Why Bosch Piezo Injectors Are Critical for Marine Performance

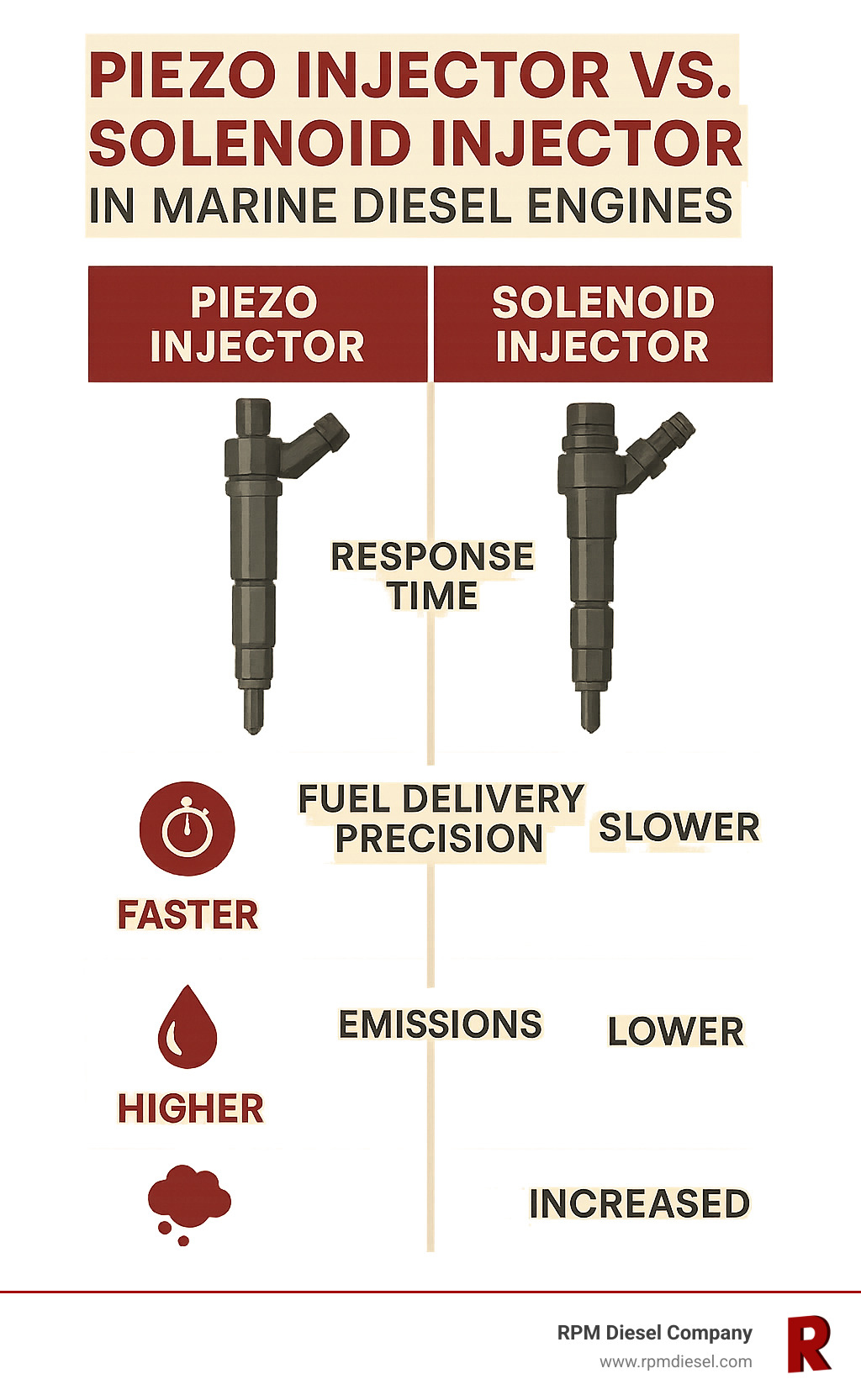

Bosch piezo injector repair is a highly specialized service in marine diesel maintenance. These advanced fuel injectors use piezoelectric crystals that expand with voltage, controlling fuel delivery with extreme precision—up to five times faster than traditional solenoid injectors.

