Why Cummins ISX Troubleshooting Matters for Marine Vessel Owners

Cummins ISX troubleshooting is essential knowledge for any marine vessel owner who depends on reliable power at sea. Understanding your engine’s warning signs can mean the difference between a smooth voyage and costly downtime far from port.

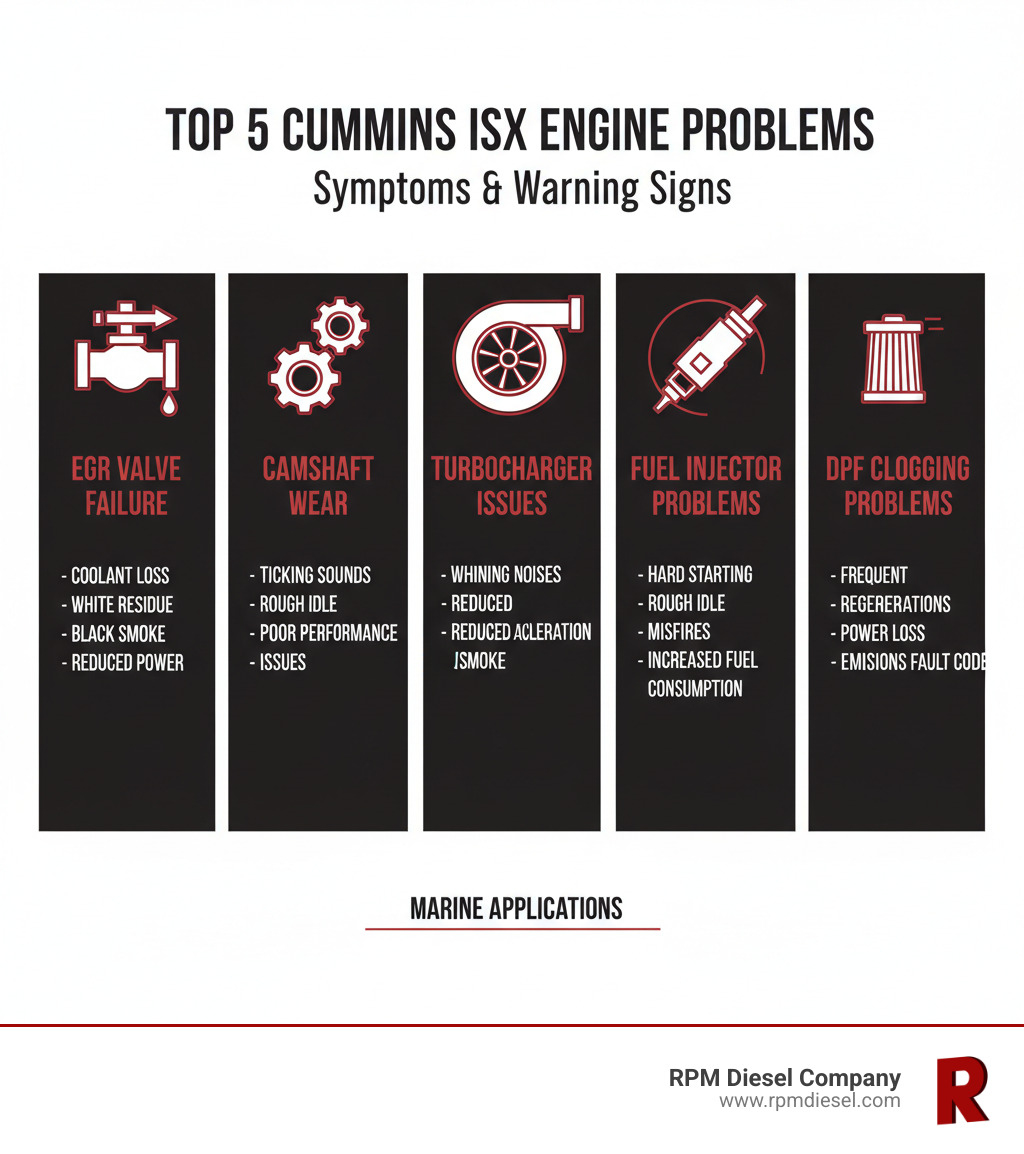

Quick Guide: Top 5 Cummins ISX Problems and Symptoms

- EGR Valve Failure – White residue, coolant loss, black smoke, reduced power

- Camshaft Wear – Ticking sounds, rough idle, poor performance, engine brake issues

