Why Your Marine Diesel Fuel System is the Heart of Your Vessel

When your marine diesel engine misfires, loses power, or produces excessive smoke, the fuel injectors are a primary suspect. These precision parts deliver atomized fuel to your engine’s cylinders. Over time, deposits from fuel and heat clog their tiny nozzles, disrupting performance. For marine vessels, a faulty injector is more than an inconvenience; it can lead to engine damage and costly breakdowns far from port.

How to fix fuel injectors depends on the problem. Here are your three main options:

-

Cleaning – For minor clogging and prevention ($50-$100 per injector for professional service). This includes using fuel additives or professional ultrasonic cleaning for stubborn deposits.

-

Rebuilding – For worn but salvageable injectors ($200-$400 per injector). This involves replacing internal parts like nozzles and seals, followed by flow testing to verify performance. It’s ideal for high-hour mechanical injectors.

-

Replacement – For failed or damaged injectors ($50-$500+ per injector). This is necessary for cracked bodies, electrical failures, or when an injector fails tests after cleaning.

This guide covers diagnosing, cleaning, rebuilding, and replacing marine diesel fuel injectors, helping you decide between DIY maintenance and professional service.

Understanding Your Marine Diesel Fuel System

Marine diesel fuel injectors act as precision nozzles, spraying a fine mist of fuel into the combustion chambers. This process, called atomization, is critical for power and efficiency. If the spray pattern is uneven, combustion is incomplete, leading to problems.

The challenge is that diesel fuel contains contaminants. Over time, these form deposits on injector nozzles. Heat soak—when residual heat bakes leftover fuel after shutdown—worsens the issue, creating varnish and carbon buildup. While injectors can last 5,000 to 10,000 engine hours, this varies with fuel quality and maintenance.

Your engine’s injection system type also matters. Mechanical systems, found in older diesels, are robust but require service every 1,000-2,000 hours. Common rail systems are electronically controlled, offering better efficiency and longer service intervals, but they are still vulnerable to poor-quality fuel.

Symptoms of Failing Marine Diesel Injectors

Your engine will signal when injectors are struggling. Look for these early signs:

- Rough idling and engine misfires: The engine feels like it’s vibrating or “missing a beat.”

- Loss of power: Your vessel feels sluggish and struggles to reach cruising speed.

- Increased smoke emissions: Black smoke indicates unburnt fuel, white smoke suggests poor atomization, and blue smoke points to burning oil.

- Poor fuel economy: You’re filling up more often without a change in your operating habits.

- A strong fuel smell: This could indicate a leaking injector body or seal, which is a serious fire hazard.

For more context on these symptoms, mechanicbase.com/engine/fuel-injector-symptoms/ offers additional details.

Can a Bad Injector Damage Your Engine?

Yes, a failing injector can cause catastrophic engine damage. The most dangerous issue is cylinder wash, where excess fuel washes the protective oil film from cylinder walls, causing rapid wear. This excess fuel can also seep past piston rings and thin your engine oil, compromising lubrication for critical components.

Other risks include engine overheating from inefficient combustion and detonation in turbocharged engines, where pressure spikes can crack pistons or bend connecting rods. Even if you avoid immediate failure, a bad injector creates vibrations and carbon deposits that stress your entire engine over time. Addressing injector problems promptly isn’t just about performance—it’s about protecting your engine from a costly rebuild.

Fixing Your Injectors: Cleaning, Rebuilding, or Replacing?

When your marine diesel injectors have issues, you must decide whether to clean, rebuild, or replace them. The right choice depends on the injector’s condition, hours, and system type. Cleaning is for routine maintenance, rebuilding restores worn parts, and replacement is for severe damage.

