Why Marine Common Rail Diesel Injector Repair Matters

Common rail diesel injector repair and service is critical for marine vessels because these precision components operate at extreme pressures up to 30,000 psi through clearances as small as 1 micron. When they fail, your yacht or commercial vessel faces costly downtime, poor fuel economy, and potential engine damage.

Quick Service Options:

- Professional Repair: Certified clean room service with Bosch EPS 815 testing

- Dockside Service: On-site removal and reinstallation

- Turnaround Time: 24-48 hours for standard overhaul

- Individual Replacement: Replace only faulty injectors vs. full set

- Cost Range: $200-800 per injector depending on type and damage

Modern marine common rail injectors deliver multiple injections per combustion cycle to maximize fuel efficiency and reduce emissions. But this precision comes at a cost – they’re highly susceptible to contamination from diesel bug, water ingress, and salt crystal fouling common in marine environments.

The stakes are high for vessel owners. A single failed injector can cause rough idle, black smoke, and hard starts that strand you in harbor. More seriously, improper repair can lead to rail over-pressure, injector seizure, or even piston damage requiring major engine work.

The good news? With proper diagnosis and certified repair procedures, most injector problems can be resolved quickly and cost-effectively. Professional marine diesel shops use specialized equipment like ultrasonic cleaning, precision lapping, and shot-to-shot metering to restore injectors to factory specifications.

How Marine Common Rail Injectors Work

Marine common rail injectors are marvels of precision engineering designed to withstand the harsh marine environment while delivering exact fuel metering. Understanding how they work helps explain why proper common rail diesel injector repair and service requires specialized knowledge and equipment.

The system maintains fuel at constant high pressure (1,600-2,200 bar) in a common rail that feeds all injectors. When the engine control unit (ECU) signals an injection event, the injector’s control valve opens, allowing pressurized fuel to flow through the nozzle into the combustion chamber. This happens with incredible precision – modern injectors can meter fuel delivery within 1/10 of one cubic millimeter between firing events.

There are two main types of marine common rail injectors:

Solenoid (Electromagnetic) Injectors use an electromagnetic coil to actuate the control valve. They’re robust and reliable but slightly slower in response time. These are common in commercial marine applications where durability matters more than ultimate precision.

Piezoelectric Injectors use piezo crystals that expand when voltage is applied, providing faster response and more precise control. However, they’re more sensitive to electrical interference and vibration – a concern on vessels with generators and other electrical equipment.

Marine injectors face unique challenges compared to automotive applications. They must handle extended duty cycles during long ocean passages, resist corrosion from salt air, and maintain performance despite fuel contamination from algae growth and water ingress common in marine fuel tanks.

