Why Proper Maintenance Keeps Your Marine Diesel Generator Ready When You Need It Most

Diesel generator maintenance tips are essential for any marine vessel owner who depends on reliable backup power. Miles from shore, a well-maintained generator can mean the difference between a minor inconvenience and a serious emergency.

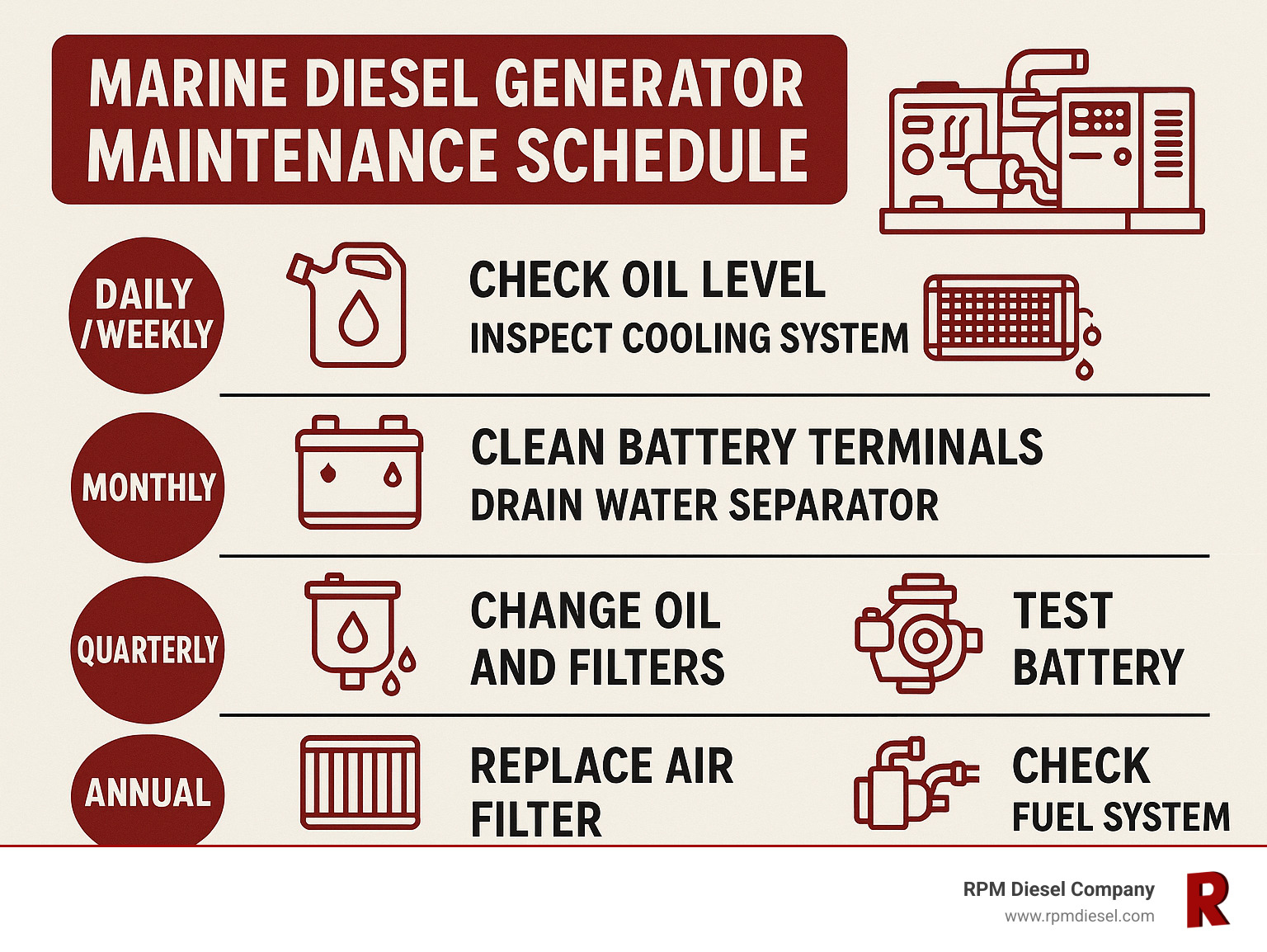

Essential Marine Diesel Generator Maintenance Schedule:

