Why Marine Diesel Injector Rebuilds Are Critical for Your Vessel

“Diesel injectors rebuild near me” is one of the most common searches among marine vessel owners facing engine performance issues. If you’re experiencing reduced power, increased fuel consumption, or rough idling, your fuel injectors may need professional attention.

Quick Answer: Finding a Marine Diesel Injector Rebuild Service

- Look for factory-authorized facilities – Check for certifications from manufacturers like Bosch, Denso, or Cummins

- Seek dockside or mobile services – Many professional shops offer on-site repairs to minimize vessel downtime

- Verify specialized marine expertise – Marine diesel systems differ significantly from automotive applications

- Check warranty coverage – Reputable shops typically offer 1-year unlimited mileage/hour warranties

- Expect 1-3 business days turnaround – Basic testing takes less time than full rebuilds

Your marine diesel fuel injection system is the heart of your engine’s performance. These precision components spray fuel at incredibly high pressures, and even minor issues can lead to significant problems at sea. The market for these systems is growing, driven by complex common rail and piezo injectors that demand specialized service knowledge.

When injectors fail, you face reduced horsepower, wasted fuel, and the risk of catastrophic engine damage. Professional rebuilding offers a cost-effective alternative to replacement, but the difference between a qualified marine diesel specialist and a general automotive shop can mean the difference between reliable operation and being stranded offshore.

Is It Time for a Rebuild? Key Signs of Failing Marine Diesel Injectors

Spotting the early warning signs of injector trouble can save you from costly repairs and breakdowns far from shore. Here are the key indicators that it’s time to search for a “marine diesel injectors rebuild near me“:

- Reduced engine power: The vessel feels sluggish or struggles to reach its usual cruising speed. Failing injectors can’t deliver the precise fuel spray needed for optimal combustion.

- Increased fuel consumption: A poor spray pattern means your engine isn’t burning fuel completely, wasting resources and costing you more.

- Black or white smoke from the exhaust: Black smoke typically indicates too much fuel, while white smoke suggests unburnt fuel is passing through the engine. Both point to injector problems.

- Rough idling: An uneven engine rumble or shake at idle is often caused by inconsistent fuel delivery from one or more injectors.

- Engine misfires: You may hear a distinct “thump” or feel a jolt as a cylinder fails to fire correctly, often due to an injector malfunction.

- Difficulty starting the engine: Faulty injectors may prevent adequate fuel from reaching the cylinders during startup.

- Fuel leaks around the injector body: This is a clear sign of damaged seals or a compromised injector body that requires immediate attention to prevent fire hazards.

Ignoring these symptoms will only make them worse. Catching them early is key to keeping your vessel performing reliably and safely.

Understanding Your Marine Diesel Injectors

Marine diesel engines use various fuel injection systems, and the specific type dictates the service required. At RPM Diesel Company, we have extensive experience rebuilding all major types:

- Mechanical injectors: Found in older engines, these are robust but still wear out. Rebuilding involves cleaning, nozzle replacement, and precise calibration.

- Common rail injectors (CRI/CRIN): Widely used in modern diesels, these are sophisticated, electronically controlled injectors operating at extremely high pressures. Rebuilding requires advanced diagnostic equipment.

- Unit injectors (UIS) and unit pump systems (UPS): Common in larger marine engines, these systems integrate the injection pump and nozzle. Rebuilding involves careful disassembly and rigorous component testing.

- Piezo injectors: A subset of common rail technology, these use a ceramic stack for even faster, more precise fuel delivery and require highly specialized tools for service.

How Poor Injector Performance Affects Your Vessel

When injectors malfunction, the consequences extend beyond minor inconvenience and can severely impact your vessel:

- Loss of horsepower and decreased fuel economy: Inefficient injectors lead to incomplete combustion, which means less power is generated and fuel is wasted.

- Potential for engine damage: This is the most critical concern. Unburnt fuel can wash lubricating oil from cylinder walls, increasing wear. An improper spray pattern can create hot spots, damaging pistons or valves. In a worst-case scenario, a failed injector can hydro-lock a cylinder, leading to catastrophic engine failure.

- Increased emissions and unreliable operation: Poor combustion generates more pollutants. More importantly, injector issues can lead to unpredictable engine behavior, stalling, or complete shutdown, creating a serious safety risk at sea.

The Professional Rebuilding Process: What to Expect

When you bring your marine diesel injectors to a professional shop, they undergo a meticulous process to restore them to peak performance. Understanding these steps helps you know what to expect when searching for “marine diesel injectors rebuild near me.”

