Understanding the Powerhouse Behind Your Marine Diesel Engine

The diesel engine cylinder head is a critical component atop the engine block. It seals the combustion chambers and houses the valves, fuel injectors, and cooling passages essential for operation. As the control center for combustion, it coordinates air intake, fuel injection, and exhaust expulsion.

Key Components of a Diesel Engine Cylinder Head:

- Intake and exhaust valves

- Fuel injector bores

- Cooling passages

- Valve seats and guides

- Combustion chamber surface

For marine diesel engines, the cylinder head faces unique challenges like saltwater corrosion, sustained high loads, and fluctuating thermal stress. It must withstand extreme pressures (over 2,000 psi) and temperatures (over 500°F). A failure can lead to overheating, power loss, or complete engine shutdown. This guide covers everything from anatomy and maintenance to replacement options.

The Heart of Combustion: What is a Marine Diesel Engine Cylinder Head?

The diesel engine cylinder head is the precisely engineered component that makes combustion possible in a marine diesel engine. It completes the combustion chamber, turning fuel into the raw power that drives your vessel. It bolts to the engine block with a specialized gasket, creating an airtight seal that must withstand combustion pressures over 2,000 psi and temperatures above 500°F. A failed seal means lost compression, power, and efficiency.

But the cylinder head is more than a seal. It’s a complex casting with passages and ports that directly affect engine performance and fuel consumption.

Primary Functions in a Marine Environment

Marine engines run for hours under heavy loads, facing constant vibration and saltwater corrosion. At RPM Diesel Company, we see how demanding these conditions are. The cylinder head’s primary jobs include:

- Sealing combustion pressure: It contains the immense pressure of the power stroke, which is essential for diesel efficiency. A blown gasket or cracked head causes an immediate loss of power.

- Mounting the valve train and fuel injectors: It houses the intake/exhaust valves, springs, and rocker arms, along with the fuel injectors. The precise placement of injectors is critical for proper fuel atomization.

- Managing heat: An intricate network of coolant passages carries away intense heat from combustion chambers, valve seats, and injectors. This is vital in marine applications with sustained high RPMs.

- Lubricating moving parts: Oil passages deliver lubrication to valve stems, rocker arms, and camshafts to prevent wear and seizure.

- Withstanding thermal stress: The head must endure constant expansion and contraction from heating and cooling cycles without warping or cracking.

The Cylinder Head’s Role in the Combustion Process

The four-stroke diesel cycle depends entirely on the diesel engine cylinder head to orchestrate each phase:

- Air Intake: The intake valve opens, and air rushes into the combustion chamber through specially designed ports that create air swirl for better fuel mixing.

- Compression and Fuel Injection: With valves closed, the piston compresses the air, raising its temperature. The injector, mounted in the head, sprays fuel into the superheated air, causing ignition.

- Power: The combustion event drives the piston down, creating power.

- Exhaust: The exhaust valve opens, and the piston pushes spent gases out through the exhaust ports, clearing the chamber for the next cycle.

This mechanical ballet happens thousands of times per minute. Proper engineering and maintenance are key to keeping your marine diesel running strong.