Here’s how the three approaches compare:

| Feature | On-Vessel Cleaning (DIY/Basic Professional) | Professional Off-Vessel Rebuilding | Full Replacement (New or Remanufactured) |

|---|---|---|---|

| Cost per Injector | $15 (DIY additive) – $100 (professional on-vessel service) | $200 – $400 | $50 – $500+ (depending on type/model) |

| When to Choose | Minor clogging, preventative maintenance, or as a first attempt for mild issues. | Significant wear, but body is intact; for high-hour mechanical injectors. | Cracked body, severe internal damage, electrical failure, or after failed rebuild/cleaning. |

| Effectiveness | Limited, may not clear heavy deposits or restore spray pattern. | Highly effective for restoring performance to near-new specifications. | Guaranteed new performance; addresses structural or electrical failures. |

| Process | Additive to fuel tank or pressurized kit run through engine. | Injectors removed, disassembled, cleaned ultrasonically, worn parts replaced, reassembled, flow tested. | Injectors removed, new/remanufactured units installed. |

| Flow Testing/Balancing | Not possible with on-vessel methods. | Essential step; ensures precise fuel delivery and matching across cylinders. | Flow testing is done by manufacturer on new units; important for remanufactured. |

| Typical Lifespan Impact | May extend life slightly; temporary fix for severe issues. | Significantly extends injector life; restores original performance. | Restores full original lifespan and performance. |

| Warranty | None (DIY); limited (basic professional service). | Typically comes with a warranty from the rebuilding specialist. | Manufacturer’s warranty. |

Professional services vary in price. On-vessel cleaning may cost $50-$100 per injector, while rebuilding runs $200-$400. Replacing a full set of injectors could cost $800-$1,500, though specialized marine units can be more.

Methods for Cleaning Marine Fuel Injectors

You have several options for cleaning injectors, from simple DIY maintenance to professional services.

- Marine-approved fuel additives: Poured into your fuel tank, these detergents gradually dissolve light deposits. They are excellent for preventative care but can’t tackle heavy buildup or rust.

- Pressurized on-vessel cleaning: A technician runs a concentrated cleaning solvent through the injectors while the engine is on. This is more effective than additives for moderate deposits but doesn’t allow for inspection or flow testing.

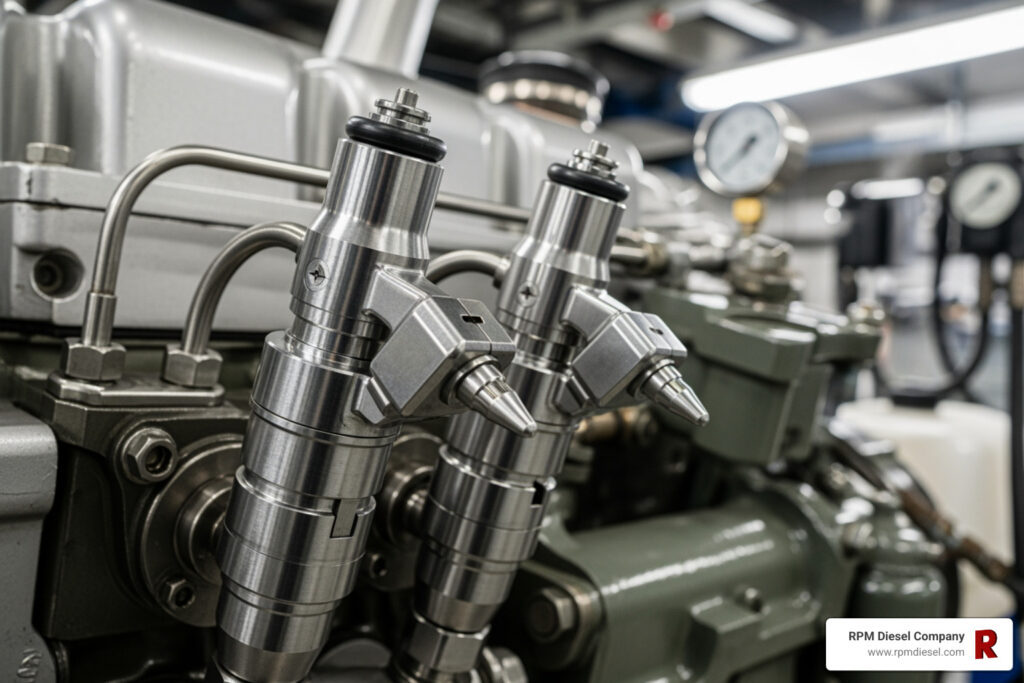

- Ultrasonic off-vessel service: This is the gold standard for cleaning. At RPM Diesel, we remove the injectors, test their initial flow, and then place them in an ultrasonic bath. This process dislodges the most stubborn deposits. After cleaning, we replace micro-filters, re-test them to verify performance is restored to manufacturer specifications, and ensure they are balanced to within 1-2% of each other for smooth operation.

