Why Your Marine Diesel Fuel Pump Is Critical to Your Vessel’s Reliability

Diesel fuel pump replacement is one of the most essential maintenance tasks for marine vessel owners who depend on reliable engine performance at sea. Whether you’re cruising international waters or running a commercial vessel, a failing fuel pump can leave you stranded miles from shore, facing costly repairs and dangerous situations.

Quick Answer: What You Need to Know About Diesel Fuel Pump Replacement

- Signs of Failure: Hard starting, loss of power, unusual whining noises, engine sputtering

- Cost Range: $100-$2,000+ for parts, plus 2-6 hours of labor

- Lifespan: Typically 100,000-200,000 equivalent miles (thousands of operating hours)

- System Type: Marine diesels use a two-stage system (lift pump + high-pressure injection pump)

- DIY vs. Professional: Complex job requiring specialized tools and knowledge; professional service recommended for marine engines

- Post-Replacement: Must bleed air from fuel system and verify proper operation before heading out

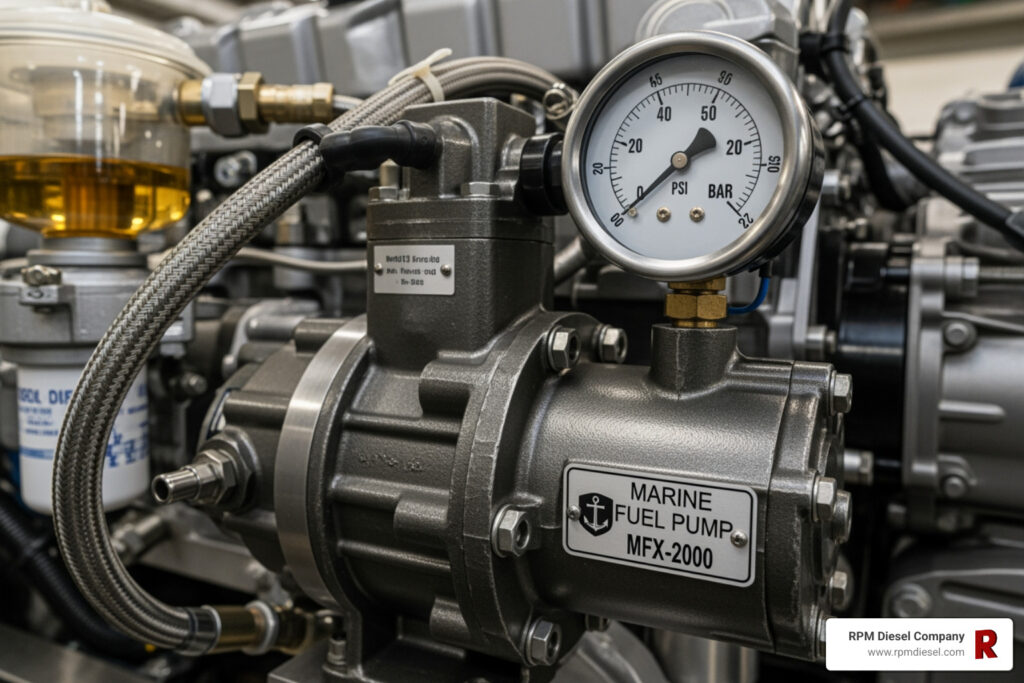

The diesel fuel pump is the heart of your marine engine’s fuel delivery system. It draws fuel from your tank, pressurizes it, and delivers it precisely to your engine’s cylinders for combustion. When this critical component fails, your vessel becomes unreliable at best and completely inoperable at worst.

Marine diesel engines operate in demanding conditions where salt air, vibration, and long operating hours take their toll on fuel system components. Understanding when and how to replace your fuel pump can mean the difference between smooth sailing and an emergency call to the Coast Guard.

This guide walks you through marine diesel fuel pump replacement, from identifying warning signs and understanding pump types to deciding between DIY and professional service. We’ll also cover essential maintenance practices that extend pump life and keep your vessel running reliably.

Identifying a Failing Marine Diesel Fuel Pump

A small hiccup from your marine diesel engine can be a serious warning sign. A failing fuel pump often gives early indicators, and recognizing them is essential for safety at sea. Your fuel pump works tirelessly to pull fuel from the tank, pressurize it, and send it to the engine for combustion. When it falters, it can’t maintain the steady flow and pressure your engine needs, leading to noticeable problems.