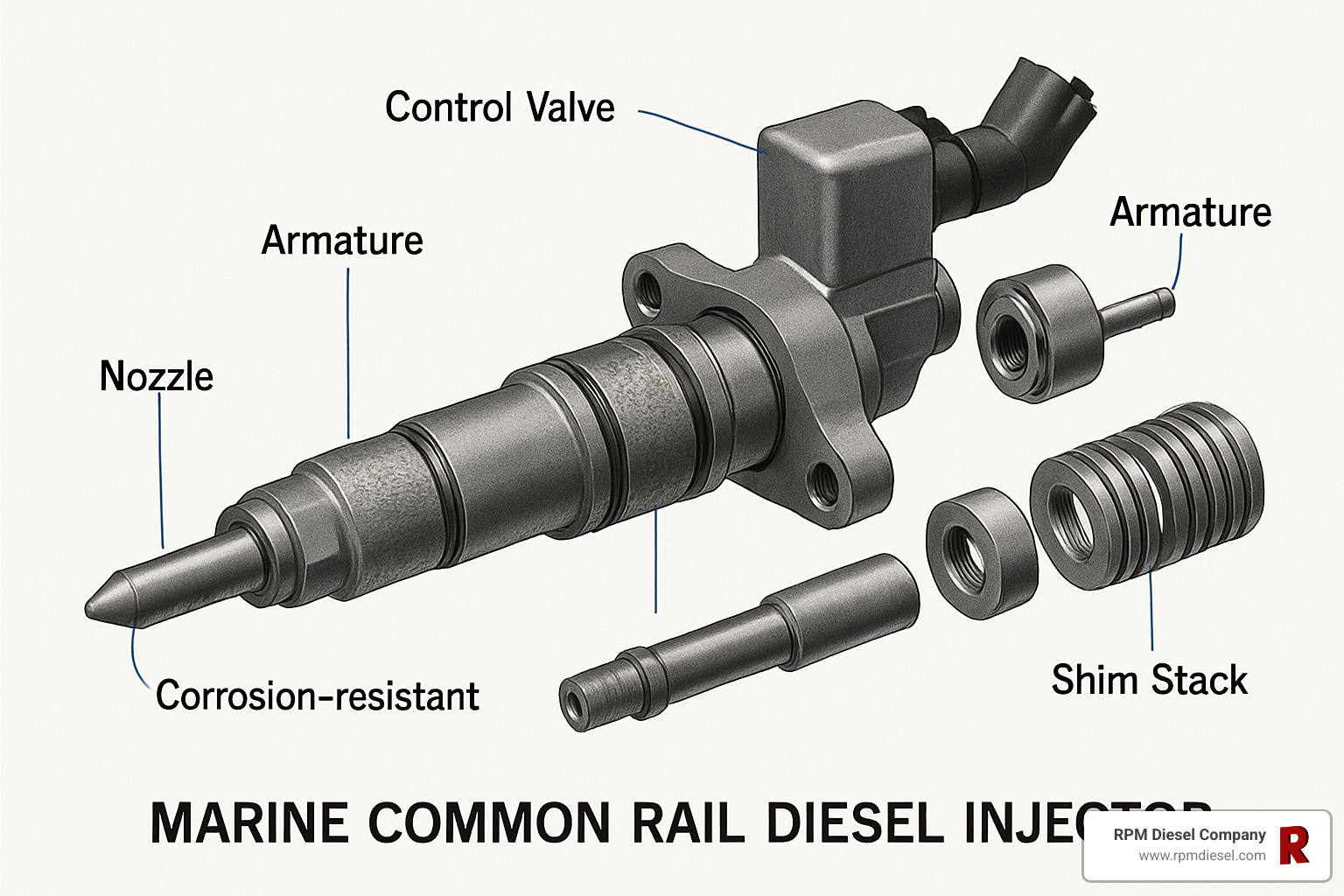

Anatomy of a Marine Injector

Each injector contains several critical components that work together:

The nozzle creates the spray pattern that atomizes fuel for complete combustion. Marine nozzles often feature special coatings like Diamond-Like Carbon (DLC) to resist wear from contaminated fuel.

The control valve regulates fuel flow through the injector. It’s actuated by either a solenoid or piezo element and must seal perfectly to prevent fuel leakage.

The armature (in solenoid injectors) moves to open and close the control valve. Precise manufacturing tolerances ensure consistent operation.

The shim stack allows fine-tuning of injector flow rates during manufacturing and repair. Professional shops stock over 500 different shim sizes to achieve exact specifications.

Injection Sequence on the Open Sea

Modern marine engines use sophisticated injection strategies to optimize performance across varying sea conditions. A typical injection sequence includes:

Pre-injection delivers a small amount of fuel to pre-heat the combustion chamber and reduce noise and emissions.

Main injection provides the primary fuel charge for power production.

Post-injection can occur after the main combustion event to help regenerate diesel particulate filters or reduce NOx emissions.

Marine ECUs adjust injection timing and quantity based on engine load, sea conditions, and operating mode. During rough seas, the system compensates for wave-induced load variations to maintain smooth operation.

Common Causes & Symptoms of Marine Injector Failure

Marine environments create unique challenges for diesel fuel systems. Understanding these failure modes helps vessel owners recognize problems early and avoid costly breakdowns.

Diesel Bug – This bacterial and fungal growth thrives in marine fuel tanks where water and fuel interface. The microorganisms produce acidic byproducts that corrode injector components and create sticky deposits that clog nozzles.

Water Ingress – Marine fuel tanks are prone to water contamination from condensation, deck washdown, and fuel supply issues. Water causes corrosion and interferes with fuel atomization.

Salt Crystal Fouling – Salt air and spray can contaminate fuel systems, leaving crystalline deposits that damage precision injector components.

Heat-Soak Coking – After engine shutdown, residual fuel in hot injectors can “cook” into carbon deposits that block nozzles and stick control valves.

Incorrect Installation Torque – Marine engines experience significant vibration. Improperly torqued injectors can work loose or over-compress sealing surfaces.

Seized Injectors – Corrosion and carbon buildup can cause injectors to seize in the cylinder head, requiring specialized hydraulic pullers for removal.

