The Heart of Your Marine Diesel Engine

Fuel injector cleaning service is a precision maintenance procedure that removes carbon deposits, varnish, and contaminants from your marine diesel injectors using ultrasonic technology and specialized flow testing equipment.

What to Expect from Professional Fuel Injector Cleaning:

| Service Component | What It Does |

|---|---|

| Ultrasonic Cleaning | Removes carbon deposits and varnish through high-frequency sound waves |

| Flow Testing | Measures fuel delivery rates before and after cleaning |

| Spray Pattern Analysis | Ensures proper atomization for efficient combustion |

| Parts Replacement | Installs new filters, O-rings, and seals as needed |

| Calibration | Restores injectors to OEM specifications |

| Cost | Typically $17-$30 per injector vs. $150+ for replacement |

Your marine diesel engine’s fuel injection system is its beating heart. As one industry expert puts it, “The fuel injection system is the heart of the engine, and if not overhauled, calibrated and set up perfectly, can alter the running efficiency and power output of an engine dramatically.”

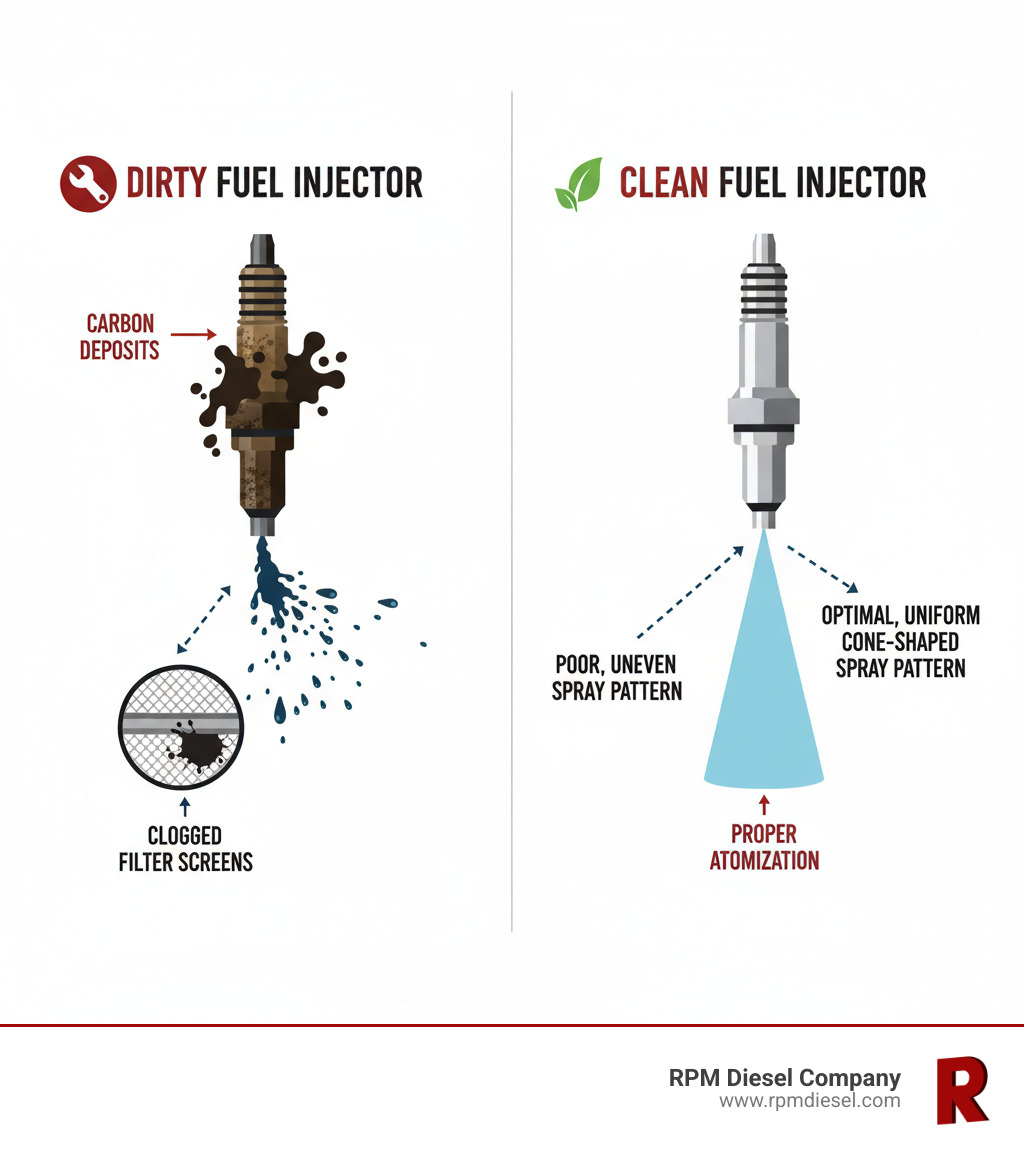

When fuel injectors deliver a precise mist of diesel into your engine’s combustion chambers, everything runs smoothly. But over time, injectors accumulate carbon deposits and varnish from combustion byproducts. This buildup distorts spray patterns, reduces atomization quality, and throws off the air-fuel ratio your engine needs for optimal performance.

