Why Marine Diesel Generator Maintenance is Essential for Every Vessel Owner

Diesel generator maintenance tips are crucial for any boat owner who depends on reliable onboard power. Your generator runs everything from navigation systems to refrigeration, making it one of your vessel’s most critical components.

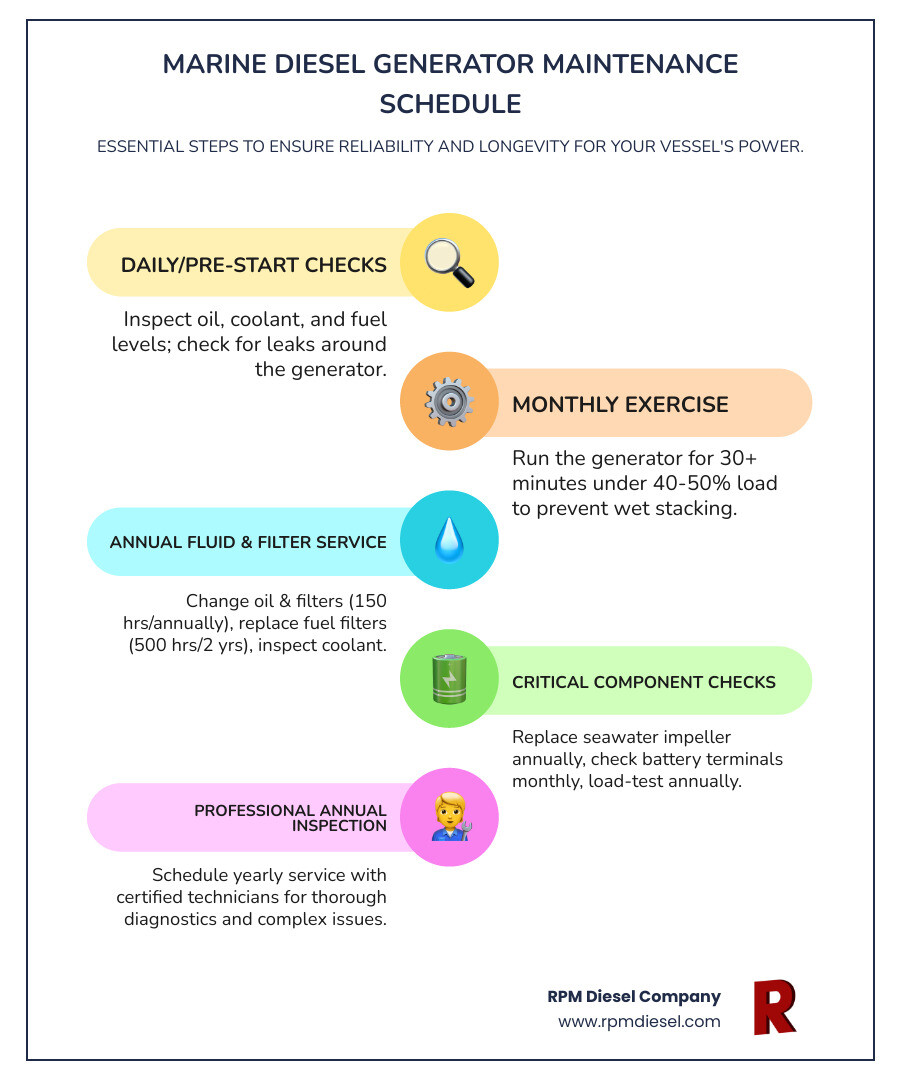

Quick Answer: Essential Diesel Generator Maintenance Tips

- Daily/Pre-Start Checks – Inspect oil, coolant, and fuel levels; check for leaks

- Monthly Exercise – Run generator for 30+ minutes under 40-50% load

- Oil & Filter Changes – Every 150 hours or annually (whichever comes first)

- Fuel Filter Replacement – Every 500 hours or every 2 years

- Seawater Impeller – Replace annually (critical for marine generators)

- Battery Testing – Check terminals monthly; load-test annually

- Coolant Service – Inspect and replace every 1,000-1,500 hours

- Professional Inspection – Schedule yearly service with certified technicians

A neglected generator is a liability. Research shows that weak or undercharged starting batteries are the most common cause of standby power system failures, a problem that is completely preventable with routine checks.

