The Bosch Injector Pump: The Heart of Your Marine Engine

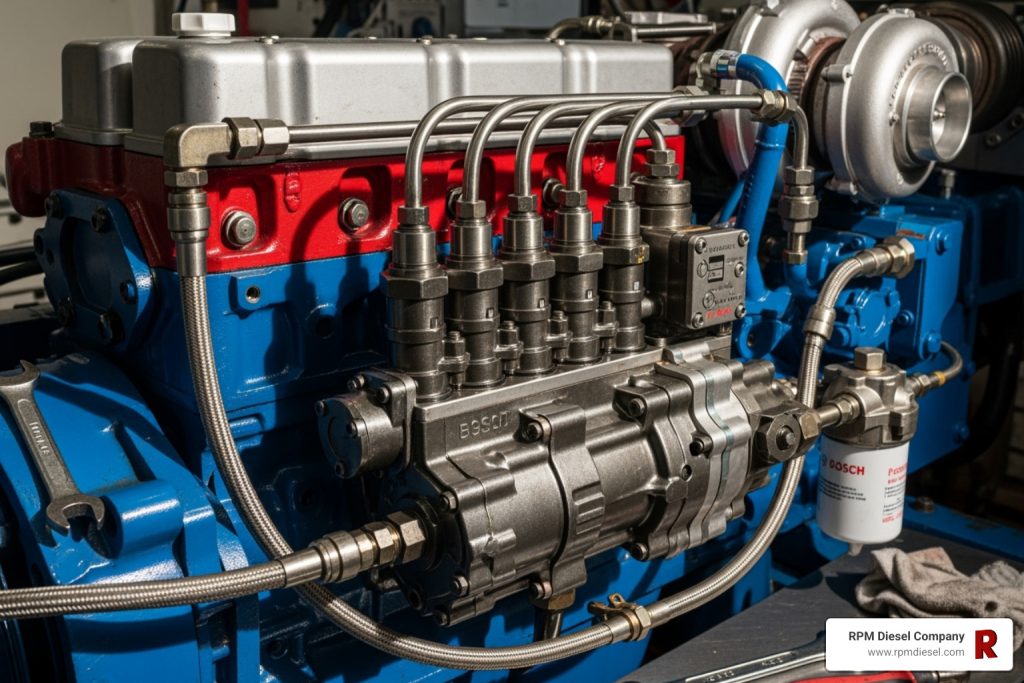

The bosch injector pump is a vital component in your marine diesel engine, ensuring it runs powerfully and efficiently. It’s the central part of the fuel system, responsible for delivering fuel precisely when and where it’s needed.

