Why Quality Marine Generator Parts Keep You Powered at Sea

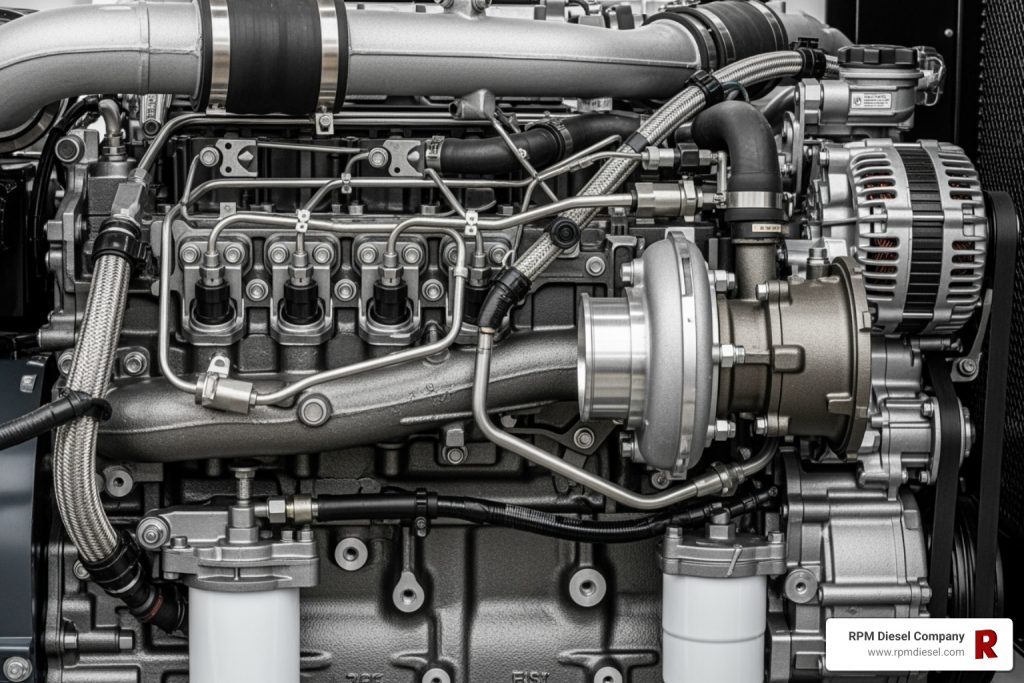

Diesel generator engine parts are your vessel’s lifeline, making the difference between smooth sailing and being stranded. Knowing which components to stock, from fuel injectors to water pumps, is crucial for any marine vessel owner.