The harsh marine environment—salt air, humidity, and constant motion—accelerates wear, meaning marine generators require more frequent attention than their land-based counterparts.

Fortunately, most generator problems give an early warning. A small leak caught during a daily inspection can prevent catastrophic failure at sea. Proper maintenance not only prevents expensive emergency repairs but also extends your generator’s lifespan to 30,000 hours or more between major overhauls.

Whether you’re a weekend cruiser or manage a commercial fleet, understanding basic generator care protects your investment and keeps your vessel powered when you need it most.

Terms related to diesel generator maintenance tips:

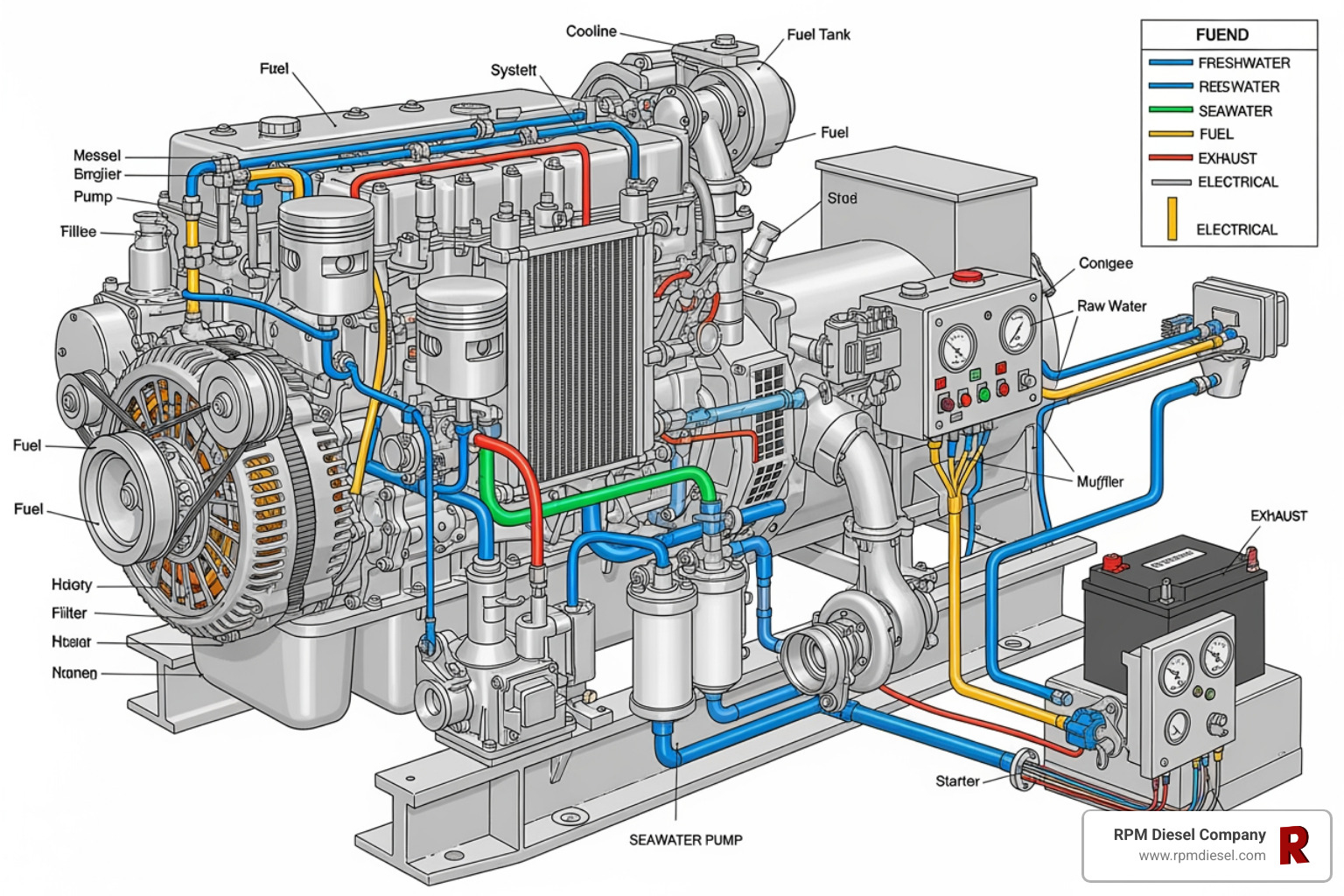

Understanding Your Marine Generator’s Anatomy and Manual

To properly maintain your marine diesel generator, you must first understand its core components. A diesel engine drives an alternator (generator head), converting mechanical energy into electrical power for your vessel’s systems.