The result? Black smoke, reduced power, higher fuel consumption, and accelerated engine wear. For marine vessels where reliability is non-negotiable, these symptoms signal a critical maintenance need.

Professional ultrasonic fuel injector cleaning offers a cost-effective solution. By removing injectors from your engine and cleaning them with specialized equipment, certified technicians restore them to factory specifications—often achieving flow rates within 2% of each other. This precision ensures each cylinder contributes equal power, protecting your engine from damage and maximizing your fuel efficiency.

Similar topics to Fuel injector cleaning service:

- marine diesel engine maintenance schedule

- marine diesel engines maintenance troubleshooting and repair

Recognizing the Red Flags: Symptoms of Dirty Marine Fuel Injectors

Your marine diesel engine has a way of speaking to you—if you know how to listen. When fuel injectors start struggling under layers of carbon deposits and varnish, your engine sends clear distress signals. The trick is recognizing these warning signs before they turn into expensive repairs.

Black smoke billowing from your exhaust is usually the first red flag. When you see dark clouds trailing behind your vessel, it means your engine is burning fuel inefficiently. Dirty injectors can’t atomize diesel properly, so instead of a fine mist, you get larger droplets that don’t burn completely. The tip holes in clogged injectors can actually elongate or reshape over time, making the spray pattern even worse.

You might also notice your vessel feels sluggish, like it’s working harder just to maintain normal speeds. Reduced engine power happens when injectors can’t deliver fuel effectively to each cylinder. That responsive acceleration you’re used to? Gone. Your boat might struggle to get up on plane or feel like it’s dragging an invisible anchor.

Here’s an expensive symptom: higher fuel consumption. When injectors are clogged, your engine works overtime trying to compensate for poor fuel delivery. You’ll find yourself at the fuel dock more often, watching your operating costs climb with each fill-up. It’s frustrating because you’re burning more fuel while getting less performance.

Rough idling tells you something’s off with your fuel delivery. A healthy marine diesel should purr at idle—smooth and steady. When you feel excessive vibration or hear uneven engine sounds at low RPMs, it usually means one or more cylinders aren’t getting the right fuel mixture. This imbalance puts unnecessary stress on your entire engine.

Engine hesitation or stuttering during acceleration is another telltale sign. You push the throttle forward expecting smooth power, but instead get jerky, inconsistent response. This happens when fuel flow becomes unpredictable, leaving some cylinders starved while others get too much. It’s not just annoying—it can be dangerous when you need precise control in tight situations.

In severe cases, you might experience engine misfires—a noticeable jerk or sudden loss of power when a cylinder fails to fire properly. Your exhaust might also change character, becoming darker, thicker, or giving off a more pungent smell than usual.

These symptoms aren’t something to ignore or hope will go away on their own. They’re your engine asking—sometimes begging—for help. The good news? A professional fuel injector cleaning service can address all of these issues, restoring your engine to smooth, efficient operation before minor problems become major headaches.

The Professional Fuel Injector Cleaning Service: A Deep Dive

When it comes to marine diesel engines, precision isn’t just a nice-to-have—it’s everything. A professional fuel injector cleaning service delivers results that no bottle of additive or quick-fix solution can match. We’re talking about a meticulous process involving advanced ultrasonic technology and rigorous flow testing that restores your injectors to factory-fresh condition.

Think of it this way: your engine deserves the same level of precision that went into building it in the first place.

Why At-Home or Additive-Only Methods Aren’t Enough

You’ve probably seen those fuel additives at the marine supply store, promising to clean your injectors and restore lost power. And yes, some quality additives do provide real benefits—they add lubricity to modern low-sulfur diesel, help prevent tip coking (that crusty carbon buildup), and can keep relatively clean injectors from getting worse.

But here’s the hard truth: they’re a preventative measure, not a cure.

When your marine diesel injectors are already clogged with heavy deposits, those additives are like trying to clear a blocked drain with dish soap. They might help a little, but they won’t solve the core problem. The chemistry simply isn’t strong enough to dissolve stubborn carbon and varnish that’s been baking onto your injectors for hundreds of operating hours.

