Why Marine Generator Cooling Systems Keep Your Vessel Running Smoothly

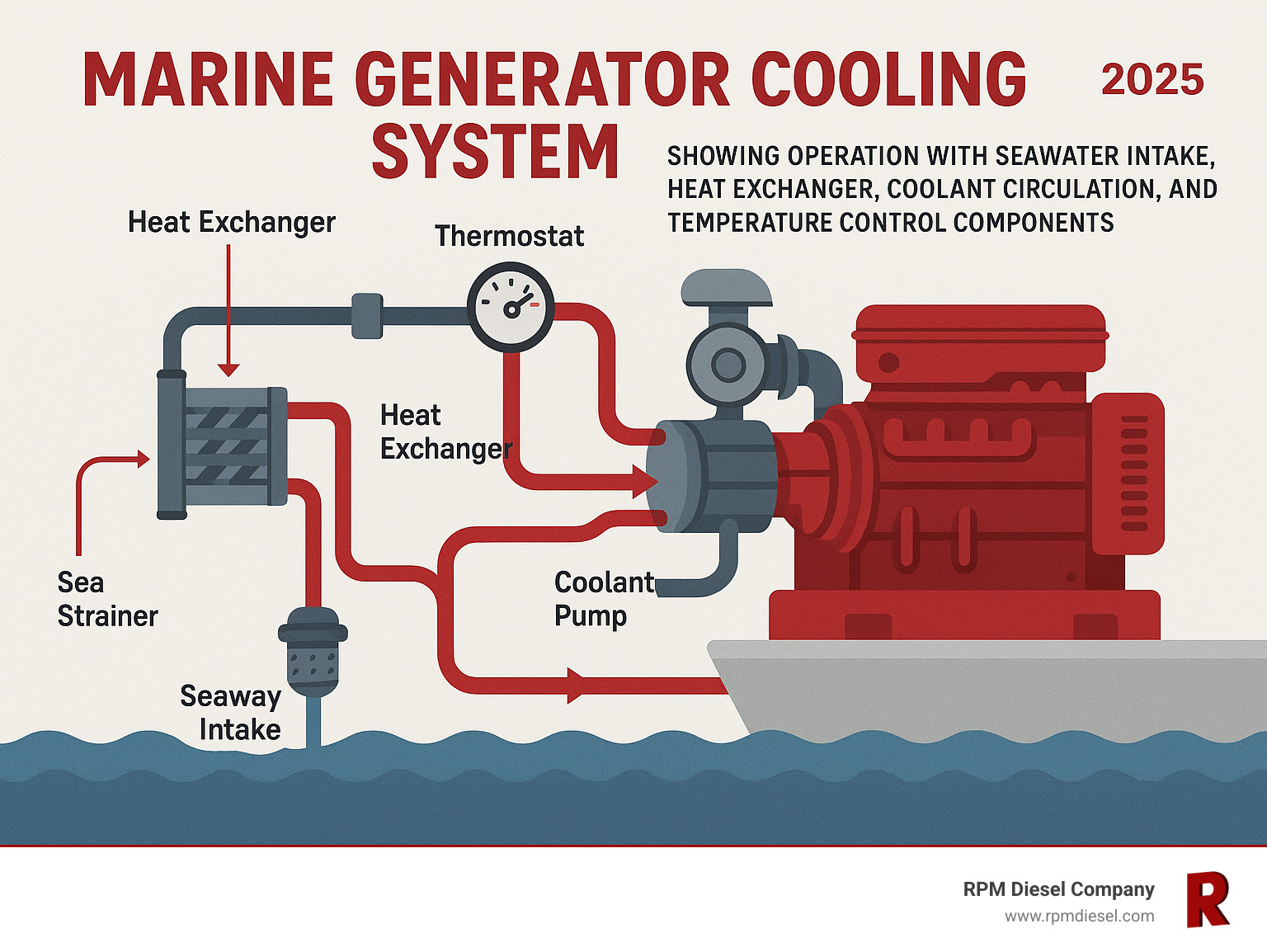

A marine generator cooling system is vital for onboard power reliability. It uses seawater or ambient water to dissipate heat from the generator’s engine, preventing overheating and ensuring you have continuous electrical power at sea.