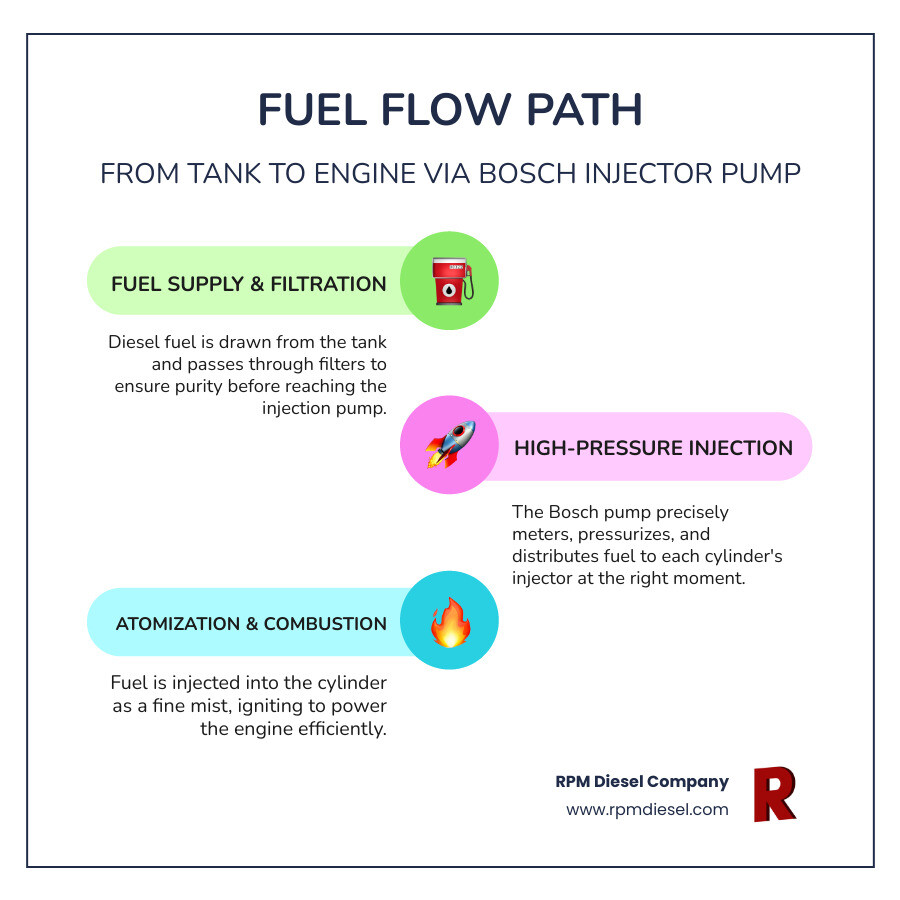

Here’s a quick look at what a Bosch injector pump does:

- Fuel Metering: Accurately measures the right amount of diesel fuel for each engine cycle.

- High-Pressure Delivery: Pressurizes the fuel to extreme levels, essential for proper atomization and combustion.

- Precise Distribution: Distributes this high-pressure fuel to each cylinder in the correct firing order and at the exact moment.

In short, it’s about getting the right fuel, at the right pressure, at the right time, every time. This precision is critical for your vessel’s performance and reliability, whether you’re cruising or navigating rough seas.

Find more about bosch injector pump:

Understanding How a Bosch Injector Pump Powers Marine Engines

At RPM Diesel, we know reliable power is everything on the water. The bosch injector pump is engineered for the tough demands of marine engines, ensuring powerful fuel delivery, excellent efficiency, and a robust combustion process. As a world leader in diesel fuel injection for over 75 years, Bosch parts are a top choice for challenging marine environments.

The precision of Bosch fuel injection systems allows for perfect fuel atomization—a fine mist that is key to efficient combustion and maximum power. This careful design ensures every drop of fuel is used wisely, leading to better fuel economy and lower emissions. For a closer look at the components, you can review Bosch’s information on Mechanical diesel injection components for large marine engines.

