPM Diesel Company come in. We specialize in marine diesel engines, we’re factory-authorized for major manufacturers, and we bring the expertise that gives you real peace of mind. Think of it this way: handle the routine maintenance yourself to stay connected with your engine, but call in the professionals when precision and specialized knowledge matter most.

Conclusion: Your Partner in Peak Performance and Reliability

So, there you have it – your ultimate diesel engine maintenance checklist. This isn’t just a list of chores; think of it as your secret weapon for worry-free days on the water. By staying on top of these proactive checks, truly understanding your engine’s marine-specific needs, and learning to “listen” to its little whispers, you’re not just preventing breakdowns. You’re investing in countless safe, reliable, and absolutely beautiful cruises through Florida’s stunning waters.

Of course, even with the best intentions and the most diligent checks, sometimes you need a helping hand. That’s exactly where RPM Diesel Company comes in. For those trickier diagnostics, the big repairs, or any factory-authorized service, our certified technicians are always here for you. We live and breathe marine diesel engines! We offer everything from sales to specialized service and maintenance, right there on-site, whether you’re in Fort Lauderdale, Miami, West Palm Beach, Boca Raton, Delray Beach, or anywhere across Broward and Dade Counties. Our team’s deep expertise, combined with our impressive stock of hard-to-find parts, means your vessel won’t just be repaired – it’ll be truly ready for anything the water throws at it.

Don’t let a small worry turn into a big headache. The best time to call in the pros is before a breakdown. Why not schedule your expert marine diesel fuel injector service today? Let us be your trusted partner in keeping your marine diesel engine purring at its absolute best. Smooth seas ahead!