Key Components of Marine Generator Cooling Systems:

- Heat exchanger – transfers heat from engine coolant to seawater

- Raw water pump – circulates seawater through the cooling circuit

- Thermostat – regulates engine temperature (typically 68-82°C)

- Coolant pump – circulates antifreeze mixture through engine block

- Sea strainer – filters debris from incoming seawater

Common System Types:

- Open-loop – seawater directly cools engine components

- Closed-loop – separate coolant circuit cooled by seawater heat exchanger

- Keel cooling – hull-mounted pipes use surrounding water for cooling

Your generator’s cooling system works constantly to maintain optimal operating temperatures. Without it, your generator can overheat in minutes, cutting power to navigation, communication, and other essential systems.

The marine environment is harsh. Saltwater corrosion, debris-clogged intakes, and varying water temperatures all challenge your system. Understanding these factors is critical for any serious vessel owner.

How Marine Generator Cooling Systems Work: Core Principles and Types

The fundamental principle of a marine generator cooling system is simple: heat flows from hot to cold. Your generator produces immense heat, and the water your vessel floats on is the perfect medium to carry it away. The type of cooling system you need depends on your operating conditions, as water temperature, debris, and vessel speed all play a role. Systems are always designed for worst-case scenarios—the hottest day and the heaviest load—because performance is paramount.

Open-Loop vs. Closed-Loop: The Fundamental Divide

Every marine cooling system is either open-loop or closed-loop.

Open-loop systems are simple: raw seawater is pumped directly through the engine’s cooling passages and then overboard. This means fewer components and lower initial cost, but it exposes the engine to seawater corrosion, salt buildup, and debris intake.

Closed-loop systems are smarter. They use a sealed circuit of dedicated coolant (antifreeze and distilled water) to cool the engine. This coolant is then cooled by raw water in a heat exchanger. While this system complexity is greater, it protects the engine, significantly increasing its longevity and reducing maintenance.