The Heart of the System: Core Operating Principles

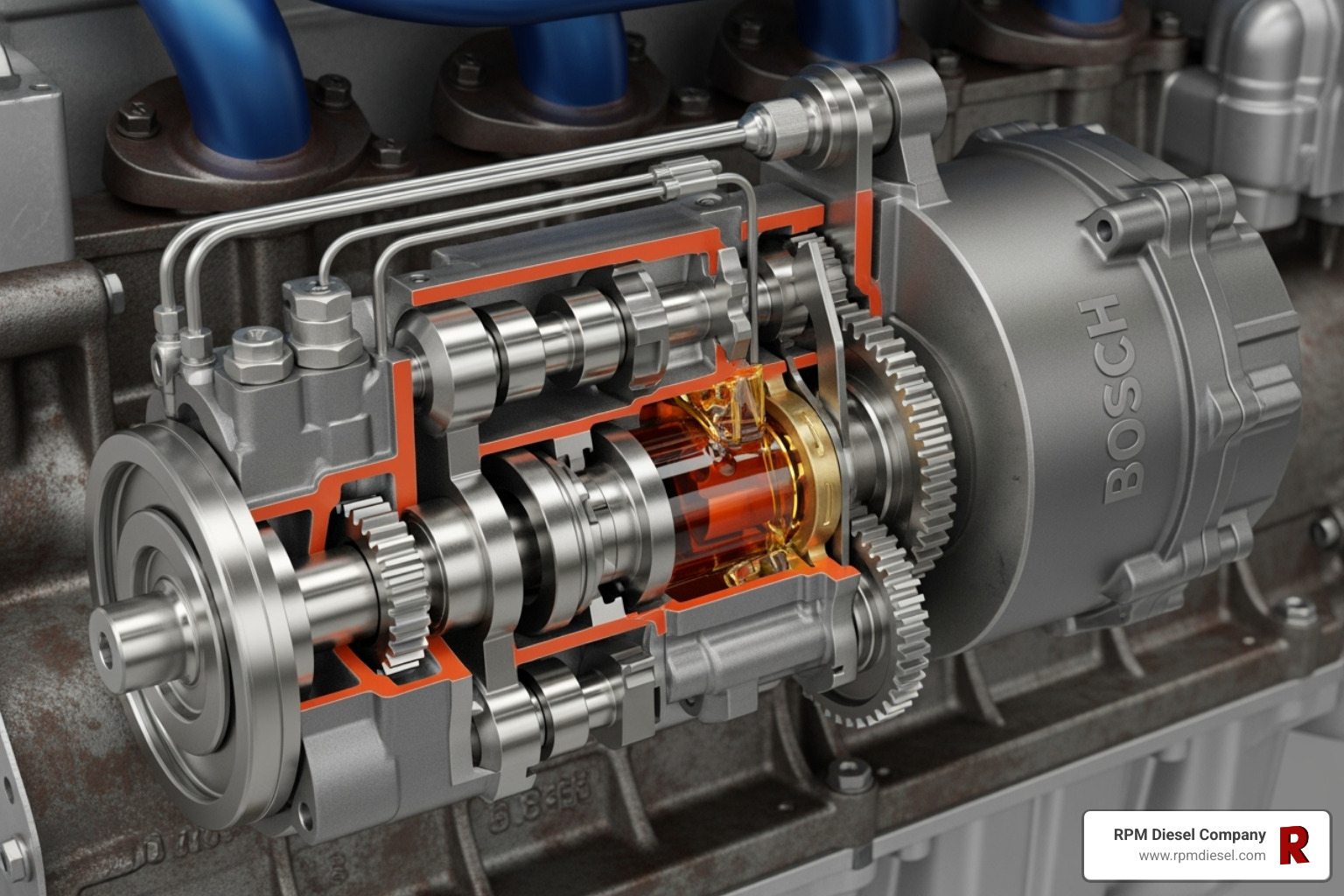

At the core of every bosch injector pump is a marvel of engineering. These pumps are typically driven by the engine’s camshaft, ensuring fuel delivery is perfectly timed with every engine cycle.

Here’s how it works:

- Plunger and Barrel: A precise plunger moves within a barrel. As the camshaft drives the plunger, it traps and pressurizes fuel to extremely high levels (up to 1,800 bar or 26,000 psi), which is vital for atomization.

- Fuel Metering: The pump precisely controls the amount of fuel injected. A special edge on the plunger or a metering sleeve determines when fuel delivery stops, giving the engine the right amount of fuel for its current speed and load.

- Pressurization: The rapid movement of the plunger creates immense pressure, which is then sent to the injectors.

- Atomization: When high-pressure fuel exits the injector nozzle through tiny holes, it becomes a fine spray. This atomization is crucial for the fuel to mix completely with air, leading to a clean and efficient burn.

- Distribution System: In inline or distributor pumps, the pump also ensures this high-pressure fuel is sent to each cylinder in the correct firing order and at the perfect moment.

Whether it’s an older mechanical pump or a modern electronic system, the goal is the same: deliver fuel with incredible precision for maximum power and efficiency.

Key Types of Bosch Injection Systems for Marine & Industrial Use

Bosch has developed various fuel injection systems, each built for specific needs. At RPM Diesel, we service a wide range of these systems, ensuring your marine engine gets the expert care it deserves.

Here are the main types of bosch injector pump systems we service:

- Inline Pumps (P-series): These durable, multi-cylinder pumps feature a dedicated pumping element for each cylinder, arranged in a line. Common in larger marine and industrial engines, their mechanical control makes them reliable and simple to maintain in harsh conditions.

- Distributor Pumps (VE-series): VE-series pumps use a single pumping element to serve all cylinders, making them more compact for small to medium-sized engines. Later versions incorporated electronic controls for improved precision. We are experts at servicing these complex units.

