Why Your Marine Engine Needs Clean Air

Air filter replacement is one of the simplest yet most critical maintenance tasks for your marine diesel engine. A clean filter is the only thing protecting your engine from the harsh marine environment.

Quick Answer:

- How often: Every 250 service hours or annually, but inspect more often in salty or dusty conditions.

- Signs of a Clogged Filter: Reduced power, poor fuel economy, black exhaust smoke, unusual engine sounds.

- Time Required: 10-20 minutes.

- Difficulty: Beginner-friendly.

- Cost: $20-$50 for most filters.

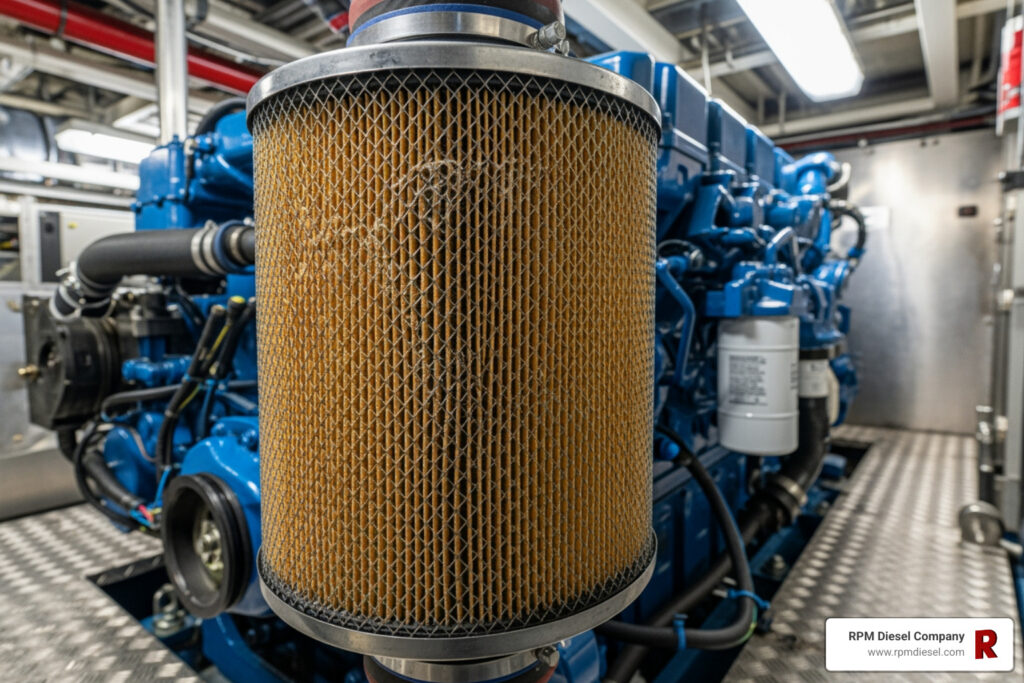

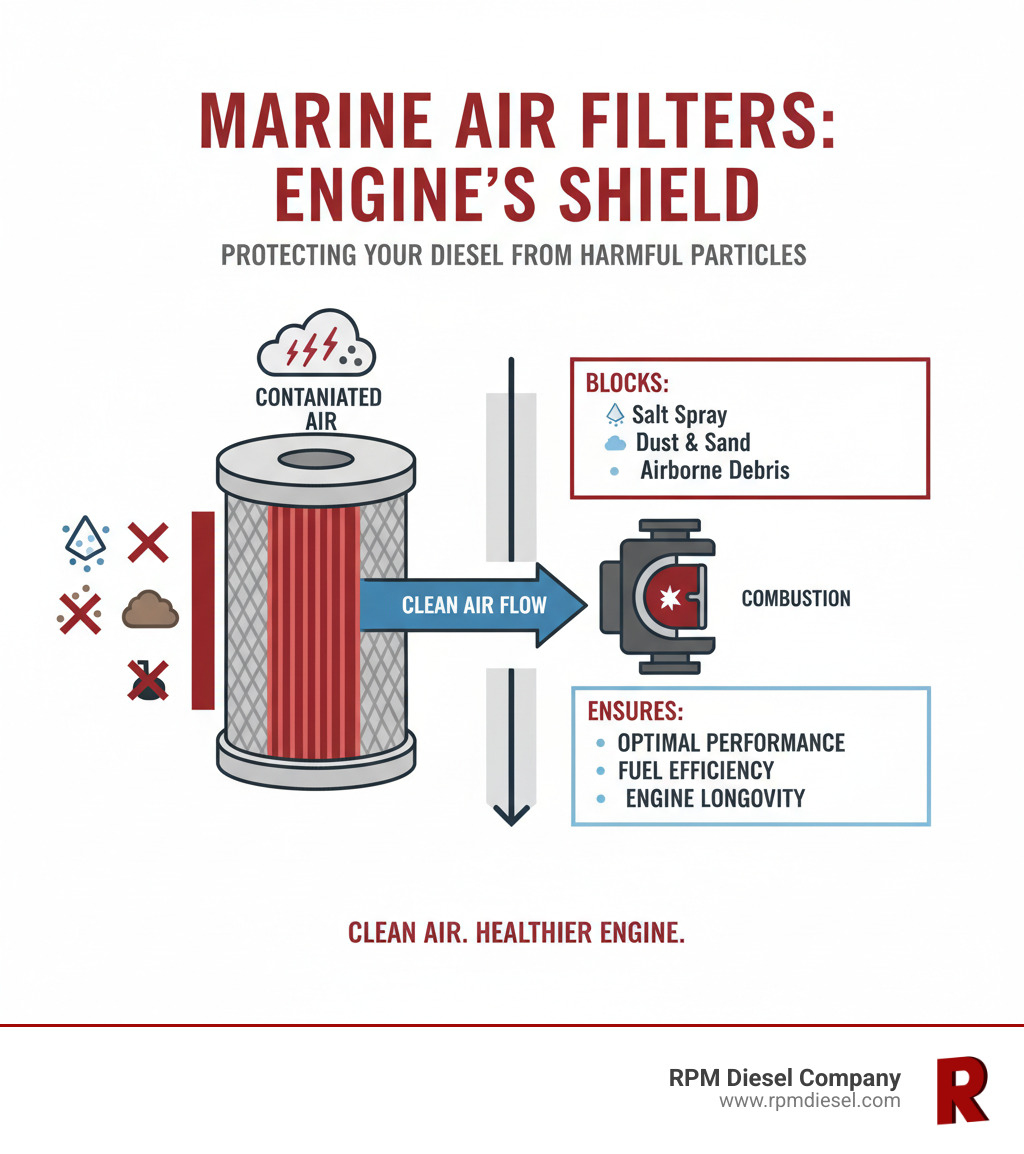

Your marine diesel engine consumes thousands of gallons of air per hour. In a marine setting, that air is filled with salt spray, sand, and dust that can cause significant engine damage. Unlike a car, your vessel’s engine breathes a punishing mix that clogs filters quickly, demanding more frequent checks and changes.

A dirty filter starves your engine of air, forcing it to burn more fuel for less power. This can lead to black smoke, misfires, and even turbocharger damage. Fortunately, replacement is a quick, affordable DIY job that keeps your engine running efficiently. This guide will show you how.

Why Your Marine Diesel’s Air Filter is Crucial

Your marine diesel engine needs a massive volume of clean air to mix with fuel for combustion. The air filter is the sole barrier protecting your engine’s internal components from the harsh marine environment. Along the Florida coast, from Miami to Fort Lauderdale, the air is laden with salt, sand, and dust—contaminants that can act like sandpaper inside your engine.

A clean filter ensures an optimal air-to-fuel ratio, giving you the power and fuel economy you expect. More importantly, it provides critical engine protection. Airborne particles can score cylinder walls and wear down piston rings. For modern marine diesels, turbocharger health is paramount. Turbos spin at incredibly high speeds, and even tiny grit passing through a dirty filter can destroy the delicate turbine blades, leading to thousands of dollars in repairs. Proper filtration is the key to engine longevity.

Signs You Need an Air Filter Replacement

Your engine will tell you when it’s struggling for air. Look for these warning signs:

- Reduced Engine Power: The vessel feels sluggish or struggles to maintain RPMs.