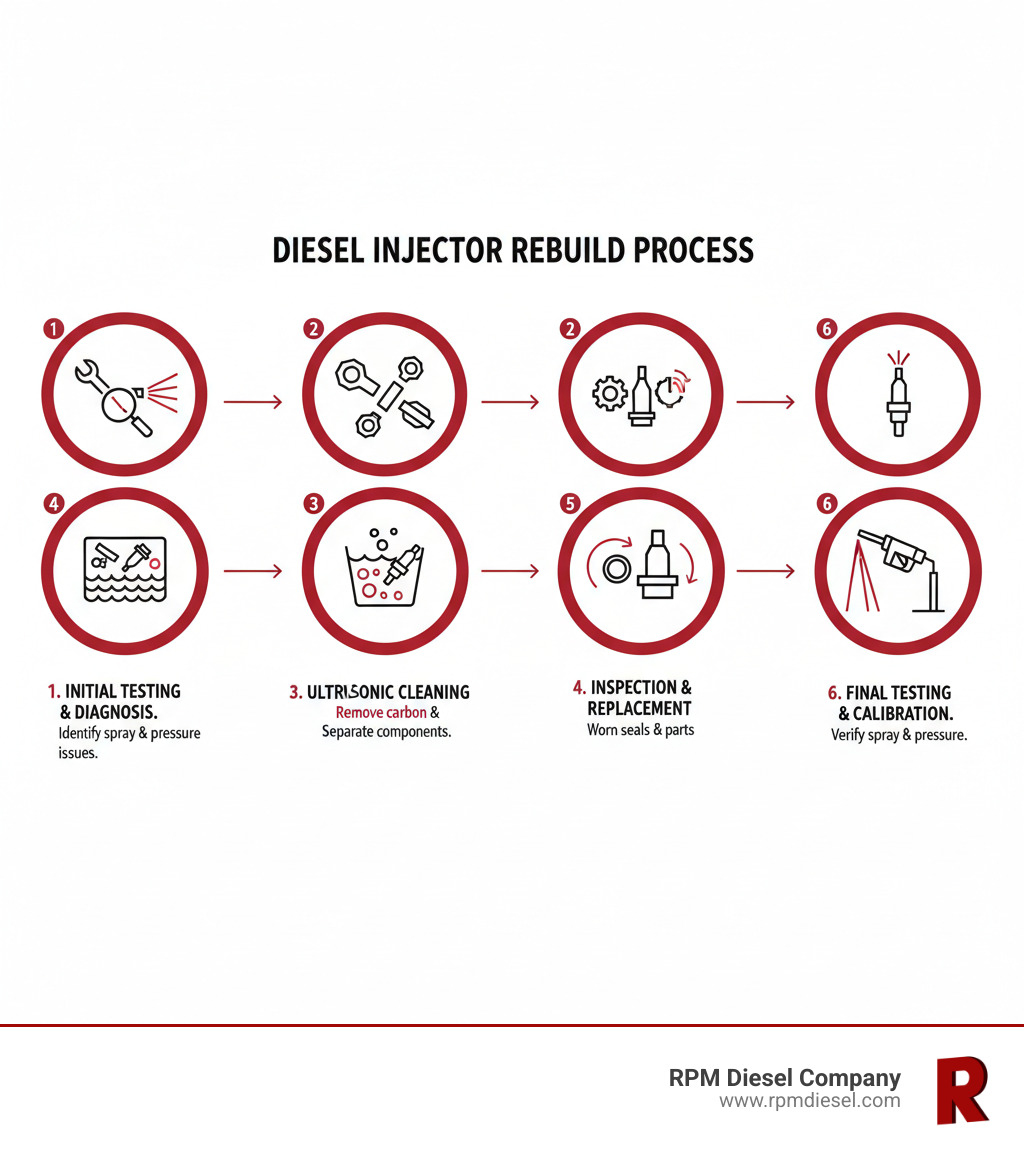

Here’s a breakdown of a professional rebuild at RPM Diesel:

- Initial Assessment and Diagnosis: We perform visual inspections, electronic checks, and “pop” tests to identify spray pattern issues, pressure faults, and other problems.

- Ultrasonic Cleaning: The injector is completely disassembled, and every component is placed in an ultrasonic bath to remove all carbon deposits and contaminants.

- Component Inspection and Replacement: Each part—nozzle, pin, spring, shim, and seal—is carefully inspected. Any component that doesn’t meet strict manufacturer standards is replaced with a new, high-quality OEM part.

- Nozzle Testing and Lapping: The nozzle is tested to ensure the fuel spray pattern is perfect. If needed, a fine grinding process called lapping is used to guarantee a perfect seal for precise fuel delivery.

- Reassembly and Calibration: The injector is reassembled using specialized tools. We then calibrate all internal pressures and settings to match the manufacturer’s exact specifications, following strict quality guidelines.

