The Heart of Modern Power and Efficiency

The dd15 engine is a 14.8-liter inline six-cylinder diesel powerplant manufactured by Detroit Diesel, designed to deliver exceptional performance and fuel efficiency. Here’s what you need to know:

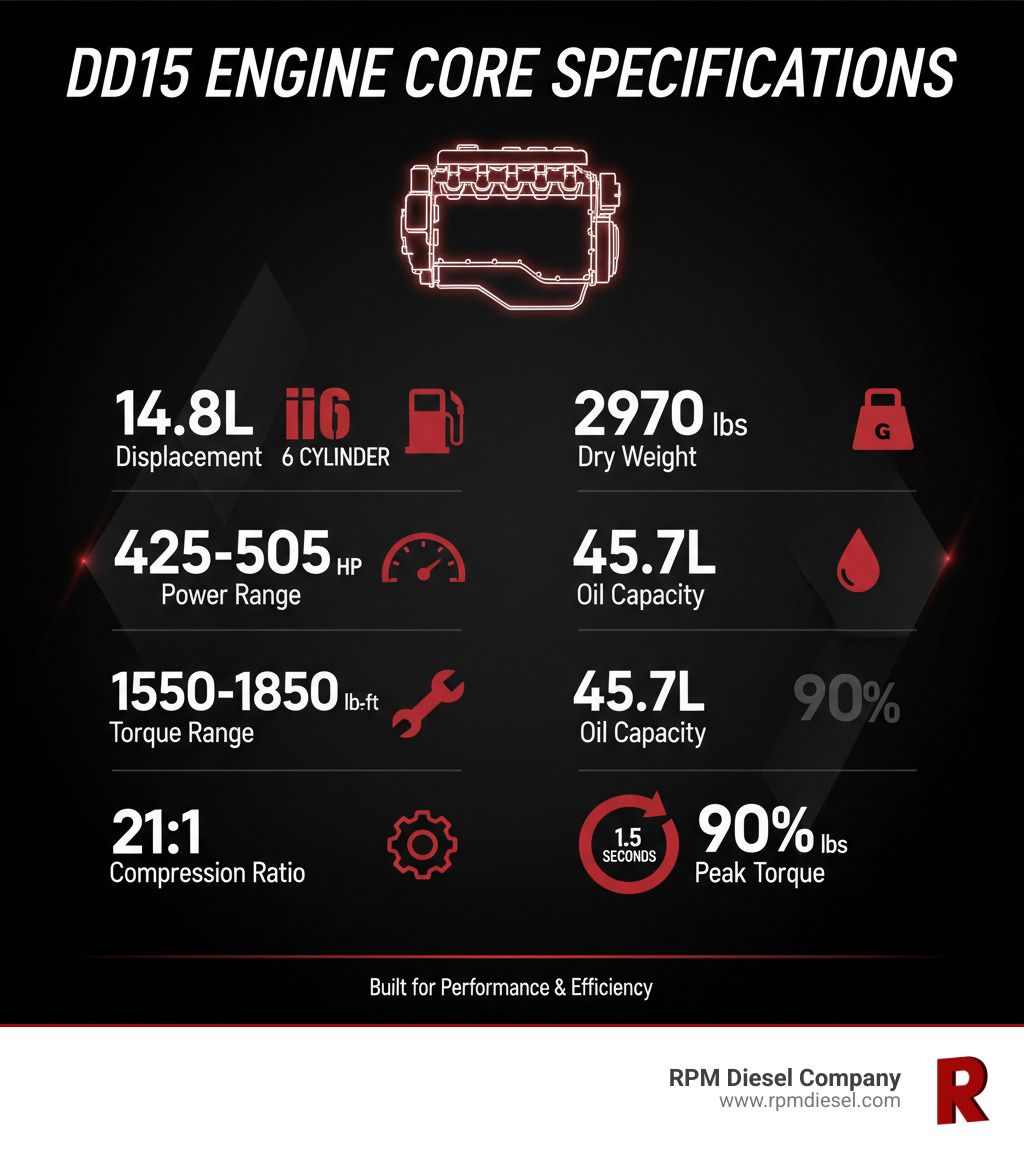

Key DD15 Engine Specifications:

- Displacement: 14.8 L (906 cu. in.)