Chemical cleaning cannot dissolve rust particles from a corroded fuel tank, which may require injector replacement.

When Rebuilding or Replacement is Necessary

Cleaning isn’t always enough. Certain conditions require a more intensive solution.

- Cracked Injector Body: This is an automatic replacement due to the extreme fire hazard from fuel leaks.

- Internal Mechanical Failure: Worn or seized internal parts (springs, needles) can often be fixed by rebuilding the injector, which is cost-effective for many mechanical units.

- Electrical Failures: In modern common rail injectors, a failed solenoid typically requires full replacement.

- Failed Flow Test: If an injector fails to meet performance specifications after a thorough ultrasonic cleaning, the wear is irreversible, and it must be rebuilt or replaced.

- High-Hour Wear: Like any mechanical part, injectors eventually wear out. For high-hour engines, replacement is often the smartest long-term investment for reliability.

- Fuel Leaks: Any external fuel leak from the injector body is a fire hazard that demands immediate replacement.

When replacing, it’s wise to change all fuel injectors as a set to ensure balanced performance across all cylinders.

How to Fix Marine Fuel Injectors: A Step-by-Step Guide

Servicing marine fuel injectors requires precision and caution. While complex rebuilds are best left to professionals, understanding the removal and replacement process is valuable for any vessel owner. You’re dealing with a high-pressure fuel system, so safety is paramount.

Safety Precautions and Tools Required

Before starting, prioritize safety.

- Safety First: Wear PPE (gloves, safety glasses), keep a fire extinguisher nearby, and ensure your workspace is well-ventilated. No sparks or flames.

- Engine Prep: Ensure the engine is completely cool. Depressurize the fuel system according to your service manual and disconnect the battery terminals.

- Essential Tools: You’ll need a socket wrench set, a screwdriver set, and pliers. A fuel line disconnect tool and an injector puller may be necessary. A torque wrench is critical for reassembly.

Step-by-Step Guide on How to Fix Marine Fuel Injectors by Removing for Service

This is a general guide; always consult your engine’s service manual for specific procedures and torque specs. For a general overview, you can review guides like this one from tlfperformanceparts.com/blog/how-to-remove-fuel-injectors.

- Preparation: With the engine cold and battery disconnected, relieve fuel system pressure. Remove any engine covers or components blocking access to the fuel rail and injectors. Take photos as you go to aid reassembly.

- Disconnect Components: Carefully unclip the electrical connectors from each injector. Place rags to catch fuel and disconnect the fuel lines, immediately capping all open ports to prevent contamination.

- Remove Fuel Rail: If your engine has a common rail, unbolt it and gently pull the assembly away from the engine to access the injectors below.

- Extract Injectors: Gently wiggle each injector to break its seal. If an injector is stuck, use a dedicated injector puller tool—never pry it out. Label each injector by its cylinder number as you remove it.

- Inspect and Clean: Clean the injector ports in the cylinder head. If installing new fuel injectors, prepare them with fresh, lubricated O-rings. Never reuse old O-rings.

- Reinstallation: Reinstall in reverse order. Seat each injector firmly, reattach the fuel rail to the correct torque specifications, and reconnect all fuel lines and electrical connectors securely.

Post-Replacement Checks

The job isn’t done until you’ve verified a safe, correct installation.

- Prime the System: Follow your manual’s procedure to prime the fuel system, removing any air that entered the lines. This usually involves cycling the key or using a manual pump.

- Initial Start-Up and Leak Check: Start the engine and let it idle. Immediately use a flashlight to inspect for any fuel leaks around the injectors and fuel rail. If you see any leak, shut down the engine immediately and fix it. A fuel leak is a severe fire hazard.