- Daily/Weekly: Check oil, coolant, and fuel levels; inspect for leaks; run generator under no load

- Monthly: Clean battery terminals, drain water separator, inspect belts and hoses

- Quarterly: Change oil and filters, lubricate moving parts, test battery capacity

- Semi-Annually: Replace air filters, inspect heat exchanger, check zinc anodes

- Annually: Professional load bank testing, fuel system cleaning, valve adjustments

With proper maintenance, diesel generators can last up to 30,000 hours, or 20-25 years of reliable service. However, marine environments present unique challenges. Salt air accelerates corrosion, moisture contaminates fuel systems, and the constant motion of a vessel puts extra stress on components.

The key to preventing shutdowns is preventive and regular maintenance. Following a structured maintenance schedule improves your generator’s efficiency and reduces the risk of breakdowns and costly repairs.

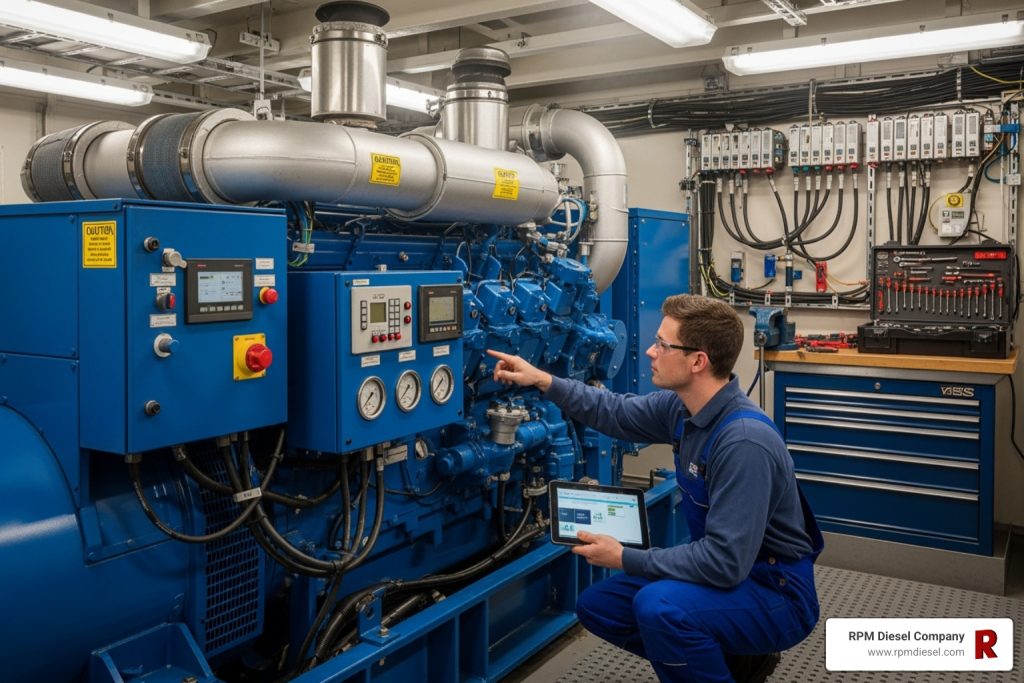

Your marine diesel generator needs regular attention to perform when called upon. The good news is that most maintenance tasks are straightforward and can be done by any vessel owner with basic mechanical skills.

Your Essential Marine Diesel Generator Maintenance Tips Checklist

This section covers routine checks crucial for any marine vessel, ensuring your generator is ready when you need it. Following a schedule is the best way to prevent unexpected failures at sea.

Essential Daily and Weekly Diesel Generator Maintenance Tips

These small daily and weekly diesel generator maintenance tips keep your generator running smoothly and take just minutes, but can prevent hours of future headaches.

Visual inspections should become second nature. Look for puddles indicating leaks, loose connections, or anything that appears unusual. Your eyes are the first line of defense.