Heat Exchanger Cooling: The Most Common Approach

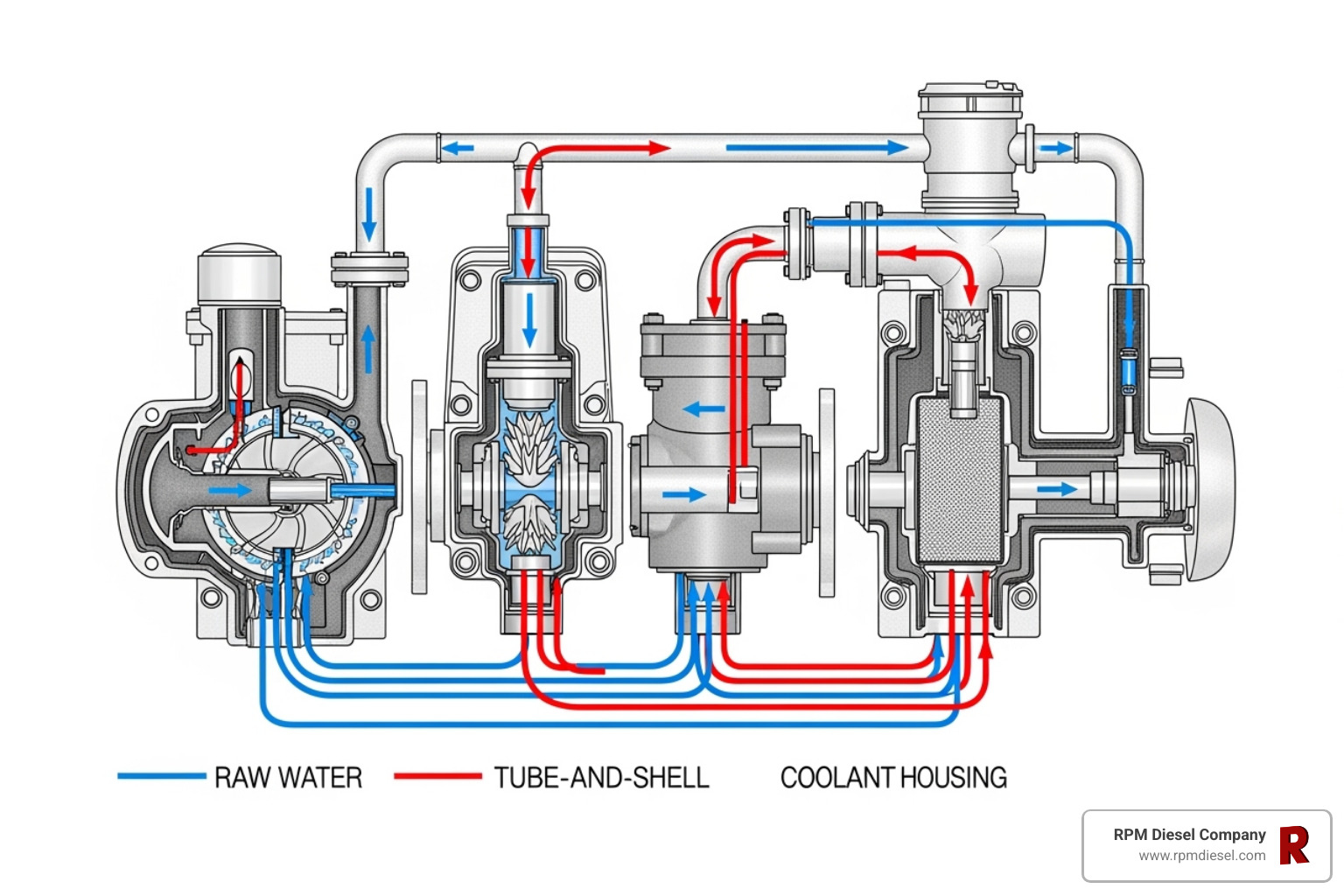

This is the most popular approach, balancing efficiency and engine protection. A heat exchanger transfers heat from the engine’s hot coolant to cool seawater without the fluids ever mixing. Shell and tube heat exchangers, with a bundle of copper-nickel tubes, are the industry standard. Plate type heat exchangers are a more modern, compact, and efficient alternative. The system uses a raw water circuit for the seawater and a separate coolant circuit to protect the engine with clean, treated fluid.

For vessels requiring extensive service work on these systems, our Marine Diesel Engine Overhaul Service provides comprehensive support to keep your cooling system operating at peak efficiency.

Keel Cooling: The Hull-Integrated Solution

Keel cooling turns the hull into a radiator. Coolant circulates through external pipes mounted on the hull, transferring heat to the surrounding water. This design is extremely durable and ideal for large units and vessels in debris-filled water, as there are no seawater intakes or strainers to clog. However, it’s most effective on slower vessels and requires significant hull space.

If you’re considering a keel cooling installation or need specialized service, our On-Site Marine Engine Service team can evaluate your specific requirements.

Radiator Cooling: A Land-Based System at Sea?

You won’t find many radiator cooling One very common type of cooling system isradiator cooling. systems on boats. Why? Because water transfers heat about 25 times more effectively than air. An air-cooled system with a fan and radiator would require massive airflow, creating significant noise, power draw, and ventilation challenges in a cramped engine room. Its limited marine use is confined to small, portable generators.

Anatomy of a Marine Generator Cooling System

Understanding your marine generator cooling system is easier when you know the role of each component. While configurations vary, the core parts are consistent. A raw water pump draws in outside water, a coolant pump circulates internal antifreeze, a heat exchanger manages the heat transfer, and a thermostat regulates temperature. These are supported by hoses and clamps, a sea strainer, an expansion tank, sacrificial anodes, and manifolds that direct flow.