- Configuration: Inline 6 Cylinder

- Horsepower: 425 – 505 HP

- Torque: 1550 – 1850 lb-ft

- Compression Ratio: 21:1

- Weight (Dry): 2,970 lbs

- Oil Capacity: 45.7 L

The Detroit DD15 has built its reputation on delivering next-generation efficiency paired with impressive power ratings. Since its introduction, this engine has been engineered to achieve 90 percent of peak torque in just 1.5 seconds—significantly faster than competing engines that typically take 4.4 seconds to reach the same level.

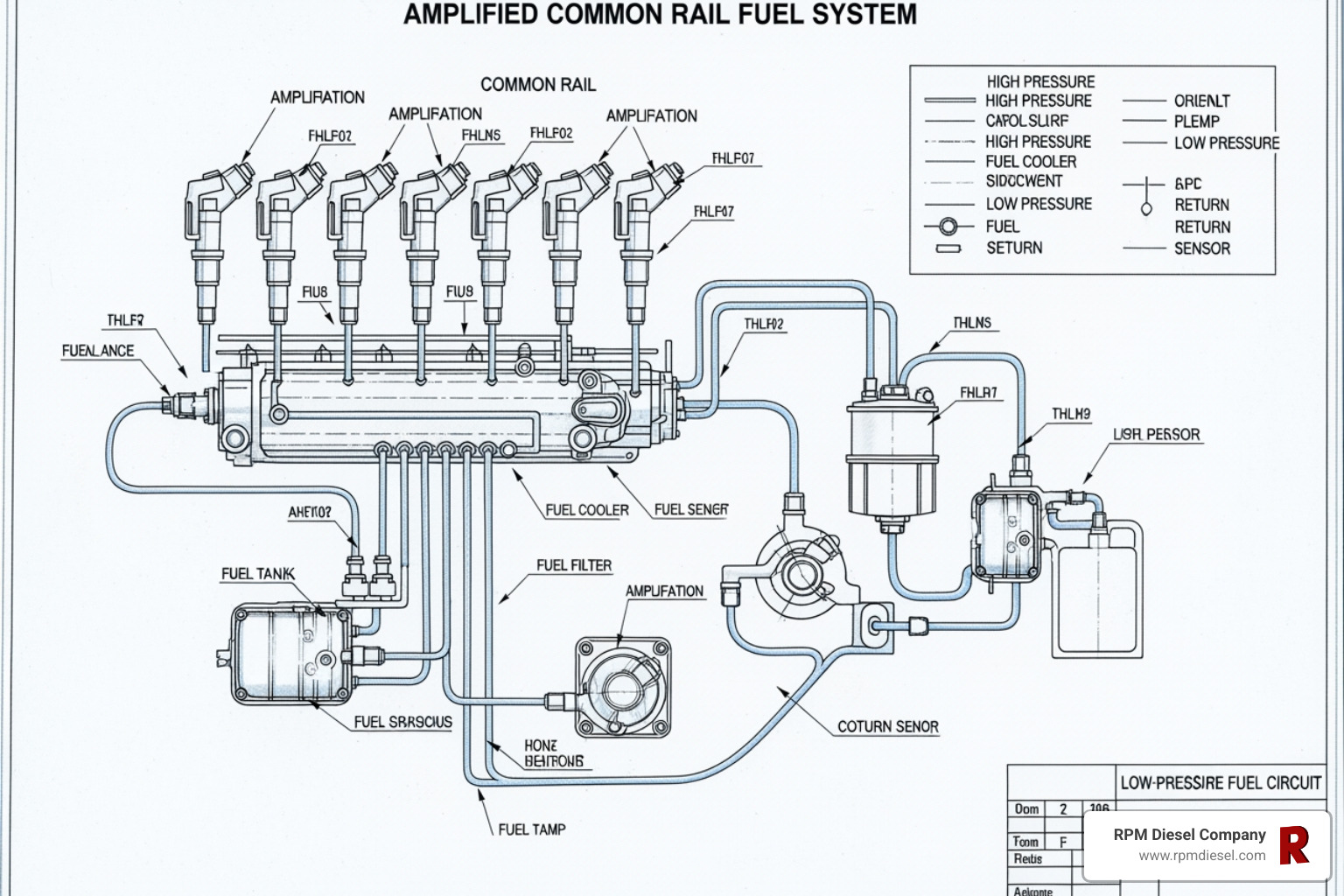

What sets the DD15 apart is its combination of advanced technologies. The engine features an Amplified Common Rail Fuel System (ACRS), a swirl piston design for maximum combustion efficiency, and an innovative aftertreatment system that shortens regeneration cycles. These engineering advances translate to up to 3% better fuel economy compared to previous models, while meeting strict EPA, CARB, GHG, and OBD emissions requirements.

The DD15’s ultra-high compression ratio and dual overhead camshafts create a long, flat torque curve that pulls down to 1,100 RPM. This means less shifting, more pulling power, and consistent performance under demanding conditions—whether you’re powering through challenging marine applications or maintaining steady operation over extended periods.

Detroit Diesel has built more than 5 million engines since 1938, with over 1 million still in operation worldwide. The DD15 continues this legacy of durability and reliability, backed by extensive parts availability and support through Detroit’s #1 rated service network.

DD15 Engine Core Specifications and Performance Metrics

The DD15 engine stands as a testament to precision engineering, built to meet the demanding needs of marine applications where reliability isn’t just important—it’s everything.

At its core, the DD15 features an inline 6-cylinder configuration—a proven design that delivers exceptional balance and smooth operation, critical factors when you’re spending long hours on the water. With a displacement of 14.8 liters (906 cubic inches), this engine generates the kind of power that marine operators depend on.