Fluid level checks are critical. Check the oil level when the engine is cool, ensuring it’s between the high and low marks on the dipstick. Keep your coolant level topped up with the correct 50-50 mixture to prevent overheating. Monitor the fuel level to avoid running out, which can introduce air into the fuel lines. While running, watch the oil pressure and water temperature gauges for early warnings.

Leak detection involves more than looking. Listen for unusual sounds and note strange odors, which often signal trouble. Address any fuel or coolant leaks immediately.

Your exhaust system needs weekly attention. Check for blockages, cracks, or rust, particularly in the wet exhaust elbow, as corrosion can cause rapid failure in the marine environment.

Running the generator weekly is a vital habit. Perform a no-load exercise by letting it warm up for at least a minute before connecting a load, and allow a cool-down period before shutdown. This practice prevents fuel degradation, lubricates parts, and maintains battery charge.

For marine installations, clean your seawater strainer weekly. A clogged strainer restricts cooling water, leading to rapid overheating. Keeping the generator clean is also important, as salt spray and grime can hide problems and accelerate corrosion.

Monthly and Quarterly Tasks

Monthly and quarterly tasks address deeper wear and tear to prevent failures.

Battery maintenance is a top priority. A generator won’t start with a dead battery. Monthly, check electrolyte levels in wet-cell batteries, adding only distilled water when needed. Terminal cleaning is essential to prevent common marine corrosion. Ensure all connection tightness meets specifications to avoid heat-related failures.

Fuel filter inspection should happen monthly. Replace the filter if you see significant debris or discoloration. Drain your water separator weekly, or at least monthly. Water in diesel fuel encourages microbial growth (the “diesel bug”) that can clog your entire fuel system.

Quarterly, check belt tension and wear. Improper tension causes slippage or premature bearing wear. Hose inspection is also crucial; look for cracks, bulges, or hardening from salt exposure and flexing, and ensure all clamps are secure.

Lubricating moving parts according to manufacturer specifications prevents expensive component failures and extends your generator’s service life.

Semi-Annual and Annual Overhaul

These comprehensive checks catch problems that shorter-term inspections might miss.

Air filter replacement should occur semi-annually. A clean air filter is vital for efficiency and power. Annually, perform a coolant system flushing to prevent buildup. Alongside this, a heat exchanger inspection is critical, as blockages or corrosion can cause catastrophic overheating.

Zinc anode replacement is essential for marine generators. Inspect these sacrificial anodes every 90 days and replace them semi-annually or when they are significantly depleted to prevent galvanic corrosion.

Annual fuel system cleaning removes sediment and water from fuel tanks. Tasks like valve clearance checks, injector testing, and fuel pump inspections require professional expertise. Diesel generators are complex machines that benefit from professional attention at least once a year.

Professional servicing ensures complex procedures are handled correctly. Our technicians can perform load bank testing, software updates, and precision adjustments, preventing costly repairs and extending your generator’s life.

Critical Systems Maintenance for Peak Performance

Beyond a simple schedule, understanding and maintaining the core systems of your marine generator is vital for longevity and efficiency.

Fuel System: The Heart of Your Generator

A clean fuel system is the heart of your generator. Without it, even a well-maintained unit will fail. Fuel quality is essential; using high-quality diesel from reputable sources prevents contamination issues.

Diesel degradation is a common problem. Modern diesel can degrade in as little as six months, creating sludge and microbial growth. The infamous “diesel bug” thrives on moisture from condensation in fuel tanks. To prevent microbial growth, regularly drain water from your fuel separator and keep tanks full to reduce condensation.

For infrequently used generators, fuel stabilizers extend fuel life. If a generator has been idle for over six months, it’s best to have the fuel professionally tested or replaced. Fuel filter replacement should happen every 500 hours or annually. Watch for signs of contaminated fuel: reduced power, black smoke, rough running, frequently clogged filters, foul odors, and water in the separator. Catching these early can save you from costly repairs.