Extensive scientific research on diesel contamination has documented how marine environments accelerate fuel system degradation compared to land-based applications.

The symptoms of failing marine injectors are often dramatic and impossible to ignore:

- Black smoke plumes visible from shore indicate incomplete combustion from clogged or worn nozzles

- White smoke suggests water contamination or severely worn injectors

- Rough idle in harbor makes docking difficult and unprofessional

- Hard starting can strand you at anchor or prevent emergency engine starts

- Excessive fuel consumption hits the wallet hard on long passages

Diagnostic Red Flags Every Engineer Should Know

Modern marine engines provide extensive diagnostic information through OBD2 or SAE J1939 communication protocols. Key warning signs include:

Rail Pressure Drop – If the high-pressure pump can’t maintain rail pressure, suspect excessive injector back-leak or pump wear.

Return-Flow Imbalance – Measuring individual injector return flow helps identify which injectors are leaking internally.

Electrical Impedance Check – Solenoid injectors should show consistent resistance readings. Piezo injectors require specialized test equipment.

Fault Codes – Modern marine ECUs store detailed fault codes that pinpoint specific injector problems, cylinder misfires, and fuel system issues.

| Failure Mode | Solenoid Injectors | Piezo Injectors |

|---|---|---|

| Electrical Failure | Coil burnout, short circuits | Ceramic cracking, capacitor failure |

| Mechanical Wear | Armature wear, spring fatigue | Actuator seizure, stack expansion loss |

| Contamination | Nozzle clogging, valve sticking | Extreme sensitivity to particles |