Key components work together to ensure reliable operation:

- The engine block is where combustion creates power.

- The alternator converts this mechanical motion into electricity.

- The fuel system delivers clean diesel via filters and injectors.

- The cooling system, vital in marine settings, uses a heat exchanger to transfer heat from a closed freshwater circuit to a raw seawater circuit.

- The seawater pump draws in ocean water for cooling.

- The exhaust system safely vents hot gases, often through a wet elbow where water and exhaust mix.

- The electrical system includes the starting battery, wiring, and the control panel, which monitors performance and displays fault codes.

Understanding these parts helps you spot problems before they become expensive failures.

The First Step: Your Manufacturer’s Manual

Your manufacturer’s manual is the single most valuable resource for keeping your generator running. It contains the exact blueprint for your model, including the model number and specification number needed for ordering parts. It specifies crucial service intervals (e.g., “every 150 hours or annually, whichever comes first”), which are based on extensive engineering, not suggestions.

The manual also details recommended fluids, such as the specific oil viscosity and API classification (e.g., 15W-40, API CF or better for most Onan diesels). Using the wrong fluids can cause significant damage. It also provides exact part numbers for filters, impellers, and belts, along with troubleshooting guides.

If you can’t find your manual, try the official Cummins QuickServe portal for manuals. We also support owners of Northern Lights Generators and can help source information for Kohler Marine Generator Parts. This step is foundational to all other diesel generator maintenance tips.

Why Genuine Parts Matter

While aftermarket parts may seem cheaper, they often lead to expensive long-term repairs. Genuine OEM (Original Equipment Manufacturer) parts are engineered and tested specifically for your generator, ensuring reliability, a perfect fit, and warranty protection that aftermarket parts can void.

Using genuine parts ensures optimized performance, as your generator was designed as an integrated system. Swapping in off-spec components can affect fuel efficiency and power output. For those maintaining Westerbeke Marine Generators or seeking Northern Lights Generators Parts for Sale, investing in genuine parts is an investment in reliability and safety.

The Ultimate Marine Diesel Generator Maintenance Schedule

A structured maintenance schedule is your roadmap to reliability. The golden rule is to perform maintenance based on engine run hours or calendar time, whichever comes first. Seals can dry out and fluids can degrade over time, even without use.

Your maintenance logbook is your generator’s health diary. Record the date, hour meter reading, tasks performed, and parts used. This log helps spot patterns, supports warranty claims, and adds value to your vessel. For an example of a thorough log, you can see a detailed 1000-hour service log. For more guidance, explore our resources on Generator Maintenance.

Essential daily and weekly diesel generator maintenance tips

These simple checks can prevent major issues.

Before Every Start: Perform a quick visual inspection. Look for leaks (oil, coolant, fuel), loose parts, corrosion, or frayed wires. Check the engine oil level and the coolant level (only when the engine is cold). Ensure you have adequate fuel. Clear any debris from the seawater strainer to prevent overheating. Visually inspect the alternator belt for cracks and proper tension, and check hoses for bulges or soft spots. Ensure battery terminals are clean and tight.

Weekly Attention: Start your generator weekly, even if docked. Let it run for a few minutes to lubricate internal parts and listen for unusual sounds. Check that your battery charger is functioning correctly. If your fuel filter has a drain, release any accumulated water.

Monthly/Periodic Exercise: The “Use It or Lose It” Rule

Generators that sit idle often fail faster than those that work regularly. This is one of the most critical diesel generator maintenance tips.

Run your generator for at least 30 minutes every month under a significant load—aim for 40-50% of its rated capacity. Running without a proper load prevents the engine from reaching optimal temperature, leading to wet stacking—a buildup of unburned fuel and carbon in the exhaust that chokes performance.