- Turbocharger Problems – Whining noises, reduced acceleration, excessive smoke

- Fuel Injector Issues – Hard starting, rough idle, misfires, increased fuel consumption

- DPF Clogging – Frequent regenerations, power loss, emissions fault codes

The Cummins ISX is a popular heavy-duty diesel engine, delivering impressive horsepower (400-600 hp) and torque (up to 2050 lb-ft). However, like any machine in the harsh saltwater environment, it has known failure points.

This guide focuses on marine ISX applications, helping you identify symptoms early. The saltwater environment creates unique challenges, accelerating corrosion. Early diagnosis saves thousands. A leaking EGR valve caught early might be a minor repair. Ignored, it can lead to a complete engine overhaul costing $15,000 to $30,000 or more.

Understanding the Most Common Cummins ISX Engine Problems

Your Cummins ISX is built tough, but the demanding marine environment—with high loads and saltwater exposure—can make problems appear faster than on land. Understanding these issues is the foundation of effective Cummins ISX troubleshooting.

Symptoms of EGR Valve Failure

The Exhaust Gas Recirculation (EGR) system reduces emissions but is a common failure point on the ISX. The problem is soot buildup, which is accelerated in marine applications with extended idling. This clogs the EGR valve and EGR cooler, leading to failure.

Watch for coolant loss without external leaks and a white residue around the EGR cooler, indicating an internal leak from burnt coolant. Performance will suffer, with a noticeable loss of power, poor fuel efficiency, black smoke from the exhaust, and an illuminated Check Engine Light. Ignoring these symptoms allows soot buildup to cause further damage.

Camshaft Wear and Engine Brake Issues

Common in high-hour marine engines, camshaft wear often starts with rocker arms that stick due to poor lubrication. The rocker arm then hammers and flattens the camshaft lobes, impairing valve operation.

Listen for ticking or knocking sounds from the top of the engine, caused by worn rocker arms. Worn camshafts disrupt valve timing, causing poor engine performance and rough idling. If your ISX has an engine brake, you’ll notice engine brake malfunction as it becomes less effective. The root cause is often oil starvation, making high-quality oil and regular changes essential.

Turbocharger Issues and Performance Loss

Your turbocharger works under extreme conditions to force air into the cylinders, creating power. In marine applications, high loads and saltwater accelerate wear.

Symptoms of turbo failure include whining or grinding noises, indicating internal damage, and reduced acceleration due to low boost pressure. Excessive exhaust smoke is another sign—black smoke means not enough air, while blue smoke points to failing oil seals. Also look for high operating temperatures and oil leaks around the turbo. A failing turbo can cause significant engine damage, so address these symptoms promptly. Find genuine Cummins ISX parts and service at RPM Diesel to get your turbo sorted out.

Fuel Injector and Fuel System Problems

Fuel injectors deliver precisely metered fuel. When they fail, the entire engine suffers. Marine fuel systems are prone to water contamination and biological growth (“diesel algae”), which can clog filters and damage injectors.

The first symptom is often rough idling, which can lead to engine misfires. You’ll also notice increased fuel consumption and hard starting. Listen for engine knocking, which indicates improper combustion. Beyond the injectors, contaminated fuel can damage the entire system. Worn injector seals can also cause leaks and performance issues. Regular fuel filter changes are your best defense.

Advanced Cummins ISX Troubleshooting for Marine Applications

Some Cummins ISX troubleshooting scenarios involve complex failures that require careful diagnosis, especially in the demanding marine environment. Let’s explore these deeper issues.

DPF Clogging and Regeneration Issues

Newer ISX marine engines (2007+) have a Diesel Particulate Filter (DPF) to trap soot. In marine use, these filters are prone to clogging. DPFs require high-temperature regeneration cycles to burn off soot, but these cycles are often interrupted on vessels that idle frequently or run at low speeds, preventing a full cleaning.