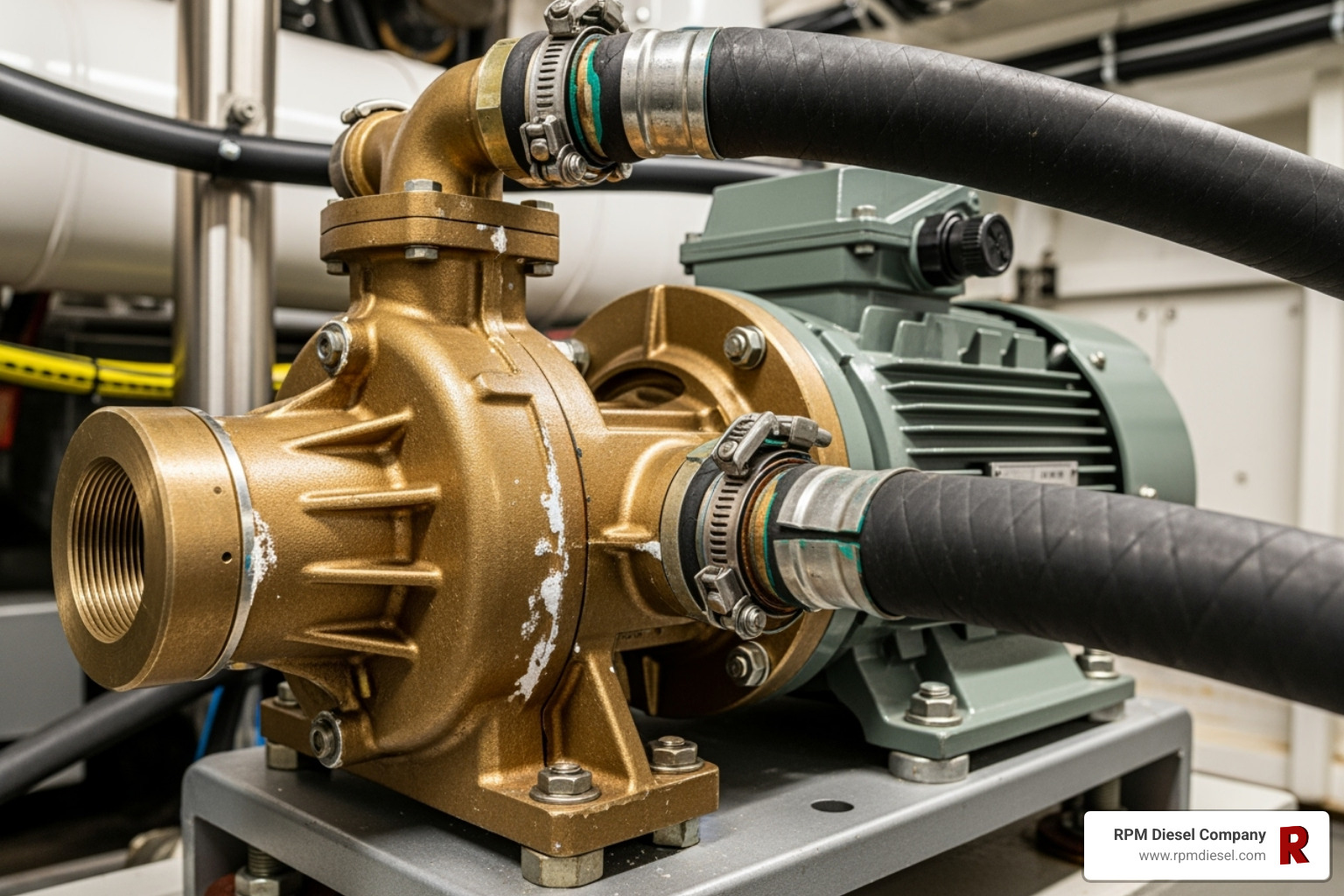

Cooling System: Preventing Overheating at Sea

Overheating is a marine generator’s worst nightmare, as saltwater environments pose unique challenges. The seawater pump impeller is a critical wear item that should be replaced annually, as its failure stops all cooling water circulation.

