Why Marine Diesel Engine Starting Problems Demand Immediate Attention

Diesel engine starting problems can quickly ruin a day on the water or leave you stranded. Marine diesels face unique challenges like saltwater corrosion and constant vibration, making reliability paramount. When things go wrong, there’s no roadside assistance.

Quick Answer: Common Causes & First Checks

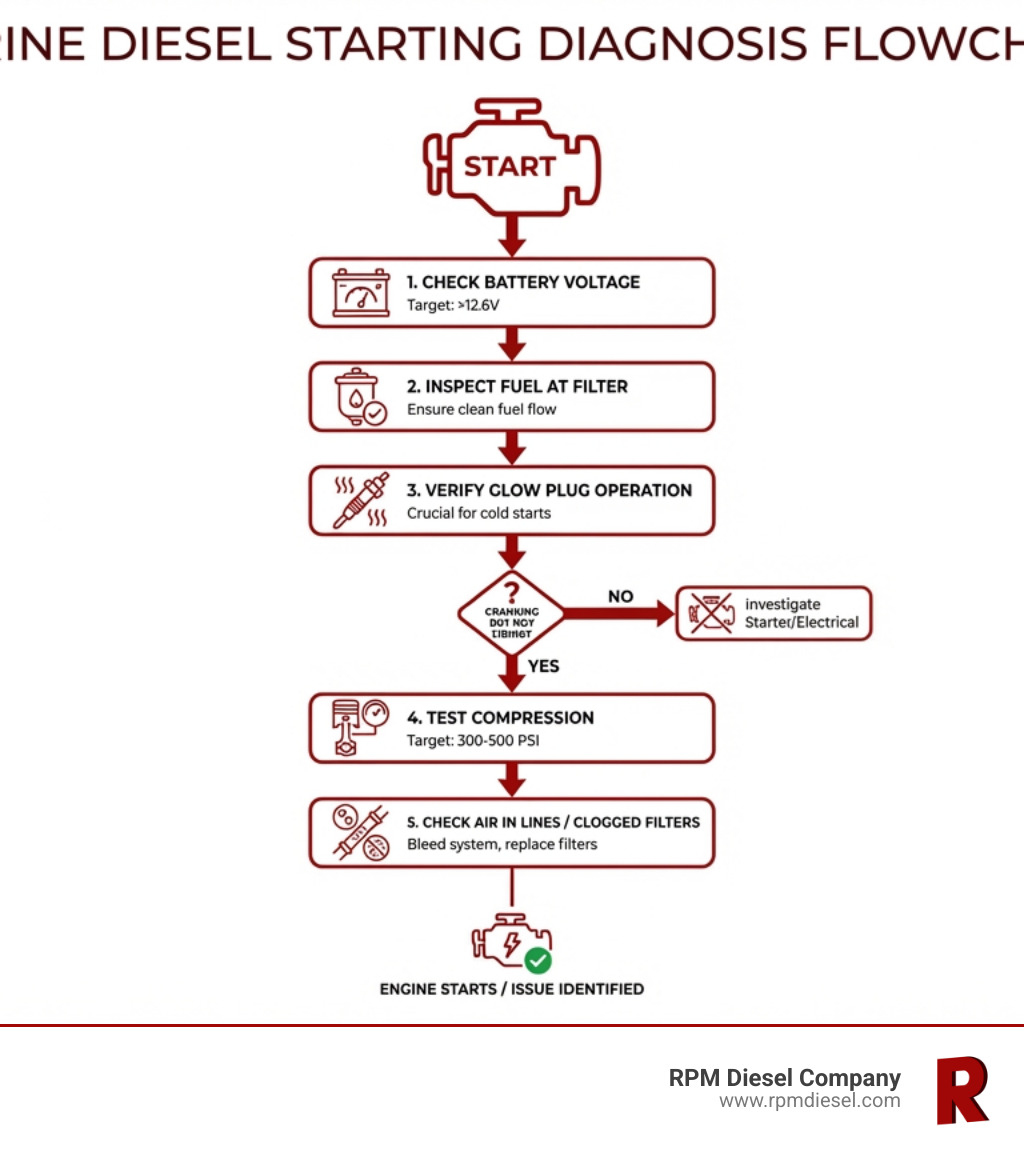

If your marine diesel won’t start, the most likely culprits are:

- Dead or weak battery – Check voltage (should be 12.6V+) and terminal connections.

- Fuel system issues – Air in lines, clogged filters, or contaminated fuel.

- Faulty glow plugs – Essential for cold starts.

- Low compression – Should be 300-500 PSI.

- Electrical failures – Corroded connections, faulty sensors, or starter motor problems.