Listen closely for these common indicators that your marine diesel fuel pump might be in trouble:

Common Symptoms of a Bad Fuel Pump

-

Whining Noise from the Pump: An unusual whining or buzzing noise from the engine room, near the fuel pump, is a classic early warning. It indicates the pump is straining due to wear or a blockage.

-

Engine Sputtering or Hesitation During Acceleration: If your engine sputters or hesitates, especially under load or when accelerating, it may not be getting enough fuel. This can also lead to stalling under load.

-

Hard Starts or No-Start Condition: A hard starting engine that cranks excessively before firing up could mean the pump isn’t holding pressure. In severe cases, this leads to a complete no-start condition.

-

Loss of Power Under Load: A general loss of power when you need it most, like pushing through rough seas, suggests a weak pump that can’t deliver the required fuel volume and pressure.

-

Poor Fuel Economy / Increased Fuel Consumption: A struggling pump can cause increased fuel consumption as your engine works harder to compensate for inefficient fuel delivery.

-

Excessive Smoke from Exhaust: Excessive smoke, particularly black smoke, can be a sign of incomplete combustion caused by inconsistent fuel delivery.

Potential Consequences of Not Replacing a Failing Pump

Ignoring these signs can lead to serious and costly problems on the water:

-

Complete Engine Failure and Stranding: The worst-case scenario is a total engine shutdown, leaving you stranded at sea and in a potentially perilous situation.

-

Costly Secondary Damage: An improperly functioning pump can starve fuel injectors, causing them to fail. It can also lead to extensive internal engine damage, with repair costs far exceeding the price of a timely diesel fuel pump replacement.

-

Unreliable Vessel Performance: An inconsistent pump makes your vessel unreliable. You’ll face unexpected power losses, making navigation and maneuvering difficult and unpredictable.

-

Safety Hazards: Losing propulsion in a busy channel, during docking, or in rough seas creates significant safety hazards.

Addressing fuel pump issues promptly is a critical safety measure. If you suspect your marine diesel engine needs attention, our team at RPM Diesel Company specializes in Diesel Engine Repair Service throughout Fort Lauderdale, Miami, and the wider South Florida region.