- Monitor Performance: Once confirmed leak-free, monitor the engine. It should idle smoothly with clean exhaust. Take the vessel for a short test run to check power delivery and listen for unusual sounds.

Preventing Future Fuel Injector Problems

An ounce of prevention is worth a pound of cure, especially for your marine diesel’s fuel system. Adopting smart habits can significantly extend injector life and help you avoid failures at sea.

- Follow a Maintenance Schedule: Religiously follow your engine manufacturer’s service intervals for fuel filters, air filters, and system inspections. For older mechanical systems, plan on service every 1,000-2,000 hours.

- Use High-Quality Fuel: This is one of the most critical factors. Source your marine diesel from reputable suppliers. Quality fuel contains detergents that help keep injectors clean.

- Use Marine-Specific Fuel Additives: Additives with detergents like Polyetheramine provide an extra layer of protection, preventing and removing deposits. They can also add lubricity to protect fuel system components.

- Run Your Engine Regularly: Engines that sit idle for long periods are prone to fuel degradation and deposit formation. If storing your vessel, properly stabilize the fuel system.

- Maintain Your Water Separator: Water is the enemy of a diesel fuel system. Regularly inspect and drain your water separator to prevent corrosion and microbial growth that can destroy injectors.

- Check Your Fuel Filters: A clogged filter restricts fuel flow and indicates contaminants in your fuel. If filters get dirty quickly, investigate your fuel source and tanks to prevent debris from reaching and damaging your injectors.

Proactive maintenance keeps you on the water instead of in the shop. Understanding how to fix fuel injectors is important, but preventing the problem in the first place is always the better option.

Frequently Asked Questions about Fixing Marine Fuel Injectors

We hear common questions from vessel owners about marine diesel fuel injectors. Here are some quick answers to help you make informed decisions.

What are the most common symptoms of a bad marine diesel injector?

The most common signs are excessive black smoke, rough idling or stuttering, a noticeable loss of power, and decreased fuel efficiency. You might also have difficulty starting the engine or smell raw diesel fuel near the engine, which is a fire hazard.

For more general information on symptoms, you can refer to mechanicbase.com/engine/fuel-injector-symptoms/.

How often should marine fuel injectors be serviced?

It depends on your engine. Older mechanical diesel systems typically require service every 1,000 to 2,000 hours. Modern common rail systems have much longer service intervals. Always follow your engine manufacturer’s specific maintenance schedule. Regardless of the system, using high-quality fuel and changing filters regularly is crucial.

Is it better to clean, rebuild, or replace marine fuel injectors?

The best approach depends on the problem.

- Cleaning: Best for preventative maintenance and minor clogging. This ranges from fuel additives to professional off-vessel ultrasonic cleaning.

- Rebuilding: A cost-effective option for high-hour mechanical injectors where the body is intact but internal parts are worn.

- Replacement: Necessary for injectors with cracked bodies, electrical failures, or irreversible internal damage that fails a flow test after cleaning.

A professional diagnosis is the best way to determine the right course of action. For expert service, the factory-authorized technicians at RPM Diesel can test, clean, rebuild, or replace your injectors. Learn more about our rebuilt fuel injectors service.

Conclusion

Your marine diesel’s fuel injection system is the heart of its performance and reliability. When injectors fail, the consequences can ripple through the entire engine, leading to poor performance and costly damage.

As this guide on how to fix fuel injectors has shown, your options range from cleaning and rebuilding to full replacement. The key is to address early warning signs like smoke, rough idling, or power loss promptly. Proactive maintenance—using quality fuel, changing filters, and maintaining your water separator—is the best way to prevent problems before they start.

At RPM Diesel Company, we understand the unique demands of marine diesel engines. Our factory-authorized technicians have the experience, specialized tools, and genuine parts to diagnose and resolve any fuel injection issue. Serving vessel owners from our Fort Lauderdale base and worldwide, we are here to restore your engine’s power and get you back on the water with confidence.