A clogging DPF leads to frequent regenerations, a decrease in engine power due to restricted exhaust, and emissions-related fault codes. If the clog is severe, a technician may need to perform a forced regeneration or remove the DPF for cleaning or replacement. Ignoring these signs can lead to severe power reduction and damage to other components.

Causes of Excessive Oil Consumption

Excessive oil consumption is a common complaint. If you’re constantly adding oil between changes, there’s likely an internal problem. The main culprits are worn piston rings, worn valve guides, or failing turbocharger seals. These issues allow oil to burn in the combustion chamber or leak into the intake/exhaust, causing blue or white smoke from the exhaust and oil fouling in the aftercooler.

The most obvious symptom is low oil levels between changes. If you’re adding a gallon or more between services, it’s a clear sign of a problem that needs a thorough inspection to diagnose.

Dropped Cylinder Liners: Signs of Catastrophic Failure

A dropped cylinder liner is one of the most catastrophic failures an ISX engine can experience. The ISX’s mid-stock liner design is vulnerable; if a piston seizes or the engine overheats, the liner can break free and drop into the crankcase, causing massive internal damage.

Signs are immediate and severe: rapid engine overheating, a sudden drop in pressure (coolant or oil), and coolant in your oil (milky appearance). The engine will likely seize. This failure causes extensive damage to the block, crankshaft, and connecting rods. It requires immediate professional overhaul or complete engine replacement, with costs often exceeding $20,000.

Proactive Maintenance and Professional Repair

Your Cummins ISX marine engine operates in a harsh environment, but most major failures are preventable with consistent care and professional help. Learn how to prevent common failures and when to call the experts.

Preventative Maintenance: The First Step in Cummins ISX Troubleshooting

The best Cummins ISX troubleshooting is preventative maintenance. Regular attention can prevent most major repairs.

- Regular oil changes (every 250-500 operating hours) with quality engine oil are foundational. This protects critical components like camshafts and turbo bearings.

- Timely fuel filter replacement is crucial. Marine fuel is prone to contamination, and fresh filters protect your injectors.

- Cooling system service is vital in corrosive saltwater environments. Check coolant levels and quality often, flush the system regularly (e.g., every 2 years/600 hours), and inspect strainers and anodes.

- Air filter inspection keeps your turbo breathing properly. A clogged filter reduces performance and can cause damage.

- For engines with EGR systems, regular cleaning prevents common failures. For newer models with DPF systems, ensure regeneration cycles complete properly.

For more information about comprehensive Cummins marine services, visit RPM Diesel’s Cummins service page.

The Risks of Ignoring Early Warning Signs

It’s tempting to ignore minor symptoms, but in marine engines, minor issues escalating into major problems is a costly lesson. A faulty injector causing rough idling or power loss can lead to a full internal rebuild if ignored. A small EGR coolant leak can lead to engine overheating and catastrophic failure.

Catastrophic engine failure at sea is dangerous and expensive. It leads to vessel downtime and puts your safety at sea at risk. We’ve seen countless engines that required complete overhauls because small symptoms were ignored, leading to costly repairs that far exceeded the price of preventative care.

When to Seek Professional Cummins ISX Troubleshooting

While some maintenance is DIY, many situations require professional expertise. At RPM Diesel, we have the specialized tools and training for complex marine diesel challenges.

Call a professional for:

- Persistent fault codes that require professional diagnostic tools like Cummins INSITE™ to find the root cause.

- Major internal repairs like camshaft replacement or fixing cylinder liner issues. These are not DIY jobs and demand specialized tools and expertise.

- When diagnostics are inconclusive after basic checks. We can perform advanced tests to pinpoint elusive problems.

- Addressing issues related to saltwater corrosion in marine environments, which requires specific knowledge.

- Servicing complex aftertreatment systems (DPF, SCR) on newer engines.

Trust your investment to technicians who specialize in marine diesel engines and have factory authorization from manufacturers like Cummins.

Older vs. Newer Cummins ISX Models: Common Problems

The Cummins ISX has evolved since 1998, largely due to emissions regulations. Knowing your engine’s generation is key for effective Cummins ISX troubleshooting, as common failure points have changed over time.

