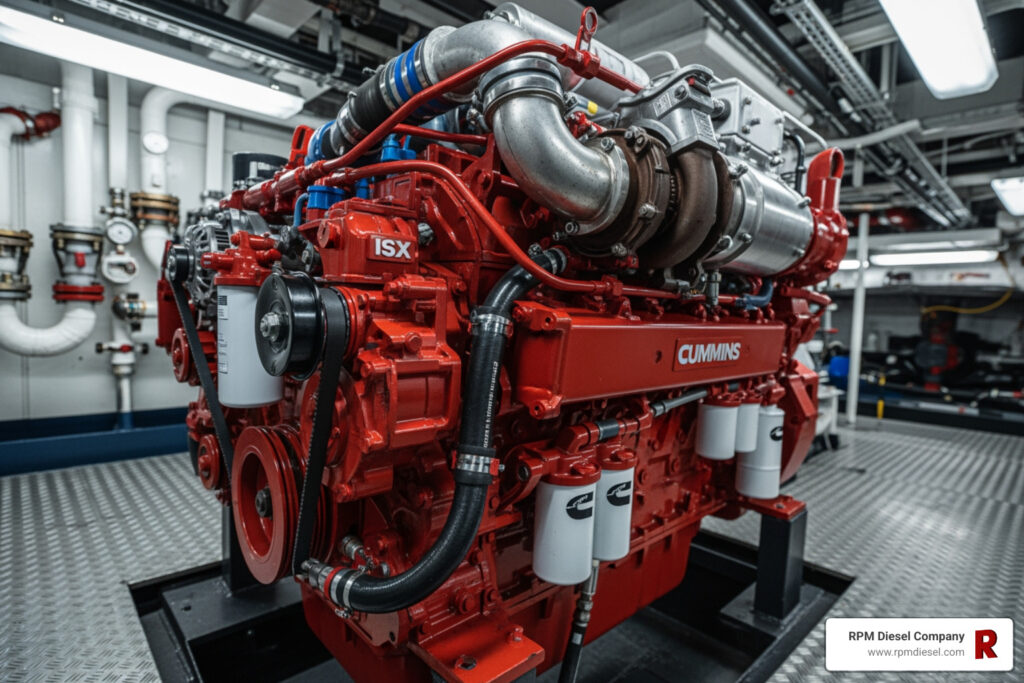

Why Cummins ISX Camshaft Problems Can Sideline Your Vessel

Cummins ISX camshaft problems are among the most common and costly issues facing marine vessel owners. If you’re experiencing unusual engine noises, power loss, or excessive smoke, your camshaft may be the culprit.

Quick Answer: Common Cummins ISX Camshaft Problems

- Ticking or knocking noises from the valve cover

- Power loss and reduced vessel performance

- Excessive smoke (white, black, or blue) from the exhaust

- Frequent injector or valve train failures

- Poor fuel economy and increased operational costs

- Metal shavings in engine oil

The Cummins ISX is a workhorse in marine applications but has a known vulnerability to camshaft failures. These issues often stem from poor lubrication, faulty rocker arms, and neglected valve adjustments. Many ISX engines experience premature camshaft wear, with the #1 intake lobe being particularly susceptible.

For marine vessel owners, a camshaft failure means unexpected downtime, missed voyages, and potential catastrophic engine damage. Fortunately, most camshaft problems are preventable with proper maintenance and early detection.

This guide covers everything you need to know about identifying, diagnosing, and preventing Cummins ISX camshaft problems in your marine engine. We’ll explore the warning signs, root causes, and the proactive steps to protect your investment and keep your vessel running reliably.

Recognizing the Red Flags: Common Symptoms of Camshaft Failure

Your Cummins ISX marine engine will usually give you warning signs before a camshaft fails completely. Recognizing these symptoms early can be the difference between a simple repair and a catastrophic engine failure.

Audible and Performance-Based Warnings

Cummins ISX camshaft problems often announce themselves with distinct sounds and performance changes.

The most common is a persistent ticking or knocking from the valve cover. This noise often points to excessive valve lash, worn cam lobes, or damaged rocker arms. If you find yourself replacing rocker arms frequently, your camshaft likely needs inspection.

On the performance side, your vessel may feel sluggish and struggle to reach its usual top speed. A worn camshaft lobe disrupts valve timing, preventing the engine from breathing properly and causing a noticeable drop in horsepower and torque.

You’ll also see the impact at the fuel dock. Poor fuel efficiency is a direct hit to your operational costs, as a compromised engine works harder and burns more fuel. If your engine is running rough, misfiring, or has an irregular rhythm, don’t ignore it.

Visual Indicators of Trouble

Pay close attention to your exhaust and your engine oil for visual clues.

Excessive smoke from your exhaust is a key indicator. The color is important:

- White smoke can indicate coolant burning, sometimes related to severe timing issues.

- Blue smoke means the engine is burning oil, a problem that camshaft wear can worsen.

- Black smoke points to incomplete combustion, which can be a symptom of incorrect valve timing from a failing cam.