- Increased Fuel Consumption: The engine burns more fuel to compensate for the lack of air, hitting your wallet.

- Black Smoke from Exhaust: This is unburnt fuel, a classic sign of a rich air-fuel mixture caused by a clogged filter.

- Unusual Engine Sounds: Sputtering or rough idling indicates the engine is struggling.

- Sluggish Acceleration: A delayed response when you push the throttle.

Consequences of a Neglected Air Filter

Ignoring a dirty air filter leads to a cascade of problems. The restricted airflow creates a rich fuel mixture, causing incomplete combustion. This leads to:

- Engine Damage: Unburnt fuel can contaminate engine oil, reducing its ability to lubricate and causing accelerated wear on pistons and cylinders.

- Premature Turbocharger Wear: A starved turbo works harder, generating excess heat and stress. If the filter fails, debris can destroy the turbine blades.

- Increased Emissions & Poor Fuel Economy: Wasted fuel means higher operational costs and more pollutants released into the water and air.

- Risk of Costly Repairs: What starts as a $50 filter replacement can quickly escalate into a multi-thousand-dollar engine or turbocharger overhaul. At RPM Diesel, we’ve seen engines ruined by this simple neglect. Don’t let yours be one of them.

Choosing the Right Filter for Your Vessel

Picking the right air filter is not a place to guess. Using the wrong one can restrict airflow, fail to filter properly, and even void your engine’s warranty.

- Standard Filters: Typically made of pleated paper, these meet the original manufacturer’s specifications and are the right choice for most applications.

- Performance Filters: Made from materials like cotton gauze, they offer higher airflow but often require periodic cleaning and re-oiling instead of simple replacement.

- Specialized Marine Filters: Systems like Walker AIRSEP are purpose-built for the marine environment, offering multi-stage filtration to handle salt spray and keep oil mist out of the engine room.

Your engine’s service manual is the ultimate authority. It will list the exact part number or specifications required. Using a filter that is “close enough” can lead to severe engine damage. If you’re unsure, the experts at RPM Diesel Company can match you with the correct OEM filter for your Detroit Diesel, MTU, or other marine engine. For additional information on marine diesel maintenance best practices, the American Boat and Yacht Council provides valuable industry standards and guidelines.

OEM vs. Aftermarket Filters: What’s the Difference?

When buying an air filter replacement, you’ll choose between Original Equipment Manufacturer (OEM) and aftermarket parts.

OEM filters are made by your engine’s manufacturer. They offer a guaranteed fit and quality, ensuring your engine performs exactly as designed. Using OEM parts is often required to maintain your warranty and provides the highest level of reliability.

Aftermarket filters are made by third-party companies and are often cheaper. However, this lower cost can come with risks. A poor fit can allow contaminants to bypass the filter, and lower-quality materials may not filter as effectively, leading to engine wear. While the aftermarket offers variety, you must ensure any filter meets or exceeds OEM specifications.

Our recommendation is to stick with genuine OEM filters. The long-term protection and peace of mind are worth more than the small initial savings.

Can You Clean and Reuse a Marine Air Filter?

Whether you can clean a filter depends entirely on its type.

-

Disposable Paper Filters: The answer is no. These filters trap fine particles in their media. Attempting to clean them with compressed air will damage the paper, creating holes for dirt to pass through, or will compact the dirt, making the filter even more restrictive. If it’s a standard paper or synthetic filter, replace it.

-

Washable/Reusable Filters: Some performance filters (e.g., cotton gauze) are designed to be cleaned and reused. This requires following the manufacturer’s cleaning procedures precisely, which typically involves a special cleaning solution, careful rinsing, complete air-drying, and re-oiling with a specific amount of filter oil. Any deviation can damage the filter or compromise its effectiveness.

When to replace vs. clean? Check your service manual. If it’s disposable, replace it. If it’s reusable, follow the instructions to the letter. For the engines we service across Florida, a new, genuine OEM filter is always the safest investment.

