The Heart of Marine Diesel Power

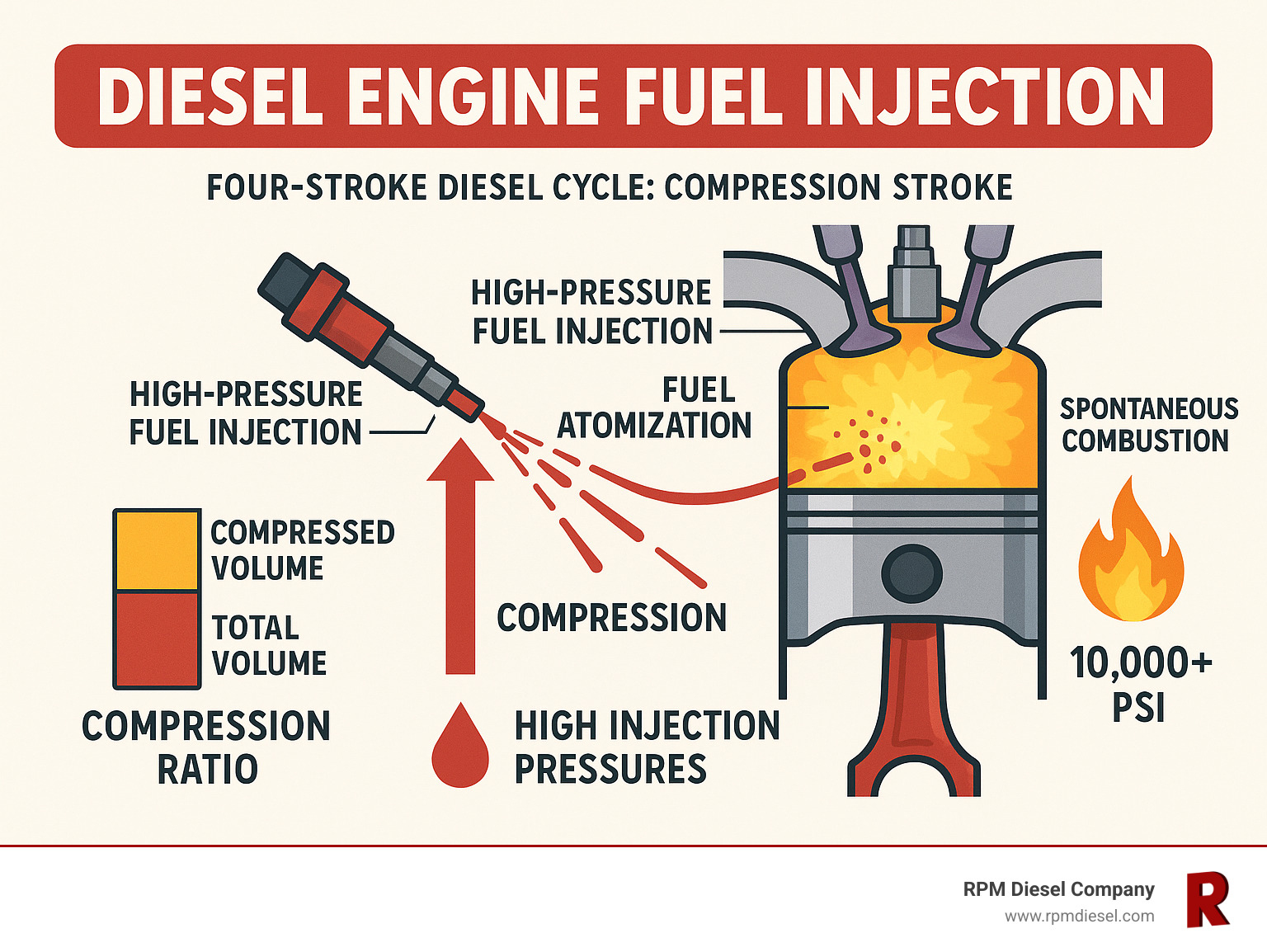

Diesel engine fuel injection atomizes and delivers pressurized fuel directly into the combustion chamber at a precise moment. Unlike gasoline engines, diesels use compression ignition, where the heat from compressed air ignites the fuel.