Here’s a quick guide to the different eras:

| Engine Era | Key Technology | Most Common Problems |

|---|---|---|

| Pre-2002 | (Similar to N14) | General wear and tear |

| 2002-2007 | EGR | EGR valve/cooler failure, camshaft/rocker arm wear |

| 2007-2010 | EGR + DPF | DPF clogging, regeneration issues, sensor failures |

| 2010+ | EGR + DPF + SCR | Complex aftertreatment faults, DEF system issues |

Pre-2002 models were simple and robust, similar to the N14. Problems were typically related to general wear and tear on mechanical parts, with no complex emissions systems to cause issues.

The 2002-2007 models introduced the EGR system. This led to the notorious EGR valve/cooler failures due to soot and corrosion. This era also saw a rise in camshaft and rocker arm wear.

The 2007-2010 models added the Diesel Particulate Filter (DPF). In marine use, this led to frequent DPF clogging, regeneration issues, and related sensor failures, adding complexity.

2010+ models added Selective Catalytic Reduction (SCR) and Diesel Exhaust Fluid (DEF). This introduced complex aftertreatment faults and DEF system issues (e.g., quality, pump failure, crystallization), requiring advanced diagnostics.

At our Fort Lauderdale and Miami locations, identifying the ISX generation is our first step. A 2005 model points us toward the EGR and camshaft, while a 2015 model suggests aftertreatment system issues. This knowledge helps us diagnose problems faster and get you back on the water.

Frequently Asked Questions about Cummins ISX Engines

What are the most common problems encountered with Cummins ISX engines?

The most common problems we see in marine ISX engines are consistent. They include:

- EGR valve and cooler failures, especially in post-2002 models, leading to coolant leaks.

- Camshaft wear, often starting with a ticking sound from rocker arm issues.

- Turbocharger issues, causing performance loss and whining noises.

- Fuel injector problems, resulting in rough idling and poor fuel economy.

- DPF clogging and regeneration issues in newer engines.

- Excessive oil consumption in high-hour engines.

Recognizing these is key to effective Cummins ISX troubleshooting.

What makes the Cummins ISX engine desirable for marine applications?

Despite known issues, the ISX is popular in marine applications for several reasons. It offers a high power-to-weight ratio and impressive torque output (up to 2050 lb-ft), which is crucial for marine propulsion. It has proven reliability, descending from the robust N14 engine, and can last for tens of thousands of hours with proper maintenance. Finally, it provides good fuel efficiency for a heavy-duty engine, reducing operational costs. This combination makes it ideal for a wide range of commercial and recreational vessels.

What are the potential risks of ignoring symptoms like rough idling or power loss?

Ignoring minor symptoms like rough idling or power loss is risky. Small problems in marine diesels create a cascade of failures. A failing injector, for example, can lead to internal engine damage, turning a small repair into a major overhaul. The worst-case scenario is a catastrophic event at sea, like a seized engine, which poses serious safety risks and leads to extensive downtime. Financially, an early, minor repair might cost a few hundred dollars, while a catastrophic failure can cost $15,000 to $30,000 or more. Taking early warning signs seriously is the most important part of Cummins ISX troubleshooting.

Conclusion

Understanding common ISX issues like EGR failures, camshaft wear, and DPF clogging is your first line of defense. Effective Cummins ISX troubleshooting begins with paying attention to early warning signs. Catching a problem early can prevent a catastrophic failure and a massive repair bill.

However, complex issues like dropped cylinder liners or advanced aftertreatment faults require professional expertise. That’s where RPM Diesel comes in. We provide expert Cummins ISX troubleshooting and repair services across South Florida, from Miami to West Palm Beach. Our factory-authorized technicians understand the unique challenges of marine engines and use advanced diagnostics to solve any problem.

Your time on the water is precious. Don’t let a minor issue keep you tied to the dock. If your engine is showing any of the symptoms we’ve discussed, or if you simply want the peace of mind that comes with professional maintenance, we’re here to help. Schedule your diesel engine repair today and let our team keep your Cummins ISX running strong for years to come.