Finding the Right Bosch Diesel Specialist for Your Marine Engine

When your marine diesel engine needs expert care, finding a qualified Bosch diesel specialist becomes critical for maintaining your vessel’s reliability and performance on the water.

Quick Answer for Marine Vessel Owners:

- Authorized Bosch Diesel Centers – Factory-trained technicians with proprietary diagnostic equipment

- Bosch Diesel Service (BDS) – Network partners authorized for warranty work and genuine parts

- Key Services – Common rail injector repair, fuel pump calibration, system diagnostics

- Global Network – Over 3,000 workshops worldwide specializing in Bosch diesel systems

- Quality Assurance – Bosch QualityScan verification and standardized repair processes

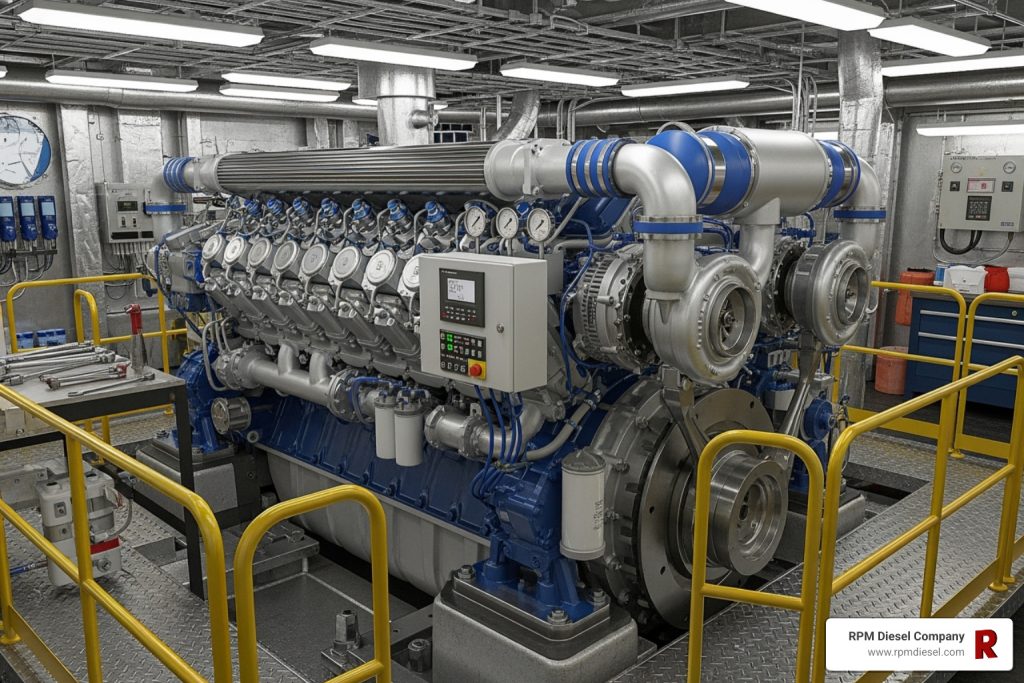

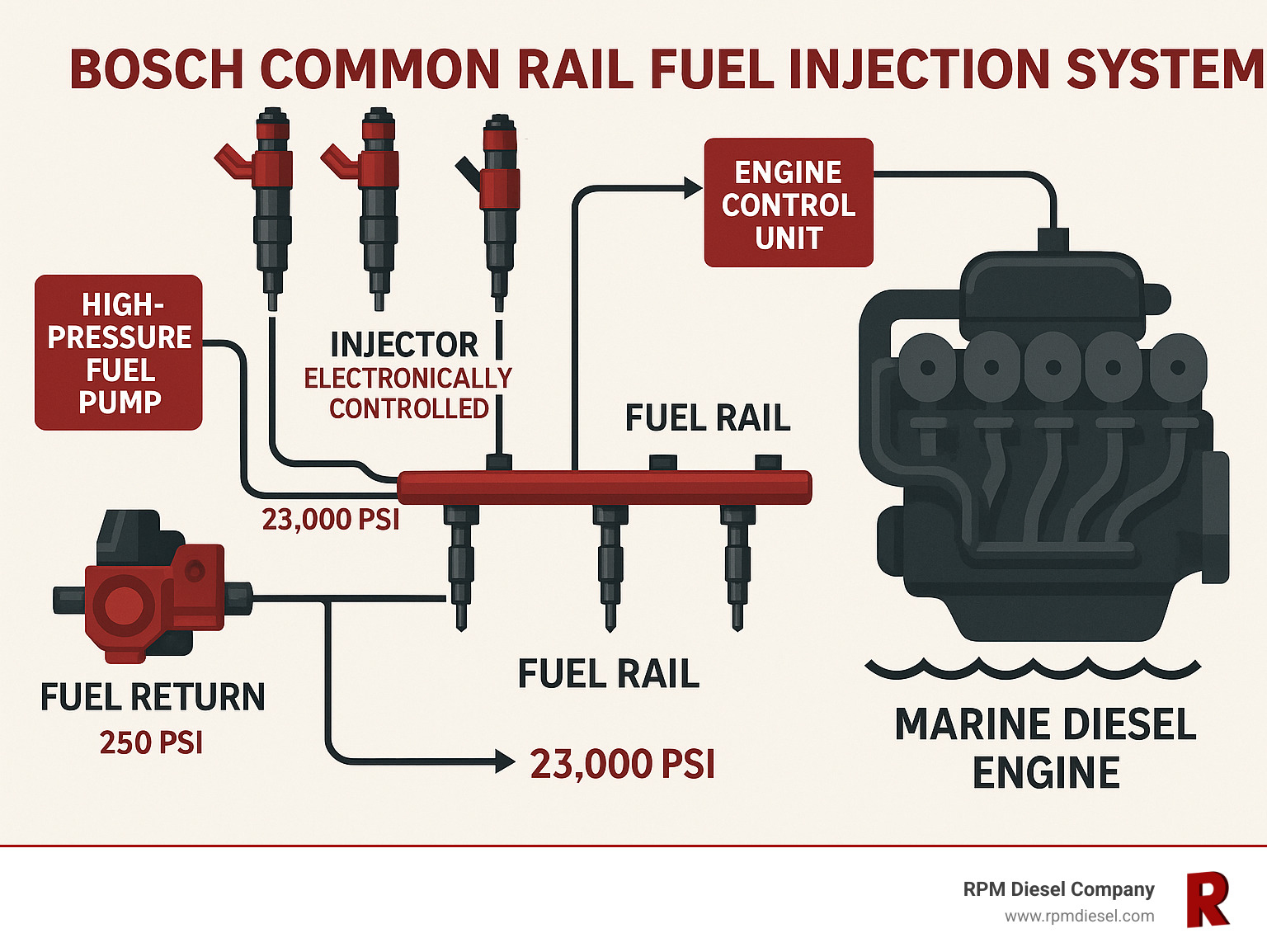

Modern marine diesel engines rely heavily on sophisticated Bosch fuel injection systems. These high-pressure common rail systems operate with microscopic tolerances that demand specialized knowledge and equipment.

The worldwide network of Bosch diesel repairers comprises around 3,500 workshops, but not all are equipped to handle the unique demands of marine applications. Authorized specialists undergo continuous training directly from Bosch and maintain access to proprietary diagnostic tools like the EPS 815 test bench.

For marine vessel owners, choosing the right specialist means the difference between a reliable repair and potential failure at sea. The complexity of modern diesel injection systems – from common rail injectors operating at pressures exceeding 30,000 PSI to electronically controlled fuel management – requires expertise that goes far beyond general mechanical knowledge.

What Defines an Authorized Bosch Diesel Specialist?

When your marine diesel engine needs expert care, understanding what makes a Bosch diesel specialist truly authorized can save you from costly mistakes and dangerous failures at sea.