Even more importantly, additives can’t do anything about clogged internal filters inside the injector body. These tiny filters trap particulate matter, and once they’re blocked, no amount of chemical cleaner poured into your fuel tank will clear them. The fuel just can’t reach the blockage in a way that matters.

But the biggest limitation? There’s no feedback. You have no idea if that additive actually worked. You don’t know if your spray pattern improved, if your flow rates are balanced, or if you’re still sending uneven fuel delivery to different cylinders. Without professional testing equipment, you’re flying blind—and an improperly functioning injector can cause serious engine damage even if it seems to be working.

As industry experts emphasize, there are no on-vessel tests that can determine if all your injectors are flowing per OEM specification. For the demanding marine environment where reliability isn’t negotiable, that’s a problem.

Here’s another critical point: DIY maintenance or repairs on marine diesel fuel injection systems should never be attempted. These systems require extensive specialized knowledge, experience, and equipment. Licensed and authorized facilities exist for a reason—your vessel’s continued operation depends on getting this right.

Temporary solutions might seem appealing, but they’re exactly that: temporary. For marine diesel engines that power your livelihood or adventures, relying on anything less than professional service is gambling with your engine’s longevity.

The Gold Standard: Off-Vessel Ultrasonic Fuel Injector Cleaning Service

The only way to truly restore your marine fuel injectors to optimal performance is through professional, off-vessel ultrasonic cleaning and flow testing. This is the gold standard—the service that actually delivers measurable, documented results.

Let’s walk through what happens when you bring your injectors in for proper service.

Initial Inspection and Pre-Cleaning Flow Testing comes first. Before we touch anything with cleaning solution, each injector undergoes a thorough inspection. We perform an Ohm test to check electrical resistance, a leak test to ensure integrity, and most importantly, a pre-cleaning flow test. During this test, we pulse the injectors and carefully measure their flow rates while analyzing their spray patterns.

This baseline data tells us exactly how each injector was performing in your engine. We can see if one is gummed up, not pulsing correctly, or causing a misfire. This isn’t guesswork—it’s hard data.

Next comes the ultrasonic bath and cavitation process. Your injectors are placed in specialized testing and cleaning equipment that uses high-frequency sound waves to create microscopic bubbles in the cleaning solution. When these bubbles collapse—a process called cavitation—they create powerful scrubbing action that dislodges stubborn carbon deposits, varnish, and contaminants from every surface, inside and out.

The beauty of this process? It happens while the injectors are simultaneously pulsed and back-flushed. A serious vacuum pulls contaminants out while the ultrasonic waves break them loose. It’s thorough in a way that chemical additives simply cannot match.

After the ultrasonic cleaning, we move to replacement parts. Old filters, O-rings, grommets, seals, and pintle caps are removed and replaced with new components. This ensures proper sealing and prevents any residual debris from re-entering your fuel system.

Then comes post-cleaning calibration and flow testing—the moment of truth. We run each injector through the same rigorous testing protocol again, checking for proper spray pattern, consistent flow rates, and leak-free operation. Our goal is to achieve flow rates that vary no more than 2% relative to each other. That level of precision ensures optimal engine balance and equal power contribution from every cylinder.

Finally, you receive a before-and-after data report. This detailed document compares the static and pulse flow rates of each injector before and after cleaning. It’s transparent proof of the improvement and gives you confidence in your engine’s fuel delivery system.

This level of precision simply cannot be replicated by in-tank additives or on-vessel cleaning methods. For marine applications where reliability keeps you on the water, professional fuel injector cleaning service is an investment in your vessel’s future.

Understanding the Difference: Mechanical vs. Common Rail Injectors

Not all marine diesel fuel injectors are created equal. The service requirements for your vessel depend largely on whether you have older mechanical systems or modern Common Rail technology.

Older mechanical systems are workhorses—robust and reliable when properly maintained. These injectors typically need service around every 1000 hours of operation or two years for turbocharged propulsion diesels. This regular attention isn’t arbitrary. Over time, the constant passage of diesel fuel through the injector can cause tip hole elongation or reshaping. When that happens, you get unequal atomization between partner holes, leading to increased smoke emissions and accelerated cylinder wear.

Periodic service ensures all injectors contribute equally. A single faulty injector can cause uneven combustion that damages cylinders over time. Following manufacturer recommendations for service intervals protects your entire engine investment.

Modern Common Rail systems represent a leap forward in fuel injection technology. These systems use electronic controls and operate at much higher pressures for incredibly precise fuel delivery. Thanks to advances in materials and machining tolerances, Common Rail injectors are remarkably reliable. Many manufacturers don’t even specify maintenance based on hourly intervals for these systems, which can drastically reduce service costs over your engine’s lifespan.