The power output ranges from 425 to 505 horsepower, giving you flexibility based on your vessel’s specific requirements. What really impresses us, though, is the torque: a commanding 1550 to 1850 lb-ft that makes moving heavy loads feel effortless. This isn’t just about raw numbers—it’s about having the muscle when you need it most.

The engine’s 21:1 compression ratio is remarkably high, playing a crucial role in squeezing every bit of energy from the fuel. Despite its impressive output, the DD15 maintains a dry weight of approximately 2,970 pounds, making it powerful without being unwieldy. The oil capacity of 45.7 liters ensures proper lubrication throughout extended operation periods, and the sophisticated DDEC electronics act as the engine’s brain, managing everything from fuel delivery to diagnostics.

Understanding DD15 Engine Power Delivery

Here’s where the DD15 engine really shines: it delivers 90 percent of peak torque in just 1.5 seconds. For perspective, that’s about three times faster than many competing engines. When you’re navigating challenging conditions or need immediate response, this rapid torque delivery makes all the difference.

The engine’s long torque range means you’re operating in the sweet spot more often. With strong low-end torque available down to 1,000 RPM, the DD15 pulls steadily without constantly hunting for the right power band. This characteristic reduces the need for frequent gear changes and creates a smoother, more predictable operating experience.

What this means in real-world terms is sustained power output when you need it. Whether you’re maintaining cruising speed or handling varying loads, the engine responds with confidence. It’s this kind of reliable performance that keeps marine vessels operating efficiently, hour after hour.

Fuel Efficiency and Emissions

In marine applications, fuel efficiency directly impacts your bottom line. The DD15 engine delivers up to 3 percent better fuel efficiency compared to previous generations. Over thousands of operating hours, that improvement adds up to significant savings.