Regular operation under load also circulates oil, moves fuel through the system to prevent degradation, and drives moisture out of electrical windings. Before applying AC loads, let the generator warm up for a minute. When finished, turn off the AC load breaker first, then let the generator cool down for a minute before shutting it off. This protects sensitive components. Learn more in our guide on Diesel Generator Maintenance.

Semi-Annual and Annual Service Deep Dive

These deeper services prevent long-term failures.

Every Six Months or 250-500 Hours:

- Change the engine oil and filter. Most marine diesels require this every 100-250 hours or twice yearly.

- Replace primary and secondary fuel filters annually or every 250-500 hours.

- Inspect the air filter; replace if you can’t see light through it.

- Check drive belt tension for cracks or glazing.

- Load test your starting batteries. A simple voltage check isn’t enough to verify cranking power.

Once a Year or Every 500-1000 Hours:

- Replace the seawater pump impeller. This is critical. A failed impeller causes overheating in minutes. Replace it annually regardless of appearance and keep the old one as an emergency spare.

- Service the coolant system. Check concentration and inspect all hoses and clamps.

- Inspect sacrificial zinc anodes and replace them before they are fully dissolved.

- Examine the exhaust wet elbow for rust, cracks, or carbon buildup.

- Schedule a professional inspection. A trained technician can perform deeper diagnostics and spot hidden issues. Our team at RPM Diesel Company provides expert Marine Diesel Generator and Engine Services throughout South Florida.

Advanced Maintenance and Troubleshooting

Even with diligent maintenance, problems can arise. Most issues, however, provide early warnings like a change in sound, a drop in performance, or a minor leak. Understanding common failure points gives you an advantage.

The most frequent issues are weak or dead starting batteries, fuel contamination (water or microbial growth), and overheating (often from a failed seawater impeller or clogged heat exchanger). Catching these problems early is key. When a problem is beyond your comfort level, our team is ready to help with professional Marine Diesel Generator Repair.

Advanced diesel generator maintenance tips for peak performance

These practices keep your generator running at its absolute best.

Load bank testing is a crucial but often overlooked service. We connect your generator to a device that simulates a full electrical load, allowing us to verify its true power output in a controlled environment. This process also burns off carbon deposits, preventing wet stacking, and reveals hidden weaknesses in the voltage or cooling systems. We recommend annual load bank testing, which is part of our comprehensive Generator Repair Service.

Fuel quality management is vital with modern ultra-low sulfur diesel, which has a shorter shelf life. Fuel polishing circulates fuel through specialized filters to remove water and sediment. Using quality fuel stabilizers and biocides also keeps fuel fresh during storage, preventing costly injection system damage.

Coolant analysis, like a blood test for your generator, can detect depleted corrosion inhibitors, combustion gas contamination (indicating a head gasket issue), or excessive wear metals, identifying problems you can’t see.

Valve lash adjustments and injector service, typically needed every 1,000-2,000 hours, are professional jobs essential for maintaining engine timing, compression, and fuel efficiency.

Special Considerations for the Marine Environment

The marine environment actively works to degrade your generator. Understanding these stressors is key to protecting your investment.

Salt air is relentless, corroding electrical connections and metal components. Regular cleaning and applying dielectric grease to electrical connections creates a protective barrier against salt intrusion.

Humidity works with salt to cause electrical problems by condensing inside control panels and windings. The monthly exercise run under load generates heat that drives out this damaging moisture.

Constant motion and vibration loosen fasteners, clamps, and connections over time. Regularly check that all mounting bolts and clamps are tight. Ensure hoses and wiring are secured and protected from chafing to prevent failures or fire hazards.

Our Marine Generator Repair Fort Lauderdale services are designed around these unique challenges. We know what the marine environment does to generators because we work on them every day.

DIY vs. Calling the Pros: Knowing Your Limits

While many owners can handle basic diesel generator maintenance tips like daily checks and fluid changes, it’s crucial to know your limits. Modern marine generators are sophisticated machines, and a well-intentioned DIY mistake can quickly turn a minor issue into a major repair bill.

The line between DIY and professional service is an important one. Routine maintenance keeps your generator healthy, but professional service ensures it stays that way for the long haul. For more on this, see our articles on DIY or Professional Diesel Generator Maintenance and Care Tips from Generator Maintenance Companies.