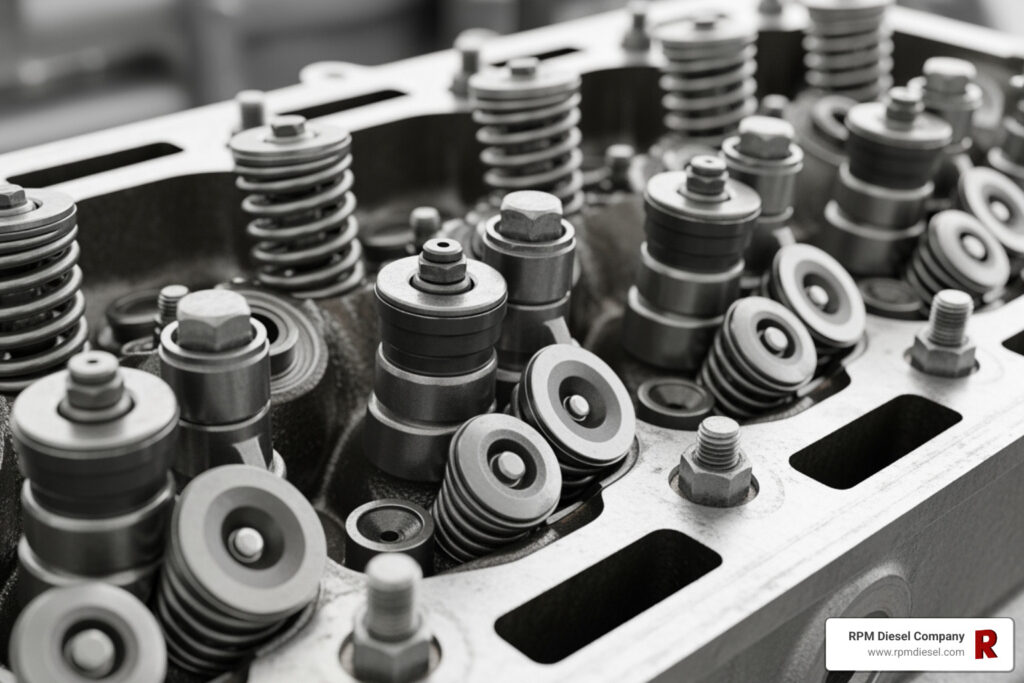

Anatomy of a Marine Cylinder Head

When you pop open a diesel engine cylinder head, you’re looking at one of the most intricately engineered components in your vessel. It’s packed with parts that must work together flawlessly for thousands of hours.

Key Components of a Diesel Engine Cylinder Head

At RPM Diesel Company, we’ve rebuilt and serviced enough marine cylinder heads to know each component intimately.

- Intake and exhaust valves: These are the engine’s lungs, made of heat-resistant alloys to control airflow.

- Valve seats and guides: Seats provide a seal for compression when valves are closed. Guides ensure valves move in a straight line; worn guides lead to poor sealing and oil consumption.

- Valve springs: These slam valves shut at high engine speeds. A broken spring means immediate trouble.

- Fuel injector bores/sleeves: These precisely machined holes hold the injectors. In many marine engines, removable sleeves protect the head from the heat and pressure of injection.

- Intake and exhaust ports: These are the highways for air and exhaust. Well-designed intake ports create air swirl for efficient combustion.

- Coolant passages: This internal maze carries coolant to prevent the head from overheating and cracking, a common problem when passages get clogged with scale or corrosion.

- Glow plug ports: Threaded holes for heating elements that aid starting in cold weather.

The Unsung Hero: The Cylinder Head Gasket

Here’s a truth from decades of marine diesel service: the cylinder head gasket is a thin, multi-layered seal between your diesel engine cylinder head and the engine block. It performs four critical jobs simultaneously:

- Seals combustion gases inside the cylinders.

- Prevents coolant from leaking externally or into the cylinders.

- Prevents oil from leaking or mixing with coolant.

- Maintains compression by ensuring a perfect seal.

A “blown head gasket” means one of these seals has failed, leading to power loss, overheating, and potentially catastrophic engine damage if oil and coolant mix. Modern marine diesels use Multi-Layer Steel (MLS) gaskets, which consist of multiple layers of spring steel to handle extreme temperatures and pressures. They offer superior durability for the harsh marine environment. Proper installation is just as critical as gasket quality; the head and block surfaces must be perfectly flat and clean, and bolts must be torqued to exact specifications.

Design, Materials, and Performance

The design and material of a diesel engine cylinder head directly affect your engine’s performance, longevity, and efficiency. These choices are critical in demanding marine conditions.

Common Materials and Their Marine Applications

The two primary materials for cylinder heads are cast iron and aluminum, each with distinct advantages.

Cast iron is the traditional choice for heavy-duty workhorses like Cummins, CAT, and Detroit Diesel engines. It is incredibly durable, handles high pressures and temperatures well, and resists warping. This makes it ideal for commercial vessels that operate under sustained loads. Its main drawback is its heavy weight.

Aluminum alloys are popular in high-performance and recreational vessels where weight is a concern. Aluminum is much lighter and dissipates heat far more quickly than cast iron, which can improve efficiency and prevent hot spots. However, it is more susceptible to warping from overheating and requires careful maintenance to prevent galvanic corrosion in saltwater environments.

Here’s a quick comparison:

| Feature | Cast Iron | Aluminum Alloy |

|---|---|---|

| Durability | Excellent, very strong | Good, but can be more prone to warp |

| Heat Dissipation | Slower, retains heat | Faster, excellent thermal conductivity |

| Weight | Very heavy | Lightweight |

| Corrosion | Good, but susceptible to rust | Good, but susceptible to galvanic corrosion |

| Marine Use | Heavy-duty, high endurance | Performance, weight-sensitive applications |

How Design Impacts Power and Efficiency

The internal architecture of the cylinder head is key to engine performance.