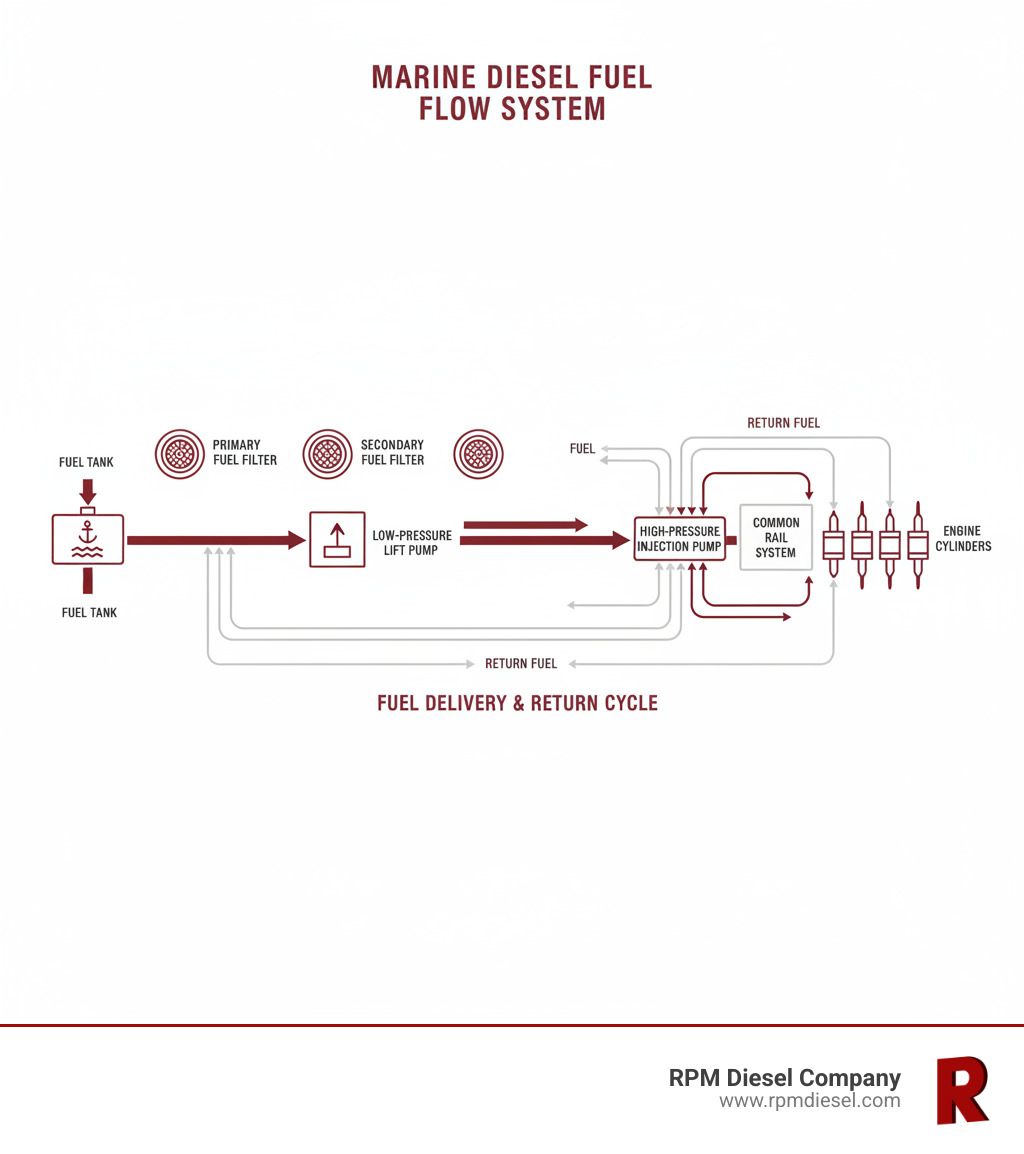

Understanding Marine Diesel Fuel Pump Systems

A marine diesel fuel system relies on two main pumps working in concert: a low-pressure lift pump and a high-pressure injection pump. The lift pump draws fuel from the tank and sends it through filters. The high-pressure pump then pressurizes it for injection and combustion. Understanding this two-stage system is key for any diesel fuel pump replacement.

Older marine engines often use mechanical systems, while modern diesels feature sophisticated electronic controls for better efficiency and power, which also increases service complexity.