This efficiency comes from intelligent design. The swirl piston design creates optimal air-fuel mixing in the combustion chamber, ensuring complete and efficient burning. Every drop of fuel contributes to forward motion rather than wasted energy.

The innovative aftertreatment system handles emissions without compromising performance. The DD15 meets all EPA, CARB, GHG, and OBD compliance requirements, proving that environmental responsibility and power can coexist. Detroit Diesel engineered this system to work seamlessly in the background, so you can focus on operations rather than emissions management.

For a deeper dive into the technology and features that make this engine exceptional, visit More about the DD15 engine. The combination of efficiency, power, and clean operation makes the DD15 an outstanding choice for serious marine applications.

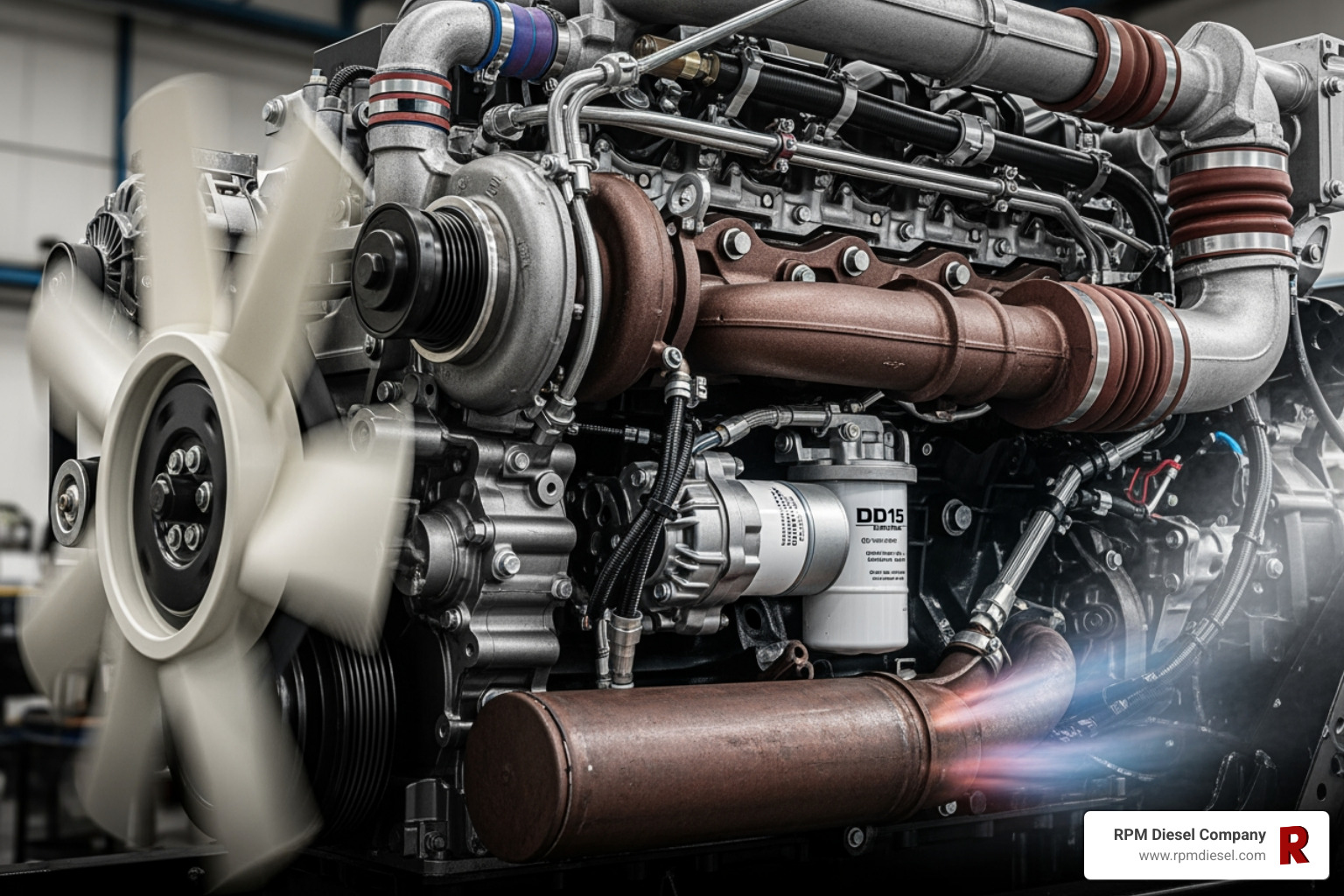

Technological Innovations That Define the DD15

When you look under the hood of a DD15 engine, you’re not just seeing metal and machinery—you’re witnessing the result of decades of engineering innovation. Detroit Diesel has packed this powerplant with technologies that work together seamlessly to deliver the kind of performance that marine applications demand.

At the heart of the DD15’s impressive performance is the Amplified Common Rail Fuel System (ACRS). Think of this as the engine’s precision delivery system—it ensures that fuel gets injected at exactly the right moment and pressure for optimal combustion. This system doesn’t work alone, though. It’s constantly communicating with the DDEC electronics, which act as the engine’s brain, making thousands of calculations per second to keep everything running perfectly.

The Ball Bearing Simple Geometry Turbo is another standout feature. Unlike traditional turbos that can lag when you need power quickly, this design uses ball bearings to reduce friction and improve response time. The result? Faster power delivery when you push the throttle, which is exactly what you want when maneuvering a vessel or handling challenging marine conditions.

Detroit Diesel also engineered the DD15 for improved downspeeding. This means the engine can operate efficiently at lower RPMs while still delivering the power you need. It’s a win-win situation—you save fuel and reduce wear on components, all while maintaining the performance your operation depends on.

One of the more clever innovations is Thermocoasting technology. During periods when the engine is coasting or under light load, this system keeps the aftertreatment components at optimal temperatures. Why does this matter? Because it leads to shorter regen cycles, which means less downtime and more productive hours on the water.