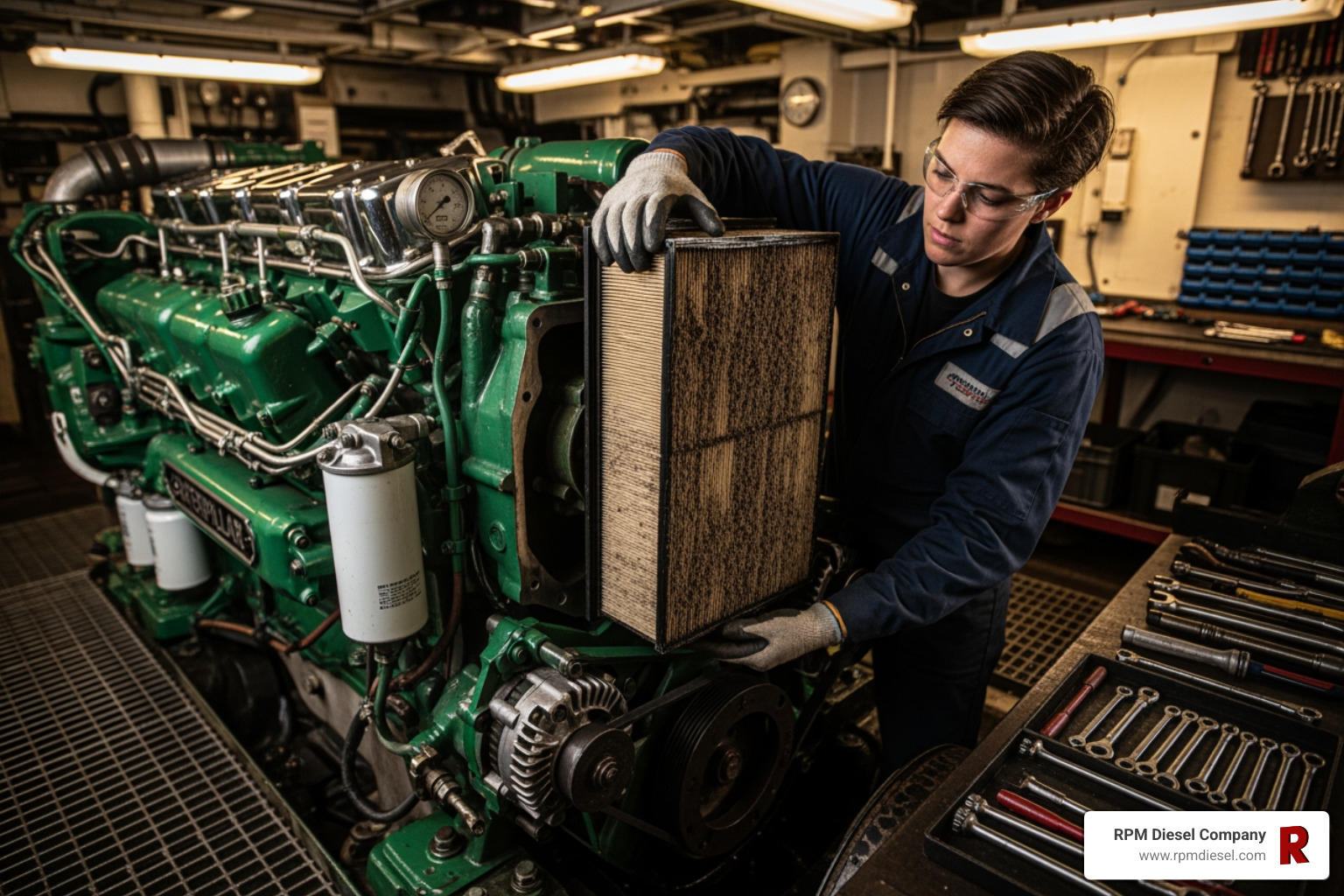

A Step-by-Step Guide to Marine Air Filter Replacement

Replacing your marine diesel’s air filter is a straightforward task most vessel owners can handle in under 20 minutes. It’s a satisfying job that directly contributes to your engine’s health.

Preparation and Safety First

Before you begin, take a few simple precautions:

- Engine Off and Cool: Ensure the engine is completely shut down and cool to the touch to prevent burns.

- Ventilation: If in an enclosed engine room, open a hatch for fresh air.