Monitor coolant concentration and maintain the correct antifreeze mixture, typically a 50/50 blend. In hot climates like Florida, consider additives to boost cooling efficiency. Regularly inspect hoses and clamps for wear, leaks, or hardening, and ensure clamps are tight and corrosion-free. Heat exchanger cleaning should be part of your semi-annual or annual service to maintain efficiency.

An annual wet exhaust elbow inspection is also important, as light loads can cause carbon buildup. If you spot rust, cracks, or leaks, replace it immediately. Finally, inspect zinc anodes every 90 days and replace them as needed to protect your cooling system from corrosion.

Electrical and Air Intake Systems

Neglecting electrical and air intake systems can lead to frustrating starting failures.

For battery care, a specific gravity test gives a more accurate picture of lead-acid battery health than voltage readings alone. Use trickle chargers to maintain battery charge during long idle periods.

Air filter importance cannot be overstated. A clogged air filter restricts airflow, forcing the engine to work harder, increasing fuel consumption, and reducing power. A severe clog can cause the engine to run rich, leading to carbon buildup.

Your air intake system inspection should verify that everything is sealed and free from obstructions, including ventilation openings around the generator. Before starting, perform a control panel check for any system alerts. If you have a standby unit, ensure “auto mode” is properly engaged. It’s one of those simple diesel generator maintenance tips that is easy to forget.

These critical systems work together. Understanding their interconnections helps you maintain peak performance and prevent problems from cascading into expensive repairs.

Advanced Practices and Troubleshooting

For optimal reliability, some advanced procedures and knowledge of common problems are necessary. This ensures your generator can handle its rated load and that you can identify issues before they escalate.

Advanced Diesel Generator Maintenance Tips: Load Banking and Professional Service

While daily checks are important, load bank testing is a critical advanced procedure. This is one of the most important diesel generator maintenance tips that many boat owners overlook. Load banking connects your generator to an artificial load, simulating real-world conditions at or near full capacity.

The biggest benefit is preventing wet stacking. This condition occurs when diesel generators run at low loads for extended periods, causing unburned fuel and carbon to accumulate in the exhaust system. This leads to black smoke, poor performance, and potential engine damage. Load banking burns off these deposits, keeping the engine clean and efficient.

Verifying performance is another key benefit. Load testing validates that your generator can deliver its rated power when you need it most. It exercises all components under full operating temperatures, revealing hidden issues with voltage, cooling, or other parts that only appear under load.

Professional servicing provides expertise beyond most owners’ capabilities. At RPM Diesel Company, our technicians use diagnostic equipment to identify subtle issues early. We handle complex tasks like software and firmware updates for modern generators. Our extensive parts inventory minimizes downtime. Whether you’re in Fort Lauderdale, Miami, West Palm Beach, or across South Florida, our on-site services keep your vessel operational.

Common Problems and Environmental Factors

Knowing common problems is key, as the marine environment is tough on generators.

Troubleshooting starting issues often begins with a few culprits. A weak battery is the most common, followed by fuel problems like low levels or clogged filters. Also, check that the emergency stop switch hasn’t been accidentally engaged.

Engine smoke analysis can diagnose internal issues. Black smoke often indicates incomplete combustion from dirty air filters, faulty injectors, or wet stacking. Blue smoke typically indicates burning oil, meaning worn piston rings or valve guides. White smoke might be unburned fuel, water in the fuel, or cooling system problems.

Managing moisture and humidity is critical in the marine environment. Run your generator regularly and ensure proper ventilation to manage moisture and prevent internal corrosion. Saltwater corrosion prevention requires constant vigilance. Fight it with regular freshwater cleaning, protective coatings, and good ventilation.

Proper engine room ventilation is essential for combustion air, heat dissipation, and preventing dangerous carbon monoxide buildup. While marine generators are built for motion, excessive vibration impact can indicate mounting or internal problems.

Keeping a detailed maintenance log is invaluable for tracking service intervals and troubleshooting. Note dates, operating hours, and any performance observations. Finally, always consult your manufacturer’s manual. It contains specific maintenance schedules and guides for your model; follow it closely.