The ACRS and Swirl Piston Design

Let’s talk about what happens inside the cylinders—because that’s where the real magic occurs. The Amplified Common Rail Fuel System delivers fuel at incredibly high pressures, up to 30,000 PSI in some conditions. This creates an ultra-fine mist of fuel that burns more completely and efficiently.

But fuel delivery is only part of the equation. The DD15’s swirl piston design creates a specific pattern of air movement inside the combustion chamber. Picture a miniature tornado of air and fuel mixing together before ignition. This swirling action ensures that every droplet of fuel finds oxygen to burn with, leading to optimized combustion and maximum energy extraction.

The engine’s ultra-high compression ratio of 21:1 works hand-in-hand with these features. Higher compression means more power from each combustion event and better thermal efficiency. The result of all these technologies working together? Improved fuel atomization that translates directly into better fuel economy, more power when you need it, and significantly reduced emissions.

It’s the kind of engineering that makes a real difference in your operating costs and environmental footprint—something we understand well at RPM Diesel Company when we’re servicing these engines in marine applications around the world.

Aftertreatment and Reliability

Modern emissions standards are strict, and meeting them while maintaining reliability is no small feat. The DD15’s innovative aftertreatment system manages to do both remarkably well. Detroit Diesel designed this system with a focus on keeping things as simple as possible—and in engineering, simpler often means more reliable.

The aftertreatment system features a simplified design with fewer components that can fail or require maintenance. This thoughtful approach leads to increased uptime, which is critical when you’re operating marine equipment that needs to stay productive. The system also benefits from longer maintenance intervals for aftertreatment components, reducing both the frequency and cost of service.

That Thermocoasting technology we mentioned earlier plays a big role here too. By maintaining optimal temperatures during coasting, it prevents the system from cooling down too much. This means regeneration cycles happen more efficiently and less frequently, keeping your engine running rather than sitting idle during maintenance.