- Unit Pump Systems (UPS): This modular system features a separate pump for each cylinder, driven by the engine’s camshaft. UPS achieves high injection pressures (up to 1,800 bar) even at low engine speeds for cleaner combustion and better performance, with a solenoid valve controlling fuel delivery.

- Unit Injector Systems (UIS): UIS integrates the pump and injector into a single unit per cylinder. This eliminates high-pressure fuel lines, enabling even higher injection pressures and more precise fuel control. Like UPS, it is camshaft-driven and uses a solenoid valve for timing and metering.

- Common Rail High-Pressure Pumps (CP): The most common modern system, common rail uses a high-pressure pump to supply fuel to a shared rail (accumulator). Electronically controlled injectors draw from this rail, allowing for extremely high pressures, multiple injections per cycle, and precise control over timing and fuel quantity. Bosch has been a leader in common rail technology since 1997.

Each system has unique benefits, but all share Bosch’s commitment to quality. Our team in Fort Lauderdale, FL, and across our service areas including Broward County, Dade County, Miami, West Palm Beach, Boca Raton, and Delray Beach, FL, has the specialized knowledge to diagnose, service, and repair all these Bosch systems.

Identifying and Troubleshooting Common Injector Pump Issues

Even a robust bosch injector pump can experience issues in the demanding marine environment. Recognizing early warning signs can save you from significant performance loss and costly repairs. At RPM Diesel, we specialize in marine engine diagnostics and preventive maintenance to keep your vessel reliable.

Symptoms of a Failing Bosch Injector Pump

When a bosch injector pump begins to fail, your engine will often give clear warning signs. Ignoring them can lead to severe engine damage.

Look out for these common indicators:

- Hard Starting: The engine cranks excessively before starting, indicating the pump isn’t delivering enough fuel or pressure for ignition.

- Rough Idle: Uneven idling, shaking, or excessive vibration points to inconsistent fuel delivery to the cylinders.

- Misfiring or Stuttering Engine: The engine hesitates, stutters, or loses power, suggesting inconsistent or incorrectly timed fuel delivery.

- Black or White Smoke from Exhaust:

- Black smoke typically indicates incomplete combustion from too much fuel.

- White smoke can signal unburnt fuel passing through the exhaust, often due to poor atomization or incorrect timing.

- Loss of Power: The vessel feels sluggish, can’t reach top speed, or lacks torque, indicating the pump isn’t delivering enough fuel or pressure for full power.

- Poor Fuel Economy: A sudden increase in fuel consumption suggests the pump’s fuel metering is inaccurate, causing waste.

Many fuel pump replacements result from misdiagnosis. Modern marine engines are complex, so professional diagnostics from experts like us at RPM Diesel are crucial.

Common Causes of Failure and Prevention Strategies

Understanding why a bosch injector pump might fail is the first step in preventing breakdowns. Proactive measures are always better than reactive repairs.

Here are the top causes of failure and how to prevent them:

- Fuel Contamination: This is the leading cause of pump failure. Dirt, rust, and debris from tanks or refueling can clog passages and damage precision components, leading to seizure.

- Prevention: Use clean, high-quality fuel from reputable sources. Have your fuel tanks inspected and cleaned regularly.

- Water in Fuel: Water reduces lubrication and causes internal corrosion. In cold weather, it can freeze, causing blockages or damage.

- Prevention: Install and regularly drain water separators. Use fuel additives that help manage water accumulation.

- Debris: Microbial growth (diesel bug) can create sludge that clogs filters and damages the pump.

- Prevention: Use biocides regularly, especially during storage. Keep fuel tanks full to minimize condensation.

- Overheating: Low fuel levels or a restricted return line can cause the pump to overheat, as diesel fuel also acts as a coolant, leading to accelerated wear.

- Prevention: Avoid running fuel tanks very low and ensure fuel return lines are clear.

- Component Wear: Normal wear and tear from high operating hours, poor fuel lubricity, or vibration degrades precision components over time.

- Prevention: Use high-quality diesel fuel and adhere to all recommended service intervals, including fuel filter changes. Always replace the fuel filter when replacing a pump.

At RPM Diesel, we emphasize preventive maintenance. Regular inspections and ensuring fuel quality are your best defenses against bosch injector pump failure. Our team in Florida, including Miami and West Palm Beach, is ready to assist with all your marine diesel maintenance needs.