Quick Answer for Marine Vessel Owners:

- Repair Complexity: Bosch piezo injectors require specialized equipment, clean room conditions, and factory-trained technicians

- Professional Testing: Repairs must include ultrasonic cleaning, precision flow testing, and calibration on Bosch-certified test benches

- Risks of DIY: Improper repair can cause engine damage, including melted pistons and oil contamination

- Best Options: New injectors, professionally remanufactured units, or authorized repair centers only

- Marine Considerations: Failed piezo injectors cause power loss, excessive smoke, and poor fuel economy at sea

The research shows that piezo injector repair is “very specialized work, and can’t be undertaken by every repair shop.” One study found that a faulty piezo injector stayed open 28% longer than normal (949µs vs 740µs), causing significant performance issues.

For marine vessel owners, this technology is crucial. Modern marine diesels use piezo injectors to meet strict emissions regulations while delivering necessary power and fuel efficiency. A failure at sea can lead to misfires, black smoke, and an irregular engine rhythm. A poorly repaired injector can spray fuel as a stream instead of a fine mist, risking catastrophic engine damage far from shore. Understanding your repair options and trusting professionals is essential for safe marine operation.

Identifying a Failing Bosch Piezo Injector in Your Marine Engine

A failing Bosch piezo injector rarely fails without warning. These precision components are the heart of your fuel delivery system, and they provide clear signs when they are in trouble.

Key warning signs include:

- Excessive Black Smoke: This indicates incomplete fuel combustion, often because a faulty injector is spraying fuel incorrectly.

- Vibration and Misfires: An uneven power delivery from a failing cylinder causes the engine to shake.

- Increased Fuel Consumption & Reduced Power: If you’re burning more diesel for less power, especially with stuttering under load, your injectors are a likely cause.

- Hard Starting & Soot: Difficulty starting the engine and excessive soot on the transom point to injectors that aren’t sealing or firing properly.

- Engine Oil Dilution: This is a critical symptom. Leaking injectors can allow unburnt fuel to contaminate your oil, destroying its lubricating properties and risking severe engine damage.

For a deeper understanding of how these vibrations can help diagnose injector problems, check out our guide on Diesel engine vibration analysis.

Common Symptoms at Sea

At sea, these symptoms become serious safety hazards:

- Irregular Engine Rhythm & Loss of RPM: Unstable engine sounds and an inability to maintain RPM, even at full throttle, indicate poor combustion.

- Poor Throttle Response & Shuddering: Hesitation during acceleration and violent shuddering under load make boat handling unpredictable and can stress other components.

- Visible Fuel Sheen: A sheen on the water near your exhaust is a clear sign of unburnt fuel escaping.

Addressing these failed injector symptoms promptly is crucial to avoid a breakdown offshore. Our team specializes in Common Rail Injector Services and can ensure your vessel is safe.

Diagnostic Warning Signs

Modern marine diesels monitor their own health. Your Engine Control Module (ECM) logs Diagnostic Trouble Codes (DTCs) that provide vital clues. A trained technician can analyze this ECM data to pinpoint the issue.

- Fuel Trim Values: These numbers show how the ECM is adjusting fuel to compensate for a failing injector. High or low trims indicate a problem cylinder.

- Cylinder Contribution Tests: These tests measure the power output of each cylinder, quickly identifying the underperforming one. A faulty piezo injector can stay open 28% longer than it should, which these tests can help reveal.

Professional diagnostics are essential for interpreting this complex data. At RPM Diesel, our technicians use specialized Bosch equipment to accurately pinpoint the problem, not just guess. For expert diagnosis, trust our Bosch Certified Repairs by RPM team.

The Great Debate: Repair, Refurbish, or Replace?

When a Bosch piezo injector fails, owners must decide whether to repair, refurbish, or replace. This choice impacts cost, reliability, and downtime. A cost analysis must consider long-term value, not just the upfront price. A new injector is most expensive initially but offers maximum long-term reliability and a full warranty. A professionally refurbished unit is a good middle ground, but its quality is dependent on the rebuilder. Downtime considerations and warranty differences are also critical factors, as a failed repair can lead to more time off the water and additional costs.

Is Bosch Piezo Injector Repair a Viable Option?

Bosch piezo injector repair is far more complex than working on older mechanical injectors. They contain a delicate piezo crystal stack and are subject to internal wear. The complexity of piezo technology makes it specialized work that most shops cannot perform. Improper repairs carry significant risks, including incorrect spray patterns that can lead to melted pistons or washed cylinder walls—damage far more costly than the repair itself.