The most alarming sign is metal shavings in your oil. This indicates severe internal wear, as the engine is tearing itself apart. Finding metal particles during an oil change or through oil analysis requires immediate attention.

Other red flags include:

- Milky oil, which signals coolant contamination that destroys lubrication and accelerates cam wear.

- Oil that smells strongly of fuel, indicating fuel dilution that strips the oil of its protective properties, leaving the camshaft vulnerable.

Recognizing these symptoms early gives you the power to act before a minor issue becomes a major one.

The Root of the Problem: Primary Causes of Cummins ISX Camshaft Problems

Cummins ISX camshaft problems are rarely caused by a single issue. They are usually the result of interconnected factors, and understanding them is key to prevention and repair.

The Critical Role of Lubrication and Oil Quality

Proper lubrication is the first line of defense for your camshaft.

- Poor Lubrication: This is the biggest culprit. A steady flow of clean oil is essential to prevent metal-on-metal grinding. Low oil pressure or clogged passages in the cylinder head can lead directly to cam failure.

- Incorrect Oil: Using the wrong oil viscosity is just as damaging as low oil levels. Your marine ISX requires oil meeting specific API CJ-4 or CK-4 specifications to handle the extreme pressures of marine operation.

- Oil Degradation and Contamination: Pushing oil changes beyond recommended intervals is a false economy. Over time, oil breaks down and becomes contaminated with soot, turning it into an abrasive paste that accelerates wear on the camshaft.

- Oil Analysis: Regular oil analysis is an early warning system. It can spot metal shavings, fuel dilution, or coolant contamination long before catastrophic failure occurs.

The Rocker Arm Connection to Cummins ISX Camshaft Problems

Often, the camshaft is a victim of faulty rocker arms. The ISX has a known history of rocker arm issues that cascade into camshaft failure. Some rocker arm designs restrict oil flow, starving them of lubrication.

This causes lobe flattening. An oil-starved rocker arm stops rolling smoothly and instead smacks or slides against the cam lobe, causing rapid wear that flattens its profile. As one diesel expert noted, “The ISX also has a history of camshaft issues… an ISX camshaft can flatten out. This is not because of an issue with the camshaft itself, but with the rocker arms.”

Crucially, if you replace a failed camshaft, you must also replace the rocker arms. Failing to do so will cause the new camshaft to fail in the same way.

The Impact of Improper Maintenance and Valve Lash Adjustments

Neglecting routine maintenance is a sure way to destroy a camshaft.

Valve lash adjustments are essential. The gap between the rocker arm and valve stem must be set to specification. If it’s too tight, it puts constant pressure on the cam lobe, grinding it down. If it’s too loose, the rocker arm hammers the lobe, causing impact damage. Overhead adjustments are recommended every two years or the equivalent in marine operating hours.

A neglected crankcase filter can also cause problems by creating pressure that starves the top end of the engine of oil, directly impacting your camshaft and rocker arms.

From Diagnosis to Solution: Inspecting and Repairing a Failing Camshaft

If you suspect Cummins ISX camshaft problems, a thorough inspection is required to determine the right repair strategy. A quick fix won’t solve the underlying issue.

How to Inspect Your ISX Camshaft for Wear

After ensuring the engine is cold and disconnected from power, remove the valve cover to access the valve train.

- Inspect the Rocker Arms: Look closely at each rocker arm for damage, excessive play, or unusual wear. The roller surfaces should be smooth; any scoring, pitting, or discoloration is a red flag.

- Visually Inspect Camshaft Lobes: Check the lobes for signs of trouble like scoring (grooves), pitting (craters), discoloration (from heat), or flattening (loss of profile). The #1 intake lobe is especially vulnerable.

- Measure Lobe Lift: For a precise assessment, use a dial indicator to measure lobe lift and compare it to factory specifications. Significant deviation confirms wear.

Oil sample analysis is also a reliable way to detect metal shavings before they cause widespread damage.

The Domino Effect: Consequences of a Failing Camshaft

A failing camshaft creates a destructive chain reaction.

- Piston and Valve Damage: Severely compromised timing can cause valves to strike pistons, a catastrophic event requiring a complete engine overhaul.

- Component Contamination: As the cam and rollers wear, they shed metal shavings into the engine oil. These abrasive particles circulate and damage bearings, the oil pump, the turbocharger, and other critical parts.

Left unaddressed, Cummins ISX camshaft problems lead to catastrophic engine failure, costly downtime, and emergency repairs far from port.

Choosing the Right Replacement: OEM vs. Aftermarket Parts

The quality of your replacement parts determines whether you get a lasting fix or a recurring headache.

When replacing a worn camshaft, you must also replace all associated rocker arms, especially if they caused the initial failure. Installing a new cam with old, faulty rockers guarantees a repeat failure.

Genuine Cummins parts or trusted, marine-grade aftermarket brands are manufactured to precise specifications for demanding marine conditions. While cheaper parts may seem appealing, they often wear out quickly, leading to more expensive repairs down the line. For your vessel’s reliability, genuine parts are an investment in uptime.

