Why Your Boat Engine Cooling System Matters More Than You Think

A boat engine cooling system is the unsung hero that prevents your marine diesel engine from turning into an expensive paperweight. Here’s what you need to know right away:

What a Boat Engine Cooling System Does:

- Prevents overheating by continuously removing heat generated by thousands of combustion events per minute

- Protects critical components from warping, seizing, and catastrophic failure

- Maintains optimal operating temperature for peak engine efficiency and fuel economy

- Extends engine life by preventing corrosion, scaling, and thermal damage

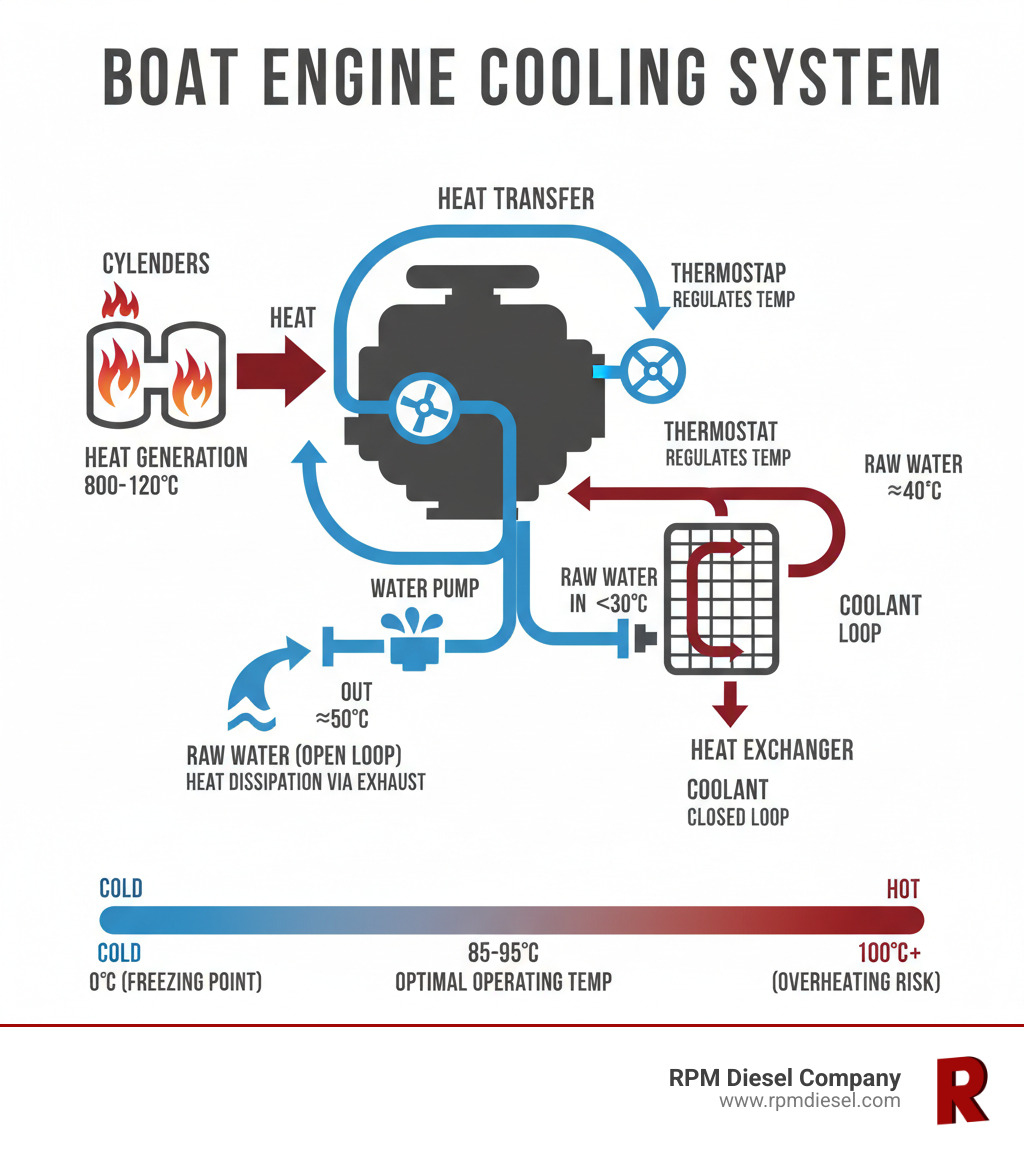

The Two Main Types:

