The Heart of Your Marine Diesel: Understanding 7.3L Injector Technology

2000 7.3 powerstroke injectors are the critical fuel delivery components in one of the most reliable marine diesel engines ever built—the International T444E, commonly known as the 7.3L Power Stroke. If you’re shopping for injectors for your marine vessel, here’s what you need to know:

Quick Injector Reference for 2000 7.3L Engines:

- Stock Replacement (AD/AE): $355-$560 CAD per injector | OEM-spec performance | Best for reliability

- Remanufactured Sets: $1,820 CAD (8 injectors) | Cost-effective | Extensive testing included

- Performance Upgrades: $1,360-$2,212 USD | 15-100% power increase | Requires custom tuning

Key Specifications:

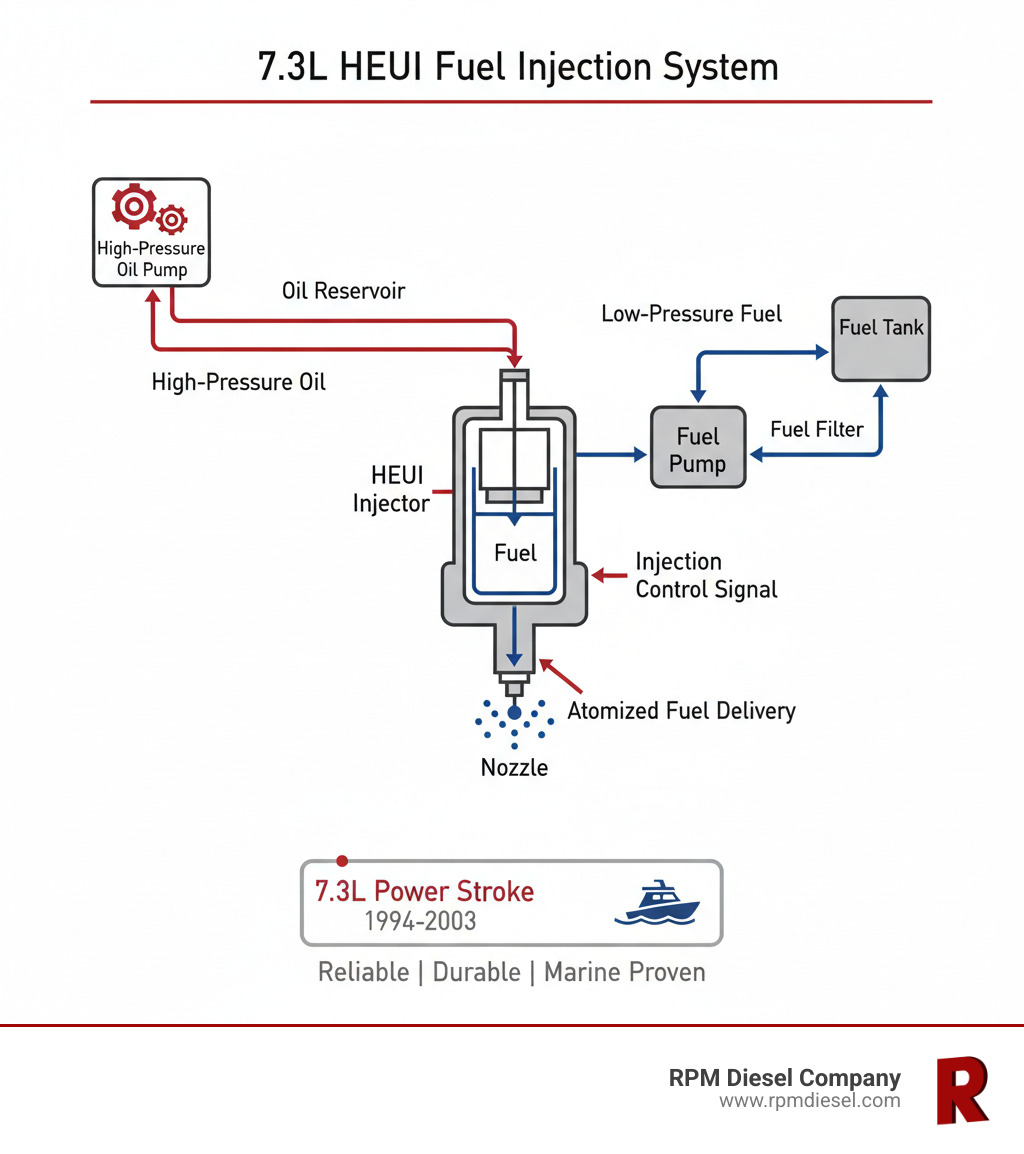

- Injection Type: HEUI (Hydraulic Electronic Unit Injection)