That said, even Common Rail injectors aren’t immune to carbon buildup and contamination. When symptoms appear, they still need professional attention. The precision of these systems means that even minor deviations can impact performance. Because of their complexity, Common Rail injectors require specialized expertise and equipment—one more reason to trust licensed professionals.

Understanding your marine engine’s specific injection system and following professional service recommendations keeps you running at peak performance. Whether you’re maintaining a classic mechanical system or a modern Common Rail setup, the right service variations make all the difference in reliability and longevity.

The Tangible Benefits: Performance, Efficiency, and Longevity

When you invest in a professional fuel injector cleaning service for your marine diesel engine, you’re not just fixing a problem—you’re open uping real, measurable improvements that you’ll notice every time you take your vessel out on the water.

Restored engine power is often the first benefit you’ll feel. Clean injectors deliver that perfect mist of fuel your engine needs for complete combustion. Suddenly, your vessel responds the way it should. Acceleration feels crisp again. Your boat handles with the confidence you remember. It’s like refinding what your engine was always meant to do.

Then there’s the improved fuel efficiency. This is where the investment really pays for itself. Dirty injectors waste fuel through incomplete combustion and distorted spray patterns. Once your injectors are properly cleaned and calibrated, your engine burns fuel the way the manufacturer intended. Many of our customers report a 10 to 15% improvement in fuel economy. Over a season of boating, those savings add up quickly—especially with today’s fuel prices.

Reduced emissions come hand-in-hand with better efficiency. When combustion is optimized, your engine produces less black smoke and fewer harmful pollutants. This isn’t just good for the environment and our waterways—it’s increasingly important for marine regulations. Plus, nobody wants to be that boat leaving a trail of dark exhaust.

You’ll also experience smoother engine operation across the board. When all your injectors are working in harmony, delivering consistent fuel to each cylinder, rough idling disappears. Engine hesitation vanishes. Those frustrating misfires become a thing of the past. Your engine simply runs the way it should—smooth, reliable, and confident.

Perhaps most importantly, professional cleaning extends your engine’s life. Here’s why this matters: when injectors are dirty, some cylinders work harder than others. This imbalance accelerates wear on your engine’s internal components. Poor spray patterns can cause carbon buildup and prevent cylinder wear that shortens your engine’s lifespan. By restoring proper fuel delivery to each cylinder, you’re protecting your entire engine from premature aging.

And let’s talk about avoiding costly engine damage. Modern engine management systems can compensate for minor variations in fuel delivery—but only up to about 15% deviation. Beyond that, the system can’t keep up. You risk catalytic converter damage, bore wash, and potentially catastrophic engine problems. Often, these issues develop before any warning light even appears on your dashboard.

A professional fuel injector cleaning service costs a fraction of what major engine repairs would run you. It’s preventative medicine for your marine diesel—the kind of smart investment that protects both your vessel’s performance and your wallet.

Frequently Asked Questions about Marine Fuel Injector Service

We’ve spent decades working on marine diesel engines in Fort Lauderdale, Miami, and throughout South Florida, and we know that when it comes to something as critical as your fuel injectors, you want straight answers. Here are the questions vessel owners ask us most often about fuel injector cleaning service.

How often should marine fuel injectors be cleaned?

The honest answer? It depends on what’s powering your vessel.

For older mechanical marine diesel motors, we typically recommend a fuel injector cleaning service every 1000 hours of operation or every two years for turbocharged propulsion diesels. This isn’t arbitrary—it’s based on how these systems age. Over time, the constant passage of diesel fuel through mechanical injectors can cause the tiny tip holes to elongate or reshape. When that happens, you get unequal atomization between partner holes, which leads to increased smoke and accelerated cylinder wear. Regular service keeps all your injectors contributing equally, preventing one faulty injector from damaging your entire engine.

Modern Common Rail systems are a different story. Thanks to remarkable advancements in injector technology, materials, and machining tolerances, manufacturers often don’t specify maintenance based on hourly intervals. These systems are built to last longer between services, which can dramatically reduce your maintenance costs over your engine’s lifespan.

That said, no system is completely maintenance-free. We always recommend following your engine manufacturer’s specific guidelines. And here’s the most important part: if you notice any of those red flag symptoms we discussed earlier—black smoke, rough idling, reduced power, or higher fuel consumption—don’t wait for a scheduled interval. Schedule an inspection right away. Proactive maintenance is always cheaper than reactive repairs, especially in the marine environment where reliability isn’t just convenient, it’s essential.