- Raw Water (Open-Loop) – Draws water directly from the lake or sea, pumps it through the engine, and expels it

- Enclosed (Closed-Loop) – Uses antifreeze coolant inside the engine, cooled by a heat exchanger that uses raw water externally

Internal combustion engines generate tremendous heat. Without an effective cooling system, that heat has nowhere to go. The result? Everything from blown head gaskets to complete engine failure. All that combustion puts off lots of heat, and your cooling system is the only thing standing between smooth sailing and being stranded at sea.

The marine environment makes cooling even more critical. Saltwater temperatures above 140°F can cause corrosive scale buildup. In raw water systems, this scaling forms inside the engine itself, potentially requiring engine replacement. In enclosed systems, only the heat exchanger faces raw water, making repairs far less catastrophic.

Whether you’re running a yacht internationally or a local fishing vessel, understanding your cooling system isn’t optional. It’s the difference between a reliable engine and an emergency tow back to port.

The Two Main Types of a Boat Engine Cooling System

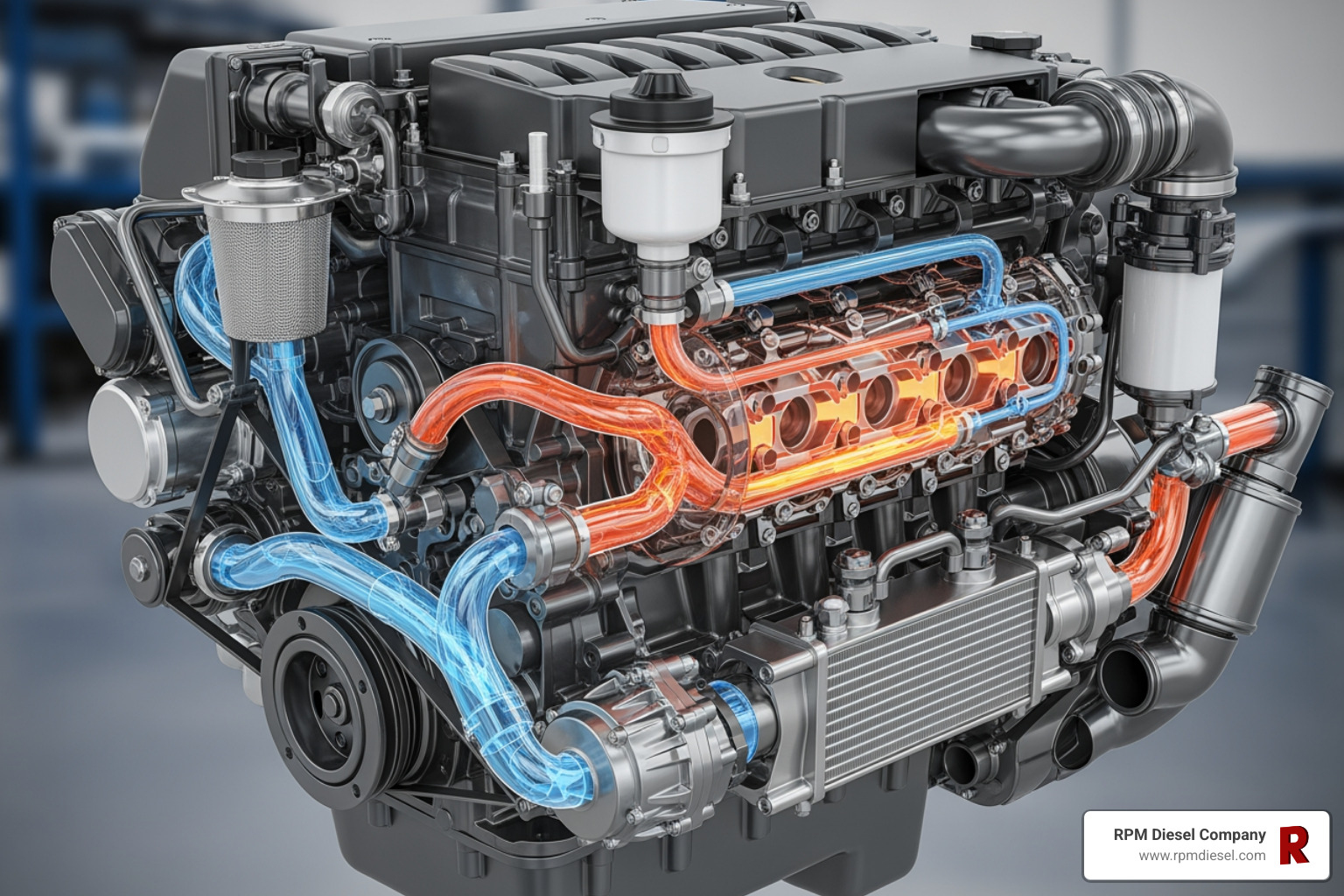

Our marine diesel engines, like all internal combustion engines, generate immense heat. Thousands of tiny explosions per minute, while powerful, also produce a significant amount of thermal energy. With no place to go, all that heat would quickly lead to lots of issues, from a blown head gasket to catastrophic engine damage. That’s where the boat engine cooling system comes in. Its primary function is to cycle a liquid coolant through the engine block to absorb this excess heat, preventing overheating and potential damage.

Unlike cars and trucks, which typically use a single cooling method, boats operate in an unlimited supply of cold liquid – the surrounding water. This unique environment allows for two primary cooling system designs: raw water (open-loop) and enclosed (freshwater/closed-loop). Each has its own complexities, cost implications, and, critically, different levels of corrosion risk, especially in the saltwater environments common in Florida.