For a closer look at how these technologies come together in action, check out this helpful resource: DD15 On-Highway Features Video. While the video focuses on highway applications, the core technologies—the fuel system, turbocharger, and aftertreatment innovations—are the same ones that make the dd15 engine such a reliable workhorse in marine environments.

At RPM Diesel Company, we’ve worked on countless DD15 engines in marine applications, and we’ve seen how these innovations translate into real-world reliability. For more information about how we can help keep your Detroit Diesel engine running at peak performance, visit our Detroit Diesel engine services page.

Common Problems and Solutions for the DD15 Engine

Let’s be honest—even the best-built engines need attention sometimes. The DD15 engine is incredibly reliable, but after years of hard work in marine applications, certain issues can pop up. We’ve seen these problems countless times at RPM Diesel Company, and the good news is that most are straightforward to fix when you know what to look for.

The most common concerns we encounter include low oil pressure, oil leaks around various components, issues with the crankcase breather, and occasionally starting problems after service. None of these are catastrophic, but they do require attention to keep your engine running at peak performance.

The real secret to solving these problems quickly and cost-effectively comes down to proper diagnostics. We can’t stress this enough. A thorough diagnostic approach saves time, money, and prevents unnecessary repairs. When you understand what’s actually happening inside the engine, you can target the real problem instead of guessing and replacing expensive parts that don’t need replacing.

Diagnosing Low Oil Pressure in a DD15 Engine

Here’s a scenario we see regularly: a DD15 engine with over 500,000 miles starts showing low oil pressure warnings. The natural reaction is to worry about the oil pump failing, which would be an expensive fix. But before you start pricing out new pumps, there’s something much simpler to check first.

After an engine passes the 500,000-mile mark, the small O-rings on the oil suction manifold tend to harden and lose their flexibility. When these O-rings fail, they allow air to sneak into the oil suction line, which drops your oil pressure. It’s not a pump problem at all—it’s a seal problem.

This is why experienced marine diesel technicians always check those O-rings first. The solution is simple: replace the hardened O-rings with fresh ones. This repair takes a fraction of the time and costs significantly less than replacing the entire oil pump. We’ve saved vessel owners thousands of dollars by diagnosing this correctly the first time. It’s one of those situations where knowing the DD15 engine’s quirks really pays off.

Addressing Oil Leaks and Service Issues

Oil leaks are another common issue, and they can show up in several places. The most frequent leak points we see are around the fuel pump, air compressor, oil coolant system, and camshaft housing. These aren’t design flaws—they’re simply the result of gasket seals loosening or deteriorating over time, especially in the harsh marine environment.

The cause is almost always loose gasket seals that have aged or weren’t properly torqued during previous service. The fix involves careful inspection of each potential leak point and proper resealing with quality gaskets. We always use manufacturer-specified sealants and follow Detroit Diesel’s torque specifications to the letter. It’s not complicated work, but it does require attention to detail.

Now, here’s something that catches people off guard: starting problems after service. You bring your vessel in for routine maintenance, everything seems fine, and then suddenly the engine won’t start properly. Frustrating, right?

The culprit is usually improper fuel system priming. When we perform maintenance on the DD15 engine, air can get into the fuel system. If that air isn’t properly bled out through correct priming procedures, the engine struggles to start. We’re meticulous about this at RPM Diesel Company because we know how critical it is.

One more important note: Detroit Diesel specifically recommends against using starter fluid on their engines. It can cause serious damage. The proper priming after service takes a bit more time, but it’s the right way to ensure your DD15 fires up reliably every single time. That’s the kind of detail work that separates good service from great service.

Maintenance, Warranty, and Support Resources

Taking care of your DD15 engine doesn’t have to be complicated. Detroit Diesel designed this powerhouse with straightforward maintenance in mind, backed by solid warranty coverage that gives you real peace of mind when you’re out on the water.