Types of Diesel Fuel Pumps

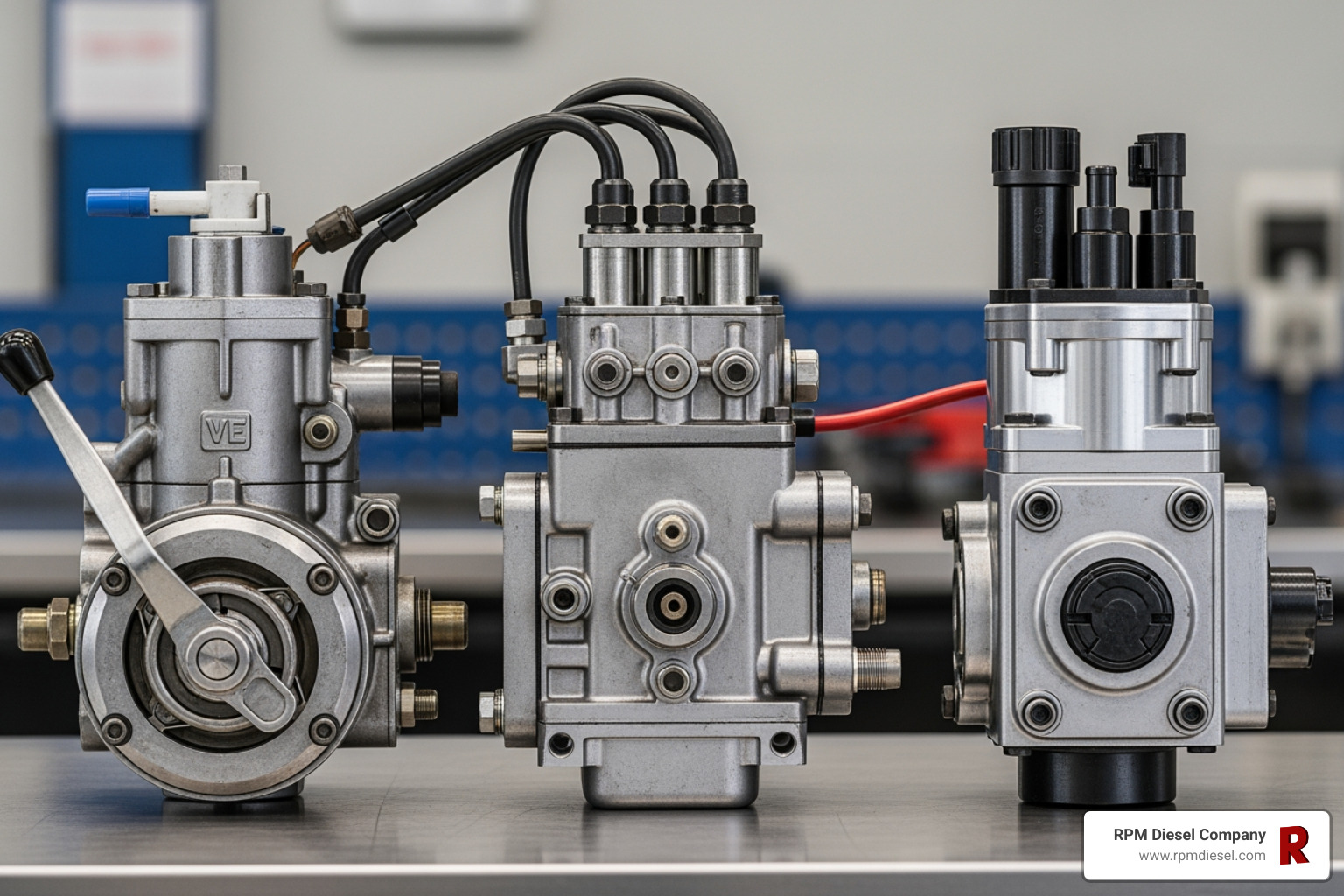

Let’s break down the different types of pumps you might find in your engine.

Low-Pressure Lift Pumps are the first step, moving fuel from the tank to the engine. Older engines may use mechanical lift pumps driven by the engine, but many modern diesels use electric lift pumps for a more consistent fuel supply.

High-Pressure Injection Pumps are the muscle, pressurizing fuel to the extreme levels needed for atomization and combustion.

- Rotary Pumps are found in many older diesel engines. They use a single spinning component to distribute fuel to each cylinder. They are simpler but less precise than modern systems.

- Inline Pumps were common in older, larger diesels. They feature a row of individual pumps—one for each cylinder—and are known for their durability.

- Common Rail High-Pressure Pumps are the standard in modern marine diesels. A single powerful pump pressurizes a ‘common rail,’ which supplies fuel to electronically controlled injectors. This allows for precise fuel delivery, improving efficiency, power, and emissions. We are experts in Common Rail Injection System diagnostics and repair.

- Unit Injector Systems, found in some heavy-duty engines, combine the injector and a small pump into a single unit for each cylinder.

Our team at RPM Diesel Company is factory-authorized to service all these systems, including specialized expertise in Bosch Diesel Services.

How Fuel Systems Differ in Marine Engines

Fuel pump systems vary significantly depending on the engine manufacturer and model. For example, older Detroit Diesel Engines may use mechanical pumps, while newer models use common rail technology. Brands like MTU Marine Diesel Engines are known for advanced, electronically controlled common rail systems. Our team is familiar with these intricate systems, including those in MTU Marine Diesel Engines. Even generators from brands like Northern Lights have unique fuel pump setups.

The key takeaway is that using the correct fuel pump and parts for your specific engine model is mandatory. A ‘one-size-fits-all’ approach is not an option on the water. Our specialists ensure any diesel fuel pump replacement uses parts perfectly matched to your engine’s specifications for reliable and safe operation.

The Complete Guide to Marine Diesel Fuel Pump Replacement

Replacing a marine diesel fuel pump is a serious task that demands precision and respect for the system’s complexity. While an experienced boat owner might handle a simple lift pump, high-pressure injection pumpsespecially modern common rail systemsare best left to professionals.

Most marine fuel pumps last for thousands of operating hours (equivalent to 100,000-200,000 miles), but this lifespan depends heavily on fuel quality and filter maintenance. When it’s time for a diesel fuel pump replacement, understanding the process is crucial. For those who prefer professional service, our team offers comprehensive Marine Diesel Engine Repair throughout South Florida and beyond.

Essential Tools, Parts, and Safety Precautions

Working with diesel fuel and high-pressure systems requires careful preparation and a focus on safety.

- Essential Tools: Flare nut wrenches (to prevent stripping fittings), a socket set, a torque wrench, clean rags, a drain pan, fuel line clamps, and a hand primer pump or diagnostic tool for bleeding the system.