How a Raw Water (Open-Loop) Cooling System Works

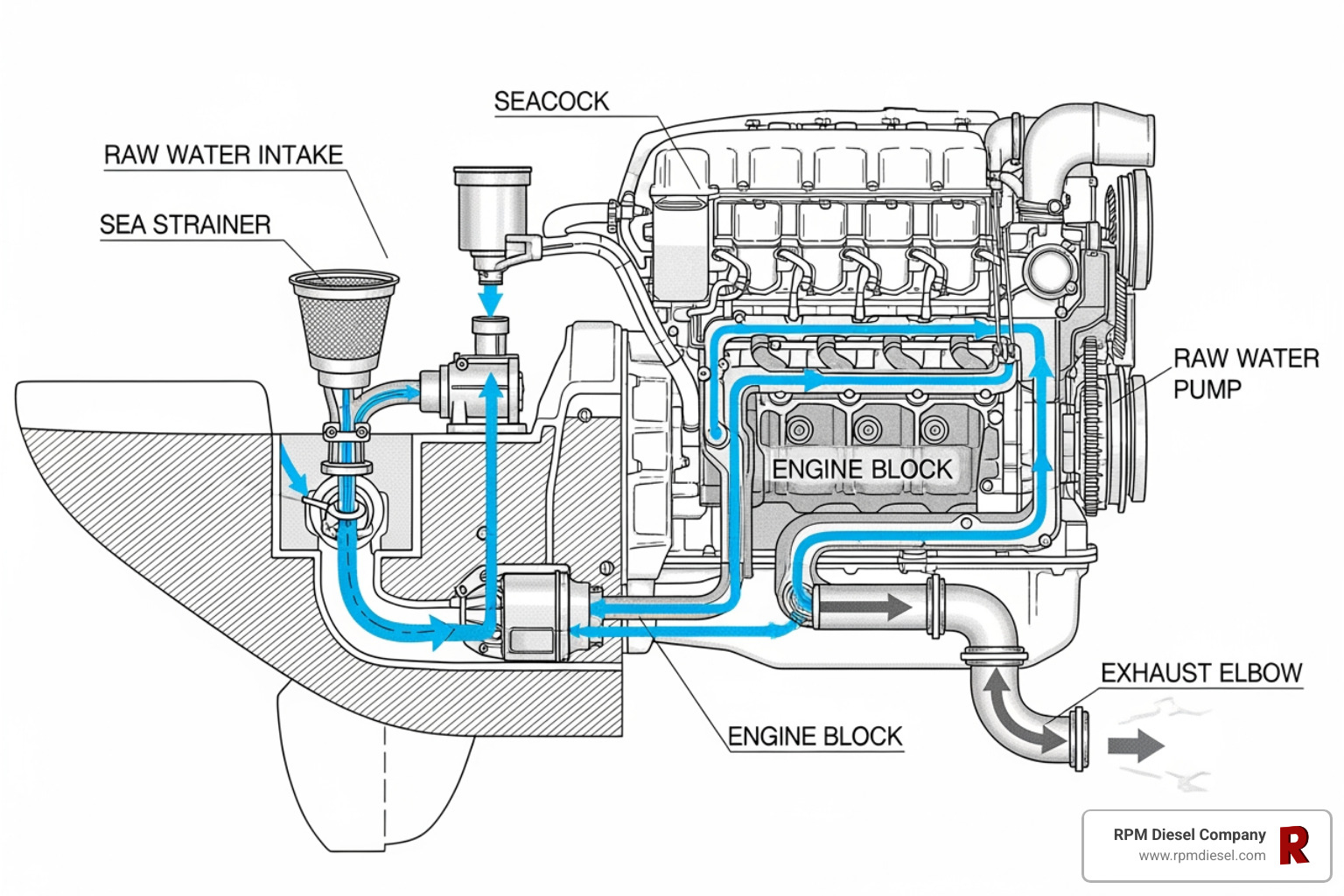

A raw water cooling system is the simpler of the two designs, often found in smaller boats, outboards, and some inboard/sterndrive systems. It’s called “raw water” because it uses the water the boat is floating in – whether it’s the freshwater of a lake or the saltwater of the Atlantic – directly to cool the engine.

The process is quite straightforward:

- Intake: A pump continuously draws water from the surrounding body of water through a seacock.

- Circulation: This raw water is then pumped directly through the engine’s water jacket and internal passages. As it flows, it absorbs heat from the engine components.

- Expulsion: Once heated, the water is expelled back into the environment, often mixed with the exhaust gases through the transom.

The main advantage of this system is its simplicity and typically lower initial cost. There’s no separate cooling circuit or complex heat exchanger to maintain. Raw water systems also offer an environmental benefit in that there’s no risk of toxic antifreeze leaking into the body of water the boat is on. This reduction in environmental risk is significant, as coolant is extremely toxic to wildlife.

However, this simplicity comes with significant drawbacks, particularly for boats operating in saltwater. Saltwater tends to build up a corrosive scale when the engine operates above 140°F. In a raw water system, this scale builds up inside the engine’s water jacket and ports. When the scaling restricts water flow, the engine starts to overheat. At this point, you’re likely looking at replacing the engine, which is a very expensive repair. You can learn more about raw water cooling systems at http://www.boatsafe.com.

How an Enclosed (Freshwater/Closed-Loop) Cooling System Works

An enclosed cooling system, also known as a freshwater or closed-loop system, is more sophisticated but offers superior protection and performance, especially for marine diesel engines operating in saltwater. This system operates much like a car’s cooling system, but with a marine twist.

Here’s how it works:

- Internal Circulation: A mixture of freshwater and antifreeze (coolant) circulates within a closed loop through the engine block, absorbing engine heat. This coolant is engineered to inhibit corrosion, neutralize acids, and have an extended service life.