- Injector Codes: AD (cylinders 1-7), AE (cylinder #8 long lead)

- Common Issues: Hard cold starts, rough idle, white smoke, loss of power

The 7.3L engine earned its legendary status through a simple but effective HEUI fuel injection system that uses high-pressure engine oil to activate fuel delivery. Unlike modern common rail systems, this design is remarkably durable and serviceable—making it ideal for marine applications where reliability matters most.

Your injectors directly control combustion quality, fuel efficiency, and engine longevity. Whether you’re experiencing cold-start problems, noticing decreased power, or simply maintaining a high-mileage engine, understanding your injector options is essential for keeping your vessel running smoothly.

The beauty of the 7.3L platform is its simplicity. With proper maintenance and quality injectors, these engines routinely exceed 300,000 miles of service. One marine diesel owner reported their engine “runs great when warm” but struggled with cold starts at 295,500 miles—a classic sign of worn injectors that’s easily addressed with the right replacement.

Is Your Engine Showing These Signs? Symptoms of Failing 7.3L Injectors

Your marine diesel has been dependable for years, powering through countless hours on the water. But lately, something feels off. Maybe it’s taking longer to start on those cooler mornings, or you’ve noticed a puff of white smoke where there wasn’t one before.

These aren’t just quirks—they’re your engine’s way of telling you the 2000 7.3 powerstroke injectors need attention. The good news? These symptoms are predictable, and catching them early means you can address the problem before it becomes a bigger headache.

Hard starting in cold weather is often the first red flag. Your engine cranks and cranks, maybe fires briefly then dies, and takes several attempts before it finally catches and runs. This happens because worn injectors can’t atomize fuel properly when temperatures drop. The fuel spray pattern becomes uneven, making combustion difficult until everything warms up.

Once your engine does start, you might notice a rough idle or pronounced “lope” at startup. One or more cylinders aren’t getting the fuel they need, creating an unbalanced combustion process. The engine might smooth out after warming up, but that underlying imbalance is still there, working against you.

Loss of power sneaks up gradually. Your vessel doesn’t quite reach the RPMs it used to. Acceleration feels sluggish. What once felt effortless now requires more throttle to maintain cruising speed. When injectors wear internally, they simply can’t deliver fuel with the precision your engine needs for peak performance.

Have you been burning through more fuel than normal? Failing injectors often drip or spray inefficiently, wasting diesel that should be powering your vessel. It’s not just hitting your wallet—it’s a clear sign your engine isn’t operating at its designed efficiency.

White or blue smoke from your exhaust tells an important story. White smoke, especially during cold starts, means unburnt diesel fuel. Worn injector tips can’t create the fine fuel mist needed for complete combustion, so larger droplets pass through partially burned. As one diesel expert explained, “when this happens, the atomization is unequal between the partner holes in the injector tip causing additional smoke emissions and accelerated wear in the cylinders.” Blue smoke can indicate overfueling or mistimed injection—both injector-related issues.

Listen closely for an unusual engine “cackle” or excessive knocking noise. While the 7.3L has its characteristic diesel clatter, a harsh metallic knocking or louder-than-normal cackle often points to uneven fuel delivery creating rough combustion events.

Finally, if you’re conducting regular oil analysis (and you should be), watch for fuel dilution in your engine oil. This indicates fuel is leaking past injector seals into the oil system—a serious problem that compromises lubrication and accelerates engine wear.

We’ve worked on marine engines pushing 300,000 miles that ran beautifully once warm but struggled terribly with cold starting, rough idle, and white smoke. These classic symptoms of worn injectors are your cue that it’s time for replacement. Address them promptly, and your marine diesel will continue delivering the reliable performance you count on.

Choosing Your Upgrade: Stock, Remanufactured, and Performance Injectors

When it’s time to replace or upgrade your 2000 7.3 powerstroke injectors, you’re faced with a decision that will directly impact your marine engine’s reliability, performance, and your budget. The good news? Each option has real merit, and the right choice depends on how you use your vessel.