Regular servicing is your best insurance against costly breakdowns and extended downtime. The recommended maintenance intervals for the DD15 are built around real-world operating conditions. You’ll want to schedule oil and filter changes every 40,000 km, which applies whether you’re running in severe-duty conditions or standard operations. Your fuel filters should be changed at the same interval to keep your fuel system running clean and efficient.

One maintenance item that’s particularly important for marine applications is valve lash adjustments. These keep your engine running smoothly and efficiently. Detroit Diesel recommends the first adjustment at 90,000 km, with subsequent adjustments every 400,000 km depending on how hard you’re working the engine. It’s one of those maintenance tasks that makes a real difference in performance.

The standard warranty coverage on the DD15 gives you solid protection right from the start. The engine itself is covered for 0-24 months with unlimited miles, while injectors have coverage for 0-24 months or 320,000 km. Major components get even more comprehensive protection at 25-60 months or 800,000 km. If you want additional security, extended service coverage options can stretch your protection up to 5 years or 1,000,000 km. The key is keeping up with maintenance according to Detroit’s operator guide—think of it as your engine’s way of holding up its end of the bargain.

DD15 Engine Inframe Kit Contents

When your DD15 engine needs a major overhaul, an inframe kit provides everything you need to bring it back to peak performance. These aren’t just random parts thrown together—each kit is carefully assembled with components that work together perfectly for a comprehensive rebuild.

Here’s what you’ll find in a typical DD15 inframe kit:

- Six Cylinder Kits including pistons, rings, and liners (often featuring APR Advanced Performance Rebuild liners for superior quality)

- Oil Pan Gasket to keep your oil where it belongs

- Complete Head Gasket Kit for a perfect seal between cylinder head and block

- Standard Rod Bearing Kit ensuring proper clearance and smooth operation

- Standard Main Bearing Kit to support your crankshaft’s rotation

- Twelve Connecting Rod Bolts for secure rod connections

- Fourteen Crankshaft Main Bolts providing high-strength support

- Two Cylinder Head Bolt Kits to properly torque down your cylinder heads

- Optional Valve Cover and Rocker Cover Gasket Sets for complete coverage

These kits take the guesswork out of major rebuilds. Everything is designed to work together, ensuring compatibility and quality throughout the process. At RPM Diesel Company, we stock these comprehensive kits and have the expertise to guide you through the rebuild process, whether you’re doing the work yourself or need our technicians to handle it.

Diagnostic and Owner Resources

Detroit Diesel knows that keeping your marine engine running isn’t just about building a tough engine—it’s about giving you the tools and support to keep it that way. The resources available to DD15 owners reflect this commitment to long-term reliability.

The standout tool in your diagnostic arsenal is Detroit Connect Virtual Technician. This sophisticated remote diagnostics system keeps constant watch over your engine’s health. Within minutes of detecting a problem, Virtual Technician sends you fault notifications that explain what’s happening, how serious it is, and what steps you should take. It’s like having an expert technician monitoring your engine around the clock. This proactive approach means you can address small issues before they turn into expensive problems or leave you stranded.

Beyond the high-tech diagnostics, Detroit provides comprehensive owner brochures and videos that walk you through your engine’s features and basic maintenance procedures. These aren’t just dry technical manuals—they’re designed to help you really understand what makes your DD15 tick. Knowledge is power, especially when it comes to making smart decisions about service and maintenance.

We can’t stress enough the importance of certified service for your DD15. Working with technicians who are specifically trained and authorized on Detroit Diesel engines makes all the difference. At RPM Diesel Company, our team has the specialized knowledge and genuine parts needed to keep your marine DD15 running at its best. Whether you need routine maintenance or complex diagnostics, our expertise ensures your engine gets the care it deserves. Learn more about our Detroit Diesel engine services and find how we can keep your operation running smoothly.

A Legacy of Innovation: The History of Detroit Diesel

When you’re working with a DD15 engine, you’re not just operating a piece of machinery—you’re experiencing the culmination of over eight decades of engineering excellence and innovation. Detroit Diesel, now part of Daimler Truck North America, has been pushing the boundaries of diesel engine technology since before World War II.