How Diesel Engine Fuel Injection Works:

- High-Pressure Delivery: Fuel pumps create pressures between 10,000-40,000 PSI

- Precise Timing: Electronic control units manage exactly when fuel enters each cylinder

- Atomization: Injector nozzles break fuel into tiny droplets for complete combustion

- Multiple Events: Modern systems can inject fuel up to 5 times per combustion cycle

- Electronic Control: Sensors monitor engine conditions to optimize fuel delivery

Think of the fuel injection system as the conductor of your engine’s orchestra, ensuring every cylinder fires with the perfect amount of fuel at the right moment. The injector is a crucial, complex component that must handle immense pressure and heat while creating a fine fuel mist.

For yacht owners, this system is critical because it directly impacts your vessel’s reliability, fuel efficiency, and performance. A perfect injection system means smooth operation, lower fuel costs, and confidence that your engines won’t leave you stranded.

Modern marine diesels have evolved far beyond simple mechanical systems. Today’s common rail systems use piezoelectric injectors that are five times faster than older solenoid types, delivering fuel with computer-controlled precision.

The stakes are high in marine applications. Unlike road vehicles, your diesel engines must perform flawlessly, whether you’re crossing the Gulf Stream or navigating into port during rough weather.

Anatomy of a Marine Diesel Fuel Injection System

A marine diesel’s fuel system is a sophisticated network delivering fuel precisely where and when it’s needed. Understanding it highlights why proper maintenance is crucial for your vessel’s reliability.