- Single vs. multi-head designs: Some engines use one long head for all cylinders (e.g., Caterpillar 3406E), offering rigidity but making repairs difficult. Others use individual heads (e.g., Cummins N14), which are easier and cheaper to service.

- Port design and airflow: The shape and size of intake and exhaust ports determine how easily the engine breathes. Good port design creates swirl and tumble—air movements that mix air and fuel thoroughly for more complete combustion, leading to better power, fuel economy, and lower emissions.

- Combustion chamber shape: The shape of the chamber, formed by the head and piston, has a massive impact on combustion efficiency.

- Crossflow vs. reverse-flow design: In a crossflow head, intake and exhaust are on opposite sides, creating an efficient path for air. This is common in modern engines. Reverse-flow heads have both on the same side, which can be less efficient.

These elements combined define an engine’s power, efficiency, and reliability.

Health and Longevity: Maintenance and Common Failures

Even the toughest diesel engine cylinder head is vulnerable in the harsh marine environment. Fortunately, most problems provide warning signs before becoming catastrophic failures. Catching issues early is the key to avoiding major overhauls.

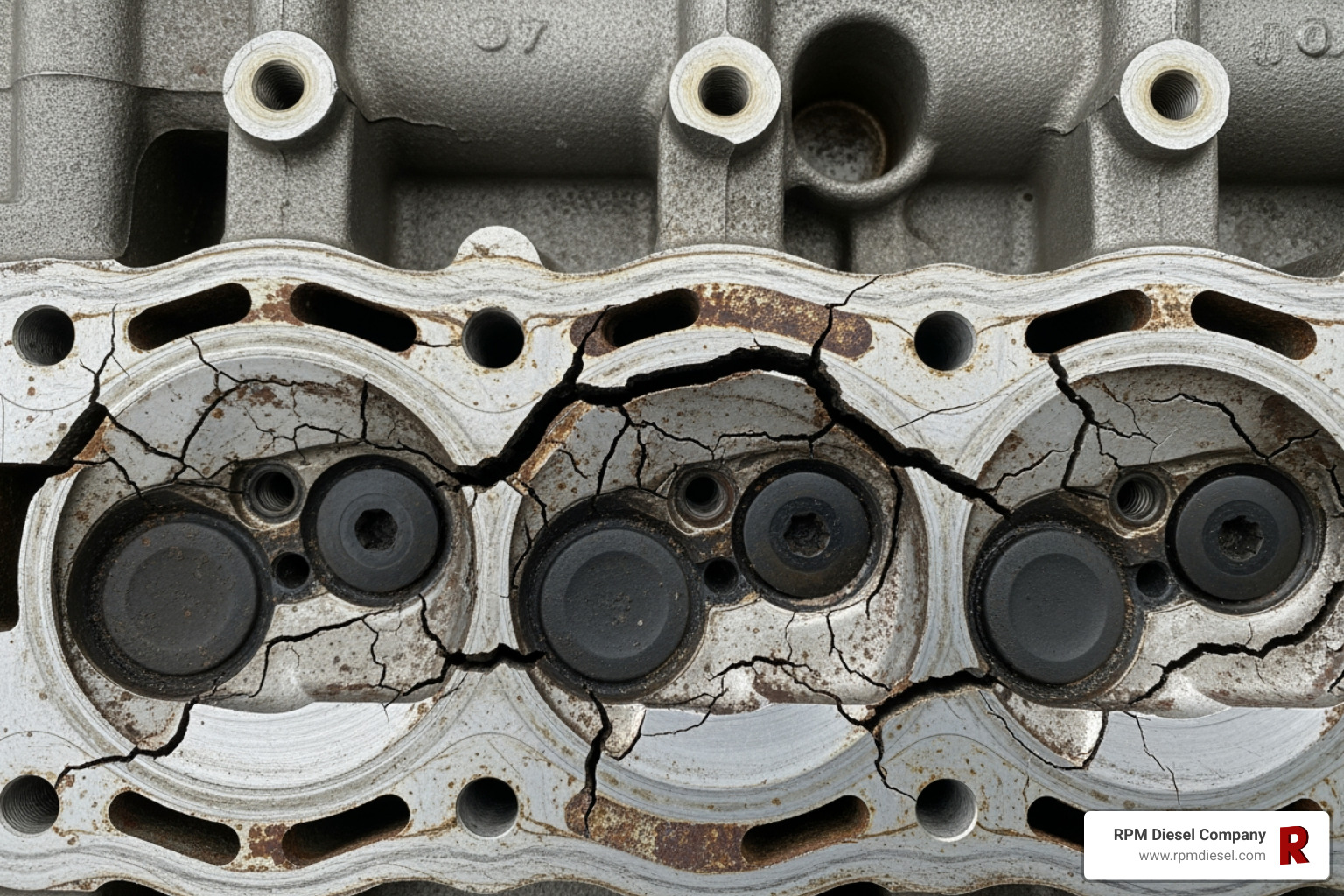

Signs and Causes of Cylinder Head Damage

Your engine will tell you when something is wrong. Common signs of a failing diesel engine cylinder head or gasket include:

- Overheating: This is the #1 cause and symptom of head failure. It can lead to warping and cracking.