An authorized Bosch diesel specialist isn’t just someone who works on diesel engines. These are service providers who have earned their credentials through Bosch’s rigorous certification process. Think of it like the difference between someone who can change your oil and a factory-trained technician who understands every intricate detail of your engine’s fuel injection system.

The strict Bosch standards these specialists must meet go far beyond basic mechanical knowledge. They need specialized diagnostic equipment, access to proprietary repair procedures, and ongoing manufacturer training. This isn’t a one-time certification either – maintaining authorized status requires continuous education as diesel technology evolves.

As part of Bosch’s global network of specialists, these workshops undergo regular quality audits and must demonstrate their commitment to excellence. The continuous training requirements ensure that every authorized technician stays current with the latest common rail technology and electronic fuel management systems that power today’s marine engines.

Most importantly for marine applications, authorized specialists must strictly follow OEM specifications. When you’re miles from shore, there’s no room for guesswork or “close enough” repairs.

The Authorization Advantage

The benefits of choosing an authorized Bosch diesel specialist become clear when you understand what’s at stake with modern marine fuel injection systems.

Genuine Bosch parts aren’t just about brand loyalty – they’re about precision. Common rail injectors operate with tolerances measured in microns. Even the smallest deviation from specifications can lead to poor performance, increased emissions, or complete system failure. Authorized specialists have guaranteed access to these precision-manufactured components.