The Pumps: Raw Water and Coolant Circulation

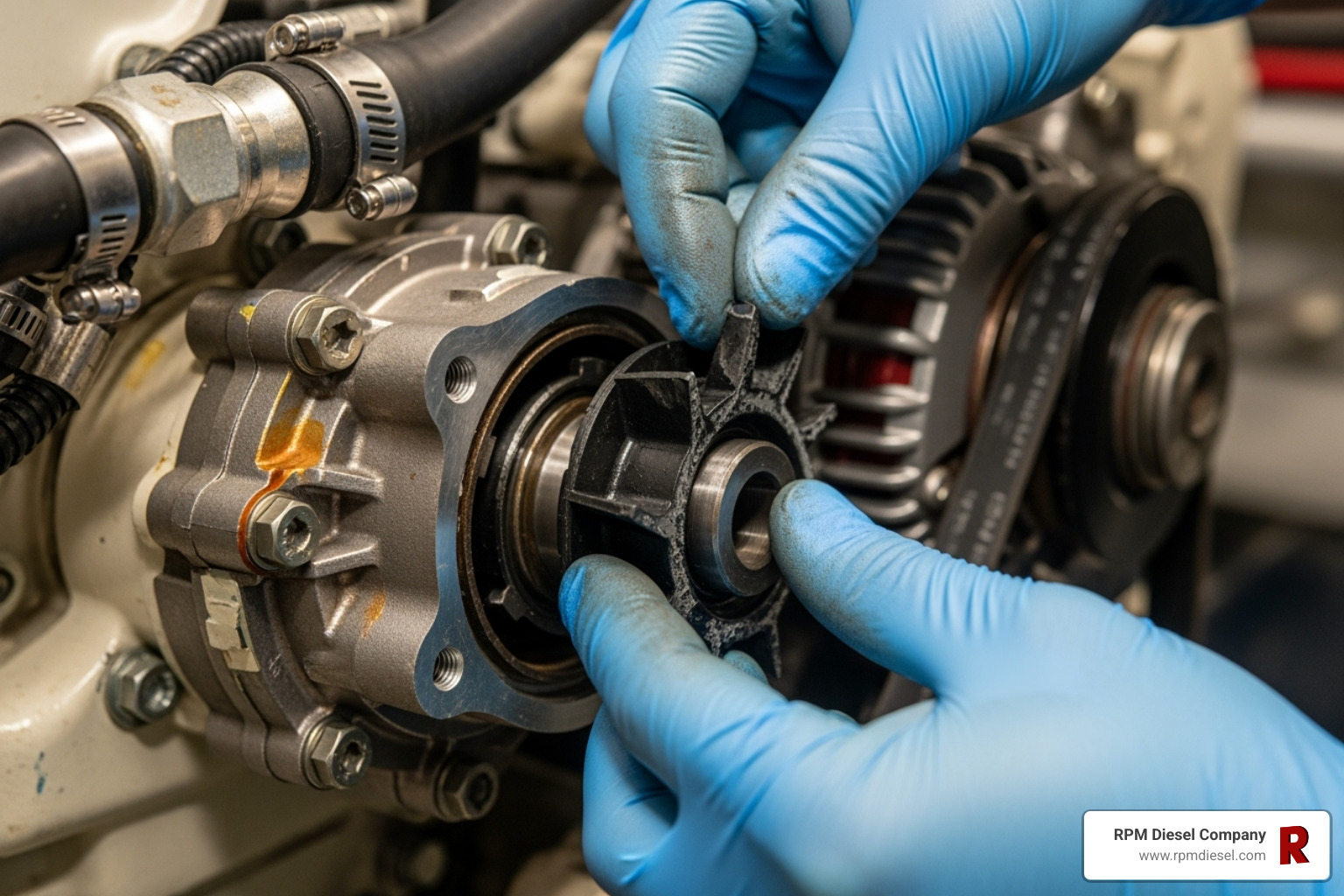

Two pumps are the heart of the system. The raw water pump, usually a belt-driven device with a flexible rubber impeller, draws seawater into the system. This impeller is a critical wear item; a failed impeller can cause rapid overheating, so it should be replaced annually. The coolant pump, typically a durable centrifugal pump, circulates the antifreeze mixture within the engine, maintaining the system pressure needed to prevent boiling and ensure steady water flow to the heat exchanger. You can learn more about their function here: How does a water pump work in a marine cooling system?

The Heat Exchanger: Where the Magic Happens

The heat exchanger transfers heat from the engine coolant to the raw water without mixing them. Most use a tube bundle of corrosion-resistant copper-nickel tubes. Hot engine coolant flows around the tubes, while cool seawater flows through them. Heat transfer occurs through the tube walls. End caps and O-rings seal the unit; their failure can lead to coolant and seawater mixing, which is disastrous for the engine. Keeping the heat exchanger surfaces clean is vital for efficiency. These components work in tandem with others, like those found in a Turbocharger for Diesel Engine, to manage overall engine heat.

The Thermostat: The Engine’s Temperature Guardian

The thermostat is a small, smart valve that provides temperature regulation. It contains a wax pellet that expands with heat. When the engine is cold, the thermostat’s valve operation is closed, allowing the engine to warm up quickly via a bypass circuit. As the engine reaches its optimal operating temperature (typically between 68-82°C), the thermostat opens, allowing coolant to flow to the heat exchanger. This precise control prevents both overheating and over-cooling, ensuring the engine runs efficiently.

Essential Maintenance for Peak Performance and Longevity

Regular maintenance of your marine generator cooling system is not just about preventing breakdowns; it’s about ensuring efficiency, fuel economy, and long engine life. Simple, routine checks can save you from a catastrophic failure at sea. This preventative approach is central to our Marine Diesel Engine Maintenance philosophy.

Your Routine Inspection Checklist

Make these checks part of your pre-trip routine:

- Coolant Level and Condition: Check the expansion tank when cold. The coolant should be at the correct level and have a clean, bright color. Brown, rusty, or milky coolant indicates a problem.