Industry research shows the fuel system is behind most diesel starting failures, with fuel contamination being a frequently overlooked issue.

Fortunately, most starting problems have logical solutions. This guide provides a systematic troubleshooting process to help you identify the problem and get back on the water, whether you’re facing a no-crank, a crank-no-start, or an intermittent issue.

Understanding Your Marine Diesel: How It Starts

Understanding how your marine diesel starts is key to diagnosing diesel engine starting problems. Unlike gasoline engines, diesels don’t use spark plugs. They rely on compression ignition.

Here’s how it works:

- The engine draws air into a cylinder.

- A piston compresses this air to extremely high pressure, causing its temperature to skyrocket to over 210°C (410°F).

- At the precise moment of peak compression, a high-pressure pump injects a fine mist of diesel fuel into the cylinder.

- The fuel instantly ignites upon contact with the superheated air, forcing the piston down and creating power.

This process explains common diesel failure points. For example, low compression from worn parts means the air won’t get hot enough. A weak battery can’t crank the engine fast enough to build that heat. And a faulty fuel system won’t deliver fuel at the right time.

The Common Diesel Engine Problems guide offers more detail on this topic.

To start, your marine diesel needs three things: robust electrical power for cranking, excellent compression to generate heat, and clean, pressurized fuel delivered at the right moment. Understanding this trio makes troubleshooting logical.

Electrical System Failures: The Spark of Life (Without the Plugs)

While they don’t use spark plugs, marine diesels are heavily dependent on a robust electrical system to start. They require significantly more cranking power than gasoline engines to achieve the high compression needed for ignition. This power comes from the battery and is converted to rotational force by the starter motor.

Another critical electrical component is the glow plug (or intake air heater on larger engines). These heating elements warm the combustion chamber, making cold starts possible. Without them, starting on a cool morning can be difficult or impossible. Cold weather exacerbates all electrical issues, as batteries lose power and engine oil thickens.

Signs of a Weak Battery or Faulty Starter

Electrical issues usually provide clear warning signs.

- Slow, labored cranking: This is a primary symptom of a weak battery or a failing starter motor. A healthy diesel should crank with authority.

- Rapid clicking sound: When you turn the key, this sound typically means the starter solenoid is trying to engage but lacks sufficient current from the battery.

- Dim or flickering lights: If your instrument or cabin lights dim significantly when you try to start the engine, the battery is struggling.

- No crank at all: Complete silence or a single click could indicate a dead battery, failed starter, tripped breaker, or a faulty ignition switch.

To diagnose, start with a multimeter. A fully charged marine battery should read at least 12.6 volts with the engine off. A reading below 12.4 volts indicates a partial charge, and below 12 volts is significantly discharged. Also, inspect the battery terminals. Saltwater environments promote corrosion, which creates resistance. Terminals should be clean, bright, and tight.

Glow Plugs and Cold Weather Starting

Faulty glow plugs are a common source of diesel engine starting problems, especially as temperatures drop.

- White smoke from the exhaust: During startup, this is a classic sign of a glow plug issue. The smoke is unburnt fuel being sprayed into cylinders that aren’t hot enough for ignition.

- Rough idling after a cold start: The engine may run unevenly or misfire until it warms up, as cylinders with dead glow plugs struggle to maintain combustion.

Testing glow plugs involves using a multimeter to check their resistance or current draw. A significant difference in readings between plugs indicates a failure. Also, check the glow plug relay, which supplies power to all plugs. As research on cold weather starting confirms, temperature-related issues often point to the battery or glow plug system. At RPM Diesel Company, we’ve found that even in Florida, cooler winter mornings can reveal glow plug weaknesses that are hidden in the summer.

Fuel System Woes: The Most Common Culprit

The fuel system is the source of most diesel engine starting problems. It’s a precision system where fuel travels from the tank, is pulled by a low-pressure lift pump (0.20 to 5.0 bar), passes through filters, and is then pressurized by a high-pressure pump (200 to 300 bar during cranking). Finally, injectors spray a fine mist of fuel into the combustion chamber. Any disruption to this process can prevent the engine from starting.

Fuel Contamination and Quality Issues

Water is the primary enemy of diesel fuel. It enters tanks via condensation or leaky deck fills and promotes microbial growth (“diesel bug”). This slimy, dark growth clogs filters and damages expensive fuel system components. Other contaminants like dirt, rust, and sediment are also highly abrasive to precision parts.

Prevention is key:

- Use a quality water separator and drain it regularly.

- Buy fuel from busy marinas to ensure freshness.

- Use a biocide additive if the boat sits for long periods.

- Keep fuel tanks as full as possible to minimize condensation.