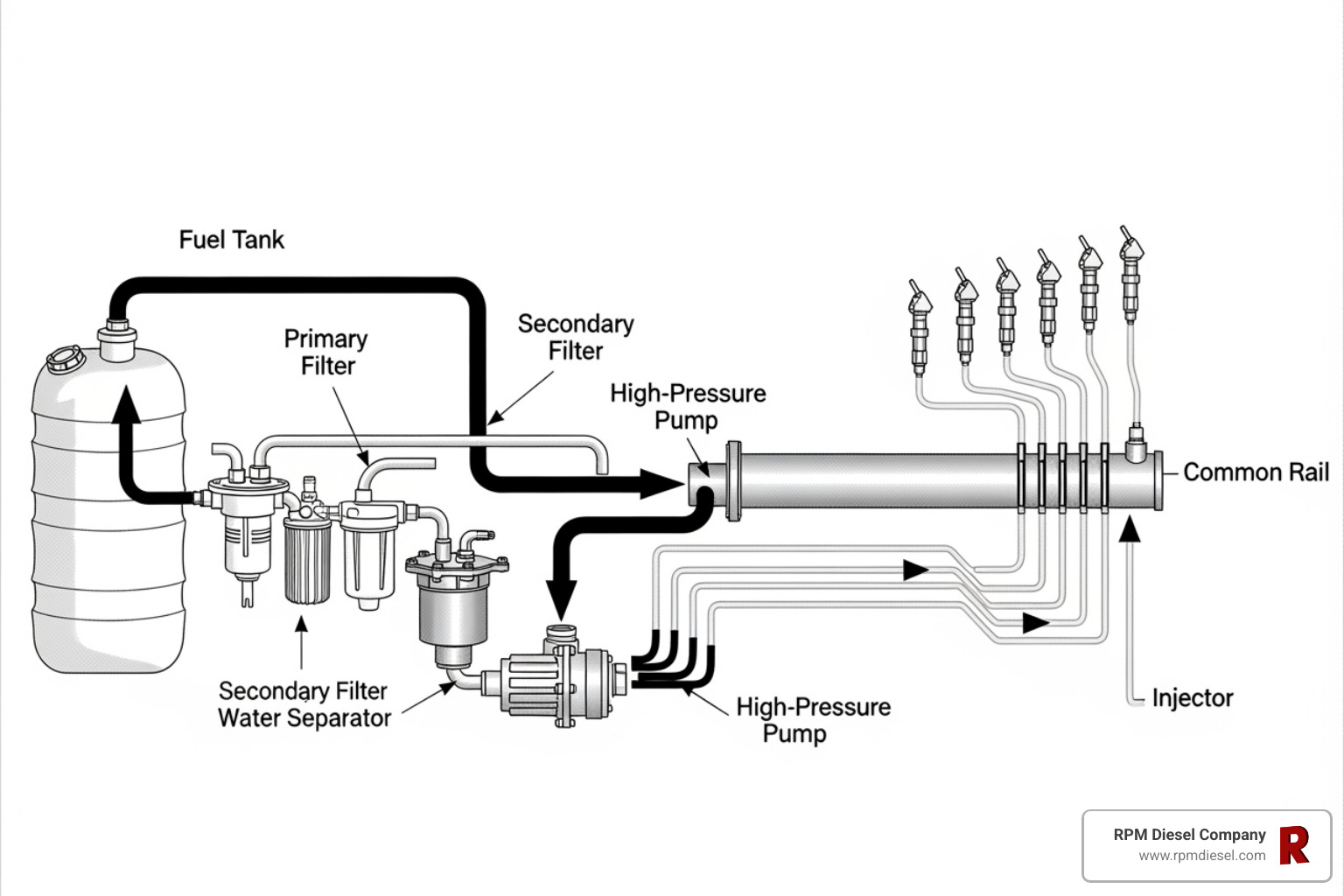

Modern marine diesel engine fuel injection systems have two main parts: a low-pressure side to prepare and move fuel, and a high-pressure side for injection. The Electronic Control Unit (ECU) is the brain, using sensor data to make split-second fuel delivery decisions.

The Low-Pressure Circuit: Getting Fuel to the Pump

Fuel starts in the fuel tank. The low-pressure circuit is the preparation stage, where fuel is cleaned and filtered before reaching the high-pressure components.

The water separator is critical in marine applications. Water contamination from salt air and condensation is a constant threat that can cause injection components to seize, leaving you stranded.

From there, the transfer pump (or lift pump) draws fuel through the fuel lines, pushing it through the primary and secondary fuel filters toward the high-pressure circuit.

These filters catch contaminants before they damage expensive injection parts. Regular filter changes are insurance against costly repairs. Using a Diesel Fuel Injection Cleaner can also help keep the system clean.

The High-Pressure Circuit: Creating Immense Force

The high-pressure circuit transforms low-pressure fuel into a precisely controlled, high-velocity spray that penetrates dense, compressed air.

The high-pressure pump creates immense pressures between 10,000 and 40,000+ PSI. It must maintain these pressures reliably for thousands of hours in harsh marine conditions.

Pressurized fuel flows into the common rail, a high-pressure reservoir that feeds all injectors, keeping pressure constant for instant delivery.

The injectors are the stars of the show. Each has an injector body with precise internal parts, a micron-tolerance nozzle, and a solenoid or piezoelectric actuator that opens and closes in milliseconds.

Modern piezoelectric injectors are particularly impressive, responding five times faster than older solenoid types. This speed allows for multiple injection events per combustion cycle, dramatically improving fuel atomization and combustion quality.

The required precision is why we use quality parts like Bosch Diesel Injection Pump Parts. With pressures that can cut steel, there’s no room for compromise on quality.