The 7.3L Power Stroke’s HEUI (Hydraulic Electronic Unit Injection) system is beautifully simple compared to modern common rail designs, but that simplicity doesn’t mean you should settle for just any injector. Quality matters—especially in marine environments where your engine faces constant challenges from moisture, vibration, and heavy loads.

Let’s break down your three main paths forward:

| Injector Type | Cost (Approx.) | Performance (vs. Stock) | Longevity (Expected) | Best For |

|---|---|---|---|---|

| Stock | $355-$560 CAD per injector | OEM-spec | Excellent | Standard marine operations, maximum reliability, maintaining factory specs |

| Remanufactured | $1,820 CAD for a set of 8 (includes core) | OEM-spec | Very Good | Budget-conscious replacement, strong reliability, environmentally friendly |

| Performance | $1,360-$2,212 USD for a set of 8 (requires chip) | 15-100% power increase | Good to Excellent | Heavy-duty marine use, increased propulsion, faster cruising, custom builds |

Stock Replacement Injectors

For most marine owners, stock replacement injectors are the smart, straightforward choice. These are built to meet or exceed OEM specifications—meaning they deliver exactly what International designed the 7.3L Power Stroke to do.

OEM-spec performance isn’t about settling for “good enough.” It’s about maintaining the precise fuel quantity and spray pattern that your engine was engineered around. This ensures optimal combustion, consistent fuel efficiency, and the reliable operation that marine applications demand.

The real beauty of stock injectors is their proven reliability. In a marine environment where an unexpected breakdown can leave you stranded miles from shore, dependability isn’t a luxury—it’s essential. These injectors provide factory function with seamless integration into your existing systems, no surprises, no complications.

Yes, they’re a cost-effective replacement when you consider the long-term picture. You’re investing in your engine’s continued health, not just patching a problem. For vessels running standard operations without special power demands, stock injectors deliver exactly what you need.

Remanufactured Injectors

If you’re budget-conscious but refuse to compromise on quality, remanufactured 2000 7.3 powerstroke injectors deserve your serious consideration. And let’s be clear—these aren’t just “repaired” injectors with a fresh coat of paint. Quality remanufacturing is a comprehensive process that brings injectors back to OEM specifications.

Here’s how it works: You’ll typically pay a core charge upfront, which gets refunded when you return your old, rebuildable injectors. This makes the process more affordable while reducing waste—a win for your wallet and the environment.

Reputable remanufacturers put every injector through extensive testing, including flow testing and spray pattern verification. They’re not guessing whether an injector works; they’re proving it meets OEM standards before it ships.

During remanufacturing, all critical wear parts get replaced—nozzles, plungers, springs, and seals. You’re essentially getting a renewed injector with fresh components where it matters most. This extends the lifespan and restores performance to like-new levels.

The budget-friendly aspect is hard to ignore. You’re saving significantly compared to brand-new units without sacrificing reliability or performance. For many marine engines, especially those with higher mileage, this represents outstanding value.

There’s also something satisfying about choosing the environmentally responsible option. Remanufacturing conserves resources and keeps perfectly good injector bodies out of landfills. If you want to connect with other diesel enthusiasts about their experiences with different injector options, communities like The Diesel Stop offer valuable real-world insights.

Performance Injectors

Now we’re talking about waking up your 7.3L Power Stroke. Performance injectors are for marine owners who need more from their engines—whether that’s pushing heavier loads, achieving faster cruising speeds, or simply wanting the extra power available when conditions demand it.

These injectors deliver increased horsepower and torque through higher flow rates (measured in cubic centimeters) and often feature larger nozzles—anywhere from 15% to 100% over stock. That translates directly to more fuel per injection cycle, which means more power at the propeller.

For marine applications, this extra power isn’t just about bragging rights. It’s about better acceleration when you need to steer challenging waters, increased load-carrying capability for those longer trips with full tanks and supplies, and the ability to maintain higher speeds more efficiently. When you’re fighting current or wind, that additional torque becomes genuinely valuable.

