Why Marine Diesel Fuel System Service Is Essential for Vessel Performance

Diesel fuel system service is the comprehensive maintenance of all components that deliver clean fuel to your marine engine—from tanks and filters to pumps and injectors. For vessel owners, this service is critical for preventing breakdowns at sea and ensuring reliable performance.

Quick Overview of Marine Diesel Fuel System Service:

- What it includes: Fuel filter replacement, water separator maintenance, injector cleaning/testing, fuel pump inspection, and fuel tank cleaning.

- Service frequency: Every 200-300 operating hours or annually for basic maintenance; injector service every 1,000 hours for older mechanical systems.

- Key benefits: Prevents engine failure, improves fuel efficiency, reduces emissions, and extends engine life.

- Professional vs. DIY: Filter changes can be DIY, but injector and fuel pump service require specialized equipment and expertise.

For a deeper technical primer on compression-ignition technology, visit the Diesel engine article on Wikipedia.

As one marine diesel expert notes: “The fuel system on the marine diesel engine needs periodic attention.” This is especially true for vessels in saltwater environments where fuel contamination, water ingress, and microbial growth pose constant threats.

Marine diesel engines face unique challenges compared to their land-based counterparts. They operate in environments where water can easily enter fuel tanks, fuel sits longer between uses, and engine failure means being stranded at sea, not just on the roadside.

At RPM Diesel Company, we know a well-maintained fuel system is the cornerstone of a healthy marine engine. It’s about optimizing performance and reliability, extending its lifespan, and reducing emissions. The marine environment’s challenges—water contamination, fuel degradation, and the dreaded “diesel bug” (microbial growth)—make a robust maintenance schedule non-negotiable.

Understanding the Impact of Neglect

Ignoring the signs of a struggling fuel system can lead to a cascade of problems far more costly than preventative care. Imagine being miles from shore when your engine sputters and dies—a serious safety hazard. Neglected fuel systems can lead to:

- Engine failure at sea: The most critical consequence, leaving you stranded.

- Clogged filters: A common issue causing fuel starvation and power loss. We’ve seen filters with less than 25 hours on them cause significant fuel flow reduction.

- Damaged injectors: Contaminants can deform spray patterns, leading to poor fuel economy, power loss, and rough starts. In extreme cases, a bad injector can damage an engine cylinder.

- Fuel pump failure: Contaminants wear down precision components, leading to costly repairs.

- Increased operational costs: A struggling engine consumes more fuel, and reactive repairs are almost always more expensive than proactive maintenance.

- Unscheduled downtime: Unexpected repairs during prime boating season are frustrating and costly.

As specialists, we know preventing these issues is paramount. Our services are designed to give you peace of mind. Learn more about how we can help by understanding What Are Diesel Injector Services For?.

Telltale Signs Your Marine Diesel Needs Attention

Your marine diesel engine provides plenty of warning before major problems strike. The key is recognizing these early signals and acting on them before you’re stuck miles from shore.

-

Engine misfires and stuttering often indicate inconsistent fuel delivery, a sign of clogged injectors or a struggling fuel pump.

-

A rough idle, where the engine’s smooth purr becomes an uneven rumble, points to deposits in the fuel system that are preventing proper fuel atomization.

-

Loss of power and slow throttle response are frustrating symptoms that directly impact your experience. If your vessel isn’t reaching its usual speed or hesitates when you accelerate, it’s likely starving for clean fuel.

-

Difficulty starting, especially in colder weather, can mean the fuel system isn’t delivering the pressure or volume needed for the engine to fire up reliably.

-

If you’re making more frequent trips to the fuel dock without changing your habits, your engine’s increased fuel consumption may be due to it working overtime to compensate for fuel system inefficiencies.

-

Excessive smoke from your exhaust is a clear warning. Thick black smoke usually indicates unburnt fuel, while white smoke can signal water contamination in your fuel.

-

Modern engines often have frequent fuel filter alarms. Don’t treat these as suggestions; they’re urgent requests for help, telling you the engine is having trouble getting the fuel it needs.