Frequently Asked Questions about Marine Diesel Generator Maintenance

Over the years working with vessel owners across South Florida, we’ve heard the same concerns time and again. These questions come up in nearly every conversation about diesel generator maintenance tips.

How often should I change the oil in my marine diesel generator?

Always start with your manufacturer’s recommendations in the owner’s manual; this is the most accurate guidance and keeps your warranty intact.

Most marine diesel generators need oil changes every 100 to 200 hours of operation. However, smaller units or those under heavy loads may need changes as frequently as every 50-60 hours. Operating conditions are key; in harsh environments like Florida summers or with heavy use, change the oil more frequently.

For larger vessels, oil analysis provides precise change intervals, often saving money while ensuring superior protection. Just as important as the interval is the type of oil. Use the high-quality oil specified for marine diesel engines by your manufacturer to avoid sludge and costly buildup. Finally, change the oil after repairing a leak to remove any potential contaminants.

Why is regular load testing important for a generator that is not used often?

This is one of the most critical diesel generator maintenance tips we can offer. Diesel engines perform poorly at low loads or when idle. Running without a proper load prevents the engine from reaching its optimal operating temperature, leading to incomplete combustion and “wet stacking”—a buildup of unburned fuel and carbon in the exhaust system.

Load bank testing is the solution. It connects the generator to an artificial load, running it at 40-50% of its rated capacity or higher. This workout does several things:

- It burns off harmful carbon deposits.

- It exercises all engine and alternator components.

- It verifies that the cooling system can handle stress.

- It confirms the generator can handle your boat’s full electrical load in an emergency.

- It reveals hidden electrical issues that only appear under load.

What are the first things to check if my marine generator won’t start?

If your generator won’t start, a systematic check can solve most issues. Before you panic, follow these steps:

- Check your battery. This is the culprit in about 80% of cases. Ensure it reads above 12 volts and that the terminals are clean and tight. Corrosion can prevent a start even with a full charge.

- Check your fuel. Make sure the tank has fresh fuel. If the generator has been idle, check the fuel filter bowl for water or debris.

- Check the emergency stop switch. It’s a large red button or switch that is easy to accidentally engage or forget to reset.

- Check the seawater intake valve. For marine generators, this valve must be open. If it’s closed, the generator may start but will quickly overheat and shut down.

- Check the control panel. Look for any fault codes, warning lights, or error messages that can point you directly to the problem.

If you recently ran out of fuel or changed filters, you might have air in the fuel lines, which will need to be bled per the manufacturer’s instructions. If these basic checks don’t solve the problem, it’s time to call a professional. Our technicians at RPM Diesel are equipped to handle complex diagnostics.

Conclusion

Caring for your marine diesel generator ensures one of your vessel’s most critical systems is reliable. When you’re navigating challenging weather or anchored in a remote bay, you need to trust that your backup power will work without hesitation. The diesel generator maintenance tips we’ve covered are your insurance policy against power failure.

Regular maintenance transforms your generator from a potential liability into a reliable partner. Every maintenance task adds up to peace of mind, which is priceless when you’re miles from the nearest marina. A well-maintained generator can serve you for decades, while a neglected one leads to emergency repairs that cost far more than preventive care.

This is where RPM Diesel Company comes in. We understand the unique needs of every vessel owner and the specific demands that South Florida’s waters place on your generator. Our experienced technicians handle everything from simple fixes to complex rebuilds.

Our commitment is keeping you on the water. With on-site service capabilities throughout South Florida, including Fort Lauderdale, Miami, West Palm Beach, Boca Raton, and Delray Beach, we bring the shop to you.

We’re not just parts suppliers; we’re your partners in reliable power. Our relationships with manufacturers like Detroit Diesel and MTU help us source hard-to-find parts quickly, and our extensive inventory often means same-day solutions.

You don’t have to be a diesel mechanic to keep your generator healthy. Focus on the basics we’ve outlined, stay consistent, and lean on professionals like us for the complex tasks. Give your generator the attention it deserves, and it will reward you with years of dependable service. After all, the best generator problems are the ones that never happen.

For genuine Northern Lights generator parts and expert service, visit our page.