| Vibration Damage | Generally robust | Ceramic elements can crack |

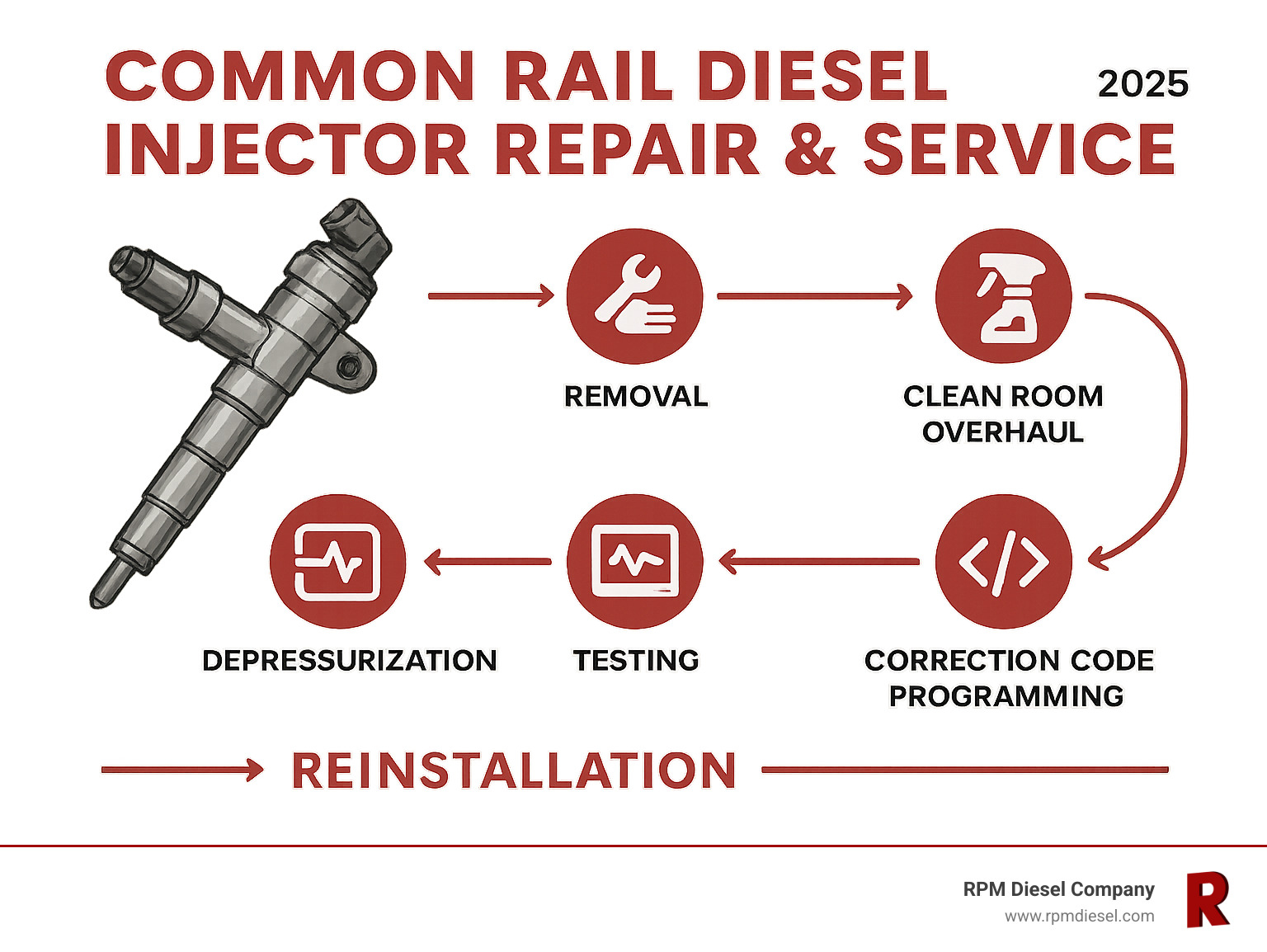

Marine Common Rail Diesel Injector Repair and Service Step-By-Step

Professional common rail diesel injector repair and service requires specialized equipment, clean room facilities, and certified technicians. Here’s what happens during a proper marine injector overhaul:

At RPM Diesel Company, we use a Bosch EPS 815 Common Rail Test Bench capable of testing Bosch CRI, CRIN I-IV injectors and CP1-4 common rail fuel pumps. This equipment measures shot-to-shot metering within 1/10 of one cubic millimeter between firing events – the precision required for marine applications.

Our certified clean room features HEPA-filtered air to maintain homeostatic conditions during injector assembly. We recalibrate our measurement tooling every 7-14 days to satisfy strict regulatory accuracy requirements.

The repair process begins with comprehensive testing to determine if an injector can be rebuilt or needs replacement. We perform part inspection using Bosch software and select precision shims from our inventory of over 500 different sizes to meet factory specifications.

Removing & Reinstalling: Common Rail Diesel Injector Repair and Service

Safety is paramount when working with high-pressure fuel systems. We always depressurize the system using diagnostic tools before beginning work. Our technicians wear proper PPE including safety glasses and gloves.

The removal process starts with capping exposed fuel lines to prevent contamination. Marine injectors can seize due to corrosion and carbon buildup, sometimes requiring hydraulic pullers generating 12-20 tons of force for removal.

Critical to the process is capturing each injector’s correction code – a unique calibration number that must be programmed into the ECU. Losing this code can result in rough running and poor performance even with a perfectly rebuilt injector.

During reinstallation, we follow manufacturer torque specifications exactly. Marine engines experience significant vibration, so proper torque is essential to prevent leaks while avoiding over-compression that can damage sealing surfaces.

Bench Procedures: Common Rail Diesel Injector Repair and Service

Our bench procedures follow strict protocols to ensure reliable results:

Ultrasonic Pre-Clean – We use specialized solvents in ultrasonic cleaners to remove carbon deposits and contamination without damaging precision surfaces.

Micron Filtration Flushing – Clean diesel fuel filtered to 2 microns flushes internal passages and removes microscopic debris.

Nozzle Lapping – Precision lapping restores proper sealing surfaces using specialized compounds and techniques.

Pop-Test Verification – We verify opening pressure and spray pattern meet manufacturer specifications.

Spray Pattern Video Capture – High-speed cameras document proper fuel atomization patterns.

Coding Print-Out – Each rebuilt injector receives documentation of its calibration values and test results.