What is the cost of a professional fuel injector cleaning service?

Let’s talk numbers, because this is where a professional fuel injector cleaning service really makes financial sense.

You can typically expect to pay between $17 to $30 per injector for a comprehensive service that includes ultrasonic cleaning, flow testing, spray pattern analysis, new filters and O-rings, calibration, and a detailed before-and-after data report. For most marine diesel engines with six or eight injectors, you’re looking at a few hundred dollars for the complete service.

Now compare that to replacement costs. A single new marine fuel injector can easily run $150 or more—often much more for specialized systems. Multiply that by six or eight injectors, add in the labor for removal and installation, and you’re suddenly looking at thousands of dollars. Our professional cleaning service restores your existing, high-quality OEM injectors to like-new condition for a fraction of that cost.

But the savings don’t stop there. Clean, properly calibrated injectors improve your fuel efficiency by 10 to 15%, which means you’re saving money every time you run your engines. They also prevent the kind of costly engine damage that happens when injectors fail—damage to cylinders, catalytic converters, and other expensive components. When you look at it that way, a fuel injector cleaning service isn’t really a cost at all. It’s an investment in reliability that pays for itself in fuel savings and avoided repairs.

Can I clean my marine diesel injectors myself?

We appreciate the DIY spirit—really, we do. Many of our customers are hands-on boat owners who handle routine maintenance themselves, and we respect that. But when it comes to fuel injectors, we have to be direct: attempting to clean marine diesel injectors yourself is a risk you don’t want to take.

Here’s why professional service matters. Effective injector cleaning requires specialized ultrasonic machines that create microscopic cavitation bubbles to scrub away carbon deposits from every internal surface. It requires flow benches that can measure delivery rates to within 2% accuracy. It requires spray pattern analyzers, leak testing equipment, and calibration tools that simply aren’t available outside professional facilities. These aren’t the kind of tools you’ll find at your local marine supply store.

But it’s not just about equipment. Fuel injectors are precision components machined to incredibly tight tolerances. Even a slight misalignment during reassembly or a missed step in the cleaning process can turn a cleanable injector into one that needs expensive replacement. Without proper testing, you have no way to verify if your cleaning actually worked or if you’re about to reinstall an injector that will damage your engine.

The marine environment makes this even more critical. Your fuel injection system needs to perform flawlessly when you’re miles offshore or navigating challenging conditions. As industry experts consistently emphasize, DIY maintenance or repairs on marine diesel fuel injection systems should never be attempted. These repairs require extensive knowledge and experience and should only be performed at licensed and authorized facilities.

At RPM Diesel, our certified technicians have the specialized training and equipment to handle both mechanical and Common Rail systems. We provide you with detailed before-and-after data so you know exactly what you’re getting. When it comes to the heart of your marine diesel engine, trust the professionals who specialize in marine applications—not general mechanics or DIY methods that can’t deliver the precision your vessel demands.

Conclusion: Invest in Precision for Peak Marine Performance

Your marine diesel engine deserves better than guesswork and temporary fixes. Throughout this article, we’ve explored how fuel injector cleaning service isn’t just another maintenance task—it’s the difference between an engine that struggles and one that performs exactly as its engineers intended.

When you invest in professional ultrasonic cleaning at a certified facility, you’re choosing precision over shortcuts. You’re ensuring that every cylinder in your engine receives the exact amount of fuel it needs, atomized perfectly for complete combustion. That precision translates directly into the performance you feel at the helm: smooth acceleration, powerful response, and the confidence that comes from knowing your engine won’t let you down when you need it most.

The math speaks for itself. Spending $17 to $30 per injector to restore factory performance beats replacing injectors at $150+ each, not to mention the catastrophic repair costs that dirty injectors can trigger if left unchecked. Better fuel efficiency means you’re saving money with every voyage. Reduced emissions protect the beautiful Florida waters we all cherish. Extended engine life protects your investment for years to come.

At RPM Diesel, we’ve built our reputation on understanding marine diesel engines inside and out. Our technicians don’t just clean injectors—they restore them to OEM specifications using the same advanced equipment and rigorous testing protocols that major manufacturers rely on. We serve Fort Lauderdale, Miami, and vessels throughout South Florida and beyond, bringing decades of specialized expertise to every service.

Whether you’re running older mechanical systems or modern Common Rail technology, whether you’re noticing black smoke or just being proactive about maintenance, we’re here to help. Your engine is the heart of your vessel, and we treat it with the respect and precision it deserves.

To ensure your vessel operates at its best, explore our comprehensive marine engine maintenance services. Your next voyage deserves an engine that’s firing on all cylinders—literally.