For widespread wear, a complete overhaul kit is often the most cost-effective long-term solution. A full ISX in-frame kit ensures all interacting components are new and matched to restore your engine to factory specs. At RPM Diesel Company, we provide genuine parts and expert guidance to find the right repair option for your vessel.

Proactive Protection: Preventing Camshaft Failure in Your Marine ISX Engine

Preventing Cummins ISX camshaft problems is far easier and cheaper than fixing them. A consistent maintenance routine is your vessel’s best insurance against catastrophic failure and costly downtime.

The Ultimate Defense: A Preventative Maintenance Schedule

Investing a few hours in preventative maintenance can save you days or weeks of emergency repairs. Here are the critical tasks:

- Regular Oil Changes: Clean, properly formulated marine-grade oil is the lifeblood of your engine. Skipping or extending oil change intervals removes the camshaft’s primary defense.

- Oil Sample Analysis: This is like a blood test for your diesel. It spots microscopic metal particles and other contaminants, providing an early warning of camshaft wear long before you hear any noise.

- Routine Valve Lash Adjustments: Proper valve lash is critical. We recommend overhead adjustments based on operating hours (equivalent to every 2 years or 250,000 miles). Incorrect lash either grinds down or hammers the cam lobes, causing premature failure.

- Crankcase Filter Maintenance: A clogged filter can build pressure and starve the top end of your engine—including the camshaft—of necessary oil.

- Use High-Quality Supplies: Always use high-quality marine-grade oil (CJ-4/CK-4 spec) and filters. Inferior products do not provide adequate protection for high-load marine applications.

- Keep a Detailed Logbook: Record all maintenance, operating hours, and unusual observations. This data is invaluable for diagnostics and increases your vessel’s resale value.

Understanding the Lifespan of a Cummins ISX Camshaft

With meticulous maintenance, an ISX camshaft can provide thousands of reliable operating hours. However, the marine environment presents unique challenges.

Sustained high loads put constant stress on internal components, accelerating wear. Unlike a truck that cruises intermittently, a marine engine often runs near full load for extended periods. Poor maintenance can cut the camshaft’s lifespan in half. Neglected oil changes or using the wrong oil will lead to premature failure.

With proper care, your ISX camshaft can serve you reliably. At RPM Diesel Company, we’ve seen how a disciplined maintenance approach keeps vessels on the water.

Frequently Asked Questions about Cummins ISX Camshaft Issues

Here are answers to the most common questions we hear about Cummins ISX camshaft problems.

Can a failing camshaft damage other parts of my marine engine?

Yes, absolutely. A failing camshaft can cause a destructive chain reaction. Worn lobes can alter valve timing, leading to catastrophic valve-to-piston contact. More commonly, the wearing cam and rollers shed metal debris into the engine oil. This abrasive material circulates and damages bearings, the oil pump, the turbocharger, and other critical components, potentially requiring a complete engine rebuild.

What is the typical lifespan of a Cummins ISX camshaft in a marine application?

With perfect maintenance, an ISX camshaft can last for thousands of operating hours. However, the harsh reality of marine applications—continuous high loads, poor oil quality, or neglected maintenance—can dramatically shorten this lifespan. Premature wear is common, especially on the #1 intake camshaft lobe. Vigilant maintenance is the key to longevity.

What’s the difference between a camshaft repair and a full engine overhaul?

A camshaft repair is a targeted fix, replacing the camshaft and its directly related components like rocker arms. It’s focused on restoring valve train function.

A full engine overhaul is a comprehensive rebuild of the entire engine. It addresses widespread wear by replacing pistons, rings, liners, bearings, and other systems to restore the engine to factory specifications. An overhaul is often necessary if metal debris from a cam failure has contaminated other parts. Contact us for all your diesel engine repair needs, and we can help determine the right path for your engine.

Conclusion: Safeguarding Your Investment Against Camshaft Failure

Cummins ISX camshaft problems are serious, but they are manageable and often preventable. A failing camshaft can lead to catastrophic engine damage, but it doesn’t have to.

The key takeaways are:

- Vigilant Monitoring: Pay attention to warning signs like ticking noises, power loss, and excessive smoke. Your engine is communicating with you.

- Proactive Maintenance: This is your best defense. Regular oil changes with marine-grade oil, routine valve lash adjustments, and oil sample analysis are your insurance against breakdowns.

- Quality Parts & Service: When repairs are needed, use genuine Cummins parts and trust professionals who understand the specific quirks of the marine ISX engine.

At RPM Diesel Company, we keep marine vessels running reliably throughout Fort Lauderdale, Broward County, Dade County, Miami, West Palm Beach, Boca Raton, and Delray Beach, Florida. Our expertise isn’t just in fixing problems—it’s in preventing them. As authorized service providers for major manufacturers like Detroit Diesel and MTU, with a vast inventory of marine diesel parts, we are equipped to handle all your ISX engine needs.

Whether you have an active camshaft issue or want to establish a robust preventative maintenance program, our team provides comprehensive marine engine service worldwide. By understanding the causes and preventative measures for Cummins ISX camshaft problems, you protect your investment and ensure reliability on the water. Don’t wait for an emergency. Contact us for all your diesel engine repair needs and let’s keep your engine running strong.