But here’s the critical part: performance injectors absolutely require custom tuning. You can’t just bolt in high-flow injectors and call it done. A programmable chip—like a Hydra chip—is essential to optimize fuel delivery, injection timing, and other parameters to match your new injectors. The Hydra, for instance, can store up to 15 custom programs and allows you to load new tunes via USB connection, giving you incredible flexibility.

Performance injectors come in various stages based on flow rates and nozzle sizes. You might choose a mild 15% increase for slightly better response, or go aggressive with 250cc injectors and 100% nozzles for serious power gains. We can help you match the right stage to your specific goals and how you actually use your vessel.

There’s also the question of single shot versus split shot design. Most stock 7.3L injectors use split shot technology—a small pilot injection before the main event—for quieter operation. Many performance injectors switch to single shot, which typically offers more power potential but produces a slightly louder, more aggressive engine note. It’s not objectionable, just more pronounced.

The investment in performance injectors makes sense when you genuinely need the capability they provide. Combined with proper tuning, they transform how your marine diesel performs under demanding conditions.

Key Considerations for 2000 7.3 Powerstroke Injectors

Understanding how your 2000 7.3 powerstroke injectors work within the HEUI system isn’t just technical knowledge—it’s the key to keeping your marine diesel running reliably for years to come. When you know what makes these injectors tick, you can make smarter decisions about maintenance, replacement, and troubleshooting those frustrating cold-start issues.

The 7.3L Power Stroke’s Hydraulic Electronic Unit Injection (HEUI) system is brilliantly simple in concept but requires attention to detail in practice. Unlike conventional fuel injectors that rely solely on fuel pressure, HEUI injectors use high-pressure engine oil—supplied by your high-pressure oil pump (HPOP)—to intensify and inject fuel directly into the cylinders. Think of it as using one fluid to power another, which is why the condition of your engine oil is just as critical as the quality of your fuel.

This unique design means you need to be vigilant about oil quality. Clean, high-quality engine oil isn’t optional—it’s essential for proper injector function. The 7.3L engine comes equipped with a high-capacity oil cooler and advanced fuel filtration system, both designed to protect your injectors and extend engine life. Regular oil changes aren’t just good practice; they’re the lifeline of your HEUI system.

When shopping for replacement injectors, you’ll encounter two main injector codes for the 1999.5-2003 7.3L engines, including your 2000 model. AD injectors are the standard injectors used in cylinders 1 through 7. AE injectors are “long lead” injectors specifically designed for cylinder #8. That longer lead wire allows for slightly different timing to compensate for the #8 cylinder’s position and exhaust gas temperatures, helping to reduce engine noise and emissions.

Here’s a question we hear often: Can a 7.3 Power Stroke run on a mix of AD and AE injectors? Absolutely. In fact, most late 1999-2003 7.3L marine engines originally came with seven AD injectors and one AE (long lead #8) injector from the factory. While some owners choose to run all eight AD injectors, this might increase engine “cackle” without specific tuning adjustments. We recommend sticking with the factory configuration—seven AD and one AE—for optimal balance in stock or mildly modified setups.

Oil viscosity also plays a bigger role than many marine owners realize, especially if you’re operating in cooler waters. While 15W-40 is a common choice, 5W-40 synthetic oil offers better cold-weather flow characteristics. That improved flow can make a noticeable difference in cold starts and reduce wear during initial engine operation when thick, cold oil would otherwise slow everything down.

How Injector Condition Affects Cold Starting

Few things are more frustrating than turning the key on a cool morning and hearing your marine diesel crank endlessly without catching. With 2000 7.3 powerstroke injectors, their condition directly impacts cold start performance, often creating that dreaded rough idle and white smoke that lingers until the engine finally warms up.

The culprit is usually worn injector internals. Over time, the armature and nozzle inside your injectors experience normal wear, which leads to increased clearances between moving parts. When your engine oil is cold and thick, these worn components create what we call a “suction cup effect.” The cold, viscous oil actually hinders the rapid movement of the injector’s internal components, preventing them from firing properly or consistently. The result? Misfires, poor fuel atomization, and that telltale white smoke.

Your glow plug system is the unsung hero of cold starting in marine diesel engines. Glow plugs heat the combustion chambers, making it easier for atomized fuel to ignite. If your glow plugs or their relay are faulty, they won’t provide adequate heat, which makes it exponentially harder for worn injectors to do their job. We’ve seen marine engines with 300,000 miles that wouldn’t start without an auxiliary heater get completely resolved simply by replacing faulty glow plugs.