- Required Parts: The correct OEM or high-quality aftermarket replacement pump for your specific engine, new gaskets and seals, and new primary and secondary fuel filters. Always replace filters when the fuel system is opened.

- Safety Precautions: Ensure proper engine room ventilation. Disconnect all battery sources to prevent accidental starts. Keep a fuel-rated fire extinguisher nearby. Wear safety glasses and fuel-resistant gloves. Always relieve system pressure according to your engine manual before starting.

Above all, cleanliness is critical. Even a tiny speck of dirt can destroy a new high-pressure fuel pump.

Step-by-Step Marine Diesel Fuel Pump Replacement

This is a general guide; always consult your engine’s specific service manual for detailed instructions.

- Locate Pump and Relieve Pressure: Find the fuel pump(s) in the engine room. Following your engine’s service manual, relieve all pressure from the fuel system.

- Disconnect Power and Clean: Turn off all battery main switches. Thoroughly clean the area around the pump to prevent debris from entering the system.

- Disconnect Lines: Place a drain pan underneath the pump. Carefully disconnect electrical connectors. Clearly label all fuel lines (inlet, outlet, return) before loosening them with flare nut wrenches. Immediately cap all open lines and ports to prevent contamination and spills.

- Remove Old Pump: Remove the mounting bolts and carefully extract the old pump. Compare it side-by-side with the new one to ensure it’s an exact match.

- Install New Pump: Position the new gaskets and seals correctly. Mount the new pump, hand-tighten the bolts, then torque them to the manufacturer’s specifications.

- Reconnect and Replace Filters: Reconnect the labeled fuel lines, using new seals or washers if required. Tighten fittings snugly with flare nut wrenches, but do not overtighten. Reconnect the electrical connectors. Install new primary and secondary fuel filtersdo not skip this step.

- Prime and Bleed the System: Trapped air will prevent a diesel engine from starting. Use a hand primer or follow your engine’s specific procedure to bleed all air from the system. Loosen bleed screws on filter housings and the pump, pump until air-free fuel emerges, then tighten the screws. Carefully check the entire system for leaks.

DIY vs. Professional Marine Diesel Fuel Pump Replacement

Deciding whether to do it yourself or hire a professional is a key consideration.

-

DIY Pros & Cons: The main benefit of DIY is saving on labor costs and gaining a deeper understanding of your engine. However, the risks are significant. Marine fuel systems are complex, and an incorrect installation can lead to fuel leaks, air in the system, or damage to expensive injectors. The job requires specialized tools, a clean working environment, and can be very time-consuming. A mistake could also void warranties.

-

Professional Service: Certified technicians bring expertise, specialized tools, and diagnostic equipment. We understand the nuances of brands like Detroit Diesel, MTU, and Bosch. Professional service is efficient, includes a warranty on parts and labor, and provides peace of mind. For a component so critical to your vessel’s safety and reliability, professional service is often the wisest investment. We offer On Site Diesel Repair directly to your vessel in Fort Lauderdale, Miami, and throughout South Florida.

Understanding your vessel’s fuel system needs is what we do every day. When you’re far offshore, the reliability that comes with expert service is invaluable.

Post-Replacement Troubleshooting and Maintenance

After a diesel fuel pump replacement, the job isn’t quite finished. It’s crucial to verify the repair, check for leaks, and monitor engine performance to ensure everything is ready for the open water. Establishing a solid ongoing maintenance routine is key to giving your new pump a long and healthy life.

Troubleshooting After Installation

If you encounter issues after installation, don’t panic. Here’s how to troubleshoot common problems.

-

Engine Won’t Start: The most likely cause is air in the fuel lines. Re-bleed the entire fuel system thoroughly, from the filters to the injection pump. Also, double-check for incorrect electrical connections and ensure you have a sufficient fuel level in your tank.

-

Engine Runs Poorly (Rough Idle, Sputtering): This could be due to residual air in the fuel lines, so try bleeding the system again. Carefully inspect all connections for fuel leaks, as even a tiny drip can introduce air or reduce pressure. Clogged fuel filters can also be a culprit if they weren’t replaced or if contamination was present. For mechanical pumps, incorrect timing can cause poor running, but this is a complex adjustment best left to professionals. Finally, a related sensor issue could have been disturbed during the repair; checking for diagnostic trouble codes (DTCs) can provide clues.