However, when performed by certified professionals using the right equipment, bosch piezo injector repair is a viable and reliable option. At RPM Diesel Company, our Bosch-certified technicians restore these components to OEM specifications, backed by a solid warranty. For more technical details, see More info about Piezo injector for common-rail systems.

| Feature | New Marine Injectors | Professionally Refurbished Marine Injectors | Basic Repair (Not Recommended) |

|---|---|---|---|

| Cost | Highest upfront | Moderate | Lowest upfront, but highest long-term risk |

| Reliability | Highest, factory warranty | Very High (when done by certified shop) | Low, high risk of premature failure |

| Warranty | Full manufacturer’s warranty | Limited, but reputable shop warranty | None, or very limited |

| Downtime Risk | Low | Low | High, frequent re-repairs, potential for catastrophic failure |

| Performance | Optimal, meets all OEM specifications | Restored to OEM specifications | Unpredictable, often leads to sub-optimal engine performance |

| Expertise | No expertise needed for installation | Requires specialized expertise and equipment | Usually DIY or unspecialized shop, lacking proper tools and knowledge |

Alternatives: New and Exchange Units

Sometimes the smartest choice is the simplest one. Factory-new injectors eliminate all guesswork – you get peak performance, full warranty coverage, and the peace of mind that comes with knowing your fuel system is operating exactly as the engineers intended.

Remanufactured units and exchange programs offer an appealing middle ground for budget-conscious owners who don’t want to compromise on quality. These programs typically work by selling you a professionally rebuilt injector while you return your failed unit as a “core” for a partial refund. The key word here is “professionally” – the difference between a proper remanufacturing job and a basic rebuild can mean the difference between years of reliable service and an expensive breakdown at the worst possible moment.

Core charges are standard in the industry, and ensuring part compatibility is crucial for marine applications where engine reliability isn’t just about convenience – it’s about safety. Our extensive inventory means we can often supply in-stock injectors within 24 hours, and our worldwide sourcing capabilities ensure we can find virtually any marine diesel part you need.

For a comprehensive look at all your injector options, visit our Bosch Diesel Injectors page. We also dive deep into the nuances of various rebuild approaches in our detailed guide, Diesel Injector Rebuild: Understanding the Differences.

The Professional Bosch Piezo Injector Repair Process

Professional bosch piezo injector repair cannot be done at a typical repair shop. It demands specialized equipment, a clean room environment to prevent contamination, and factory-trained technicians. At RPM Diesel Company, we have invested in the necessary infrastructure and training. Our clean room and strict adherence to manufacturer specifications are critical for these precision components. This commitment to quality is why we are a Certified Bosch Repair Center.

Key Steps in a Professional Bosch Piezo Injector Repair

The repair process begins with complete disassembly of the injector. Each component then undergoes ultrasonic cleaning to remove all carbon and fuel varnish deposits. Our technicians perform a detailed component inspection under magnification to identify any wear or damage. All replacement of wear parts, such as seals and springs, is done with genuine OEM parts. A critical step is nozzle replacement, as worn nozzles can alter the fuel spray pattern and cause engine damage. Finally, the injector is reassembled to strict reassembly to OEM specs, ensuring every tolerance matches Bosch’s original standards. For preventive care, consider our Rail Injector Cleaning service.

Specialized Equipment and Expertise Required

The demanding nature of bosch piezo injector repair comes from the required equipment. Our Bosch test benches (EPS series) simulate engine conditions to perform high-pressure flow testing, measuring fuel delivery with extreme accuracy. We use Corona test equipment to check the piezo stack’s electrical integrity and perform atomization pattern analysis to verify a perfect fuel mist. The final, crucial step is injector coding/calibration. Each repaired injector gets a unique code that must be programmed into the engine’s computer for optimal performance. This specialized process is central to our Bosch Common Rail Injector Service and is essential for a reliable repair.

Post-Repair Diagnosis: Ensuring Peak Performance

The final phase of repair is rigorous testing on our advanced test benches. We analyze the electrical and mechanical performance of each injector to ensure it’s ready for marine duty. Our waveform analysis examines the electrical signals controlling the piezo element, confirming it opens and closes with perfect timing. This is how we catch issues like an injector staying open too long.