Direct manufacturer support means your repair isn’t based on guesswork. Authorized centers receive proprietary diagnostic software and repair procedures that aren’t available to general mechanics. This includes access to exact specifications for precision shims and calibration data that can make the difference between a repair that lasts and one that fails prematurely.

The warranty processing advantage is particularly valuable for marine applications. Authorized specialists can handle warranty claims directly, streamlining what could otherwise be a complex process when you’re dealing with expensive fuel system components.

Perhaps most importantly, authorized centers have access to proprietary repair data that enables precise troubleshooting. This expertise translates directly into reduced vessel downtime – getting you back on the water faster with confidence in your repairs.

For a closer look at how this authorization translates into superior service, explore our Bosch Certified Repairs by RPM.

Quality Assurance and The Bosch Guarantee

Quality in marine diesel repair isn’t just about doing good work – it’s about having systems in place to verify and track that quality over time.

Regular quality audits by Bosch ensure that authorized workshops maintain their high standards consistently. These aren’t casual inspections – they’re comprehensive evaluations of facilities, equipment calibration, and repair processes.

The Bosch QualityScan app represents a breakthrough in repair verification. Every component we repair receives a unique identifier that connects to a comprehensive database. This means you can verify the quality and specifications of your repair long after the work is completed.

Standardized testing processes eliminate variability between different repair centers. Whether your injectors are serviced in Florida or anywhere else in the Bosch network, the procedures and quality standards remain identical.

The traceability of repaired components through systems like Verifiable repair quality with Bosch QualityScan provides peace of mind that extends far beyond the initial repair. You have documented proof that your fuel system components meet factory specifications.

This level of quality assurance is particularly crucial for marine applications, where component failure can mean more than just inconvenience – it can mean safety risks and costly emergency repairs in remote locations.

Core Services for High-Performance Marine Diesel Systems

When your marine diesel engine needs expert attention, understanding what services a Bosch diesel specialist provides can make all the difference. At the heart of our approach is component-level expertise – we don’t just look at symptoms, we dive deep into the precise diagnostics and troubleshooting that modern marine engines demand.

Our philosophy centers on repair over replacement whenever it makes economic sense. Why? Because marine diesel components are built to last, and with the right expertise, many issues can be resolved without the expense of brand-new parts. When repair isn’t viable or cost-effective, we offer Bosch eXchange units – these are remanufactured components that meet Bosch’s stringent quality standards, giving you reliable performance at a fraction of the cost of new parts.

Advanced Diagnostics and Component Repair

The magic happens in our certified clean room with HEPA-filtered pressurized air, where we perform injector assembly and repair. This isn’t just about being neat – modern common rail injectors work with tolerances so tight that even a speck of dust can cause premature failure. It’s like performing surgery on your engine’s most critical components.

Our state-of-the-art Bosch EPS815 test bench is where precision meets performance. This sophisticated equipment can measure fuel delivery with shot-to-shot metering accuracy down to 1/10 of one cubic millimeter between firing events. That’s the kind of precision that separates guesswork from genuine expertise.

Here’s what we specialize in for marine applications:

- Common rail injector testing and repair for CRI, CRIN, CRIN I, II, III and IV injectors

- Fuel pump calibration and repair covering CP1, CP2, CP3 and CP4 common rail systems

- Nozzle holder assembly repair to ensure proper fuel atomization

- Unit injector system (UIS) and Unit pump system (UPS) service for integrated components

- Electronically controlled distributor pumps (VP, VE-EDC) and conventional mechanical systems

What sets us apart is our ability to choose from over 500 different sized shims, allowing us to recalibrate injectors to original factory specifications with surgical precision. This isn’t something you can achieve with generic repair shops – it requires the specialized tools and training that come with being an authorized Bosch Common Rail Injector Service provider.

Servicing a Wide Range of Marine Applications

The marine environment presents unique challenges that land-based engines never face. Continuous operation, salt air exposure, and the simple fact that breaking down at sea isn’t an option – these realities shape everything we do as a Bosch diesel specialist.

We work with yachts and superyachts where sophisticated engines need to operate flawlessly for both leisurely cruises and long ocean passages. For commercial vessels – fishing boats, tugs, and cargo ships – reliability isn’t just important, it’s the foundation of successful business operations. Our expertise also extends to industrial marine engines used in specialized applications where performance and dependability are non-negotiable.

Our OE coverage includes major marine engine brands like MAN, MTU, and Volvo Penta. This broad expertise means that regardless of your vessel’s engine manufacturer, if it features Bosch diesel components, we have the knowledge and equipment to service it to the highest standards.