Selecting the Right Bosch Injector Pump: New vs. Remanufactured

Choosing the correct bosch injector pump for your marine engine is a critical decision. At RPM Diesel, we guide you through the process, from component sourcing to part identification. We’ll help you understand OEM specifications to make a choice that offers both long-term reliability and value for your vessel.

New vs. Remanufactured: Making the Right Choice

When you need a replacement bosch injector pump, you have two primary options: a brand new pump or a remanufactured one. Both are held to strict quality standards, but their differences can help you make the best choice.

A new Bosch injector pump is brand new from the factory, built to the latest original equipment (OE) specifications and subject to rigorous quality control.

A Bosch remanufactured injector pump is completely disassembled, cleaned, and inspected. Worn components are replaced with new ones, and the unit is rebuilt and calibrated to meet or exceed OE specifications. These pumps undergo the same rigorous testing as new parts, including flow, leak, and pressure checks.

Here’s a quick comparison:

A new pump has no core charge, while a remanufactured one does (a refundable deposit for your old pump). Remanufactured units often have excellent availability for common marine engines. Both new and remanufactured pumps are backed by Bosch’s comprehensive warranty programs.

A new pump represents a higher initial investment, but a Bosch remanufactured pump is more cost-effective, offering fantastic value without compromising quality. Choosing remanufactured is also better for the environment. Our insight at RPM Diesel is that Bosch remanufactured common rail injectors and pumps meet the same high standards as new parts. They undergo a rigorous remanufacturing process to OEM specifications, meaning you get OEM quality and performance without the premium price. For many marine applications, a Bosch remanufactured pump is an excellent, reliable, and economical choice.

How to Identify the Correct Pump for Your Marine Engine

Selecting the exact bosch injector pump is vital for performance and compatibility. At RPM Diesel, our parts inventory and technical expertise make this process straightforward.

The most reliable method is the part number plate on the pump itself. This unique Bosch number (often starting with “0 400…”) ensures an exact match for model, specs, and calibration.

If the part number is missing, your engine’s make, model, and serial number are the next best thing. We can cross-reference this information to find the correct pump.

Engine manufacturers often use their own OEM part numbers. If you have this number, we can cross-reference it to the original Bosch part number.

For older or custom engines, technical specifications like displacement, cylinder count, and power output can help identify the correct pump. Physical dimensions can also be a clue.

At RPM Diesel, we pride ourselves on matching pumps by Bosch numbers, OEM cross-references, and engine specs. This meticulous approach ensures you receive the exact bosch injector pump your marine engine needs. Our team is ready to assist you in Fort Lauderdale, Miami, West Palm Beach, and across Florida.

Maintenance, Installation, and Timing for Peak Performance

Proper installation, calibration, and maintenance are key to getting the most from your bosch injector pump. These systems operate at incredibly high pressures, where a small mistake can lead to dangerous fuel leaks or catastrophic engine damage. We always recommend having your pump installed by certified marine diesel technicians who understand these precision systems.

Professional installation includes critical steps like engine calibration and fuel system bleeding. Bleeding removes air bubbles that can cause erratic performance or prevent the engine from starting, ensuring smooth fuel flow.

Essential Maintenance for Longevity

With clean fuel, bosch injector pump systems are very reliable. However, internal problems typically require professional rebuilding or replacement. This makes preventive care your best strategy.

- Regular fuel filter changes are absolutely critical to protect your pump from contamination. Consider changing filters more frequently than the manufacturer suggests if operating with questionable fuel quality.

- Periodic inspection of your engine compartment can help you spot fuel weeping, corrosion, or loose connections before they become major problems.

- Seal replacement is necessary as pumps age. Hardened or cracked seals can cause fuel leaks and should be addressed promptly. Resealing a pump requires specialized tools and expertise but can dramatically extend its life.

- Governor oil maintenance is essential for older mechanical pumps with separate oil reservoirs. Check your owner’s manual for the specific oil requirements and service intervals.

- External cleanliness is also important. A dirty pump can overheat, as grime traps heat. A clean pump also makes it easier to spot potential issues.