The story begins with the Winton Engine Company, founded in 1912 and later acquired by General Motors in 1930. By 1938, the Detroit Diesel Engine Division was officially manufacturing engines, and they quickly made their mark with something unique: robust two-stroke engines that became legendary for their reliability and raw power. During World War II, these engines proved their worth by powering everything from tanks to landing craft, earning Detroit Diesel a reputation for building engines that could handle the toughest conditions imaginable.

For decades, those iconic two-stroke designs were synonymous with Detroit Diesel. But as the industry evolved and efficiency became increasingly important, the company recognized the need to adapt. The shift from two-stroke to four-stroke engines wasn’t just a minor adjustment—it represented a complete rethinking of diesel engine design philosophy.

The breakthrough came in 1987 with the introduction of the Series 60. This engine changed everything. It was the first heavy-duty diesel engine to feature fully integrated electronic controls as standard equipment, setting a completely new benchmark for engine management and diagnostics. Suddenly, operators had unprecedented insight into their engines’ performance and health. The Series 60’s success proved that electronic controls weren’t just a gimmick—they were the future.

Building on those lessons and technological advances, Detroit Diesel started on an ambitious project: creating an entirely new engine platform for modern demands. This vision became reality in 2007 with the launch of the DD platform. This family of engines—including the DD13, DD15, and DD16—shares a common DNA of advanced engineering while being custom for different applications and power requirements.

The DD15 engine emerged as a flagship within this platform, embodying everything Detroit Diesel had learned over its long history. The engine represents the company’s unwavering commitment to electronic controls and efficiency, combining cutting-edge technology with the durability that made Detroit Diesel famous in the first place. It’s this legacy of continuous improvement—always listening, always innovating—that makes the DD15 such a reliable partner in demanding marine applications today.

Conclusion: Using the Power of the DD15 for Your Needs

If there’s one thing we’ve learned about the DD15 engine, it’s that this powerhouse delivers on every promise. Throughout this guide, we’ve walked through its impressive capabilities—from that substantial 14.8L displacement to the remarkable ability to reach 90 percent of peak torque in just 1.5 seconds. We’ve explored how its advanced technologies, like the Amplified Common Rail Fuel System and swirl piston design, work together to create an engine that’s both powerful and up to 3% more fuel efficient than previous generations.

The DD15 engine represents more than just engineering excellence. It embodies decades of Detroit Diesel innovation, refined through continuous improvement and real-world testing. The sophisticated Thermocoasting technology, the intelligent DDEC electronics, and the innovative aftertreatment system all work in harmony to deliver reliable, consistent power while meeting stringent environmental standards.

We’ve also covered the practical side—those common issues that can arise after hundreds of thousands of miles, and the straightforward solutions that experienced technicians know to look for first. Whether it’s addressing hardened O-rings causing low oil pressure or ensuring proper priming after service, understanding these details makes all the difference in maintaining your engine’s longevity.

At RPM Diesel Company, we bring specialized expertise to marine diesel applications. Our team understands the unique demands placed on marine engines and the critical importance of keeping your vessel operational. We’re authorized by Detroit Diesel and maintain an extensive inventory of parts—including those hard-to-find components that can make or break your timeline. Whether your vessel is docked in Fort Lauderdale, cruising near Miami, anchored off West Palm Beach, or anywhere else our worldwide service reaches, we’re equipped to provide the expert care your DD15 engine deserves.

The combination of Detroit Diesel’s engineering prowess and our commitment to comprehensive marine diesel service creates a partnership that keeps you moving. From routine maintenance to complex diagnostics using tools like Detroit Connect Virtual Technician, we ensure your engine operates at peak performance when you need it most.

For marine operators who demand unwavering reliability and performance from their diesel engines, the DD15 delivers. And when it comes to servicing this remarkable engine, trust the specialists who understand both the technology and the unique challenges of marine applications.