The glow plug relay deserves special mention because it’s often overlooked. A relay can sometimes test fine with a multimeter but still fail to deliver sufficient amperage to the glow plugs, rendering them completely ineffective. Before you condemn your injectors, make sure you’ve thoroughly tested the entire glow plug system—it might save you a significant expense.

Using an auxiliary heater can be a game-changer for cold starting. By pre-heating your engine, you warm the oil and reduce its viscosity, making it much easier for even slightly worn injectors to operate effectively. If your engine starts easily with the heater on but struggles without it, that’s a strong indication you’re dealing with either worn injectors or glow plug issues—and now you know which to check first.

Installation Best Practices for 2000 7.3 Powerstroke Injectors

Proper installation of your 2000 7.3 powerstroke injectors is just as important as choosing quality replacements in the first place. We’ve seen expensive injectors fail prematurely simply because installation shortcuts were taken. In marine applications where reliability isn’t just convenient—it’s essential—following best practices isn’t optional.

Before you install new injectors, always inspect the bottom of the injector cups in your cylinder head for cracks. While you’re there, check carefully to ensure the old copper crush washer from the previous injector wasn’t left behind. Any debris or damage here will cause leaks and improper sealing, which can lead to immediate problems or long-term damage.

When seating your injectors, use a gentle but firm approach. Lightly tap them into place until they’re fully seated—don’t rely on the hold-down bolts to pull the injectors into position. That’s a recipe for damage or improper sealing that will haunt you later.

Diesel fuel systems are incredibly sensitive to contamination. Keep your new injectors sealed in their packaging until you’re ready to install them. If possible, perform the installation in a clean, indoor environment where wind-blown dust or debris can’t enter the system. Even 10 microns of contamination—that’s smaller than you can see with the naked eye—can damage an injector and compromise its spray pattern.

After installation, bleeding air from the system is absolutely critical. Air in the fuel system can lead to cavitation, where air bubbles collapse under pressure and literally erode your injector nozzles and spray patterns. Whatever you do, don’t rev the engine immediately to purge air quickly—that’s a common mistake that can cause serious damage.

Instead, allow your engine to idle for a minimum of 45 minutes after installation. This gives the fuel system time to slowly purge air naturally. Following this initial idle period, operate your vessel for about 50 miles or equivalent engine hours to dissipate any remaining air bubbles and ensure the injectors are fully primed and functioning optimally. Listen for any engine hiccups during this initial run-in period, which might indicate lingering air that needs more time to work its way out.

Maximizing Injector Lifespan: Essential Maintenance for HEUI Systems

Your 2000 7.3 powerstroke injectors represent a significant investment in your marine vessel’s heart. The good news? With proper care and attention, these robust components can deliver reliable service for hundreds of thousands of miles. The HEUI system’s unique design—using high-pressure engine oil to actuate fuel delivery—means that maintenance isn’t just important; it’s absolutely critical.

We’ve seen marine engines with well-maintained injectors run smoothly past the 300,000-mile mark, while neglected systems fail much earlier. The difference? Consistent, thoughtful maintenance practices that address both fuel and oil quality.

Fuel quality and filtration form your first line of defense. The precision components inside your injectors simply cannot tolerate contamination. Water, debris, and poor-quality diesel fuel will rapidly degrade even the finest injectors. Always source high-quality diesel fuel from reputable marine suppliers, and treat your vessel’s fuel filtration system as a vital piece of equipment. Your fuel-water separator isn’t just another filter—it’s protecting thousands of dollars worth of injectors from moisture damage. Replace your fuel filters according to your engine’s service schedule, and don’t wait for performance issues to appear before changing them.

We strongly recommend incorporating quality fuel additives into your regular maintenance routine. Modern diesel fuel, especially ultra-low sulfur diesel, lacks the natural lubricity that older formulations provided. Quality additives restore this lubrication while providing cleaning agents that prevent “tip coking”—the carbon buildup on injector nozzles that ruins spray patterns and fuel atomization. Think of it as insurance for your injectors. The small cost of additives pays enormous dividends in extended injector life and maintained performance.