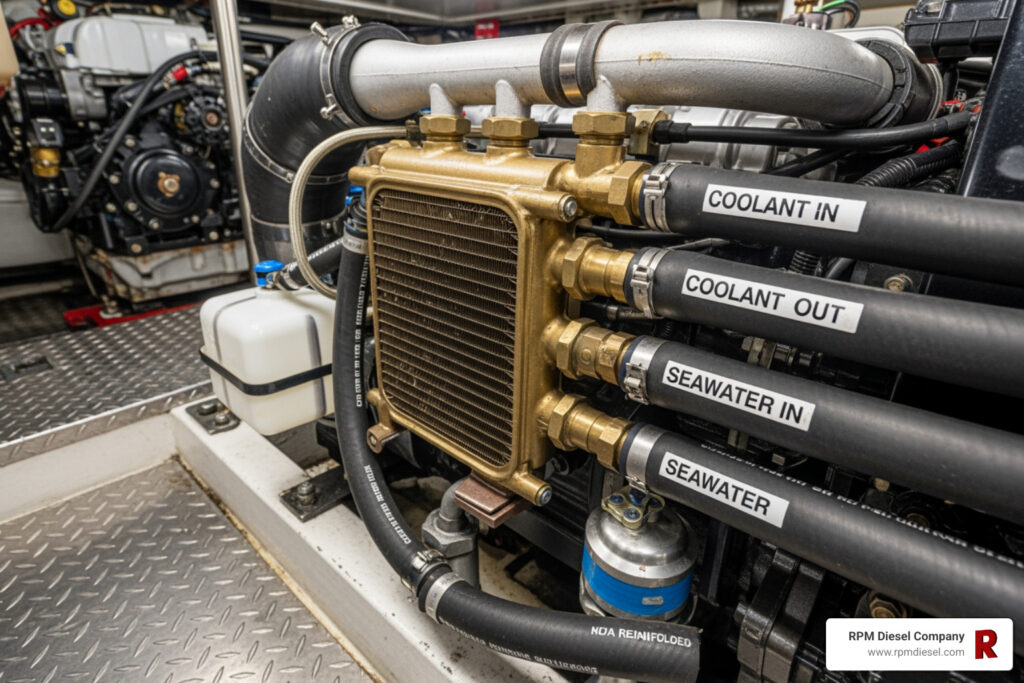

- Heat Transfer: The heated engine coolant then flows to a component called a heat exchanger.

- External Cooling: Simultaneously, a separate raw water circuit draws water from the surrounding environment (just like in a raw water system). This raw water is pumped through the heat exchanger, but it never comes into direct contact with the engine coolant. Instead, the raw water flows around tubes containing the hot engine coolant. Heat is transferred from the engine coolant through the walls of these tubes to the cooler raw water.

- Expulsion: The now-heated raw water is then pumped out of the boat, often into the exhaust system to cool exhaust gases before being expelled overboard. The cooled engine coolant returns to the engine to continue its work.

This indirect cooling method offers substantial advantages. Enclosed cooling systems are more effective at cooling the engine, allowing it to operate at higher, more efficient temperatures safely. By increasing the pressure inside the closed part of the system, the boiling point of the coolant is improved. For every pound of pressure added, approximately 3°F can be added to your engine’s operating temperature, improving its thermal efficiency. Modern automotive engines, for example, typically run at 215°F, achieving much better mileage than their older counterparts.

Crucially, because the corrosive raw water doesn’t flow through the engine itself, corrosion and scale buildup are largely prevented within the engine’s vital internal passages. If scaling occurs, it’s typically within the heat exchanger, which is much less expensive to clean or replace than an entire engine. This is why most newer marine engines, particularly those for marine diesel applications like the ones we service at RPM Diesel, use an enclosed cooling system. You can learn more about how intercooled engines work at https://www.pbo.co.uk/all-latest-posts/how-an-intercooled-engine-works-73853.

Comparing Raw Water vs. Enclosed Cooling Systems

To help you decide which system is right for your vessel or to better understand your current setup, here’s a quick comparison:

| Feature | Raw Water Cooling System | Enclosed Cooling System |

|---|---|---|

| Pros | Simple design, lower initial cost, no risk of antifreeze leaks. | Superior engine protection, better temperature control, higher efficiency, longer engine life. |

| Cons | Prone to internal corrosion and scaling in saltwater, lower efficiency, risk of major engine damage from clogs. | More complex, higher initial cost, requires more maintenance (coolant, anodes). |

Keeping Your Cool: Maintenance and Troubleshooting

Here’s the truth about your marine diesel engine: a little preventative maintenance now saves you from catastrophic repairs later. We’ve seen it time and again in South Florida – a boat owner skips routine cooling system checks, and suddenly they’re facing an engine rebuild or replacement. When it comes to your boat engine cooling system, staying proactive isn’t optional. It’s the difference between reliable performance and being towed back to the marina.