If you’re experiencing any of these symptoms, it’s time to schedule diesel fuel system service before small problems become big headaches. Most of these issues are preventable with proper maintenance. For modern systems, we recommend our comprehensive Common Rail Diesel Diagnostics to pinpoint the exact cause.

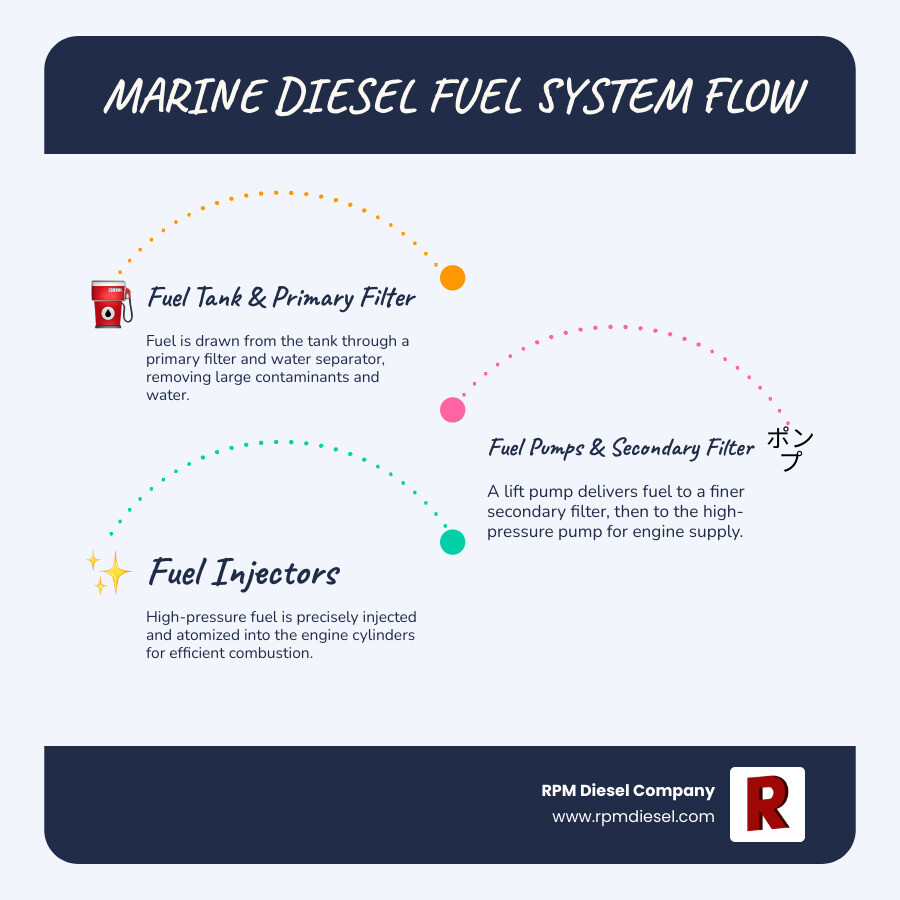

Core Components of a Marine Diesel Fuel System Service

A proper diesel fuel system service involves a sophisticated network of components. At RPM Diesel Company, we know that reliable performance comes from understanding how every part works together to keep your vessel running smoothly.

A thorough service includes a full fuel system inspection for leaks, corrosion, and wear. We perform component cleaning to remove deposits and microbial growth, followed by component replacement of worn parts like filters and lines. Finally, we use professional diagnostics to test fuel pressure and injector performance, ensuring everything meets specifications.

The First Line of Defense: Fuel Filters and Water Separators

Your filters are the gatekeepers protecting your engine from harmful contaminants. Marine diesels use two main types:

- Primary filters are the first checkpoint, catching larger particles (10-30 microns) and, crucially, separating water from fuel. They often have a clear bowl for visual inspection.

- Secondary filters are located closer to the engine and are much finer, catching particles as small as 2.5 to 5 microns to ensure only ultra-clean fuel reaches sensitive components.