- White smoke from exhaust: This is typically steam, indicating coolant is leaking into the combustion chamber.

- Milky, discolored oil: A sign that coolant and oil are mixing, which can destroy an engine.

- Loss of power or misfiring: Caused by a loss of compression from a cracked head, bad valve seal, or blown gasket.

- External coolant or oil leaks: Visible weeping from the seam between the head and block.

The primary causes of this damage are:

- Thermal shock: Rapid temperature changes, like adding cold water to an overheated engine, can crack the metal.

- Improper torque: Failing to tighten head bolts to the manufacturer’s exact specifications and sequence will cause gasket failure.

- Corrosion: Saltwater and neglected coolant can eat away at metal and clog cooling passages, leading to hot spots and cracks.

- Poor fuel quality: Incomplete combustion can create carbon deposits and hot spots, stressing the head.

Best Practices for Maintaining Your Diesel Engine Cylinder Head

Proactive maintenance is the best way to ensure longevity.

- Maintain your cooling system: Flush the system and replace coolant per your manual’s schedule (typically every 2 years/2,000 hours). Always use a quality marine-grade coolant with corrosion inhibitors.

- Watch your temperature gauge: If the engine starts to overheat, shut it down and investigate immediately. Don’t try to “nurse it” back to the dock.

- Allow for warm-up and cool-down: Let the engine idle for a few minutes after starting and before shutting down to prevent thermal shock.

- Use proper torque specifications: If the head is ever removed, ensure bolts are torqued correctly. Many bolts are single-use and must be replaced.

- Perform regular compression tests: An annual test can detect developing issues with seals, valves, or gaskets before they become major problems.

- Check for leaks: During regular engine checks, look for any signs of weeping coolant or oil.

For all your boat diesel engine repair needs, our team has the experience to keep your vessel running reliably.