Blocked Filters and Air in the System

A clogged fuel filter will starve the engine of fuel, causing it to struggle to start, lose power under load, or die when throttled up.

Diesel fuel systems are intolerant of air. Air can enter if you run the tank dry, or through loose connections or failing seals—common issues due to engine vibration. An engine with air in the lines will crank endlessly without firing, or it may start briefly and then die. The solution is to bleed the air from the fuel lines by opening bleeder screws and using the lift pump or cranking the engine until a steady, bubble-free stream of fuel appears. Always consult your engine’s manual for the specific procedure and use genuine manufacturer filters to ensure a proper seal.

Fuel Pumps, Injectors, and Pressure Problems

These are the most critical and expensive fuel system components. A weak lift pump won’t supply enough fuel to the high-pressure pump. A failing high-pressure pump that can’t generate 200-300 bar during cranking will prevent the engine from starting. When these pumps fail internally, they can send metal particles (“swarf”) through the entire system, requiring a complete and costly flush.

Injectors operate under extreme heat and pressure. Signs of failure include:

- Hard starting, especially when cold.

- Rough idling.

- Excessive smoke (white for unburnt fuel, black for over-fueling).

- Loss of power and increased fuel consumption.

An injector back-leakage test can diagnose wear without removing the injectors. Faulty sensors or pressure regulators can also mimic pump or injector problems, making professional diagnosis crucial for these complex issues.

Air, Exhaust, and Compression: The Engine’s Ability to Breathe

An engine needs to breathe freely to start and run properly. Issues with air intake, exhaust, or internal compression are common sources of diesel engine starting problems.

Diesel engines require a massive volume of clean air for combustion. A dirty or clogged air filter restricts airflow, creating an improper air-fuel mixture. This leads to hard starting, loss of power, and excessive black smoke.

Similarly, the exhaust system must be clear. A blockage from marine growth or a damaged muffler creates back pressure, hindering the engine’s ability to expel exhaust and draw in fresh air. This can contribute to poor performance and starting difficulty.

The Critical Role of Engine Compression

Diesel engines rely on high compression to generate the heat that ignites fuel. If compression is too low, the engine will not start, no matter how good the fuel and electrical systems are.

For a reliable start, compression should be 300 to 500 PSI (20 to 35 bar). An engine with under 350 PSI will have significant trouble starting, especially when cold, because the air won’t get hot enough.

Common causes of low compression include:

- Worn Piston Rings: Allows compression to leak past the piston.

- Damaged Valves: Burnt or improperly seated valves won’t seal the cylinder.

- Blown Head Gasket: Lets compression escape between cylinders or into the cooling system.

- Worn Cylinder Walls: Scratches or wear on cylinder liners reduce the seal.

A compression test, which measures the pressure in each cylinder, is essential for diagnosing these internal engine health issues.

Your Step-by-Step Guide to Diagnosing Diesel Engine Starting Problems

A systematic approach can quickly identify the cause of most starting issues. Safety first: Ensure the boat is secured, the transmission is in neutral, and you wear eye protection. Keep clear of rotating parts when cranking the engine. You will need a multimeter and basic hand tools.

Initial Checks: What to Do When It Won’t Crank

If the engine doesn’t turn over or cranks very slowly, the issue is almost always electrical.

- Check Battery Voltage: Use a multimeter on your battery terminals. A fully charged battery should read 12.6V or higher. Below 12V, it needs charging or replacement.

- Inspect Terminals: Look for corrosion on battery terminals and cable ends. Clean them with a wire brush and ensure all connections are tight.

- Listen for a “Click”: A single click when you turn the key means the starter solenoid is getting power but the starter motor isn’t, often due to a weak battery or bad connection. No sound at all could mean a dead battery or a break in the ignition circuit.

- Check Fuses/Breakers: Consult your manual to locate and check the main fuses and circuit breakers for the starting system.

Troubleshooting When the Engine Cranks But Won’t Fire

If the engine turns over but won’t start, the problem lies with fuel, air, or compression. The smoke from the exhaust (or lack thereof) is a key clue.

| Symptom (Exhaust Smoke) | Likely Cause | First Checks |

|---|---|---|

| No Smoke | No fuel. | Check fuel level, fuel shutoff valve, and look for air in the system. Bleed fuel lines if necessary. |

| White Smoke | Fuel is present but not igniting. | Low compression or faulty glow plugs (in cold weather). Could also be water in the fuel. |

| Black Smoke | Too much fuel or not enough air. | Check for a clogged air filter or leaking/stuck injectors. |

If you suspect air in the fuel system (e.g., after running out of fuel), you must bleed it. Consult your engine manual for the specific procedure, which typically involves opening bleed screws and using a primer pump until fuel flows without bubbles. For cold starts, ensure the glow plug indicator light on your dash cycles correctly before cranking.