The beauty of working with an authorized specialist is that we understand how these systems integrate with different marine engine platforms. Each manufacturer has specific requirements and tolerances, and our comprehensive approach ensures your engine performs optimally in the demanding marine environment. Learn more about our full capabilities at Diesel Engine Fuel Injection Services (Bosch Common Rail Repair).

When to Consult a Marine bosch diesel specialist

Your marine diesel engine works hard in one of the harshest environments imaginable. Salt spray, constant vibration, and continuous operation all take their toll. That’s why proactive maintenance isn’t just smart—it’s essential for preventing the kind of catastrophic failure that can leave you stranded miles from shore.

Think of it this way: you wouldn’t ignore a strange sound from your car engine while driving through the city. But when you’re out on the water, that same ignored warning sign could mean the difference between a pleasant day of cruising and an emergency call to the Coast Guard.

Recognizing the Warning Signs in Your Marine Engine

Your marine diesel engine is constantly communicating with you. The trick is learning to listen to what it’s trying to say before a whisper becomes a shout.

Excessive black or white smoke coming from your exhaust is one of the most obvious red flags. Black smoke typically means unburnt fuel is escaping—often pointing to injector problems or poor combustion. White smoke can indicate coolant leaks or incomplete fuel combustion, both serious issues that need immediate attention.

Loss of power or RPM is another clear signal something’s wrong. If your vessel feels sluggish or struggles to reach its usual cruising speed, you’re likely dealing with fuel system problems, turbocharger issues, or internal engine wear.

Increased fuel consumption without any change in how you operate your vessel suggests your engine is working harder than it should. This inefficiency often traces back to the fuel injection system—exactly the kind of problem a Bosch diesel specialist can diagnose and repair.

Hard starting or rough idling are particularly common in marine environments. Cold morning starts shouldn’t be a wrestling match with your engine, and your idle should be smooth and steady. Problems here often point to issues with glow plugs, fuel delivery, or injector performance.

Unusual engine noises deserve immediate investigation. Any new knocking, ticking, hissing, or grinding sounds are your engine’s way of asking for help. Don’t ignore them.

High exhaust temperatures can signal various problems, from improper fuel combustion to turbocharger issues. Your engine’s temperature gauges are there for a reason—pay attention to them.

Early detection and professional diagnosis can save you thousands of dollars and prevent dangerous situations at sea. For detailed guidance on identifying common problems, check out our comprehensive resource on Bosch Diesel Injector Troubleshooting.

The Critical Role of a Marine bosch diesel specialist

When warning signs appear, you need someone who understands the unique challenges of marine diesel engines. Modern marine diesels aren’t the simple mechanical engines of decades past—they’re sophisticated systems controlled by complex electronics that require specialized knowledge to diagnose and repair properly.

A qualified Bosch diesel specialist brings the advanced diagnostic tools and training necessary to accurately identify problems in these intricate electronic systems. We can quickly pinpoint whether that rough idle is caused by a faulty injector, a programming issue, or something else entirely.

High-pressure fuel systems present particular dangers that general mechanics often aren’t equipped to handle safely. These systems operate at pressures exceeding 30,000 PSI—enough to cause serious injury if handled improperly. Our technicians receive specific training on safely working with these systems.

Beyond safety, there’s the matter of emissions compliance. Properly functioning Bosch components ensure your engine operates within manufacturer specifications and meets environmental regulations. This isn’t just about following rules—it’s about maintaining your engine’s efficiency and longevity.

Perhaps most importantly, choosing a marine Bosch diesel specialist helps maximize your engine’s lifespan and performance. We understand how salt air, constant vibration, and continuous operation affect these systems. Our maintenance approach accounts for these unique stresses, ensuring reliable operation for years to come.

Regular maintenance and prompt attention to problems isn’t just about avoiding breakdowns—it’s about maintaining the confidence that comes with knowing your engine will perform when you need it most. Learn more about keeping your fuel injection system in peak condition at Bosch Fuel Injection Maintenance and Repairs.

Frequently Asked Questions about Bosch Diesel Service

When marine vessel owners start looking for expert diesel service, they often have questions about what makes a Bosch diesel specialist different from other repair options. Let’s address the most common concerns we hear from boat owners who want to make sure their engines get the best possible care.

What is the difference between a Bosch Diesel Center and a regular diesel mechanic?

The difference comes down to training, tools, and direct manufacturer backing. As an authorized Bosch diesel specialist, we’ve met strict requirements that go far beyond what a general mechanic can offer.