Modern common rail systems are especially sensitive to contamination, making these micron ratings critical. Water separator inspection should be a regular part of your routine, as water is diesel’s worst enemy. It causes rust, promotes microbial growth (the “diesel bug”), and can destroy injection components. We recommend checking the separator bowl weekly and draining it until clean fuel flows out. Cleanliness during filter changes is paramount; a single grain of sand can destroy an expensive injection system. Your filter replacement schedule should be every 200-300 operating hours or annually, whichever comes first. We stock high-quality options like our Fuel Filter Product and Secondary Fuel Filter Product.

The Heart of the System: Fuel Pumps and Injectors

Fuel pumps and injectors are precision instruments that deliver the right amount of fuel at the right time.

- Mechanical injection systems, found in many older marine diesels, are tough and reliable. Their injectors require regular service—typically every 1,000 hours for turbocharged engines—to prevent increased smoke, poor fuel economy, and engine damage.

- Common Rail Fuel Injection System technology is found on modern vessels. These systems deliver fuel at pressures over 30,000 PSI, allowing for incredible precision and efficiency to meet strict EPA emission standards for marine engines. The trade-off is an extreme sensitivity to fuel contamination.

Injector cleaning and testing restore proper spray patterns and require specialized equipment to simulate operating conditions. For complex issues, a full rebuild may be the most cost-effective solution, which we cover in our Diesel Injector Rebuild: Understanding Differences services. Servicing modern high-pressure fuel pumps and injectors is not a DIY job; it demands professional tools and expertise, especially when dealing with genuine Bosch Diesel Injection Pump Parts.

Fuel Tanks and Lines: Ensuring a Clean Supply

Many fuel system problems start in the fuel tank. Water accumulation from condensation and deck fills creates a breeding ground for microbial growth (the “diesel bug”), which produces corrosive acids and sludge buildup that clogs the entire system.

Fuel polishing is a process that cleans contaminated fuel in your tank, removing water, sediment, and microbes without the need to dispose of expensive diesel. Regular fuel line inspection is also vital to find cracks, chafing, or loose connections caused by vibration and the harsh marine environment. Leak prevention is a top safety priority, as a fuel leak in an engine room is a serious fire hazard. For more on this topic, see our Diesel Fuel Information guide.

Service Intervals and Preventative Care

Timing is everything in marine diesel maintenance. Understanding when to schedule diesel fuel system service can be the difference between smooth sailing and being stranded. The marine environment is harsh, so while manufacturer recommendations are a great starting point, they should be adapted to your real-world conditions.

Service intervals are based on operating hours, a more accurate measure for marine engines. However, factors like poor fuel quality, high humidity, or long periods of storage can accelerate the need for service.

Recommended Marine Diesel Fuel System Service Schedule

Think of fuel system maintenance in layers: daily attention prevents weekly problems, and weekly care prevents annual headaches.

- Daily Routine: Before starting your engine, scan for fuel leaks and check the primary fuel filter bowl for water or debris. This two-minute check can save hours of trouble.

- Weekly Inspections: If you use your vessel regularly, take a closer look at fuel lines for any signs of chafing or wear, which can prevent dangerous leaks.

- Annual Service (or every 200-300 hours): This is your engine’s major check-up. It includes replacing all primary and secondary fuel filters, cleaning water separators, and inspecting all fuel lines. If your boat sits for long periods, this is the time to add fuel stabilizers or biocides.

- Major Service (every 1,000 hours for older mechanical systems): Older workhorse engines need periodic injector service, which involves removing, testing, cleaning, and often rebuilding the injectors. Our Injector Repairs for Marine Diesel Engine service is designed for this. This is also a good time to inspect fuel pumps and consider fuel tank cleaning if contamination is present.

A comprehensive service checklist includes fuel filter replacement, water separator draining, fuel line and tank inspection, fuel sample analysis, injector performance checks, fuel pressure testing, and proper use of fuel additives.

Proactive Maintenance: Is It an Upsell or a Necessity?

For marine diesel engines, proactive maintenance isn’t an upsell—it’s survival insurance. Consider being miles offshore when your engine sputters in worsening weather. The service you skipped last spring suddenly seems essential.