Essential Onboard Spare Parts Kit

Being prepared with the right spares can be the difference between a quick fix and a ruined voyage. Your onboard kit should include:

- Oil filters (at least two)

- Fuel filters (primary and secondary, two sets minimum)

- A fresh seawater impeller

- Drive belts for the alternator and accessories

- Zinc anodes (if applicable)

- Fuses and control relays

- Coolant concentrate and pre-mix

- Spare engine oil

- An assortment of hose clamps

Having the right Northern Lights Generator Parts on hand can save your trip.

When to Schedule Professional Marine Generator Service

Some situations demand professional expertise and specialized equipment:

- Complex diagnostics for persistent fault codes or mysterious behavior.

- Major component failures involving the engine block, alternator, or fuel injection pump.

- Recurring issues that point to a deeper root cause.

- Engine overhauls or rebuilds, which require a specialized facility.

- Injector service, including cleaning, testing, and calibration.

We also strongly recommend an annual professional inspection. A trained technician can perform load bank testing, analyze coolant, check compression, and uncover hidden issues before they become emergencies.

Our team at RPM Diesel Company is factory-trained and equipped to handle any challenge. Our Marine Diesel Generator Services by RPM and Generator Repair Service Center in South Florida are ready to assist. The real mistake is letting a small problem become a big one.

Frequently Asked Questions about Marine Generator Maintenance

We talk to boat owners every day at our Fort Lauderdale facility. Here are answers to the most common questions about marine generator maintenance.

What are the biggest risks of neglecting my marine generator?

Neglecting your generator is not just inconvenient; it’s dangerous and expensive. The primary risks include:

- Catastrophic failure at sea, leading to the loss of critical navigation, communication, and safety systems.

- Loss of onboard systems like refrigeration, air conditioning, and bilge pumps.

- Costly emergency repairs, which are often far more expensive than routine maintenance.

- Voided warranty, as most manufacturers require documented service.

- Reduced vessel resale value due to a poor maintenance history.

How often should I run my generator if I’m not using my boat?

This is one of the most vital diesel generator maintenance tips. Run your generator at least once a month for a minimum of 30 minutes under a significant load of 40-50% of its rated capacity.

Simply idling the generator is harmful and can cause “wet stacking.” A proper loaded run does the following:

- Burns off carbon deposits and unburned fuel.

- Drives out moisture from electrical windings and contacts.

- Circulates oil to keep seals and internal parts lubricated.

- Prevents fuel degradation and varnish buildup in the fuel system.

If you need professional help with storage maintenance, our team at RPM Diesel Company is always available.

What’s the most common cause of a generator failing to start?

The vast majority of no-start situations are caused by a few preventable issues:

- Weak or dead starting batteries. A battery can show good voltage but still lack the cranking amps to start a diesel engine. Regular load testing is essential.

- Corroded battery terminals. Corrosion prevents the flow of current from a healthy battery. Regular cleaning is a simple fix.

- Clogged fuel filters. A restricted filter will starve the engine of fuel.

- Old or contaminated diesel fuel. Modern diesel degrades over time and can accumulate water or microbial growth, which clogs filters and damages injectors.

All of these common failures are preventable with the routine maintenance covered in this guide.

Conclusion: Ensure Your Power, Ensure Your Peace of Mind

On the water, your generator is a lifeline. The diesel generator maintenance tips in this guide are your roadmap to confident, worry-free cruising. Think of maintenance as an investment, not an expense. Every hour spent on proactive care saves you days of frustration and thousands of dollars in reactive repairs.

A well-maintained generator brings peace of mind. You can enjoy your time on the water, confident that your power system is ready for whatever comes, instead of worrying about system failures or emergency service calls.

We understand that some tasks are for the hands-on owner, while others require professional expertise. That’s where RPM Diesel Company comes in. For over three decades, we’ve helped vessel owners across Fort Lauderdale, Miami, West Palm Beach, and throughout South Florida keep their marine diesel generators running flawlessly. We are authorized by major manufacturers, stock hard-to-find parts, and bring factory-trained expertise to every job.

Give your generator the care it deserves. Follow your maintenance schedule, and don’t hesitate to call us for professional support. For comprehensive marine diesel generator services backed by decades of experience, trust the team that South Florida vessel owners rely on. Learn more about how we can help at Diesel Generator Repair Florida: Expert & Easy 2025.

Ensure your power. Ensure your peace of mind. We’re here to help you do both.