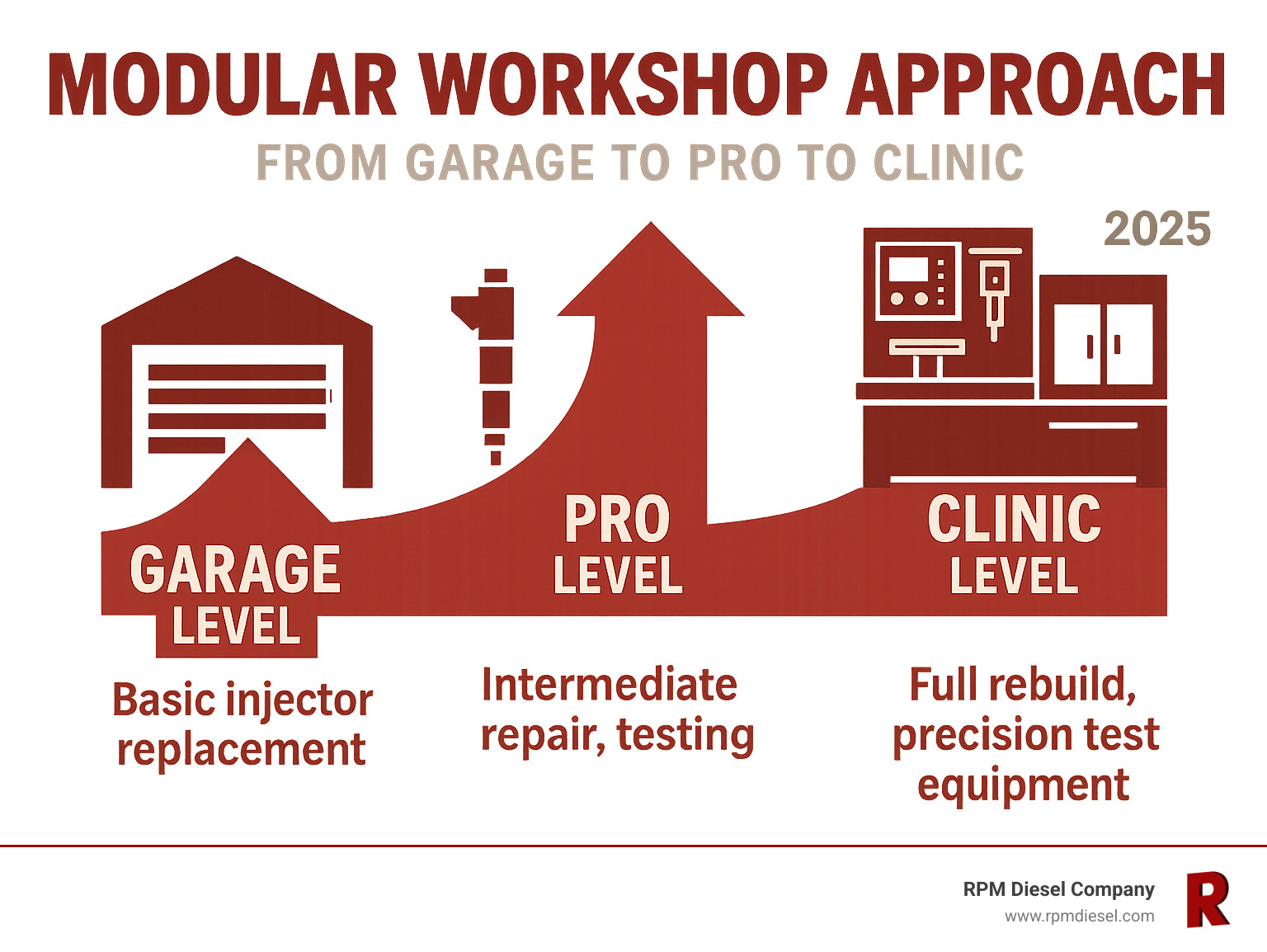

Quality Assurance & Modular Workshop Strategies

The marine diesel industry has adopted modular approaches to injector service, offering different levels of capability based on workshop needs and customer requirements.

Garage Level – Basic injector replacement and simple diagnostics suitable for smaller marine service shops.

Pro Level – Intermediate repair capabilities including cleaning, seal replacement, and basic testing.

Clinic Level – Full rebuild capability with precision test equipment and clean room facilities.

This modular approach allows marine service providers to match their capabilities to customer needs while maintaining quality standards. At RPM Diesel Company, we operate at the Clinic level, providing comprehensive rebuild services for all types of marine common rail injectors.

Our quality assurance process includes individual injector isolation testing to ensure accurate diagnostics. We maintain our certified clean room with HEPA filtration and follow strict contamination control procedures.

Training & Certification

Proper common rail diesel injector repair and service requires ongoing training and certification. Our technicians receive hands-on training at manufacturer facilities and maintain current certifications on the latest injector technologies.

We follow ISO 9001 quality management principles and maintain a culture of contamination control throughout our facility. Even minor contamination can cause injector failure, so we emphasize proper handling procedures and clean work practices.

Regular skill refresher training keeps our team current with evolving injector technologies and diagnostic techniques. The marine industry’s adoption of new emission standards and fuel types requires continuous learning.

Risk of Improper Service

The consequences of improper injector service can be severe and expensive:

Rail Over-Pressure – Incorrectly calibrated injectors can cause excessive pressure that damages the entire fuel system.