Our technicians receive specialized training directly from Bosch, not just general diesel knowledge. We use proprietary diagnostic equipment like the Bosch EPS 815 test bench, which can measure fuel delivery to 1/10 of one cubic millimeter between firing events. That’s the kind of precision you simply can’t get with standard shop equipment.

We also have access to genuine Bosch parts and exclusive precision shims that are only available to Bosch Factory Authorized repair shops. This means when we calibrate your common rail injectors, we’re using exact measurements and components specified by the manufacturer – not making educated guesses.

A regular diesel mechanic might be skilled and well-intentioned, but they typically lack this direct manufacturer support, specialized equipment, and access to proprietary repair data. When you’re dealing with high-pressure fuel systems operating at over 30,000 PSI, you want certainty, not guesswork.

Can a Bosch specialist service older mechanical injection systems?

Absolutely! While modern common rail systems get a lot of attention, our expertise as a Bosch diesel specialist covers the full spectrum of Bosch diesel technology. We’re not just about the latest and greatest – we understand that many reliable marine engines still run on proven mechanical systems.

Our capabilities extend from cutting-edge common rail injectors (CRI/CRIN) and high-pressure pumps (CP) all the way back to conventional mechanical distributor and in-line pumps. We also service nozzle holder assemblies and other components from Bosch’s extensive history of marine diesel innovation.

Whether your vessel has a brand-new electronically controlled system or a seasoned mechanical injection setup that’s been running strong for decades, we have the specialized knowledge and proper equipment to keep it performing at its best. Experience matters, and we’ve seen it all.

Why is a ‘clean room’ important for Bosch common rail repairs?

Here’s where the precision of modern diesel technology becomes crystal clear. Today’s common rail injectors operate with tolerances measured in microns – that’s smaller than what your eye can see. Even a tiny speck of dust or lint can cause catastrophic damage to these incredibly precise components.

Our Bosch certified clean room uses HEPA-filtered pressurized air to create an environment completely free from airborne particles. Think of it like a medical operating room, but for your injectors. During assembly and repair, every surface and component must remain absolutely pristine.

Without this controlled environment, contamination is almost inevitable. That contamination leads to premature failure, which means you could find yourself with a dead engine miles from shore. When you’re depending on your marine diesel for safety and reliability, cutting corners on cleanliness isn’t worth the risk.

The clean room isn’t just a nice-to-have feature – it’s an essential requirement for proper common rail repair that ensures your components will perform reliably when you need them most.

Your Trusted Partner for Marine Diesel Excellence

When you’re out on the water, your diesel engine’s reliability becomes everything. The difference between a perfect day and a dangerous situation often comes down to one critical decision: choosing the right Bosch diesel specialist for your marine engine’s care.

The benefits of working with an authorized specialist extend far beyond basic repairs. You gain access to genuine Bosch parts, factory-trained technicians, and diagnostic equipment that simply isn’t available elsewhere. More importantly, you get the peace of mind that comes from knowing your engine is being serviced to the exact standards Bosch intended.

For marine applications specifically, this expertise becomes even more valuable. The harsh marine environment, continuous operation demands, and the critical nature of reliable power at sea make professional care essential. Whether you’re running a luxury yacht, commercial fishing vessel, or industrial marine operation, your engine deserves nothing less than factory-authorized service.

RPM Diesel Company stands as a premier example of what an authorized specialist should be. We’re incredibly proud to be one of only two Bosch factory authorized repair shops in Broward and Dade counties, Florida. Even more remarkable, we’re the oldest fuel injection shop in South Florida, serving the marine community since 1956.

This combination of longevity and specialized authorization isn’t just impressive on paper – it translates directly into better service for your vessel. Our decades of experience mean we’ve seen virtually every type of marine diesel issue imaginable. Our Bosch authorization ensures we have the latest tools, training, and genuine parts to handle today’s sophisticated common rail systems.

The importance of choosing an authorized specialist cannot be overstated. When you’re dealing with high-pressure fuel systems operating at over 30,000 PSI, there’s simply no room for guesswork. Our Certified Bosch Repair Center status means every repair meets factory specifications, every diagnostic follows Bosch protocols, and every component is verified through their QualityScan system.

For comprehensive and authorized care for your marine diesel engine, whether you’re in Fort Lauderdale FL, Miami FL, West Palm Beach FL, Boca Raton FL, or Delray Beach FL, explore our complete Bosch Diesel Services.

Don’t guess when it comes to your marine engine’s health. The water doesn’t forgive mechanical failures, and your vessel’s reliability depends on expert care. Trust the specialists who have been keeping South Florida’s marine engines running strong for nearly seven decades. Give us a call today and experience the difference that true Bosch expertise makes.