The Evolution of Injection: From Mechanical to Electronic Precision

The story of diesel engine fuel injection is one of constant evolution, from simple hand tools to computer-controlled machinery. Each leap forward has brought marine engines more power, better fuel economy, and cleaner operation to meet strict environmental regulations.

| System Type | Pressure Range (PSI) | Control Method | Efficiency/Emissions | Typical Marine Applications |

|---|---|---|---|---|

| Mechanical (Pump-Line-Nozzle, Rotary) | 1,500 – 8,000 | Mechanical, Governor | Lower efficiency, higher emissions, audible “diesel knock” | Older vessels, smaller auxiliary engines, some industrial |

| Unit Injector (UI/EUI) | 20,000 – 30,000 | Mechanical/Electronic | Improved efficiency, better emissions than mechanical | Medium to large marine engines (e.g., older Detroit Diesel, some MTU) |

| Common Rail (HPCR) | 20,000 – 44,000+ | Fully Electronic (ECU) | Highest efficiency, lowest emissions, quietest | Modern yachts, commercial vessels, high-performance marine engines |

Mechanical Injection Systems: The Foundation

Mechanical injection systems were the workhorses of their era: tough, reliable, and straightforward. They used a Pump-Line-Nozzle design, where a mechanical injection pump (inline or rotary) pushed fuel through high-pressure lines to individual injectors.

Operating at 1,500-8,000 psi, these systems used mechanical governors to respond to engine speed and load. Fuel quantity and timing were controlled by mechanical linkages, with no electronic sensors.

While durable, their lower injection pressures resulted in less efficient combustion and higher emissions. These systems are still found on older vessels and auxiliary engines where simplicity is key.

We maintain extensive expertise with cornerstone components from these systems, like the Zexel Injection Pump. The engineering principles share connections with other fuel delivery innovations, as explored in A Brief History of Aircraft Carburetors and Fuel Systems.

Unit Injector (UI) and Electronic Unit Injector (EUI) Systems

The next leap was combining the pump and injector into one unit. This eliminated long, high-pressure fuel lines, which could lose pressure and create timing inconsistencies.

Unit Injector systems placed a pump-injector assembly at each cylinder, actuated by a camshaft lobe. This design boosted pressures to 20,000-30,000 psi by eliminating pressure loss from long fuel lines.

The game-changer was the Electronic Unit Injector (EUI), which added computer control. The ECU could precisely manage fuel delivery, allowing engines to adapt to changing conditions, thus improving efficiency and reducing emissions.

These systems bridged the gap between mechanical and modern technology in heavy-duty marine applications. We have experience with quality components like Delphi Injectors, which were common in these installations.

High-Pressure Common Rail (HPCR): The Modern Standard for Marine Diesels

High-Pressure Common Rail (HPCR) systems are the pinnacle of diesel engine fuel injection technology. They revolutionized the process by separating pressure generation from fuel injection.

A single high-pressure pump supplies fuel to a common rail (a fuel reservoir) at constant pressures up to 44,000 psi or more. Each injector connects to this rail and is operated independently by the ECU.

The magic is in the piezoelectric injectors, which are five times faster than older solenoid types. This speed allows for multiple injection events per cycle: a pilot injection to reduce noise, a main injection for power, and a post-injection to burn off soot.

This control transforms engine operation. The “diesel knock” disappears, fuel economy improves, and emissions drop to meet IMO Tier III and IV standards. The engine room becomes much quieter.

For yacht owners, this means more time enjoying the vessel and less worry about fuel costs or compliance. The system continuously optimizes combustion based on load, sea conditions, and operating needs. Learn more by Understanding Common Rail Injection System.

Why Precise Fuel Injection is Critical for Marine Performance

In marine operations, reliability is paramount. Miles from shore, your diesel engine fuel injection system can be the difference between a successful voyage and a dangerous one. Its precision directly impacts your vessel’s power, fuel costs, environmental footprint, and engine longevity.

Maximizing Power and Fuel Efficiency

Proper combustion requires fuel to become a fine mist, a process called fuel atomization. High-pressure injection systems create millions of tiny droplets that mix perfectly with the hot, compressed air in the cylinders.

Finer droplets lead to more complete combustion. Just as kindling burns better than a log, finely atomized fuel burns more efficiently in your marine diesel engine.

Injection timing is also crucial. The ECU constantly monitors conditions and adjusts when fuel enters each cylinder. This ensures combustion occurs at the perfect moment to maximize power to the propeller.