Advanced Diagnostics: When the Basics Don’t Work

If the basic checks don’t solve the problem, it’s time for more advanced diagnostics. These often require specialized tools and may point to a job for a professional.

- Fuel Pressure Test: Use a gauge to verify the lift pump and high-pressure pump are meeting specifications.

- Air Leak Inspection: Carefully check all fuel lines, filter housings, and seals on the suction side for tiny leaks that can introduce air.

- Injector Testing: An injector back-leakage test can identify worn injectors that are robbing the system of pressure.

- ECU Fault Codes: On modern engines, a diagnostic scanner can read fault codes from the Electronic Control Unit (ECU), pointing directly to failed sensors (like a crankshaft position sensor) or other electronic issues.

- Compression Test: If all else fails, a compression test is the definitive way to check for internal engine problems like worn rings, bad valves, or a blown head gasket. A reading below 300 PSI in any cylinder is a major red flag.

Air, Exhaust, and Compression: The Engine’s Ability to Breathe

An engine needs to breathe freely to start and run properly. Issues with air intake, exhaust, or internal compression are common sources of diesel engine starting problems.

Diesel engines require a massive volume of clean air for combustion. A dirty or clogged air filter restricts airflow, creating an improper air-fuel mixture. This leads to hard starting, loss of power, and excessive black smoke.

Similarly, the exhaust system must be clear. A blockage from marine growth in the wet exhaust system, a damaged muffler, or even a foreign object, creates back pressure that can hinder the engine’s ability to draw in fresh air and complete the combustion cycle. This can contribute to poor performance and starting difficulty.

The Critical Role of Engine Compression

Diesel engines rely on high compression to generate the heat that ignites fuel. If compression is too low, the engine will not start, no matter how good the fuel and electrical systems are.

For a reliable start, compression should be 300 to 500 PSI (20 to 35 bar). An engine with under 350 PSI will have significant trouble starting, especially when cold, because the air won’t get hot enough.

Common causes of low compression include:

- Worn Piston Rings: Allows compression to leak past the pistons and into the crankcase.

- Damaged Valves: Burnt or improperly seated valves won’t seal the cylinder during the compression stroke.

- Blown Head Gasket: Lets compression escape between cylinders, into the cooling system, or out of the engine.

- Worn Cylinder Walls: Scratches or wear on cylinder liners can also lead to compression loss.

A compression test, which measures the peak pressure in each cylinder, is essential for diagnosing these internal engine health issues and can pinpoint which cylinder is the culprit.

Your Step-by-Step Guide to Diagnosing Diesel Engine Starting Problems

When your marine diesel refuses to start, it’s easy to panic. But a systematic, logical troubleshooting process can save you time, money, and a lot of frustration. Safety first, always! Ensure the boat is secured, the transmission is in neutral, and you have appropriate personal protective equipment, including eye protection. You’ll want a multimeter, basic hand tools, and potentially a fuel pressure gauge and a compression tester. Keep clear of rotating components when cranking the engine, and never stand in front of or in line with the fan.

Initial Checks: What to Do When It Won’t Crank

If your engine doesn’t crank at all, or cranks very slowly, we always start with the electrical power for cranking:

- Battery Voltage Check: As discussed, use a multimeter to check your battery’s static voltage. A healthy, fully charged marine battery should read 12.6V or higher. If it’s below 12V, it needs charging or replacement. Diesel engines require more cranking power than gasoline engines, so even a slightly undercharged battery can make starting difficult.

- Terminal Inspection: Visually inspect the battery terminals and cable connections. Are they clean, tight, and free of corrosion? Even slight corrosion creates electrical resistance and can severely impede current flow. Clean them thoroughly with a wire brush if needed, and ensure all connections are tight.

- Starter Solenoid Test: When you turn the key to start, do you hear a single “click” from the engine bay, but no engine crank? This often indicates the starter solenoid is engaging, but not enough power is getting to the starter motor itself, often due to a weak battery or bad cable connection. If you hear nothing, check the solenoid’s wiring for power.

- Checking Main Fuses and Breakers: Marine engines have various fuses and circuit breakers protecting the starting circuit. Consult your engine manual to locate them and check for any tripped breakers or blown fuses. A simple blown fuse can prevent the starter from engaging.

Troubleshooting When the Engine Cranks But Won’t Fire

This is where the troubleshooting gets a bit more involved. The engine is turning over, but it’s not catching fire. This usually points to issues with fuel, air, or compression. A quick visual check for smoke from the exhaust while cranking can give us a big clue:

| Symptom (Smoke from Exhaust while Cranking) | Likely Cause