Engine oil quality and regular oil changes deserve equal attention. Your HEUI system uses engine oil under extreme pressure to actuate the injectors. Contaminated, degraded, or wrong-specification oil directly impacts how well your injectors function. Follow the manufacturer’s recommended oil change intervals religiously—in marine applications, this is even more critical than in automotive use. Always use the specified grade and quality of engine oil. The 7.3L engine is equipped with a high-capacity oil cooler precisely because oil quality matters so much to this system.

Regular oil analysis provides an early warning system for injector problems. Fuel dilution in your engine oil—detectable through lab analysis—signals that injectors are leaking internally. Catching this early prevents catastrophic damage and allows for planned maintenance rather than emergency repairs at sea.

Periodic service intervals are essential for marine diesel engines. For turbocharged propulsion diesels like your 7.3L, we recommend injector service every 1000 hours of operation or every two years, whichever comes first. This interval ensures that all eight injectors continue working correctly and delivering equal power to each cylinder. A single malfunctioning injector can cause uneven combustion that damages cylinder walls and pistons over time. As we tell our customers, the fuel system on your marine diesel engine needs periodic attention—it’s not optional maintenance.

Advanced fuel filtration systems represent an excellent investment for serious marine operators. These systems provide multiple stages of filtration and water separation, catching contaminants as small as 10 microns before they reach your injectors. Given that even microscopic particles can damage injector components, this level of protection makes sense for vessels operating in demanding conditions or covering long distances.

Top 3 Maintenance Tips for HEUI Injectors:

- Prioritize Clean Fuel: Use premium marine diesel from trusted suppliers and replace your fuel filters and fuel-water separator according to your engine’s service schedule—not when you remember.

- Maintain Pristine Oil: Use only manufacturer-recommended engine oil and change it diligently. Consider regular oil analysis to monitor for fuel dilution and other warning signs.

- Use Quality Fuel Additives: Incorporate additives with lubricity improvers and cleaning agents to protect nozzles and prevent carbon deposits that compromise performance.

At RPM Diesel Company, we’ve serviced countless marine 7.3L engines around the world. The vessels that run longest and strongest share one common trait: owners who treat maintenance as an investment rather than an expense. Your injectors will reward diligent care with years of reliable service, smooth operation, and the peace of mind that comes from knowing your vessel’s engine is ready for whatever voyage lies ahead.

Conclusion: The Heart of Your Diesel’s Performance

Your 2000 7.3 powerstroke injectors aren’t just components—they’re the beating heart of your marine diesel engine. Every smooth cold start on a cool morning, every reliable hour at cruising speed, every pound of thrust when you need it most—it all comes down to these precision-engineered fuel delivery systems doing their job flawlessly.

Throughout this guide, we’ve walked through the warning signs that tell you when your injectors need attention: the frustrating hard starts, the telltale white smoke, the rough idle that smooths out only after warm-up, and that gradual loss of power you’ve been noticing. These symptoms aren’t just annoyances—they’re your engine’s way of asking for help.

We’ve also explored your options when replacement time comes. Whether you choose stock injectors for rock-solid reliability, remanufactured units for budget-conscious quality, or performance upgrades for increased power, each path has its place depending on how you use your vessel and what you need from your engine.

Understanding the HEUI system’s unique design—how it relies on high-pressure oil to activate fuel delivery—changes how you think about maintenance. It’s why we emphasize clean oil as much as clean fuel. It’s why those injector codes (AD for most cylinders, AE for that long-lead #8) matter more than you might think. And it’s why proper installation, from checking those injector cups to patiently bleeding air from the system, makes the difference between years of trouble-free operation and ongoing headaches.

The 7.3L Power Stroke earned its legendary reputation through straightforward engineering and bulletproof reliability. With quality 2000 7.3 powerstroke injectors and consistent maintenance—clean fuel, regular oil changes, and quality additives—your marine diesel will continue delivering the dependable performance that makes these engines so respected in the marine world.

At RPM Diesel Company, we’ve built our reputation on understanding marine diesel engines inside and out. We know these injectors aren’t just parts on a shelf—they’re critical to your vessel’s operation, your confidence on the water, and your ability to complete every voyage successfully. Our worldwide on-site service and extensive inventory of hard-to-find parts mean you’re never left stranded.

When you’re ready to give your marine diesel the expert care it deserves, we’re here with the knowledge, parts, and service your engine needs.