This harmony results in optimized fuel-to-air ratios, squeezing maximum energy from your diesel. This means lower fuel bills and more power when you need it most.

Controlling Emissions and Engine Noise

Strict marine regulations like IMO Tier III and IV compliance protect our waters. Your diesel engine fuel injection system is key to meeting these standards.

Modern common rail systems shine here, using multiple injections per cycle. A pilot injection warms up combustion, eliminating the harsh “diesel knock” and making your time aboard more pleasant.

Post-injection burns off soot, preventing black smoke. This clean combustion also means reduced NOx emissions and lower particulate matter, ensuring environmental compliance.

If you’re noticing increased noise or visible exhaust, it might be time for Marine Diesel Fuel Injector Service to restore smooth, clean operation.

Ensuring Engine Reliability and Longevity

Proper diesel engine fuel injection protects your significant engine investment. Uneven spray or large droplets cause problems inside your cylinders.

Cylinder wash is when liquid fuel washes away the protective oil film on cylinder walls, leading to expensive repairs. Properly atomized fuel burns completely, preventing this.

Precise injection also prevents carbon buildup on injector nozzles, pistons, and valves. Incomplete combustion leaves deposits that interfere with operation and reduce efficiency.

Minimizing wear and tear on pistons and cylinder liners is crucial for marine applications, ensuring engines run reliably for thousands of hours. If you experience issues, our Diesel Injector Troubleshooting services can identify problems early, saving you from costly repairs and downtime.

Maintaining Your Marine Diesel Engine Fuel Injection System

Taking care of your diesel engine fuel injection system is vital. Neglecting maintenance can lead to poor performance, higher fuel costs, or being stranded. Fortunately, keeping your system healthy is straightforward with the right approach.

Common Issues and Symptoms of Failure

Your engine will signal when the fuel injection system has a problem. Recognizing these signs can prevent costly breakdowns.

- Black smoke from the exhaust usually indicates too much fuel or poor atomization.

- White smoke, especially on a cold start, often points to unburnt fuel from clogged or failing injectors.

- Hard starting or long crank times are often the first clue of inefficient fuel delivery.

- A loss of power often means one or more cylinders aren’t getting enough fuel.

- Increased fuel consumption for the same performance points to inefficient combustion.

- Rough idling creates a “lumpy” sound and vibration, caused by injectors sticking or delivering inconsistent spray patterns.

- Engine knock or misfire produces sharp, metallic sounds, often from improper timing or over-fueling.

Proactive Maintenance for a Healthy System

Preventive care is crucial in the tough marine environment and acts as insurance for your engines.

- High-quality marine diesel fuel is your first defense. Contaminated fuel is a leading cause of failure. Water contamination is especially damaging, causing corrosion and seizing expensive injector components.

- Regular fuel filter changes are essential. Filters catch contaminants before they reach expensive injection parts. Follow manufacturer recommendations; new filters are far cheaper than new injectors.

- Draining water separators must be a regular routine. Water, diesel’s worst enemy, enters tanks via condensation. Make this check as routine as checking your oil.

- Consider using a Diesel Fuel Injection Cleaner periodically to prevent carbon buildup. For deeper cleaning, our Common Rail Injector Cleaning Service can restore performance.

The Importance of Professional Diesel Engine Fuel Injection Service

While owners can handle basic maintenance, diesel engine fuel injection systems, especially common rail, require professional expertise, tools, and facilities.

These systems operate at over 40,000 PSI. Specialized diagnostic tools are needed to read fault codes and monitor data. We use high-pressure testing equipment to precisely measure spray patterns, flow rates, and opening pressures to exact OEM specifications.

Injector service requires a clean room environment. Microscopic particles can cause catastrophic damage to the tight tolerances inside modern injectors. Our facility provides the sterile conditions needed for this work.

Our technicians understand the critical nuances explained in Diesel Injector Rebuild: Understanding Differences. We ensure every component meets exact specifications.