- Hoses and Clamps: Inspect for cracks, bulges, or soft/hard spots. Check clamps for leaks, indicated by weeping or salt deposits.

- Belts: Check for proper tension (about half an inch of deflection) and look for cracks, fraying, or a glazed appearance.

- Sea Strainer: This is your first line of defense against debris. Clean the basket regularly to ensure proper water flow.

- Leaks: Look for puddles (freshwater leaks) or white, crusty salt deposits (raw water leaks). Check the raw water pump’s weep hole for excessive dripping.

- Sacrificial Anodes (Zincs): Inspect these regularly and replace them when they are about half-consumed to prevent galvanic corrosion.

The Importance of the Right Coolant Mixture

In a closed-loop system, the coolant mixture is critical. Use a 50/50 mix of ethylene glycol and distilled water—never tap water, which causes scale buildup. The coolant’s corrosion inhibitors protect internal engine components but deplete over time. Change the coolant every 1000 operating hours or two years to maintain this protection. Always flush the system thoroughly when changing coolant. This is a key part of any comprehensive Diesel Generator Maintenance plan.

Tackling the Raw Water Circuit: Impellers, Strainers, and Flushing

The raw water circuit requires special attention. The raw water pump impeller is a wear item and should be replaced annually as a preventative measure. Clean your sea strainer frequently, even daily in debris-heavy waters. After use in salt water, flush the raw water system with fresh water to prevent salt crystallization and buildup. For heavy scale, you can clean the exchanger bundle with a descaling solution like Barnacle Buster on the raw water side only.

Common Problems and How to Troubleshoot Your Marine Generator Cooling System

Know the warning signs and how to react:

- Overheating: The most common issue. First, check for a clogged sea strainer. If it’s clean, suspect a failed raw water pump impeller. A stuck-closed thermostat or a scaled-up heat exchanger are other common causes.

- Steam from Exhaust: This indicates a severe lack of raw water flow. Stop the engine immediately and check the entire raw water intake system.

- Dropping Coolant Levels: This points to a leak in the freshwater circuit. Look for external leaks (puddles, stains) or signs of internal leaks, like oil in the coolant or vice-versa.

- Oil in Coolant: This often indicates a failed oil cooler and requires professional service.

When problems escalate beyond simple fixes, our Marine Diesel Generator Repair team can diagnose and resolve the issue.

Advanced Considerations for a Flawless System

For a truly flawless system, consider advanced engineering and environmental factors. This means moving beyond basic function to ensure peak performance in all conditions through proper system sizing, smart engine room design, and accounting for environmental challenges.

The Impact of Environment: Water Temperature and Ventilation

Two environmental factors are key: water temperature and ventilation. Tropical waters are warmer and reduce heat dissipation capacity, so a system must be sized for the warmest conditions it will face. Proper ventilation is also crucial. An engine room needs constant fresh airflow for both combustion air and to cool the space. Poor ventilation leads to a hotter engine, straining the cooling system.

Beyond Cooling: Utilizing Recycled Heat

Don’t just waste the heat your generator produces. Waste heat recovery systems can use this energy to power hot water heaters or provide cabin heating. This clever integration improves overall system efficiency and reduces fuel consumption. Proper plumbing considerations are essential to prevent air locks and allow for easy servicing.

Meeting the Standard: Classification Society Requirements

For commercial or charter vessels, vessel certification is often required. Classification societies like Lloyd’s Register, DNV, and the American Bureau of Shipping set mandatory construction standards and safety regulations for cooling systems. Building to these standards from the start ensures compliance and typically results in a more reliable and durable system for any application.

Conclusion

Your marine generator cooling system is the guardian of your onboard power. We’ve seen how different systems—from open-loop and closed-loop to keel cooling—are designed for specific marine environments. Understanding the anatomy, from the raw water pump and heat exchanger to the thermostat, is key to proper operation.

Knowledge is useless without action. The maintenance routines we’ve covered, like annual impeller replacements, regular coolant changes, and diligent sea strainer cleaning, are your best insurance against overheating. Advanced considerations, like accounting for tropical water challenges or meeting classification society requirements, lift a system from good to great.

At RPM Diesel Company, we know that a well-maintained marine generator cooling system is fundamental to a great boating experience. Our worldwide on-site service and extensive parts inventory mean we’re ready to help, wherever you are.

Reliable power underpins everything on your vessel. By being proactive with maintenance and partnering with experts, you invest in worry-free time on the water. For specific components and expert guidance, explore our selection of Northern Lights Generator Parts. A happy cooling system means a happy boat.