The good news? Most cooling system maintenance is straightforward. You don’t need an engineering degree to keep your engine running cool. What you do need is consistency and attention to detail. Let’s walk through what actually matters.

Essential Maintenance Tasks for Your Boat Engine Cooling System

Think of cooling system maintenance as an investment in your engine’s future. Every hour you spend on prevention saves you from days of downtime and thousands in repair costs.

Flushing the raw water side should happen at least annually, especially during your winter layup. Even if you’re in Florida where “winter” is relative, that annual flush removes the micro-organisms, calcium, and lime that gradually build up inside your system. Products like Seaflush or Forté cooling system flush work well for this. The buildup happens slowly, so you might not notice it until flow is seriously restricted.

Your raw water pump impeller deserves special attention. We recommend replacement every season or two, depending on how much you use your boat, or at the 1000-hour mark. Even if the impeller looks fine to the naked eye, rubber degrades. It can “take a set” – those blades get bent and stay bent, reducing efficiency dramatically. This is especially common if your boat sits idle for extended periods, which happens more than you’d think, even here in South Florida where we can boat year-round.

For enclosed systems, those sacrificial anodes in your heat exchanger are doing exactly what their name suggests – sacrificing themselves to protect more expensive components. Check them annually, particularly in saltwater. If they’re more than 25% eroded, replace them. It’s cheap insurance.

Engine coolant testing and replacement keeps your enclosed system healthy. Test the coolant annually for alkalinity using litmus paper. If the paper doesn’t change color, your coolant has lost its protective properties and needs replacing. Most coolants should be changed every two years, though some extended-life products (like Mercury Marine’s five-year or 1000-hour coolant) last longer. We typically use a 50/50 mixture of coolant and fresh water. In colder climates, you’d adjust that ratio, but that’s rarely a concern here in South Florida.

Visual inspections of hoses, clamps, and belts should happen every single time you check your oil – which should be before every start-up. Look for cracks, brittleness, excessive softness, or corrosion. Hoses below the waterline must be double-clamped, always. If you spot any damage, replace the component immediately with manufacturer-specified parts. Don’t improvise here.

Your sea strainer needs regular cleaning. Check that removable filter or screen frequently and remove any debris. It’s your first line of defense against clogs, and a clean strainer prevents problems downstream.

Pay attention to your manufacturer’s service intervals, usually expressed in hours. The 1000-hour and 3200-hour services for marine diesel engines aren’t suggestions – they’re critical maintenance points that ensure proper water flow and prevent gradual deposit buildup on both the freshwater and raw water sides.

Signs of a Malfunctioning Cooling System

Your engine talks to you. The question is whether you’re listening. Most cooling system failures give you warning signs before they become catastrophic.

The overheating alarm or warning light is your engine screaming for help. If you hear that alarm or see that light, shut down immediately. Running an overheating engine even for a few minutes can cause permanent damage.

Steam from the exhaust or engine compartment means temperatures have gotten dangerously high. Similarly, reduced or absent water flow from the tell-tale (that little stream of water you see coming out of outboards and some inboards) indicates a blockage or pump failure. On a properly functioning system, that stream should be steady and strong.

Watch your temperature gauge. It should stay within the normal operating range consistently. A reading that creeps higher and higher, or suddenly spikes, tells you something’s wrong with heat dissipation.

Coolant leaks are usually visible – look for puddles under the engine or drips from hoses, clamps, or the heat exchanger. Any breach in a closed-loop system compromises its ability to maintain proper pressure and temperature.

You might also notice diminished engine performance. When an engine starts to overheat, it often reduces power automatically as a protective measure. The engine might run rough or simply feel weak compared to normal.