If these steps don’t resolve the issue, it’s time to call for professional help. Our technicians are equipped to diagnose and resolve complex marine diesel problems throughout South Florida.

Best Practices for Marine Fuel Pump Longevity

Protect your investment and ensure your vessel is always ready for adventure with these maintenance practices.

-

Use High-Quality Fuel: Always use clean, marine-grade diesel from reputable suppliers. Contaminated fuel is the #1 enemy of fuel pumps and injectors.

-

Regularly Change Fuel Filters: This is non-negotiable. Filters protect your system from harmful contaminants. Follow your manufacturer’s service intervals, or change them more often if fuel quality is questionable.

-

Use Biocides: Prevent microbial growth (the “diesel bug”) in your fuel tanks with a quality biocide. This stops sludge from forming that can clog filters and damage pumps.

-

Keep Tanks Free of Water: Regularly inspect and drain water and sediment from the bottom of your fuel tanks. Water is corrosive and destructive to fuel system components.

-

Avoid Running Tanks Low: This helps prevent the pump from drawing air or sediment from the bottom of the tank.

-

Maintain the Entire Engine: A well-maintained engine puts less strain on all its components, including the fuel pump. Our comprehensive Diesel Engine Maintenance services ensure your entire system receives the expert care it needs.

Frequently Asked Questions about Marine Diesel Fuel Pump Replacement

Here are some common questions we hear regarding diesel fuel pump replacement for marine engines:

How much does it cost to replace a marine diesel fuel pump?

The cost varies widely based on the engine, pump type, and installation complexity.

- Parts Cost: A low-pressure lift pump can range from $100 to $300+. A high-pressure injection or common rail pump can cost $500 to over $2,000.

- Labor Cost: Professional labor typically takes 2 to 6 hours. With service rates from $100-$150+ per hour, labor can be a significant portion of the cost, especially for complex jobs.

- Total Cost: Expect a total of approximately $400 for a simple lift pump replacement to $1,500 – $3,000+ for a high-pressure pump replacement, including parts and labor.

How long does a marine fuel pump last?

Most marine diesel fuel pumps are built to last for thousands of operating hours (equivalent to 100,000 to 200,000 miles). However, this lifespan is heavily influenced by:

- Fuel Quality: Contamination from water, sediment, or microbes is a primary cause of premature failure.

- Maintenance: Regular fuel filter changes are crucial. A clogged filter forces the pump to work harder, shortening its life.

- Operating Conditions: Consistent heavy loads or high heat can increase strain on the pump.

With proper maintenance and clean fuel, a marine diesel fuel pump can provide many years of reliable service.

What are the main types of marine diesel fuel pumps?

Marine diesel engines use a two-stage system with two primary pump types:

- Low-Pressure Lift Pump: This pump draws fuel from the tank and delivers it at low pressure to the high-pressure pump. They can be mechanical or electric.

- High-Pressure Injection Pump: This is the core of the system, pressurizing fuel to extremely high levels for injection. Common types include:

- Rotary or Inline Pumps: Found in older diesel engines.

- Common Rail High-Pressure Pumps: Used in modern marine diesels for superior performance and efficiency.

Knowing your engine’s pump type is essential for correct diagnostics and diesel fuel pump replacement.

Conclusion

Your marine diesel fuel pump is the lifeline that keeps your vessel running reliably. Recognizing the warning signs—from a whining noise to a loss of power—is critical to avoiding being stranded, facing costly repairs, and preventing safety risks at sea. Understanding the difference between a low-pressure lift pump and a high-pressure injection or common rail system helps you appreciate the engineering behind every smooth voyage.

When it comes to diesel fuel pump replacement, the technical knowledge required is substantial. You’re dealing with high-pressure fuel, precise components that demand absolute cleanliness, and complex bleeding procedures. The confined space of an engine room adds another layer of difficulty. While we’ve provided a guide, the reality is that the complexity and risks often make professional service the wisest investment. The cost of a botched DIY attempt can quickly exceed any labor savings.

At RPM Diesel Company, our factory-authorized technicians have decades of experience with brands like Bosch, Detroit Diesel, and MTU. We understand the uncompromising standards marine diesel engines require. Whether your vessel is in Fort Lauderdale, Miami, or anywhere in South Florida, we are ready to provide the expert service your engine deserves.

Don’t wait for a failing fuel pump to ruin your voyage. Contact us for expert Diesel Fuel Injection Service and let us keep your marine diesel running strong.