Calibrating injectors to OEM specifications is about protecting your entire engine. Improperly calibrated injectors can cause cylinder wash, carbon buildup, and premature wear. Professional service protects your entire powerplant investment.

Frequently Asked Questions about Diesel Fuel Injection

We often get the same questions from marine engine owners about their fuel injection systems. These answers should help clarify common concerns.

How do common rail systems improve marine engine performance over older mechanical systems?

The leap from mechanical to common rail diesel engine fuel injection is a night-and-day difference for marine applications, similar to upgrading from a flip phone to a smartphone.

Higher injection pressures are key. Common rail systems reach 44,000+ psi versus 8,000 psi in older mechanical systems. This creates finer atomization, allowing tiny fuel droplets to mix completely with air for maximum energy extraction.

Multiple injection events per cycle add flexibility. The ECU can deliver pilot, main, and post-injections. This precise electronic control allows the engine to automatically adjust to changing conditions.

The benefits are impressive: better fuel economy, lower emissions to meet environmental standards, and quieter operation without the harsh diesel knock of older engines.

What are the most common causes of fuel injector failure in a marine environment?

The marine environment is tough on fuel systems, with several common culprits for failure.

- Fuel contamination is the top cause. Water enters via condensation or poor fuel and promotes bacteria and microbes. These corrosive organisms clog filters and damage injector components.

- Debris like dirt or rust can damage injector nozzles. This is why clogged or neglected filters are so dangerous, as they allow contaminants to reach expensive injection components.

- Other causes include internal wear from high pressure, corrosion from the salt environment, and solenoid or electronic failures due to heat and vibration, highlighting the need for regular maintenance.

Can I clean my marine diesel injectors myself?

While a DIY spirit is appreciated, your options are limited. Simple fuel additives can help clean and prevent deposits.

However, true cleaning and testing requires specialized equipment like test benches, ultrasonic cleaners, and precision measuring tools that most owners don’t have.

Professional service ensures proper spray pattern, flow rate, and opening pressure. An injector can look clean but still function incorrectly, which is impossible to diagnose without the right equipment until performance suffers.

When we Repair Fuel Injectors, we verify that each one meets the manufacturer’s exact specifications, ensuring everything works perfectly.

Conclusion: The Power of Precision in Your Engine

Your marine diesel’s diesel engine fuel injection system is the conductor of its orchestra, controlling power, fuel efficiency, noise levels, and longevity. It’s a sophisticated system governing every aspect of performance from the first key turn to long ocean crossings.

We’ve seen the evolution from robust mechanical pumps to today’s lightning-fast piezoelectric common rail technology. Modern systems perform multiple injections per cycle at extreme pressures, all managed by computers making split-second decisions.

The reality is simple: your fuel injection system’s health directly impacts your wallet and your peace of mind. A healthy system means smooth operation, better fuel economy, and confidence on the water. When things go wrong, a relaxing day can quickly turn expensive.

The key takeaway is that modern diesel engine fuel injection systems are sophisticated and demand professional attention. While you can handle basics like filter changes, diagnosing problems requires specialized equipment.

At RPM Diesel Company, we’ve built our reputation on understanding these intricate systems. Our technicians work with the diagnostic tools and clean-room environments that modern common rail systems demand. Whether you’re dealing with a Detroit Diesel or a new MTU, we have the expertise and genuine parts to keep you running.

Your vessel deserves more than guesswork when it comes to fuel injection service. The difference between a properly calibrated injector and one that’s “close enough” can mean the difference between smooth cruising and costly breakdowns. That’s why we’re authorized by major manufacturers and maintain an extensive parts inventory—because when you need service, you need it done right the first time.

Don’t gamble with your engine’s most critical system. Ensure your vessel is always ready with professional diesel engine maintenance from people who understand that your time on the water should be about enjoyment, not engine troubles. Whether you’re based in Fort Lauderdale, cruising from Miami, or exploring from any port in South Florida, we’re here to keep your diesel running like the precision machine it was designed to be.