Preventative care beats reactive repairs every time, not just in cost but in safety and peace of mind. Catching a clogged filter during routine service costs a fraction of replacing damaged injectors or a failed fuel pump. Most importantly, it prevents the heart-stopping moment when your engine quits in rough seas. Reliability at sea is non-negotiable. Your engine must run flawlessly when you need it most.

Quality fuel additives, like our Diesel Fuel Injection Cleaner, are valuable allies. Products like BG 245 clean deposits from combustion chambers and injectors, restoring power and efficiency. The long-term savings are substantial, but the confidence that comes from knowing your engine is ready for anything is priceless.

Frequently Asked Questions about Marine Diesel Fuel System Service

We get a lot of questions from boat owners about diesel fuel system service. An informed owner is a prepared owner. Here are some of the most common questions we answer.

Can I perform diesel fuel system service myself?

The answer depends on the task. Basic maintenance like changing fuel filters and draining water separators is well within reach for most boat owners with basic tools. However, cleanliness is absolutely critical; a single speck of dirt can ruin an expensive injector.

Professional help is required for injectors, fuel pumps, and diagnostics. Testing injectors and high-pressure pumps requires specialized, expensive equipment to measure spray patterns and flow rates with precision. Attempting this service without the right tools can cause more damage than it solves, turning a simple cleaning into a costly rebuild.

What’s the difference between servicing older mechanical and modern common rail systems?

The difference is dramatic. Older mechanical injection systems are robust workhorses that need periodic hands-on service. Their injectors typically require removal, cleaning, and testing every 1,000 operating hours.

Modern common rail systems are electronically controlled, operate at extremely high pressures, and are highly sensitive to fuel quality. They don’t require the same frequent service intervals as mechanical systems, but when they do need attention, it demands advanced diagnostic equipment and specialized procedures. Our Common Rail Injector Service and specialized Bosch Common Rail Injector Repair use sophisticated tools to restore these components to factory specifications.

How important is fuel quality for my marine diesel engine?

Fuel quality is absolutely critical for marine diesel engines. Poor fuel quality is the fastest way to cause serious engine damage.

Water inevitably gets into fuel tanks in a marine environment, promoting microbial growth (the “diesel bug”). This sludge clogs filters and can destroy injectors. Contaminated fuel also acts like liquid sandpaper, causing abrasive wear inside your high-precision fuel injection system.

The consequences escalate from poor performance to complete engine failure. Being stranded offshore because contaminated fuel overwhelmed your system is not just expensive—it’s dangerous.

Your best defense is using reputable fuel sources and maintaining your system. If your boat sits for extended periods, use quality fuel stabilizers and biocides. Cutting corners on fuel quality is a costly mistake in the long run.

Conclusion

Your marine diesel engine’s performance and reliability depend on proper diesel fuel system service. It is the foundation of engine health; without a clean, steady supply of fuel, even the most powerful engine will falter.

At RPM Diesel Company, we’ve seen how professional fuel system maintenance transforms a vessel’s performance and, more importantly, provides owners with peace of mind. The marine environment is unforgiving, with salt air, moisture, and long periods of storage creating challenges that make professional service essential.

Our technicians bring decades of expertise to every job, understanding the unique demands of marine diesels, from older mechanical systems to the latest common rail technology. As an authorized dealer for major manufacturers like Detroit Diesel and MTU, we have the right parts and technical knowledge.

Our comprehensive approach sets us apart. We view the fuel system as an interconnected network, allowing us to identify potential issues before they become emergencies. With an extensive parts inventory, we can often complete repairs on the spot, getting you back on the water faster.

Whether you’re in Fort Lauderdale, Miami, West Palm Beach, or need our worldwide service, we are here to help. Don’t wait for warning signs. Proactive maintenance is always less expensive and far less stressful than emergency repairs.

Ready to give your marine diesel the care it deserves? Get expert advice on your diesel engine maintenance schedule and find how proper diesel fuel system service can keep your vessel running reliably for years to come.