- Final Testing and Quality Control: Every rebuilt injector is placed on a specialized test bench to verify spray patterns, fuel flow, opening pressures, and overall performance. Only after it meets or exceeds original factory standards is it ready to be returned to your engine.

DIY vs. Professional Service: Why Expertise Matters

While DIY repairs can be satisfying, marine diesel injectors are not the place to experiment. Their proper function is critical to your engine’s health and your safety. Here’s why professional service is essential:

- Complexity of Marine Injectors: Modern injectors are complex, with microscopic tolerances, and operate under extreme pressures (over 30,000 PSI). Mishandling can easily cause permanent damage.

- Need for Specialized Tools: Professional shops invest in manufacturer-specific tools for proper disassembly, torqueing, and handling of delicate components without causing harm.

- Calibration Equipment: This is what truly sets professionals apart. Advanced test benches are required to fine-tune injectors to the manufacturer’s exact specifications. Without this, even a perfectly assembled injector will perform poorly.

- Risk of Engine Damage from Improper Rebuild: A badly rebuilt injector can damage pistons, score cylinder walls, or harm the turbocharger. The cost of fixing this damage is far greater than the cost of a professional rebuild. This is precisely Why to use a certified professional like our team at RPM Diesel.

Levels of Service and Turnaround Time

We know that not every situation is the same. We offer different levels of service to meet your specific needs and timeline.

- Basic Cleaning and Testing: For injectors with minor issues, this service includes ultrasonic cleaning and thorough testing on our benches. This can often be completed in 1-2 business days.

- Full Overhaul with New Parts: For worn or damaged injectors, this comprehensive service includes complete disassembly, replacement of all worn parts with OEM components, and full calibration. This typically takes 2-5 business days.

- Exchange Units: For urgent situations, this is our fastest emergency repair option. We provide a fully rebuilt and tested injector from our stock in exchange for your old injector (the “core”). This can significantly reduce your vessel’s downtime.

Rebuilding vs. Replacing: A Cost-Benefit Analysis

When your marine diesel injectors fail, you face a choice: rebuild or replace? For vessel owners in Fort Lauderdale, Miami, and across South Florida, this decision impacts your budget, engine health, and the environment. Let’s weigh the options.

Cost Savings of Rebuilding

The primary benefit of rebuilding is significant cost savings. A professional rebuild typically costs 40% to 70% less than buying new injectors. This is because we expertly reuse the main injector body, which is often in great shape, and only replace the worn internal parts. This smart approach keeps more money in your pocket for other aspects of your vessel’s upkeep.

Environmental Benefits

Choosing to rebuild is also an eco-conscious choice. By giving existing components a new life, we reduce the demand for new manufacturing. This conserves raw materials and energy while keeping old parts out of landfills. It’s a sustainable approach to marine maintenance that helps protect the waterways we all enjoy.

Availability of New vs. Rebuilt Parts

For older or less common marine engines, sourcing new injectors can be difficult or impossible if the parts are discontinued. Rebuilding is often the most reliable solution. At RPM Diesel Engine Co., our authorization by major manufacturers like Detroit Diesel and MTU, combined with our extensive parts inventory, means we can almost always source what’s needed for a quality rebuild, getting your vessel back on the water faster.

The Lifespan and Value of Rebuilt Injectors

It’s natural to ask, “What is the lifespan of rebuilt marine diesel injectors rebuild near me?” When rebuilt by professionals using high-quality OEM (Original Equipment Manufacturer) parts and calibrated with precision, these injectors can perform just like new ones.

You can expect an excellent service life from a properly rebuilt injector, often matching that of a new unit. For your peace of mind, reputable services like ours offer a comprehensive warranty. We stand behind our work with a one-year unlimited mileage, unlimited hour warranty on our parts and services.

Rebuilding often involves a “core charge“—a refundable deposit you pay for your old, failed injector. When you return the core, you get the deposit back. This system supports the sustainable cycle of remanufacturing and helps keep costs down. Some services also offer trade-in programs, further reducing your upfront expense.

How to Find a Reputable Marine Diesel Injectors Rebuild Near Me

When your engine’s critical fuel injectors need service, finding a reputable provider is paramount. If you’re searching for “marine diesel injectors rebuild near me” in the Fort Lauderdale or Miami area, you need a service that combines expertise, reliability, and convenience.

To find the right marine diesel specialist, prioritize the following:

- Dockside Service Availability: Look for providers who offer mobile repairs directly at your vessel’s location. This minimizes downtime and logistical headaches. We at RPM Diesel pride ourselves on offering dockside services throughout South Florida.

- Online Reviews and Testimonials: Check for consistent positive feedback regarding quality of work, professionalism, and customer service. These are a great source of real-world information.

- Word-of-Mouth Referrals: Ask fellow mariners, yacht captains, or marina staff for recommendations. A personal referral from a trusted source is often the most reliable way to find excellent service.