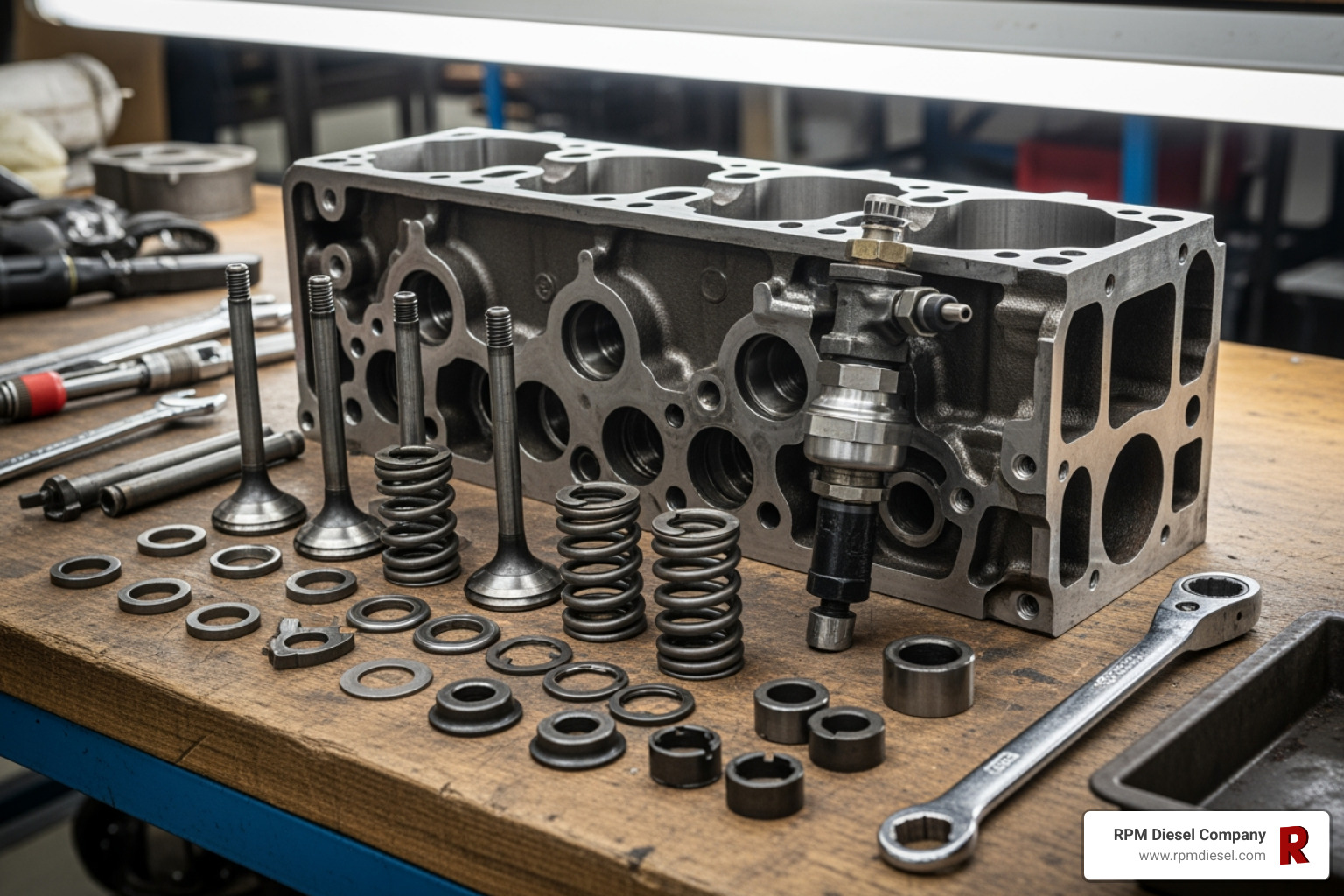

Replacement and Upgrades: Making the Right Choice

When your diesel engine cylinder head fails, you must decide whether to repair or replace it. The choice depends on the extent of the damage, cost, downtime, and desired reliability. Minor warping may be fixable with resurfacing, but significant cracks, severe corrosion, or multiple points of failure usually demand replacement.

A cheap repair that fails later can cost more in downtime and secondary damage than a proper replacement. For commercial vessels, getting back on the water quickly is paramount. At RPM Diesel Company, we can assess your cylinder head and help you make an informed decision that balances cost, performance, and long-term reliability.

OEM, Remanufactured, and Aftermarket Heads

If you choose replacement, you have three main options:

-

OEM (Original Equipment Manufacturer) Heads: These are brand-new heads from your engine’s manufacturer (e.g., Cummins, CAT, Detroit Diesel). They guarantee a perfect fit and meet original design specifications. While they are the most expensive option, they offer the highest level of reliability and come with a manufacturer’s warranty, making them the best choice for critical marine applications where failure is not an option.

-

Remanufactured Heads: These are used heads that have been completely rebuilt to OEM specifications. A reputable remanufacturer will inspect, machine, and assemble the head with new components like valves, springs, and guides. They offer a great balance of quality and cost, often saving 30-50% compared to OEM, and usually come with a solid warranty. This is an excellent value proposition for many boat owners.

-

Aftermarket Heads: These are new heads made by third-party companies. Quality can vary widely. Some offer performance upgrades like improved port designs, while others are simply low-cost replacements. For marine use, it’s crucial to choose a high-quality aftermarket brand, as parts designed for trucks may not withstand the sustained loads of a marine engine. We can help you steer these options to ensure you get a reliable part that’s suitable for the marine environment.

Your choice depends on your engine, budget, and how you use your vessel. We can help you find the right balance of quality and cost for your specific situation.

Conclusion

Your diesel engine cylinder head is the mastermind of your engine, orchestrating the combustion process that powers your vessel. It seals extreme pressures, manages intense heat, and houses critical components. A healthy cylinder head is essential for reliability at sea, preventing you from being left dead in the water.

We’ve covered the anatomy, materials, and common failure modes of marine cylinder heads. The key takeaway is that proper maintenance—especially of the cooling system—is your best defense against costly failures. In the harsh marine environment, a well-maintained diesel engine cylinder head is your ticket to safe, efficient, and reliable operation.

At RPM Diesel Company, we have decades of experience servicing marine diesel engines for vessels across South Florida and beyond. Our technicians understand these engines inside and out, from compression testing to precise torque specifications.

Don’t wait for a catastrophic failure. If you notice warning signs like overheating, power loss, or leaks, let our experienced team take a look. We’re here to keep your marine diesel running strong.