We also conduct precise fuel delivery measurement, comprehensive leak testing, and response time testing to confirm the injector’s fast reaction. This process generates unique calibration values for each injector, a digital fingerprint for your engine’s computer. This level of detail defines our Fuel Injector Repairs with RPM.

How Repaired Injectors are Tested

Our test benches are programmed for recreating engine operating conditions, from idle to full throttle. Full load testing pushes the injector to its limits, while idle testing verifies its precision at low speeds. We also measure pre-injection and post-injection quantities—the small, critical fuel shots that ensure quiet, clean combustion. Every result is compared to OEM data from Bosch. An injector only passes if it meets these exact specifications, ensuring your bosch piezo injector repair is equivalent to a new part. For more technical details, see this Technical documentation for testing Piezo injectors.

The Importance of Injector Calibration

Even new injectors have microscopic variations. These are measured and assigned unique injector IMA/ISA codes. It is essential to program these codes into your engine’s ECM after repair or installation. Without this step, the ECM cannot control the injector precisely, leading to unbalanced power delivery, poor fuel economy, and increased emissions. Proper calibration ensures each cylinder works in harmony, optimizing performance and compliance with marine regulations. This final step is a cornerstone of our Bosch Common Rail Injector Repair service, ensuring perfect integration with your engine.

Frequently Asked Questions about Marine Piezo Injector Service

When it comes to bosch piezo injector repair for marine engines, vessel owners often have plenty of questions. After decades of working with these sophisticated components, we’ve heard just about every concern from captains and marine engineers. Let’s tackle the most common questions we get at RPM Diesel Company.

Why are piezo injectors used in modern marine diesel engines?

Piezo injectors are used for their incredible speed and precision, operating up to five times faster than older solenoid types. Their rapid response allows for multiple small injections per combustion cycle (up to ten), leading to a more complete and efficient burn. For marine owners, this means improved fuel economy, quieter, smoother operation, and lower emissions. This precise control allows modern marine diesels to deliver high power while meeting strict environmental regulations, making them essential for today’s vessels.

Can I repair a Bosch piezo injector myself?

No, this isn’t a DIY project. Even for experienced mechanics, bosch piezo injector repair is too complex. It requires a dust-free, clean room environment, as microscopic particles can cause failure. It also demands highly specialized test benches for calibration and deep, factory-level knowledge of the technology. As one expert noted, it is “very specialised work.” Improper repair attempts can lead to catastrophic engine damage, such as melted pistons or washed cylinder walls, from incorrect fuel spray. This is a risk no mariner should take.

What are the risks of using poorly refurbished piezo injectors?

Poorly refurbished injectors are a serious risk for any marine engine. The dangers include:

- Incorrect Fuel Delivery: Leads to poor spray patterns that can cause melted pistons and washed cylinder walls.

- Oil Dilution: Leaking fuel contaminates engine oil, compromising lubrication and causing accelerated wear.

- Engine Hydro-lock: An accumulation of liquid fuel in a cylinder can cause catastrophic damage when compressed.

These issues often lead to persistent performance issues and more expensive future repairs. The old saying, “Buy cheap, buy twice,” is often true. Always use a Bosch-certified repair facility to ensure reliability and peace of mind at sea.

Conclusion: Trust the Experts with Your Marine Diesel Engine

The world of bosch piezo injector repair is complex, and when you’re at sea, engine reliability is paramount. Due to the piezo injector complexity, the importance of professional service cannot be overstated. It requires specialized knowledge, equipment, and a clean-room environment to protect your engine and your investment.

The benefits of proper repair include optimal fuel efficiency, smooth power delivery, and improved engine longevity. Choosing a certified expert ensures you can operate your vessel with confidence.

At RPM Diesel Company, we understand the needs of marine vessel owners. With locations across Southeast Florida—including Fort Lauderdale, Miami, and West Palm Beach—and worldwide on-site services, we are positioned to help mariners in the Caribbean and beyond. Our factory authorizations and comprehensive approach set us apart. We are not just a repair shop; we are partners in ensuring your vessel performs flawlessly.

For expert diagnostics and authorized Bosch Diesel Services, contact our team today. Let us help you keep your marine diesel engine at its peak. Explore our full range of services at Bosch Injection Services by RPM Diesel.