- Gather Your Tools: You’ll need your new, correct-model air filter, a screwdriver or socket wrench (depending on the housing), and clean rags. A small vacuum is also helpful.

Step 1: Locate and Open the Air Filter Housing

The air filter housing is typically a large plastic or metal box connected to the engine’s air intake hose. It’s usually easy to spot. Examine how the cover is secured—it will be held by spring clips, screws, or bolts. Carefully unfasten them and lift the cover off. If it’s stuck, double-check that all fasteners are removed before wiggling it loose.

Step 2: Remove the Old Filter and Clean the Housing

Note the orientation of the old filter before lifting it out. You’ll want to install the new one the same way. Once the old filter is out, inspect the inside of the housing. You’ll likely find dirt, salt crystals, and other debris. Use a vacuum or a damp rag to thoroughly clean the entire interior. Be very careful not to let any debris fall into the air intake tube leading to the engine.

Step 3: Install the New Filter and Close the Housing

Place the new filter into the clean housing, ensuring it’s oriented correctly. Press down gently around the filter’s edge to make sure it is seated snugly and forms a complete seal. An improper seal will allow unfiltered air to bypass the filter. Replace the cover and tighten all the clips, screws, or bolts securely to create an airtight seal. Give the housing a gentle tug to confirm it’s secure. That’s it—you’ve just performed a vital maintenance task for your engine.

Frequently Asked Questions about Marine Air Filters

At RPM Diesel Company, we answer questions about air filters daily for vessel owners from Fort Lauderdale to Miami. Here are the most common ones.

How often should I perform an air filter replacement?

Your manufacturer’s service manual is the primary guide. Many recommend replacement every 250-500 service hours or annually, whichever comes first. However, operating conditions are critical. If you operate in salty air, dusty environments, or areas with heavy boat traffic, you must inspect your filter more frequently. The best rule is to perform a visual inspection during routine engine checks. If the filter looks dark, dirty, or clogged, replace it—regardless of the service hours.

How does a dirty air filter affect fuel economy and emissions?

A dirty filter restricts airflow, forcing your engine to work with a rich fuel mixture (too much fuel for the available air). This causes incomplete combustion, which has two major effects:

- Poor Fuel Economy: Your engine burns more fuel to produce the same amount of power, increasing your operating costs.

- Higher Emissions: Unburnt fuel is expelled as soot (black smoke), polluting the air and water and contributing to carbon buildup in your engine and exhaust system.

A clean filter is one of the easiest ways to improve fuel efficiency and reduce your vessel’s environmental impact.

Can I replace my marine air filter myself?

Yes, in most cases. An air filter replacement is a basic maintenance task that is well within the skill set of the average vessel owner and requires only basic hand tools. It’s a great way to become more familiar with your engine.

However, you should call a professional if your engine has a highly specialized or complex filtration system, if the filter housing is in a location that is difficult or unsafe to access, or if you feel uncomfortable with any part of the process. If you encounter unexpected issues, like oil in the housing, it’s best to consult an expert. Your safety and your engine’s health are the top priorities. At RPM Diesel, our technicians are always ready to assist with parts, advice, or professional service.

Conclusion: Keep Your Engine Breathing Easy

Regular air filter replacement is simple, inexpensive, and one of the most effective forms of preventive maintenance you can perform on your marine diesel engine. For the price of a filter and 15 minutes of your time, you protect your engine from abrasive contaminants, ensure optimal fuel efficiency, and prevent thousands of dollars in potential repairs.

The marine environment is relentless. Salt spray and dust are a constant threat to your engine’s health. Don’t wait for warning signs like black smoke or power loss. Be proactive by following your manufacturer’s service schedule and performing regular visual inspections.

At RPM Diesel Company, we’ve built our reputation on expertise and quality. We stock a massive inventory of genuine OEM parts for major brands like Detroit Diesel and MTU because we know that in the harsh marine world, quality is not optional. Whether you need the right part for a DIY job or require professional on-site service anywhere in the world, our team is ready to help.

Keep your engine breathing easy, and it will reward you with reliability and performance for years to come. Contact RPM Diesel for expert service and parts.