A quick, careful touch of the engine block (not prolonged – you can burn yourself) can sometimes reveal excessive heat that your gauges haven’t caught yet. If it’s uncomfortably hot to touch briefly, something’s wrong.

If you experience any of these symptoms, don’t ignore them. We’re here in South Florida to help diagnose and repair cooling system issues before they turn into major problems.

Environmental and Advanced Considerations

Beyond the nuts and bolts, your boat engine cooling system exists in a broader context – both environmental and technical.

Antifreeze is highly toxic to wildlife. Traditional ethylene glycol-based coolant can devastate marine ecosystems if it leaks into the water. When you’re changing coolant, proper disposal isn’t optional – it’s a responsibility. The good news is that propylene glycol-based coolants offer a more environmentally friendly alternative while still providing excellent protection. Raw water systems avoid this concern entirely since they don’t use coolant, eliminating any risk of antifreeze entering the water.

Most boats come with stock cooling systems, and they work well for typical applications. But sometimes, you need something more. Custom-designed cooling systems offer benefits like improved durability, better corrosion resistance, greater reliability, and superior efficiency. This is particularly valuable for high-performance marine diesel engines or vessels with unique space constraints. At RPM Diesel, we bring over 50 years of experience in marine engine cooling systems and heat exchangers. Whether you need a stock replacement or a custom solution, we can design the optimal setup for your engine protection needs.

Different engine types have different cooling needs. Outboards typically use water-cooled systems with raw water cooling because of their efficiency. Some smaller or older outboards use air-cooling, but that’s generally less effective, especially in warm Florida waters. Inboard marine diesels overwhelmingly use enclosed freshwater cooling systems. The precision temperature control, corrosion prevention, and longevity benefits are essential for these valuable, critical engines. Sterndrives vary – they might use either raw water or enclosed systems depending on the manufacturer and model.

Here’s an interesting fact about engine efficiency: the hotter an engine runs without causing damage, the more efficient it becomes. Modern engines are designed to operate at higher temperatures for better thermal efficiency and fuel economy. A typical modern automobile runs at 215°F – much hotter than engines from decades past. Enclosed, pressurized cooling systems allow marine diesel engines to safely operate at these higher, more efficient temperatures. The result? Extended engine life, improved performance, and better fuel economy. It’s all about finding that sweet spot where the engine runs hot enough for peak efficiency but cool enough to avoid damage.

Conclusion

Think of your boat engine cooling system as your engine’s lifeguard – always on duty, always watching, always ready to prevent disaster. It’s not the flashiest part of your vessel, but it’s absolutely essential to keeping everything running smoothly out on the water.

Throughout this guide, we’ve walked through the fundamentals: how raw water systems offer simplicity while enclosed systems provide superior protection, especially in our Florida saltwater environment. We’ve examined the hardworking components – from the seacock that starts it all to the heat exchanger that does the heavy lifting – and we’ve covered the maintenance tasks that keep everything functioning as it should.

Here’s the bottom line: proactive maintenance pays off. The cost of regularly checking your impeller, cleaning your sea strainer, and testing your coolant is a fraction of what you’d spend on emergency repairs or, worse, a complete engine replacement. A small investment of time and attention now saves you from those expensive, boat-season-ending surprises later.

We know marine diesel engines inside and out. With over 50 years of experience in marine engine cooling systems, we’ve seen it all – from simple impeller failures to complex custom cooling solutions for high-performance vessels. Whether you’re cruising the Intracoastal, fishing offshore, or maintaining a commercial vessel, we’re here to ensure your engine stays cool and reliable.

Our team at RPM Diesel specializes in marine engine sales, service, and maintenance, with on-site services available throughout South Florida and worldwide. We’re authorized by major manufacturers and maintain an extensive inventory of parts, including those hard-to-find components that can make or break a repair job.

Don’t wait until you see steam or hear that dreaded overheating alarm. Whether you need routine maintenance, emergency repairs, or advice on upgrading your cooling system, we’re ready to help.

Get expert help with your boat engine repair

Your engine works hard for you. Let us help you take care of it.