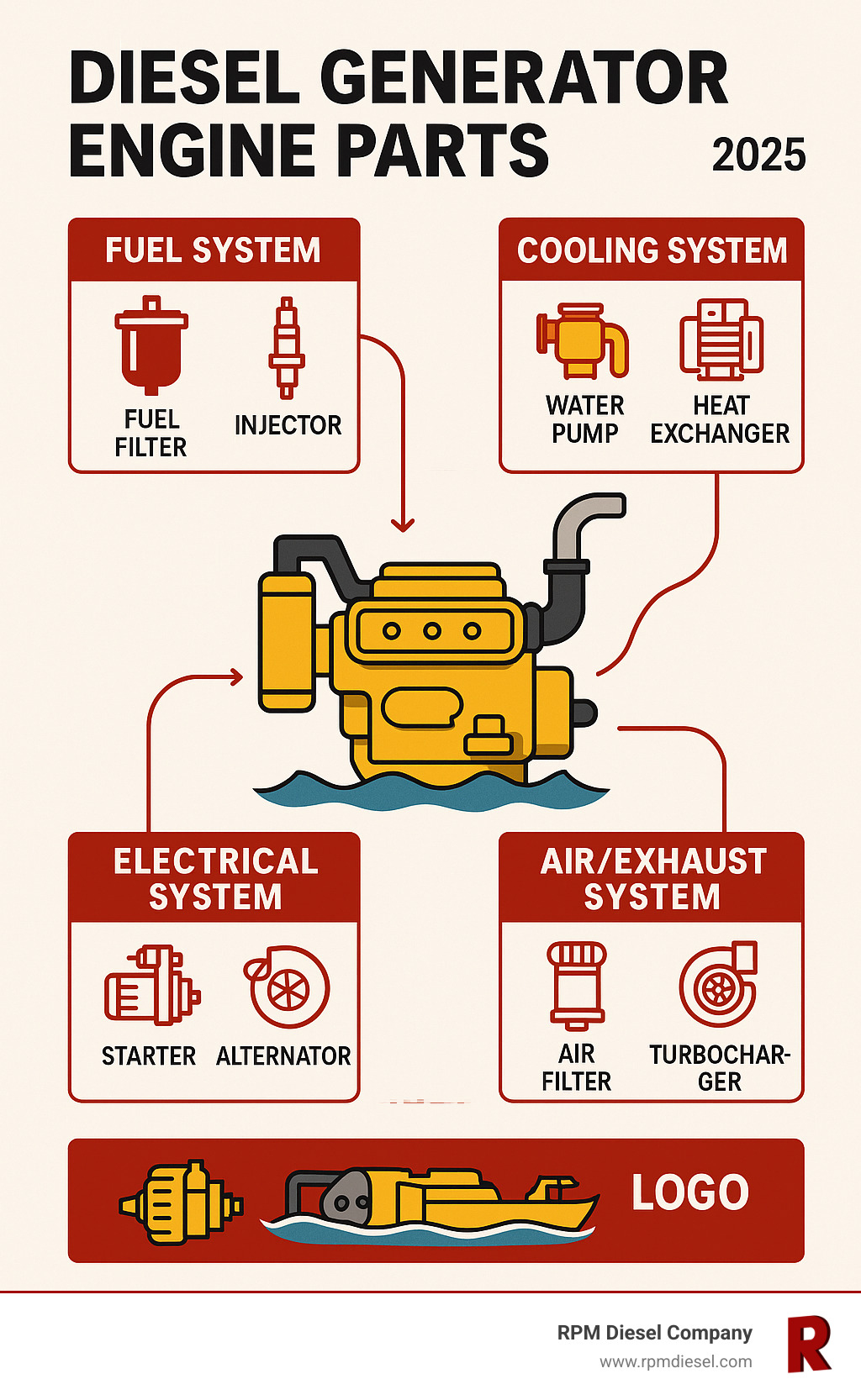

Essential Diesel Generator Engine Parts by System:

- Fuel System: Fuel filters, injectors, pumps, gaskets and seals

- Cooling System: Water pumps, impellers, thermostats, heat exchangers

- Electrical System: Starters, alternators, batteries, voltage regulators

- Air & Exhaust: Air filters, turbochargers, exhaust manifolds

- Internal Components: Pistons, rings, bearings, cylinder heads

The marine environment—with its salt air, constant vibration, and temperature swings—puts unique stress on every component. As one industry expert notes: “A broken or worn belt may fail without warning, causing significant engine damage and hefty repair costs.”

For those who travel internationally, finding replacement parts in remote locations can be nearly impossible, making preventive maintenance and a well-stocked spare parts kit essential for safe passage.

The key is knowing what parts you need, when to replace them, and where to source quality components. Genuine OEM parts consistently outperform aftermarket alternatives in durability and reliability, which is critical when you’re miles from shore.

The Core Components: Your Essential Marine Diesel Generator Parts Checklist

Each component in your marine diesel generator has a critical role. Understanding these diesel generator engine parts is your insurance policy against being stranded at sea. Knowing what makes your generator tick is the first step to keeping it running smoothly.

The Fuel System: Powering Your Engine

The fuel system delivers clean, pressurized fuel to the engine. Any failure can bring your power system to a halt.

- Fuel filters are your first defense against contaminants. Regular replacement is essential to prevent costly damage.