The Critical Role of Injection Timing Adjustment

If the injector pump is the heart of your fuel system, injection timing is its rhythm. Incorrect timing hurts performance, fuel economy, and can even damage your engine.

Proper timing ensures optimal combustion by delivering fuel at the precise moment. Advanced timing can cause engine knock and damage, while retarded timing wastes fuel and reduces power.

Fuel efficiency and power output depend heavily on timing. An engine with correct timing responds crisply and produces its rated horsepower. A poorly timed engine will feel sluggish and unresponsive.

Modern emissions requirements have made timing even more critical. Precise timing minimizes harmful pollutants and ensures compliance with environmental regulations.

Warning signs of incorrect timing include engine misfires, excessive smoke, and poor fuel economy. Timing adjustment is not a DIY job. It requires specialized diagnostic tools, software, and experience for both modern electronic and older mechanical systems. A mistake can lead to catastrophic engine failure.

At RPM Diesel, our technicians have the training and tools to properly diagnose and adjust timing on all types of bosch injector pump systems. We serve the marine community throughout Florida, from our base in Fort Lauderdale to Boca Raton and beyond. When it comes to your engine’s performance, precision timing is everything.

Frequently Asked Questions about Bosch Injector Pumps

What are the main advantages of using genuine Bosch components?

For marine applications, reliability is critical. We always recommend genuine Bosch components for your diesel engine. Genuine Bosch parts ensure optimal performance, durability, and compatibility that aftermarket alternatives may not match. They are manufactured to strict OEM standards, designed to fit and function exactly like the original parts.

This precision engineering is vital. Bosch nozzles, for example, are built to withstand heavy demands while delivering exact pressure and fuel atomization. Using genuine parts protects your investment by minimizing failure risk, ensuring manufacturer-intended operation, and preserving warranty coverage.

How often should a marine diesel injector pump be serviced?

The service schedule for a bosch injector pump depends on the system type and vessel usage. Older mechanical systems often require service every 1000-2000 hours of operation. Over time, wear can cause poor fuel atomization, leading to increased smoke and cylinder wear.

Modern common rail systems are more robust, and many manufacturers no longer specify hourly maintenance intervals due to their advanced design. This has significantly reduced lifetime service costs.

Regardless of the system, the most crucial maintenance is using clean fuel and performing regular fuel filter changes. If you notice any symptoms of a failing pump, such as poor performance or excessive smoke, seek professional service promptly to avoid more expensive repairs.

Can a faulty injector pump damage my engine?

Yes, a malfunctioning bosch injector pump can cause severe engine damage. Incorrect fuel delivery can lead to serious problems that go beyond poor performance.

For example, too much fuel can cause “cylinder wash,” stripping lubricating oil from cylinder walls and causing premature wear on pistons and rings. Too little fuel or poor atomization leads to incomplete combustion, creating carbon buildup and causing components to overheat.

Incorrect injection timing from a faulty pump puts excessive stress on engine components and can lead to misfires or even catastrophic failure. Timely diagnosis and repair are essential. If you notice symptoms like hard starting, rough idle, smoke, or power loss, don’t ignore them. Getting professional help right away can save you from a major engine rebuild.

Conclusion

The bosch injector pump is a testament to precision engineering, serving as the heart of your marine diesel engine’s fuel system. From robust inline pumps to sophisticated common rail systems, Bosch quality ensures reliable power and optimal efficiency.

We’ve covered how these systems work, the warning signs of failure, and the importance of maintenance. Clean fuel, regular filter changes, and proper maintenance are key to your pump’s longevity. When service is needed, choosing between new and remanufactured parts depends on your budget and needs.

At RPM Diesel, we understand that reliability is non-negotiable. Our expert technicians serve all of South Florida, from Miami to West Palm Beach, equipped with advanced diagnostic tools and genuine Bosch parts. With our extensive inventory and worldwide service capabilities, we can handle any bosch injector pump issue, from vintage mechanical pumps to modern common rail systems.

When it comes to your marine diesel fuel system, don’t leave anything to chance. Your vessel deserves the expertise that comes from years of specialized experience. Get expert Bosch diesel services for your marine engine with RPM Diesel – because reliable power is what gets you home safely.