Injector Seizure – Poor installation techniques can cause injectors to seize in the cylinder head, requiring expensive removal procedures.

Piston Damage – Faulty injectors can cause fuel wash-down that damages pistons and cylinder walls.

Class Society Compliance Issues – Commercial vessels must maintain certification compliance, which requires proper documentation of all repairs.

Preventive Maintenance & Cost Considerations for Vessel Owners

Smart vessel owners understand that preventive maintenance costs far less than emergency repairs. We recommend inspecting marine injectors every 300 operating hours or annually, whichever comes first.

Premium Fuel Sourcing – Using high-quality fuel from reputable suppliers reduces contamination and extends injector life.

Dual-Stage Filtration – Primary filters (30 micron) remove larger particles and water, while secondary filters (5 micron) provide final protection.

Fuel Polishing – Regular fuel polishing removes water and contaminants that cause injector problems.

Additive Strategy – Proper fuel additives can prevent diesel bug growth and improve lubricity.

The economics of injector service favor individual replacement over full-set replacement. Replacing only faulty injectors can save thousands of dollars while maintaining engine performance.

Partial vs. Full Overhaul ROI – Individual injector replacement typically costs 60-70% less than full-set replacement while achieving the same performance improvement.

Downtime vs. Dock Fees – Quick turnaround injector service minimizes expensive dock time and gets you back on the water faster.

Smart Budgeting

Successful vessel owners plan injector maintenance as part of their overall engine budget. A lifecycle cost model helps predict when injectors will need service based on operating hours and conditions.

Spare Set Strategy – Keeping a spare set of injectors on board allows immediate replacement during extended voyages, with rebuild of the removed set at the next port.

Predictive Analytics – Modern engine monitoring systems can predict injector problems before they cause failures, allowing planned maintenance instead of emergency repairs.

At RPM Diesel Company, we work with vessel owners to develop customized maintenance programs that minimize costs while maximizing reliability. Our global service network means we can provide support wherever your travels take you.

Frequently Asked Questions about Marine Common Rail Injectors

Why does my yacht smoke under load even after filter changes?

Black smoke under load typically indicates incomplete combustion caused by worn or clogged injector nozzles. Even with clean filters, degraded injectors can’t properly atomize fuel, leading to poor combustion and visible smoke. This often occurs when injectors haven’t been serviced for several years or when contaminated fuel has caused internal deposits.

White smoke suggests water contamination or severely worn injectors allowing fuel to enter the combustion chamber during the exhaust stroke. This requires immediate attention as it can cause serious engine damage.

Can I replace one faulty injector or must I change all six?

You can absolutely replace individual faulty injectors rather than the entire set. Modern diagnostic equipment allows us to identify specific problem injectors through back-leak testing and electronic diagnostics. Replacing only faulty injectors saves significant money while maintaining engine performance.

However, if multiple injectors show wear or if the engine has very high hours, replacing the complete set may be more economical long-term. We can help you analyze the cost-benefit based on your specific situation.

How long does a professional marine injector overhaul take dockside?

Our typical dockside injector service takes 24-48 hours for standard overhauls. We can remove injectors on-site, transport them to our facility for rebuild, and reinstall them the next day. For emergency situations, we offer same-day service when possible.

Complex cases requiring specialized procedures may take longer, but we always communicate timing clearly and work to minimize your downtime. Our mobile service units carry common replacement injectors to get you running quickly when needed.

Conclusion

Marine common rail diesel injector repair and service is essential for reliable vessel operation and fuel efficiency. These precision components operating at extreme pressures require specialized knowledge, equipment, and procedures to service properly.

At RPM Diesel Company, we combine decades of marine diesel experience with state-of-the-art testing equipment and certified clean room facilities. Our locations throughout South Florida – including Fort Lauderdale, Miami, West Palm Beach, and Boca Raton – provide convenient access to professional injector services.

The investment in proper injector service pays dividends in improved fuel economy, reduced emissions, and reliable operation. Whether you need emergency dockside service or planned maintenance, our team has the expertise and equipment to keep your vessel running smoothly.

Don’t let injector problems strand you at sea or in harbor. Schedule your injector health check today and experience the difference professional service makes. Our global service network means we’re available wherever your maritime trips take you.

For comprehensive fuel system service including common rail fuel injection system maintenance and common rail injector service plans, contact RPM Diesel Company today. We’re here to keep you on the water, not tied to the dock.