- Bosch Fuel Injectors are precision instruments that atomize diesel for optimal combustion. Black smoke or sputtering can indicate they need attention.

- Fuel pumps move diesel from the tank through the system at the correct pressure.

- Gaskets and seals prevent fuel leaks and maintain system pressure, a critical safety function on any vessel.

For comprehensive care, we offer Fuel Injection Service and recommend a Secondary Fuel Filter for extra protection.

The Cooling System: Preventing Overheating

A marine diesel generator produces immense heat. The cooling system is essential to prevent engine failure and must work flawlessly.

- Water pumps circulate coolant through the engine and raw seawater through the heat exchanger.

- Impellers are rubber wear items inside the raw water pump. Keep a spare Impeller Kit on hand, as failure is a common cause of overheating.

- The thermostat regulates coolant flow to maintain optimal engine temperature, while heat exchangers transfer heat from the engine’s coolant to raw seawater.

- Cooling system hoses are prone to cracking from heat and vibration and require regular inspection.

- In saltwater, Anode Zinc components sacrificially corrode to protect vital metal parts.

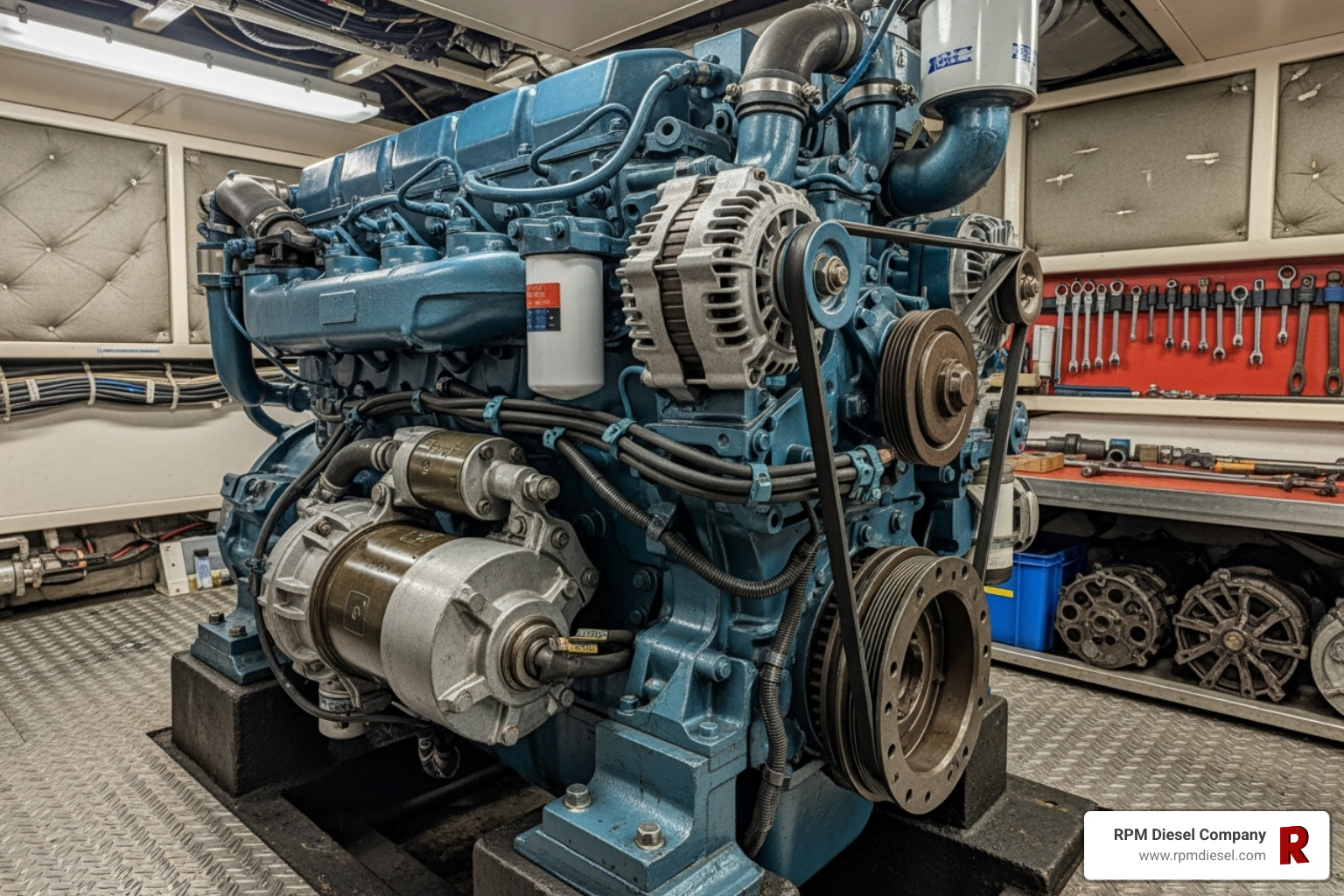

The Electrical System: Starting and Charging

A reliable electrical system is vital. It starts the generator and powers your vessel’s electrical systems.

- The starter motor provides the initial power to start the engine.

- The alternator converts mechanical energy into electrical power to charge batteries and run your boat’s systems.

- Batteries provide starting power and buffer the electrical system.

- Voltage regulators ensure the alternator provides steady power without overcharging batteries.

- Glow plugs heat the combustion chambers for reliable cold-weather starting.

The Air & Exhaust System: Engine Breathing

Your generator needs clean air for combustion and a clear path to expel exhaust.

- Air filters protect the engine from salt spray and dust. A clogged filter reduces power and increases fuel consumption.

- A Turbocharger for Diesel Engine forces more air into the cylinders, boosting power and efficiency. We stock a full range of Holset Turbo Parts for these systems.

- Exhaust manifolds collect hot gases and are typically water-cooled in marine applications.

- Mufflers reduce engine noise.

Internal Engine Components