- Strategic Location: With facilities in Fort Lauderdale and serving Dade County, Miami, West Palm Beach, and beyond, we are positioned to provide prompt service across the region.

What to Look for in a Diesel Injectors Rebuild Near Me

Not all diesel shops are equipped for marine engines. When vetting a service, look for these specific qualifications to ensure top-tier work:

- Factory Authorizations: This is non-negotiable. Authorization from manufacturers like Detroit Diesel and MTU means technicians are properly trained, use the correct tools, and adhere to the highest service standards.

- Use of OEM Parts: Insist on Original Equipment Manufacturer (OEM) parts. Aftermarket components often lack the precision and durability required for the harsh marine environment.

- Advanced Diagnostic and Testing Equipment: A top-tier shop must have specialized test benches capable of simulating operating conditions and accurately calibrating injectors to factory specifications.

- Specialized Marine Expertise: The shop must specialize in marine diesel engines, not just general diesel repair. This ensures they understand the unique demands of saltwater, continuous loads, and other marine-specific factors.

The Risks of a Low-Quality Diesel Injectors Rebuild Near Me

Choosing a service based on the lowest price is a risky gamble. The dangers of a low-quality rebuild far outweigh any initial savings and can lead to much higher costs and safety concerns.

- Premature Failure: A poorly rebuilt injector will fail much sooner than expected, forcing you to pay for the same repair twice and causing significant inconvenience.

- Catastrophic Engine Damage: This is the most severe risk. An injector that dribbles fuel or has incorrect pressures can cause piston damage, cylinder scoring, turbocharger failure, or even hydro-lock, which can seize the entire engine.

- Voided Engine Warranties: Using an unauthorized service provider for injector work can void your manufacturer’s engine warranty, leaving you unprotected against other failures.

- Unsafe Vessel Operation: A faulty engine is a major safety hazard. Engine misfires, power loss, or sudden shutdowns create an unsafe environment at sea. Never attempt DIY repairs or trust your vessel to an unqualified mechanic.

Proactive Maintenance: Extending the Life of Your Marine Injectors

A little prevention is always less expensive than a major repair. This is especially true for your marine diesel injectors. A consistent maintenance routine can significantly extend their lifespan, delaying the need for a rebuild and keeping your engine running efficiently.

Here is how you can be proactive in caring for these vital components:

- Use High-Quality Marine Diesel Fuel: Low-quality or contaminated fuel is the primary cause of injector problems, leading to carbon buildup, varnish deposits, and corrosion. Always source your fuel from trusted suppliers.

- Regular Fuel Filter Changes: Your fuel filters are the first line of defense, stopping dirt, rust, and water from reaching your sensitive injectors. Follow your engine manufacturer’s recommended schedule for filter changes, or replace them more often if you suspect poor fuel quality.

- Use of Proper Fuel Additives: Not all additives are the same. Use marine-specific products that help clean deposits, disperse water (a major cause of corrosion), and restore lubricity to protect the moving parts inside your injectors and fuel pump.

- Schedule Regular Engine Diagnostics: A marine diesel specialist can use advanced equipment to spot minor shifts in injector performance before they become major problems. Catching issues early often means a simple cleaning is all that’s needed, which is far less costly than a full diesel injectors rebuild near me.

- Monitor Engine Performance: You know your boat best. Pay close attention to any changes in how your engine sounds, how much fuel it’s using, or the color of its exhaust smoke. Any deviation from normal behavior could be an early warning sign that your injectors need service.

By incorporating these practices into your routine, you are safeguarding the health and reliability of your entire marine diesel engine.

Conclusion

Your marine diesel injectors are critical to your engine’s performance, efficiency, and reliability. Understanding the signs of failure and the importance of professional service is key to ensuring safe operation on the water. When you’re searching for “marine diesel injectors rebuild near me” in the Fort Lauderdale or South Florida area, remember these key takeaways:

- Recognize the Signs: Reduced power, increased fuel consumption, smoke, and rough idling all indicate that your injectors need attention.

- Trust Professional Expertise: DIY attempts or unqualified service on these complex components can lead to catastrophic engine damage and serious safety risks.

- Rebuilding Offers Smart Value: A professional rebuild is a cost-effective, environmentally friendly alternative that restores injectors to like-new performance with a solid warranty.

- Proactive Maintenance is Key: Using high-quality fuel, changing filters regularly, and scheduling routine diagnostics are your best defense against injector problems.

At RPM Diesel Company, our factory-authorized technicians use OEM parts and advanced diagnostic equipment to rebuild marine diesel injectors to the highest standards. We provide the expertise, reliability, and dockside convenience you need to keep your vessel running smoothly and safely. Let us help you ensure your engine’s heart beats strong for every journey.