Internal components convert fuel into mechanical power under extreme stress. Quality and proper maintenance are non-negotiable.

- Pistons and piston rings convert combustion force into motion and seal the cylinder.

- Bearings support the crankshaft, which converts the pistons’ up-and-down motion into rotational force.

- The cylinder head houses the valves and often the fuel injectors.

We maintain a comprehensive inventory of Diesel Engine Parts and Components because we know that when you need internal parts, you need them urgently.

OEM vs. Aftermarket: Why Genuine Parts Matter for Marine Performance

When a part needs replacing on your marine diesel generator, you face a critical choice: genuine OEM diesel generator engine parts or aftermarket alternatives? We’ve seen it countless times: an owner saves a little on an aftermarket part, only to face a catastrophic failure at sea. A “universal fit” fuel injector can cause a cascade of engine problems, turning a small saving into a huge expense.

Your generator faces salt spray, constant vibration, and extreme temperature swings. In this environment, the difference between genuine and aftermarket parts isn’t just about quality—it’s about survival.

| Feature | Genuine OEM Parts | Aftermarket Parts |

|---|---|---|

| Quality | Built to exact manufacturer specifications, premium materials, rigorous testing. | Quality varies widely; may use inferior materials or less stringent processes. |

| Fit | Perfect fit, designed for seamless integration. | May require modifications, potentially leading to installation issues or stress. |

| Warranty | Comprehensive manufacturer warranty, protecting your investment. | Warranties often limited or non-existent; can void OEM warranties on other parts. |

| Reliability | Designed for peak performance and durability, proven in specific applications. | Performance and lifespan can be inconsistent, higher risk of premature failure. |

| Long-term Cost | Higher upfront, but prevents costly repairs, downtime, and extends component life. | Lower upfront, but higher risk of frequent replacements, collateral damage, and lost time. |

The engineering that goes into genuine OEM parts represents years of research and refinement. Manufacturers like Detroit Diesel design components to perform after thousands of hours in harsh marine conditions. Aftermarket manufacturers often reverse-engineer a product, which may or may not meet these demanding standards. Do you want to find which category your part falls into when you’re 50 miles from shore?

Trust matters in this business. We recommend genuine parts because we’ve seen what happens when boats cut corners. The marine environment doesn’t forgive shortcuts. Manufacturer specifications exist for a reason—they represent the minimum standards for peak performance and durability in marine environments. When you choose genuine parts, you’re buying peace of mind.

That’s why we maintain an extensive inventory of genuine parts, including hard-to-find Detroit Diesel Engine Parts. The upfront cost difference often disappears when you factor in reliability, longevity, and warranty coverage. More importantly, it vanishes completely when you consider the cost of being stranded at sea.

Proactive Maintenance: Extending Your Generator’s Life at Sea

Think of your marine generator as a hardworking crew member that needs regular care to perform its best. Proactive maintenance is about getting the most life and value from your investment by preventing breakdowns before they happen.

The secret to a long-lasting generator is sticking to manufacturer-recommended maintenance schedules. These intervals, typically based on operating hours or annual timelines, are designed to catch small issues before they become expensive problems. A small investment in preventive care for your diesel generator engine parts can save you thousands in repairs.

Key Signs You Need Replacement Diesel generator engine parts

Learning your generator’s warning signs can save you from major trouble. Do not ignore these symptoms:

- Sputtering: Often indicates a fuel delivery issue, such as clogged filters, a failing pump, or injector problems.

- Black smoke: Typically points to incomplete combustion, caused by a dirty air filter, faulty injectors, or turbocharger issues.

- Difficulty starting: Usually an electrical system problem, like a weak battery, failing starter, or worn glow plugs.

- Overheating: A critical warning that your cooling system is compromised. This could be a failing water pump, clogged heat exchanger, broken impeller, or stuck thermostat. Shut down the engine immediately.

- Leaks: Visible fuel, oil, or coolant leaks are red flags indicating worn gaskets, seals, or cracked hoses.

- Unusual noises: Clunking, grinding, or knocking often signals serious internal engine wear. Investigate new sounds immediately.

If these symptoms sound familiar, our Marine Generator Maintenance services can diagnose and fix them quickly.

Creating a Spare Parts Kit

A well-stocked spare parts kit is your insurance policy against being stranded. Your kit for essential onboard readiness should include:

- Filters: Spare fuel, oil, and air filters are your first line of defense against common problems.

- Belts: A broken alternator or water pump belt can disable your generator. They can fail without warning.

- Impellers: These rubber components in your raw water pump are critical wear items that need regular replacement.

- Fuses: These small components protect your electrical system. A blown fuse is an easy fix, but only if you have a spare.

While a spare parts kit handles immediate needs, sometimes you need professional help. Our Onsite Diesel Generator Service is available whether you’re docked locally or anchored abroad. Your trip shouldn’t be limited by generator problems.

Sourcing Your Diesel generator engine parts: A Buyer’s Guide

Finding the right diesel generator engine parts for marine environments can be overwhelming. Success requires a partner who combines an extensive inventory of genuine OEM parts with the expert knowledge to guide you. Add global reach for worldwide shipping, and you’ve found a supplier you can depend on.

We’ve built our reputation on getting it right the first time, whether you’re docked in Fort Lauderdale or anchored off a remote island.

How to Find the Right Diesel generator engine parts

Accuracy is critical when ordering parts. One wrong digit can mean days of waiting for the correct component.

- Your engine serial number is the most precise identifier. It’s your generator’s fingerprint.

- The model number of both the generator and engine also helps narrow down the exact specifications.

- Manufacturer documentation like owner’s manuals contains diagrams and part numbers that save time.

When in doubt, ask. Our team of marine diesel specialists would rather spend a few minutes consulting with you to ensure accuracy than have you deal with the frustration of wrong parts. Whether you need Kohler Generator Parts or Westerbeke Generator Parts, we’ll make sure you get exactly what your generator needs.

Major Marine Generator Brands and Parts Availability

The marine generator world is dominated by trusted brands, each with specific part requirements. We’ve made it our business to understand these differences.

- Kohler generators are known for being robust workhorses.

- Westerbeke engines are prized for their quiet operation.

- MTU represents the pinnacle of high-performance marine diesel engineering, demanding equally precise components. Our expertise with MTU Marine Diesel Engines includes a comprehensive inventory of their specialized parts.

- Detroit Diesel engines bring serious power and deserve genuine parts that match their performance.

Working with a specialized supplier means we don’t just stock parts; we understand the engines they go into. Our global inventory ensures that whether you’re dealing with routine maintenance or an unexpected breakdown, we have the genuine diesel generator engine parts you need, ready to ship wherever your voyage takes you.

Frequently Asked Questions about Marine Diesel Generator Parts

Here are straightforward answers to the most common questions we hear from vessel owners about diesel generator engine parts.

How often should I replace my generator’s fuel and oil filters?

Filter replacement frequency depends on several factors. Start with your manufacturer’s recommendations, typically every 250-500 operating hours or annually, whichever comes first. However, heavy usage, questionable fuel quality, or dusty/humid environments may require more frequent changes. A safe rule of thumb for most boaters is to replace filters annually as part of routine maintenance. It’s cheap insurance against expensive problems. We stock a wide selection of Oil Filter options to keep you ahead of schedule.

What are the signs of a failing water pump or impeller?

A failing water pump or impeller can cause catastrophic engine damage quickly. Knowing the warning signs is critical.

- Engine overheating: If your temperature gauge climbs, shut down the engine immediately.

- Reduced exhaust water flow: A weak or intermittent stream of water from your exhaust is often the first sign of impeller failure.

- Visible leaks: Puddles or drips around the pump housing indicate seal failure.

- Unusual noises: Grinding or squealing from the pump area can mean worn bearings or a disintegrating impeller.

We recommend annual impeller replacement as preventive maintenance. If you notice any of these signs, our Diesel Generator Repair Service can diagnose and fix the issue before it becomes a major problem.

Can I use aftermarket parts on my marine generator?

While aftermarket parts may seem cheaper, they are often a false economy for marine generators. We advise sticking with genuine OEM parts for critical components for several reasons:

- Quality & Fit: Aftermarket parts are often reverse-engineered for a “close enough” fit, not the exact tolerances your engine requires.

- Warranty: Using non-OEM parts can void your generator’s warranty, leaving you responsible for repair costs if a failure occurs.

- Materials: Genuine parts use marine-grade materials designed to withstand salt, vibration, and temperature extremes. Aftermarket parts may not.

- The Domino Effect: A cheap, faulty part can cause a cascade of damage to expensive internal components.

The peace of mind that comes with knowing your diesel generator engine parts are built to original specifications is worth the investment, especially when you’re miles from shore.

Conclusion: Sail with Confidence

Sailing with confidence comes from understanding your marine diesel generator, from the diesel generator engine parts that keep it running to the maintenance practices that extend its life. We’ve covered the essential fuel, cooling, electrical, and air systems, all of which play a crucial role in keeping you powered at sea.

The choice between genuine OEM and aftermarket parts is a choice for reliability. Quality components, proactive maintenance, and a well-stocked spare parts kit are the pillars of smart seamanship. By recognizing warning signs early, you can address small issues before they become trip-ending problems.

We’ve been helping vessel owners steer these waters for years, serving customers from our base in Fort Lauderdale to ports around the world. Our expertise with major manufacturers like Detroit Diesel and MTU means we understand what it takes to keep marine generators running in the toughest conditions.

Your generator is your connection to comfort, safety, and independence on the water. For a complete inventory of genuine marine diesel engine parts and expert service, explore our Northern Lights Generator Parts and ensure your vessel is always ready for the journey ahead. The best trips happen when you’re confident in your equipment.